Modified nickel, cobalt and lithium manganite three-element material and preparation method thereof

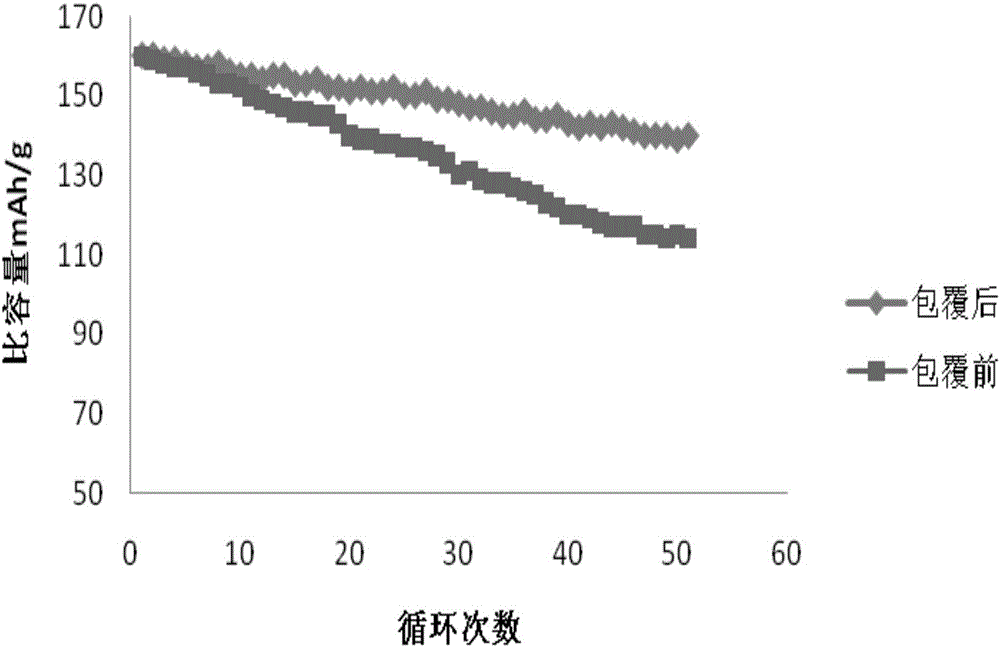

A technology of nickel-cobalt lithium manganate and ternary material, which is applied in the field of modified nickel-cobalt lithium manganate ternary material and preparation thereof, modified high-nickel-nickel-cobalt lithium manganate ternary material and preparation field thereof. Solve the problems of affecting the electrical performance, low initial charge and discharge efficiency of the battery, dissolution of Ni and Mn, etc., to optimize the cycle performance, increase the first cycle efficiency, and reduce the change of the surface microstructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention provides a method for preparing a modified nickel-cobalt lithium manganese oxide ternary material, comprising the following steps:

[0052] 1) After the nickel-cobalt-lithium-manganese-oxide material is dispersed in water, the nickel-cobalt-lithium-manganate material containing water on the surface is obtained by processing;

[0053] The chemical formula of described nickel cobalt lithium manganate material is as shown in formula (I),

[0054] LiNi 1-x-y co x mn y o 2 (1); Wherein, x>0, y>0, 1>1-x-y>0;

[0055] 2) After mixing the nickel-cobalt-lithium-manganese-oxide material with water on the surface obtained in the above steps, the titanium source and the organic solvent, the hydrolysis reaction is carried out to obtain the nickel-cobalt-lithium-manganate composite material;

[0056] 3) Calcining the nickel-cobalt lithium manganate composite material obtained in the above steps to obtain a modified nickel-cobalt lithium manganate ternary material....

Embodiment 1

[0072] 4g D 50 = 12-14μm high-nickel ternary material Li[Ni0.6Co0.2Mn0.2]O2 is dispersed in 2ml of water, and after magnetic stirring for 30 minutes, the surface of the high-nickel ternary material is fully wetted, and two layers of filter paper with a pore size of 3μm Filtration is performed to obtain a high-nickel ternary material containing water on the surface.

[0073] Then 0.114g of tetraethyl titanate was uniformly dispersed in 250mL of absolute ethanol solution, and the above-mentioned high-nickel ternary material with water on the surface was added, and stirred for 4 hours to allow tetraethyl titanate to undergo in-situ hydrolysis on the surface of the high-nickel ternary material React, react uniformly on the surface of the high-nickel ternary material to generate metatitanic acid, after the reaction is completed, use two layers of filter paper with a pore size of 3 μm to filter, put the product in an oven for 2 hours at 120°C, and obtain a uniformly coated metatitan...

Embodiment 2

[0080] 4g D 50 =12~14um high nickel ternary material Li[Ni 0.6 co 0.2 mn 0.2 ]O 2 Disperse in 2ml of water, stir magnetically for 30 minutes, and filter with two layers of filter paper with a pore size of 3 μm to obtain a high-nickel ternary material with water on the surface.

[0081] Evenly disperse 0.0114g of tetraethyl titanate in 25ml of absolute ethanol solution, add the above-mentioned high-nickel ternary material with water on the surface, stir for 5h, filter with two layers of filter paper with a pore size of 3μm, and put the product in an oven at 120°C Bake for 2 hours to obtain a high-nickel ternary material uniformly coated with metatitanic acid.

[0082] The mass ratio of the substances used in the above steps is tetraethyl titanate: nickel-rich ternary material: water: ethanol = 1:350:175:1750.

[0083] The resultant was heated up to 500°C at a heating rate of 10°C per minute, and calcined at a constant temperature for 5 hours to fully pyrolyze the metatitan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com