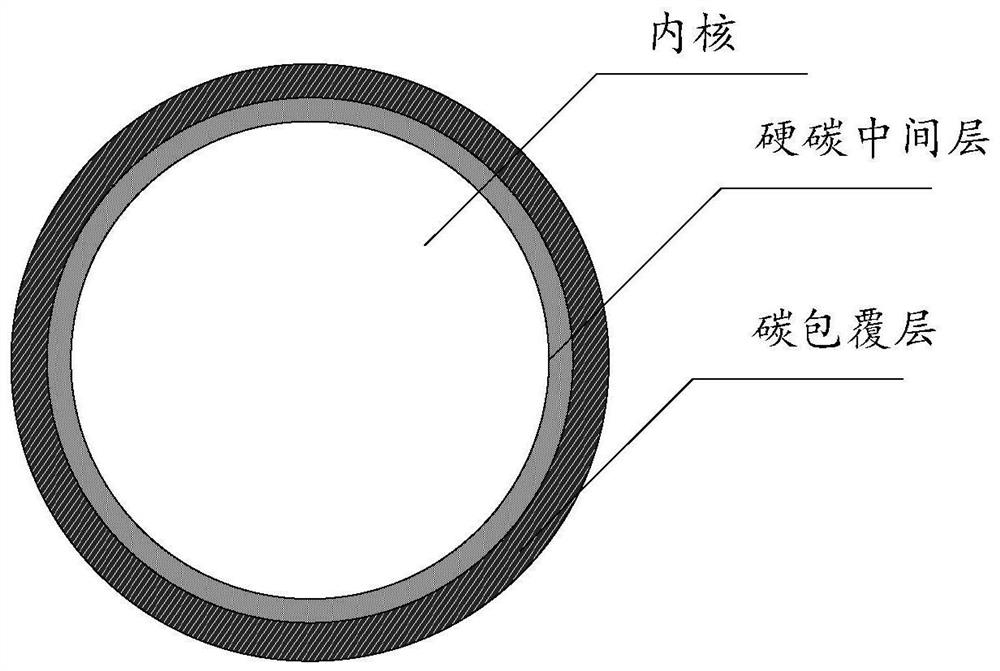

Hard carbon negative electrode material with multilayer core-shell structure and preparation method and application thereof

A technology of multi-layer core-shell structure and negative electrode material, applied in the direction of negative electrode, structural parts, battery electrode, etc., can solve the problems such as hindering the application of hard carbon materials, low reversible capacity, and low first effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

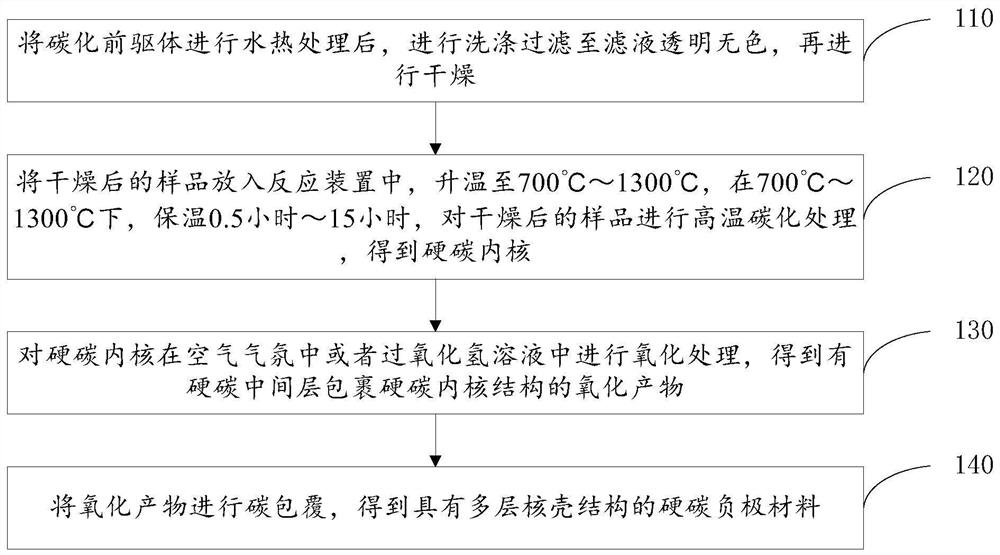

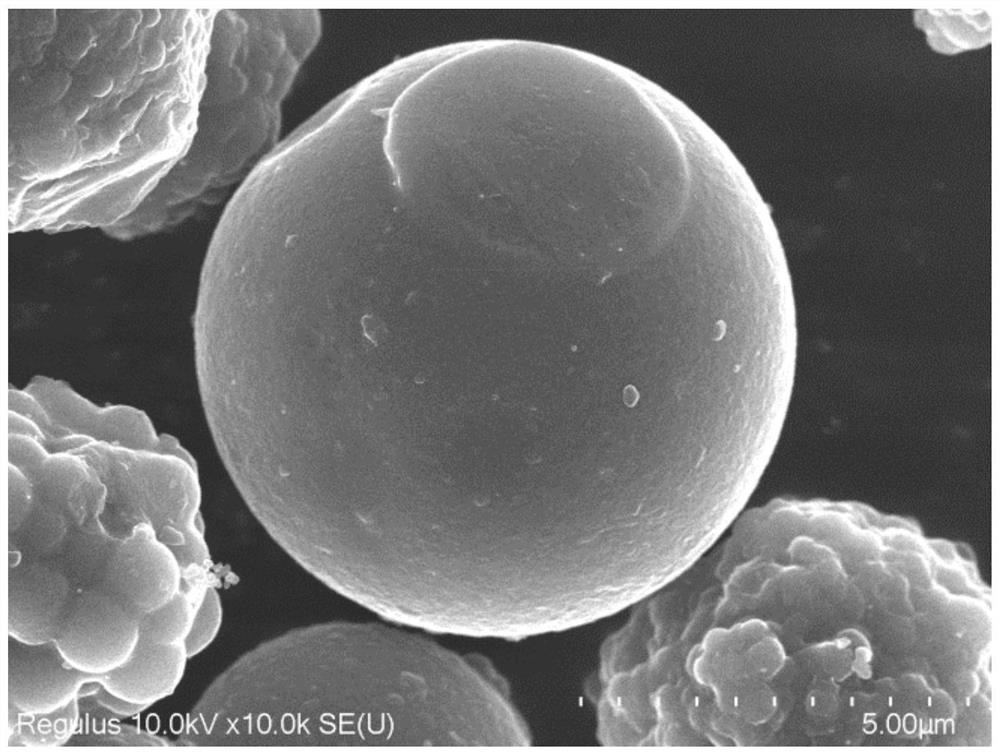

[0069] This embodiment provides a method for preparing a hard carbon negative electrode material with a multilayer core-shell structure, including:

[0070] Step 1: Take 100g of glucose, add 50ml of distilled water, stir evenly, and heat in a hydrothermal kettle at 5Mpa and 200°C for 5 hours to obtain a black powder;

[0071] Step 2: Wash the black powder obtained in Step 1 with deionized water until the filtrate is transparent and colorless, and after drying at 100°C for 10 hours, put it into a tube furnace and heat it at a heating rate of 3°C / min to 900°C, keep warm for 2 hours;

[0072] Step 3: Heat the sample obtained in step 2 to 400°C at a heating rate of 3°C / min in an air atmosphere, and keep it warm for 4 hours;

[0073] Step 4: Put the sample obtained in Step 3 into a chemical vapor deposition (CVD) device, and keep it at 900° C. for 1 hour with argon:methane=1:1 ratio to obtain a hard carbon negative electrode material with a multilayer core-shell structure.

[007...

Embodiment 2

[0089] This embodiment provides a method for preparing a hard carbon negative electrode material with a multilayer core-shell structure, including:

[0090] Step 1: Take 100g of glucose, add 50ml of distilled water, stir evenly, and heat in a hydrothermal kettle at 6Mpa and 150°C for 5 hours to obtain a black powder;

[0091] Step 2: Wash the black powder obtained in Step 1 with deionized water until the filtrate is transparent and colorless, and after drying at 100°C for 10 hours, put it into a tube furnace and heat it at a heating rate of 3°C / min to 1000°C, keep warm for 6 hours;

[0092]Step 3: Heat the sample obtained in step 2 to 600°C at a heating rate of 3°C / min in an air atmosphere, and keep it warm for 2 hours;

[0093] Step 4: Put the sample obtained in Step 3 into CVD equipment, and keep it at 1000° C. for 3 hours with nitrogen: acetylene = 1:1 ratio to obtain a hard carbon negative electrode material with a multilayer core-shell structure.

[0094] In the obtaine...

Embodiment 3

[0097] This embodiment provides a method for preparing a hard carbon negative electrode material with a multilayer core-shell structure, including:

[0098] Step 1: Take 100g of glucose, add 50ml of distilled water, stir evenly, and heat in a hydrothermal kettle at 5Mpa and 200°C for 5 hours to obtain a black powder;

[0099] Step 2: Wash the black powder obtained in Step 1 with deionized water until the filtrate is transparent and colorless, and after drying at 100°C for 10 hours, put it into a tube furnace and heat it at a heating rate of 3°C / min to 800°C, keep warm for 10 hours;

[0100] Step 3: Heat the sample obtained in step 2 to 500°C at a heating rate of 3°C / min in an air atmosphere, and keep it warm for 2 hours;

[0101] Step 4: Add 5 g of polyvinylpyrrolidone (PVP) to the sample obtained in Step 3, mix it evenly, put it into a ball mill, mill it at 200 r / min for 1 hour, discharge it into a tube furnace, and keep it at 1000 ° C for 3 hours in a nitrogen atmosphere ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Raman spectroscopy | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| Raman spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com