High-gram-capacity lithium ion battery silicon-carbon negative electrode material, and preparation method and lithium battery thereof

A lithium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, carbon preparation/purification, negative electrodes, etc., can solve the problems of low first efficiency, poor cycle performance, etc., achieve high gram capacity, improve performance, and high first cycle efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

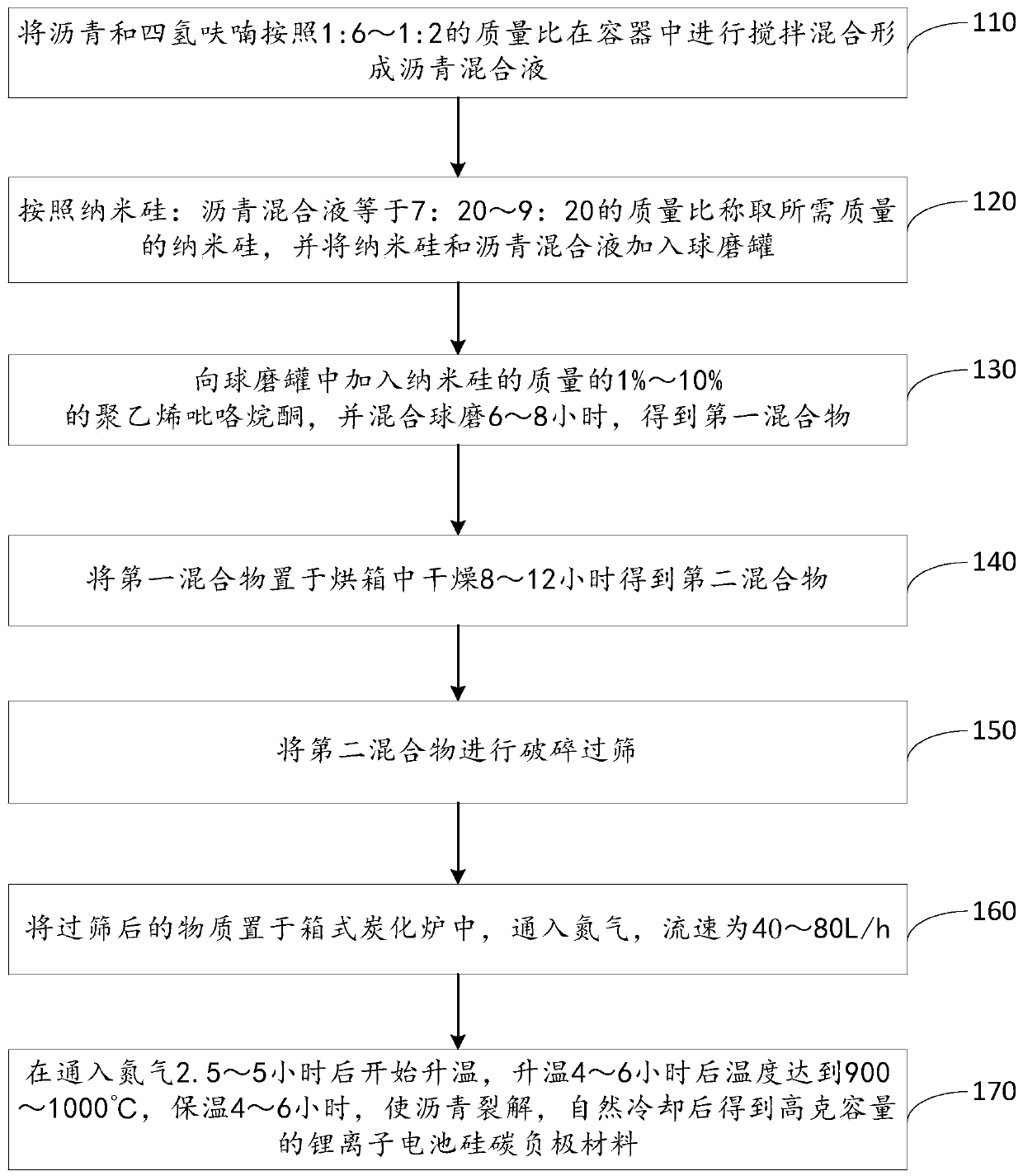

[0045] This embodiment provides a method for preparing a silicon-carbon negative electrode material for a lithium-ion battery with a high gram capacity, which specifically includes the following steps:

[0046] A: Add 0.5g of asphalt to 3g of tetrahydrofuran and mix;

[0047] B: Weigh 10g of nano-silicon with a median particle size of 100nm

[0048] C: Add the mixed solution obtained in step A and the nano-silicon in step B into the ball mill tank;

[0049] D: Add 0.1 g of PVP to the mixture obtained in step C, and ball mill the mixture for 6 hours;

[0050] E: Dry the mixture in step D in an oven with a temperature of 80°C for 12 hours, and dry until all the organic solvents are volatilized;

[0051] F: The mixture obtained in step E is crushed and passed through a 300-mesh sieve;

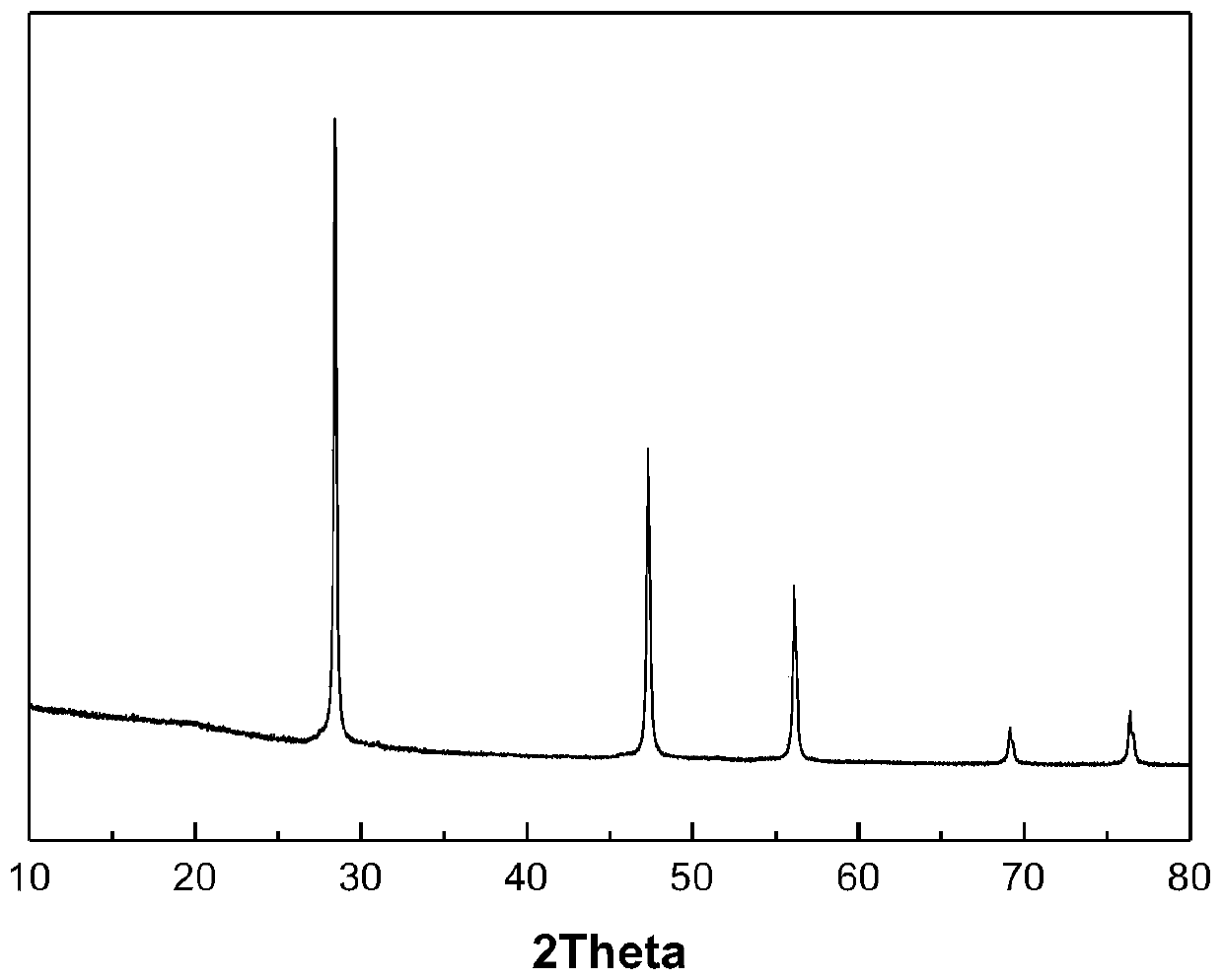

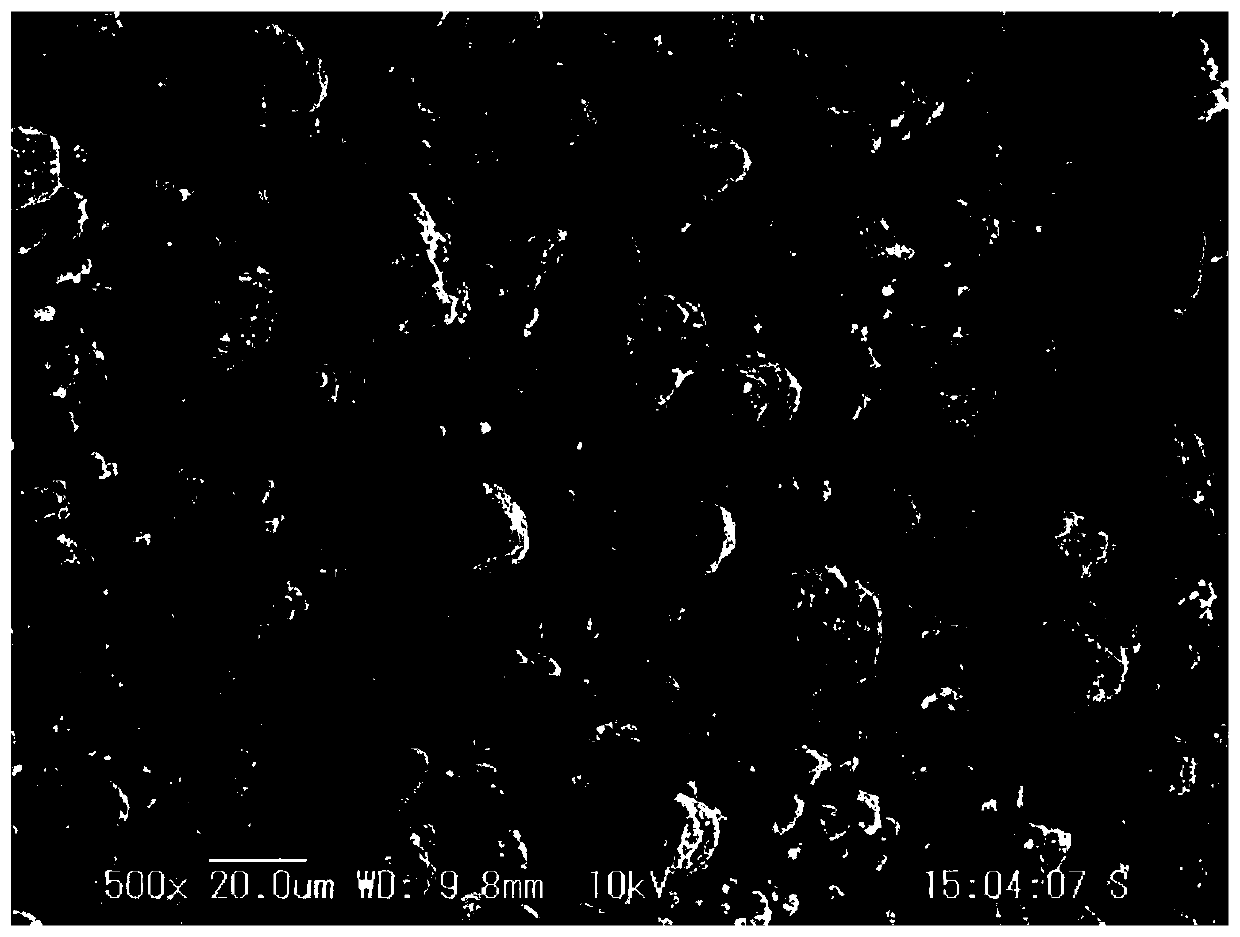

[0052] G: Put the mixture obtained in step F in a box-type carbonization furnace, use nitrogen as a protective gas, flow rate is 80L / h, start to heat up after 2.5 hours of nitrogen gas, raise t...

Embodiment 2

[0058] This embodiment provides a method for preparing a silicon-carbon negative electrode material for a lithium-ion battery with a high gram capacity, which specifically includes the following steps:

[0059] A: Add 0.5g of asphalt to 3g of tetrahydrofuran and mix;

[0060] B: take 10g of nano-silicon whose median particle diameter is 50nm;

[0061] C: Add the mixed solution obtained in step A and the nano-silicon in step B into the ball mill tank;

[0062] D: Add 0.1 g of PVP to the mixture obtained in step C, and ball mill the mixture for 6 hours;

[0063] E: Dry the mixture obtained in step D in an oven with a temperature of 80°C for 12 hours, and dry until all the organic solvents are volatilized;

[0064] F: The mixture obtained in step E is crushed and passed through a 300-mesh sieve;

[0065] G: Put the mixture obtained in step F in a box-type carbonization furnace, use nitrogen as a protective gas, flow rate is 80L / h, start to heat up after 2.5 hours of nitrogen g...

Embodiment 3

[0068] This embodiment provides a method for preparing a silicon-carbon negative electrode material for a lithium-ion battery with a high gram capacity, which specifically includes the following steps:

[0069] A: Add 1g of asphalt to 3g of tetrahydrofuran and mix;

[0070] B: Weigh 10g of nano-silicon with a median particle size of 100nm

[0071] C: Add the mixed solution obtained in step A and the nano-silicon in step B into the ball mill tank;

[0072] D: Add 0.1 g of PVP to the mixture obtained in step C, and ball mill the mixture for 6 hours

[0073] E: Dry the mixture in step D in an oven with a temperature of 80°C for 12 hours, and dry until all the organic solvents are volatilized;

[0074] F: The mixture obtained in step E is crushed and passed through a 300-mesh sieve;

[0075] G: Put the mixture obtained in step F in a box-type carbonization furnace, use nitrogen as a protective gas, flow rate is 80L / h, start to heat up after 2.5 hours of nitrogen gas, raise the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com