Coated modified high-nickel positive electrode material as well as preparation method and application thereof

A cathode material, high-nickel technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of potential safety hazards, difficult to ensure coating uniformity, use, etc., to improve thermal stability, cycle performance and safety. The effect of improved performance, optimal cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

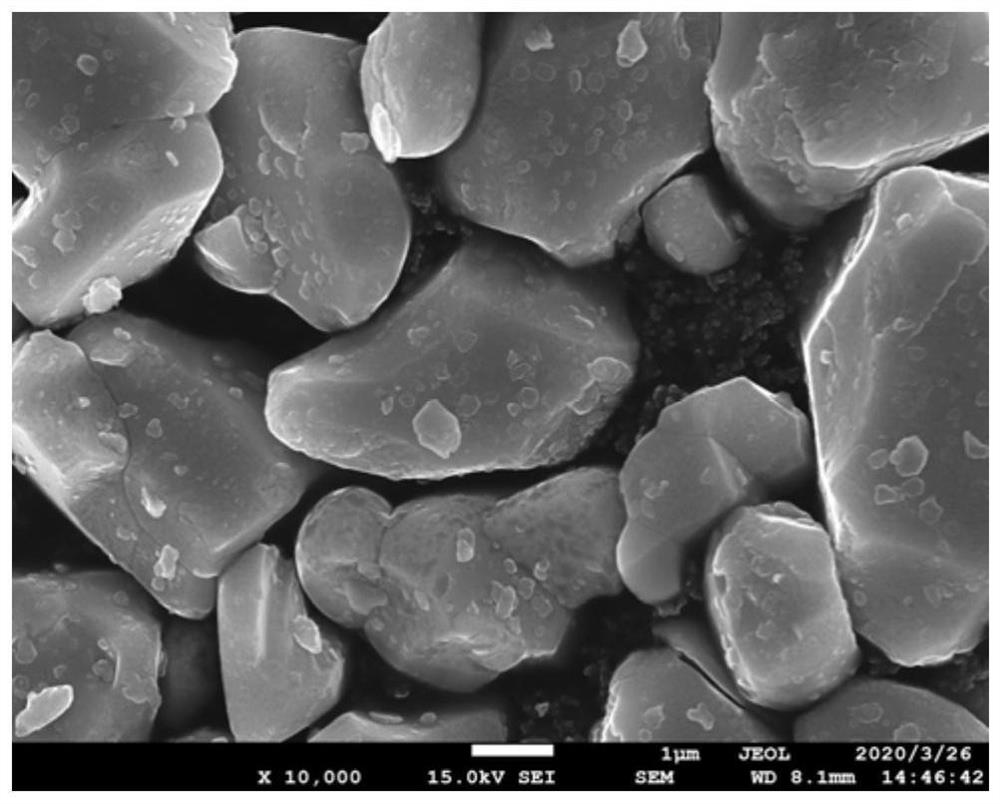

Image

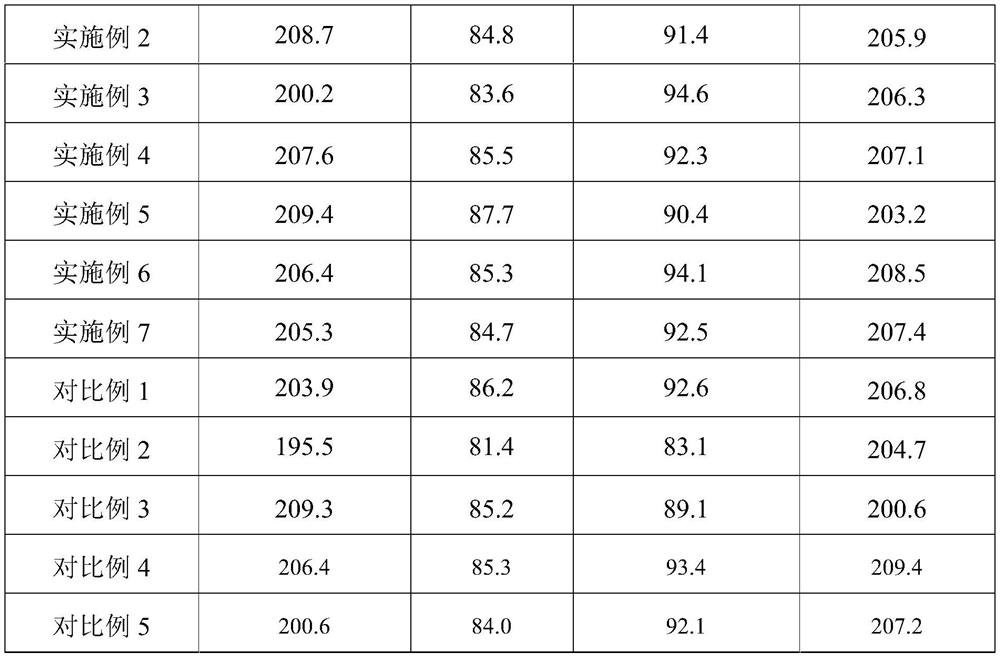

Examples

Embodiment 1

[0054] The preparation method of the coated modified high-nickel positive electrode material comprises the following steps:

[0055] (1) mixing the dispersion solution of the high-nickel positive electrode material and the aluminum source solution to obtain a mixed solution;

[0056] Among them, the molecular formula of the high-nickel cathode material is LiNi 0.88 co 0.05 mn 0.05 Zr 0.02 o 2 ;

[0057] Based on the mass of the high-nickel positive electrode material as 100%, the addition of the aluminum source makes the corresponding mass percentage of aluminum oxide 0.5%;

[0058] The preparation method of high-nickel cathode material comprises the following steps:

[0059] (a) mixing high-nickel precursor, lithium hydroxide and nano-zirconia solid phase method;

[0060] (b) sintering the mixture in step (a) at 800° C. for 8 hours under an oxygen atmosphere, cooling, crushing, and sieving to obtain the high-nickel positive electrode material;

[0061] (2) Add urea to...

Embodiment 2

[0065] The difference between this example and Example 1 is that the amount of the aluminum source in step (1) is such that the corresponding alumina content is 0.1% by mass; other parameters and conditions are exactly the same as in Example 1.

Embodiment 3

[0067] The difference between this example and Example 1 is that the amount of the aluminum source in step (1) is such that the corresponding alumina content is 0.8% by mass; other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com