Magnesium compound material and preparation method and application thereof

A magnesium compound and compound technology, applied in the field of materials, can solve the problem of easy precipitation of metal lithium on the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] MgO, CuCO 3 and NiO are dispersed in ethanol solvent, stirred in the beaker for 4 hours, after the stirring is stopped, add the sedimentation aid NH 4 HCO 3 , get the precipitate;

[0056] Vacuum dry the precipitate in an oven at 120°C for 12 hours; the powder obtained by oven drying is calcined at 1000°C for 20 hours under a nitrogen protective atmosphere, and the material obtained after cooling is dispersed in a deionized aqueous solution, and then titanium oxide is added for dispersion. The magnesium compound material is obtained by spray drying. The magnesium compound material is MgCu coated with titanium oxide 0.5 Ni 0.5 o 2 .

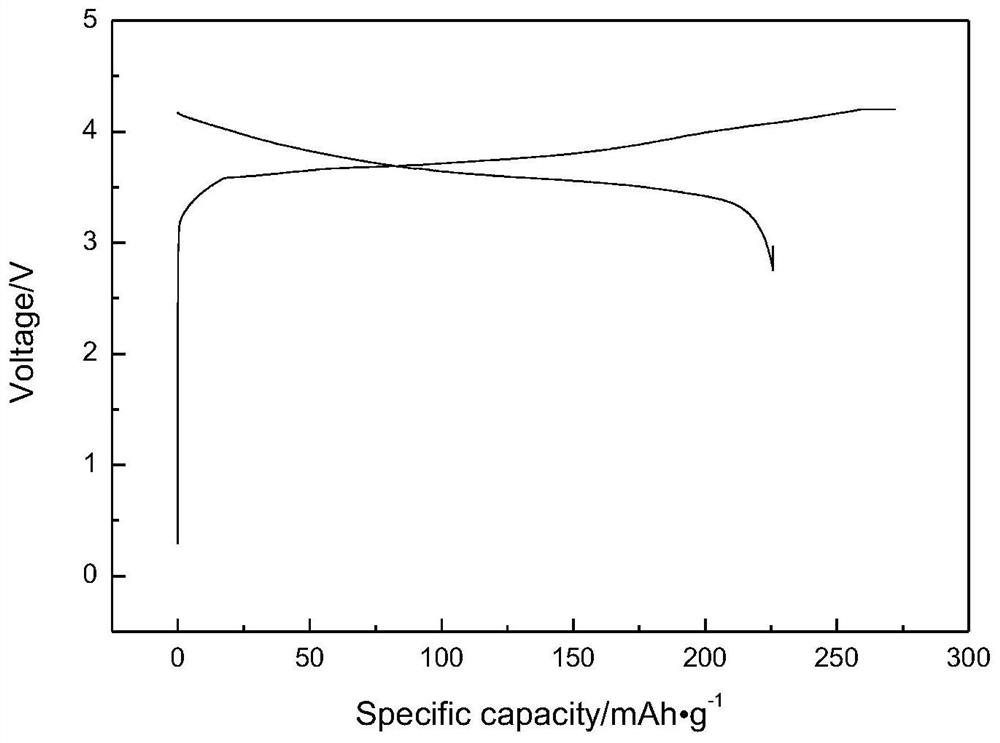

[0057] The synthesized magnesium compound material was uniformly mixed with acetylene black and polytetrafluoroethylene at a mass ratio of 8:1:1 to make a research electrode. The research electrode is used as the positive electrode, metal magnesium is used as the negative electrode, polyethylene (PE) film is used as the diaphragm, an...

Embodiment 2

[0059] Accurately weigh 0.1mol MgO, 1mol MnO and 0.1mol NiO and mix them evenly, put them into the agate tank of the planetary ball mill, add absolute ethanol as the mixing medium, and fully ball mill with agate balls for 4 hours; then dry at 120°C Finally, put the powder in a tube furnace and heat it to 400°C at a heating rate of 3°C / min under the protection of high-purity nitrogen, keep it for 1 hour, continue to heat up to 1200°C, and keep it for 15 hours; the obtained product is deionized After washing with water, put it into a vacuum drying oven, dry it at 80°C for 12 hours, and grind the dried product into powder to obtain the magnesium compound material Mg 2 NiMnO 4 .

[0060] The synthesized magnesium compound material Mg 2 NiMnO 4 Mix it with acetylene black and polytetrafluoroethylene at a mass ratio of 8:1:1 to make a research electrode. The research electrode was used as the positive electrode, the lithium sheet was used as the negative electrode, the PE film w...

Embodiment 3

[0062] Add MgO, CuO and vanadium oxide to the deionized water solvent according to the mass fraction ratio of 1:1:0.5, uniformly disperse through polyethylene glycol, and adjust the pH value of the system to 8, so that vanadium oxide is evenly adsorbed on MgO, CuO materials On the particles; calcined at 1100°C for 20 hours under a protective atmosphere, and the magnesium compound material obtained after cooling is MgCuO coated with vanadium oxide 2 .

[0063] The synthesized vanadium oxide-coated MgCuO 2 Mix it with acetylene black and polytetrafluoroethylene at a mass ratio of 8:1:1 to make a research electrode. The research material was used as the positive electrode, metal magnesium was used as the negative electrode, PE film was used as the diaphragm, and 0.25mol / L Mg(AlCl 2 BuEt) 2 / THF is the electrolyte, and it is assembled into a CR2032 button cell in a glove box. The charge and discharge current is 0.2C, discharge to 20mV, and then cycle 50 times. The first disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com