Pure cation valence-variable P2-phase layered oxide material with high sodium content, preparation method and application

An oxide and cation technology, applied in the field of materials, can solve the problems of unstable P2 phase material, poor electrochemical cycle performance, low first-week charging capacity, etc., and achieve great practical value, improve cycle stability, and improve charging capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a high-sodium content P2 phase layered oxide material with pure cations changed in valence, the general chemical formula is: Na x [Li i Ni j mn k m y ]O 2+β ;

[0060] Among them, Li, Ni, Mn, and M jointly occupy the transition metal ion position in the crystal structure; M is an element for doping and replacing the transition metal position, and M is specifically Cu 2+ , Mg 2+ , Mn 2+ ,Zn 2+ , Al 3+ , B 3+ , Zr 4+ , Ti 4+ One or more of them; x, y, i, j, k, and β are the molar percentages of the corresponding elements; the relationship between x, y, i, j, k, and β satisfies y+i+j +k=1, and x+my+i+2j+4k=2(2+β); where 0.8≤x≤0.85; 0<i≤0.1; 0<j≤0.4; 0<k≤0.65; -0.05 ≤β≤0.05; m is the valence state of M.

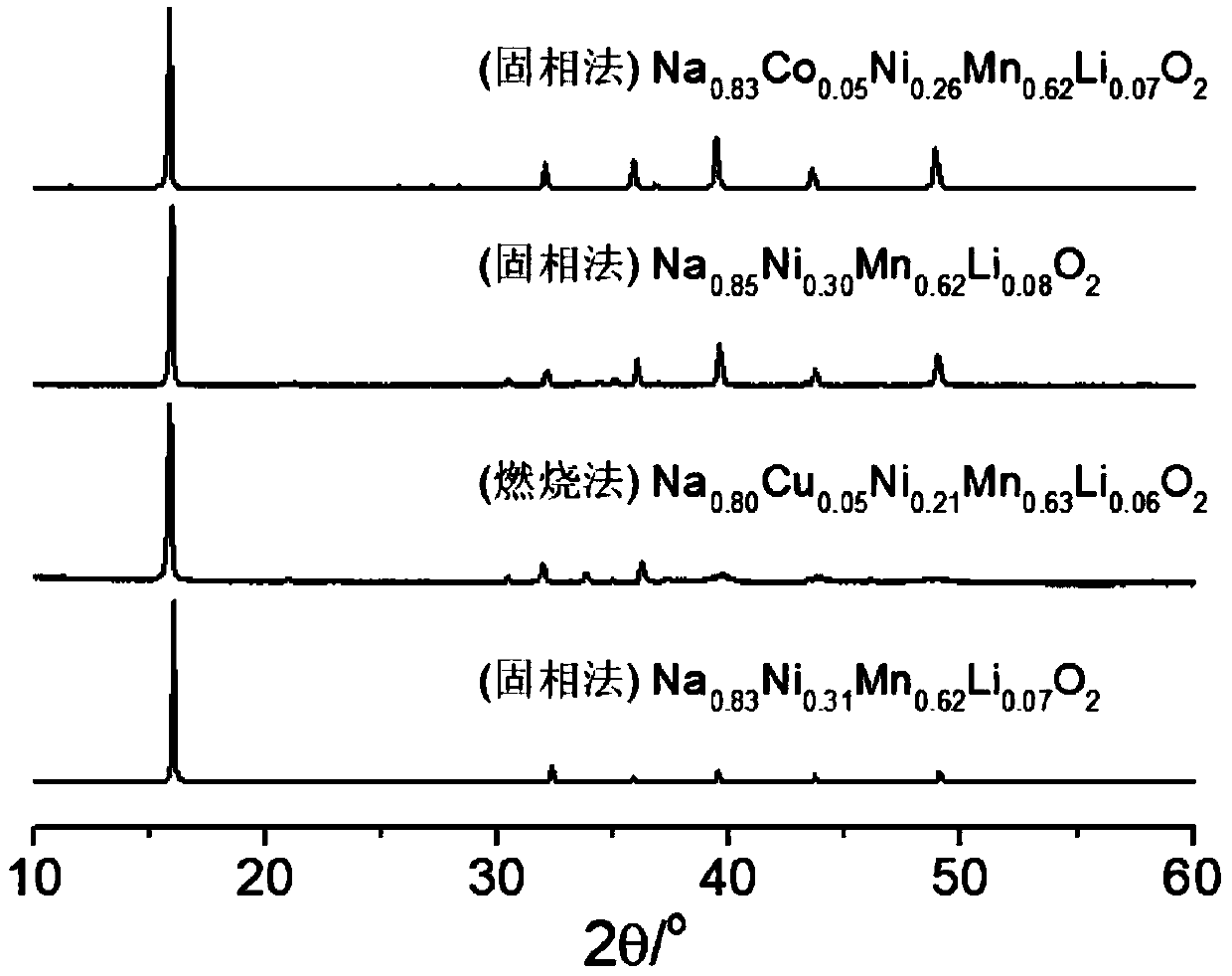

[0061] The space group of P2-phase layered oxide materials with high sodium content is P6 3 / mmc or P6 3 / mcm, the corresponding structure is P2 phase structure. The XRD collection of illustrative plates in several concrete example...

Embodiment 2

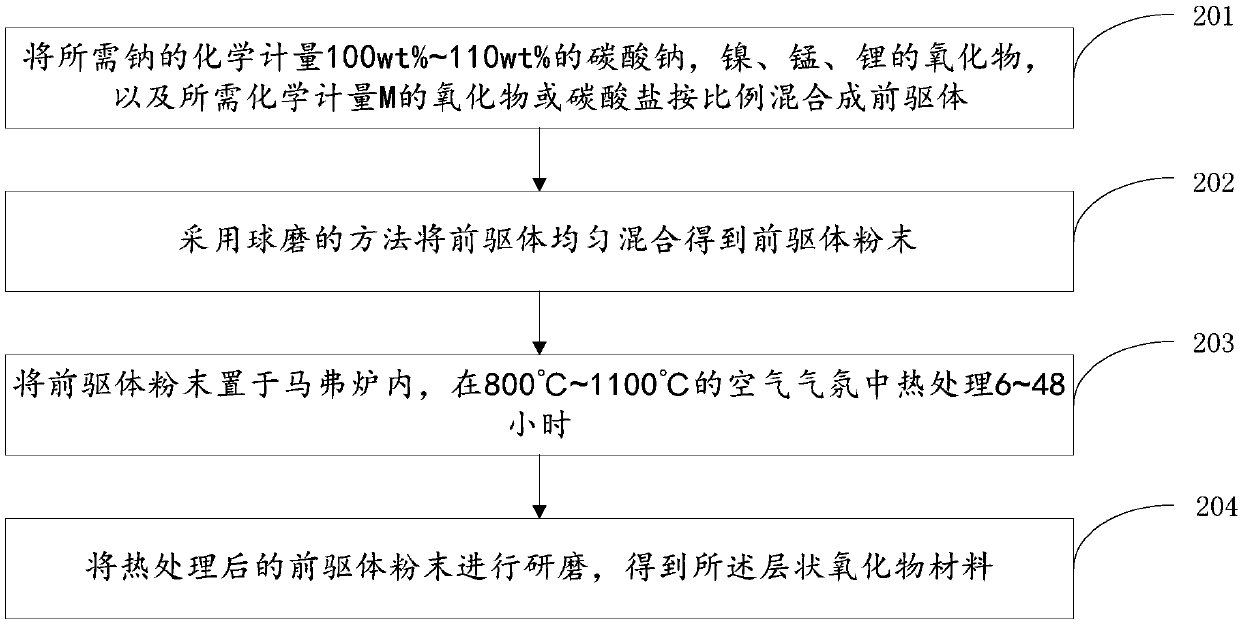

[0066] This example provides a method for preparing a high-sodium-content P2 phase layered oxide material with pure cations changed in price, specifically a solid-phase method, such as figure 2 shown, including:

[0067] Step 201, mixing sodium carbonate with a required stoichiometric amount of 100wt% to 110wt% of sodium, oxides of nickel, manganese, and lithium, and oxides or carbonates with a required stoichiometric amount M to form a precursor;

[0068] M is as described in the above examples, specifically Cu 2+ , Mg 2+ , Mn 2+ ,Zn 2+ , Al 3+ , B 3+ , Zr 4+ , Ti 4+ One or more of them; they are the same in the following embodiments and will not be repeated here.

[0069] Step 202, using a ball milling method to uniformly mix the precursor to obtain a precursor powder;

[0070] Step 203, placing the precursor powder in a muffle furnace, and heat-treating it in an air atmosphere at 800° C. to 1100° C. for 6 to 48 hours;

[0071] Step 204, grinding the heat-treated ...

Embodiment 3

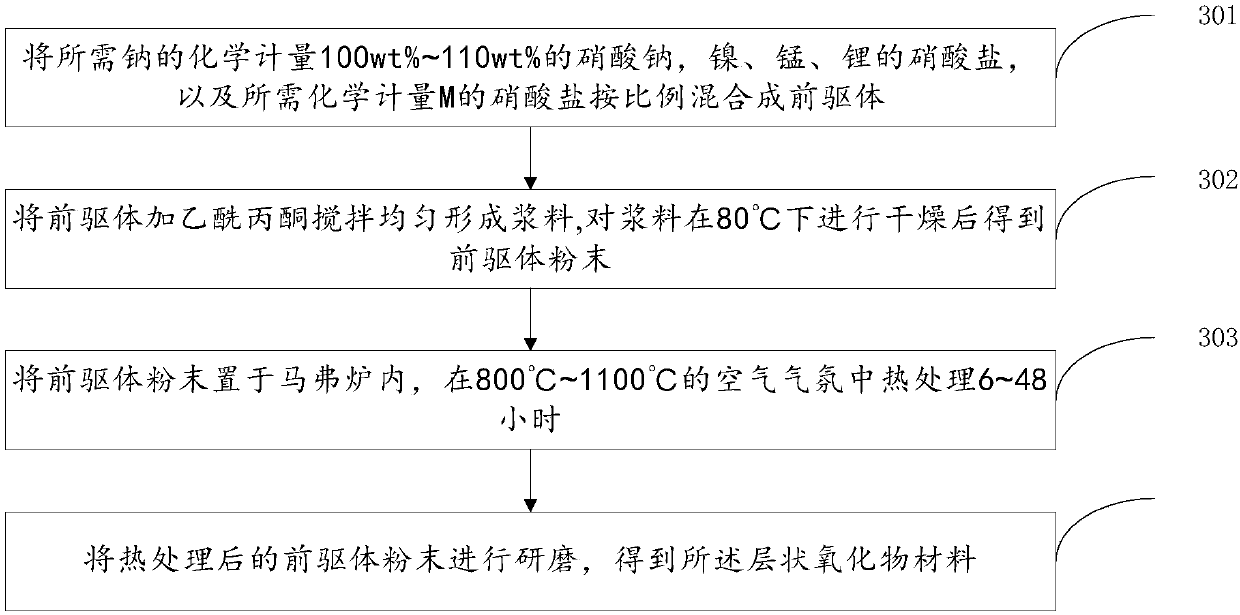

[0074] This example provides a method for preparing a high-sodium content P2 phase layered oxide material with pure cations changed in price, specifically a combustion method, such as image 3 shown, including:

[0075] Step 301, mixing sodium nitrate with a required stoichiometric amount of 100wt% to 110wt% of sodium, nitrates of nickel, manganese, and lithium, and a required stoichiometric M nitrate in proportion to form a precursor;

[0076]Step 302, stirring the precursor with acetylacetone to form a slurry evenly, drying the slurry at 80°C to obtain a precursor powder;

[0077] Step 303, placing the precursor powder in a muffle furnace, and heat-treating it in an air atmosphere at 800° C. to 1100° C. for 6 to 48 hours;

[0078] Step 304, grinding the heat-treated precursor powder to obtain the layered oxide material.

[0079] The preparation method of a high-sodium-content P2-phase layered oxide material provided in this embodiment can be used to prepare the high-sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com