Vibration aging treatment method of copper-aluminum-silicon nano alloy material and application of vibration aging treatment method

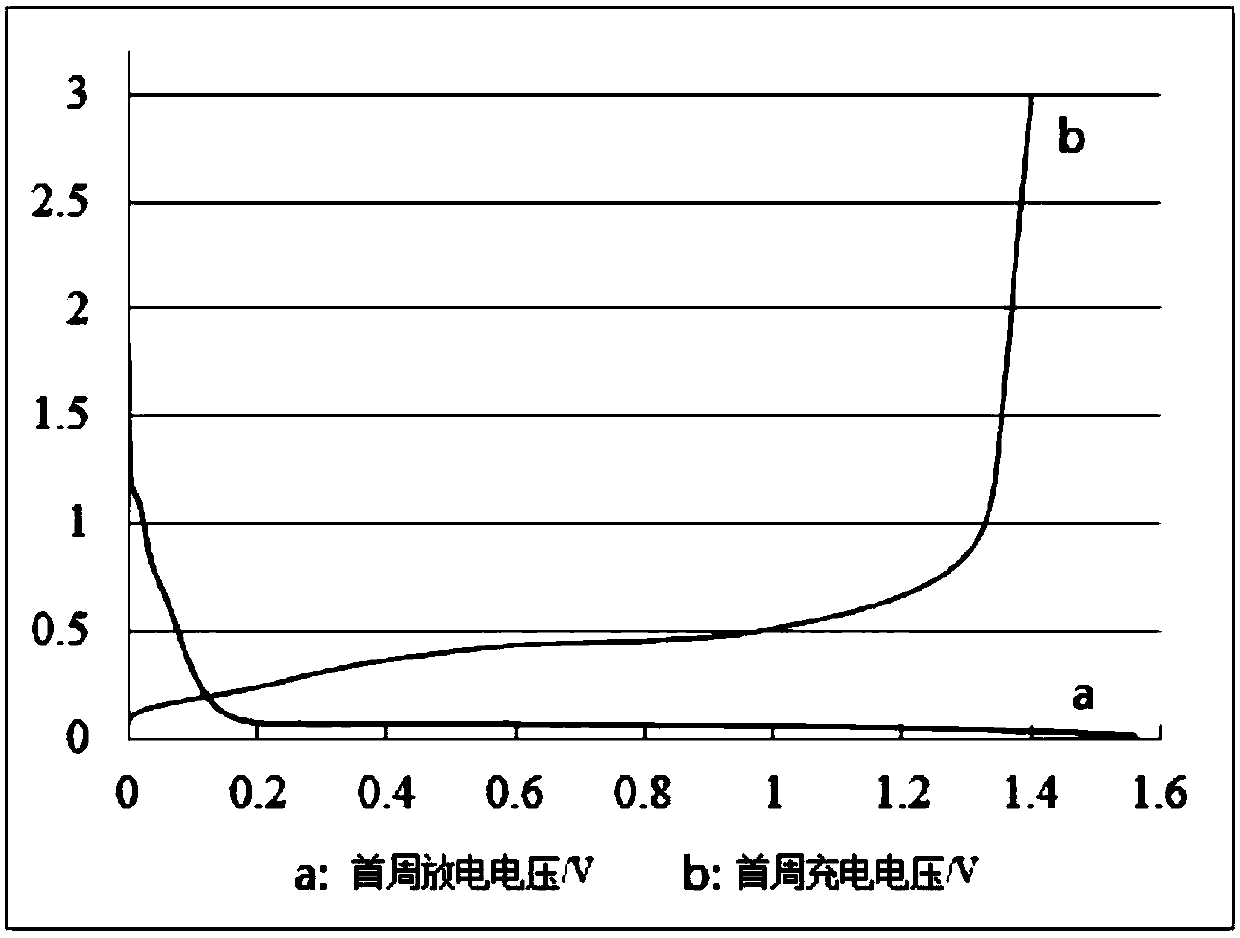

A technology of vibration aging and treatment methods, which is applied in the direction of negative electrodes, electrical components, electrochemical generators, etc., can solve the problems of short cycle life, low first-week efficiency, long charge and discharge time, etc., achieve reasonable particle size distribution, meet coating Cloth requirements, unique effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

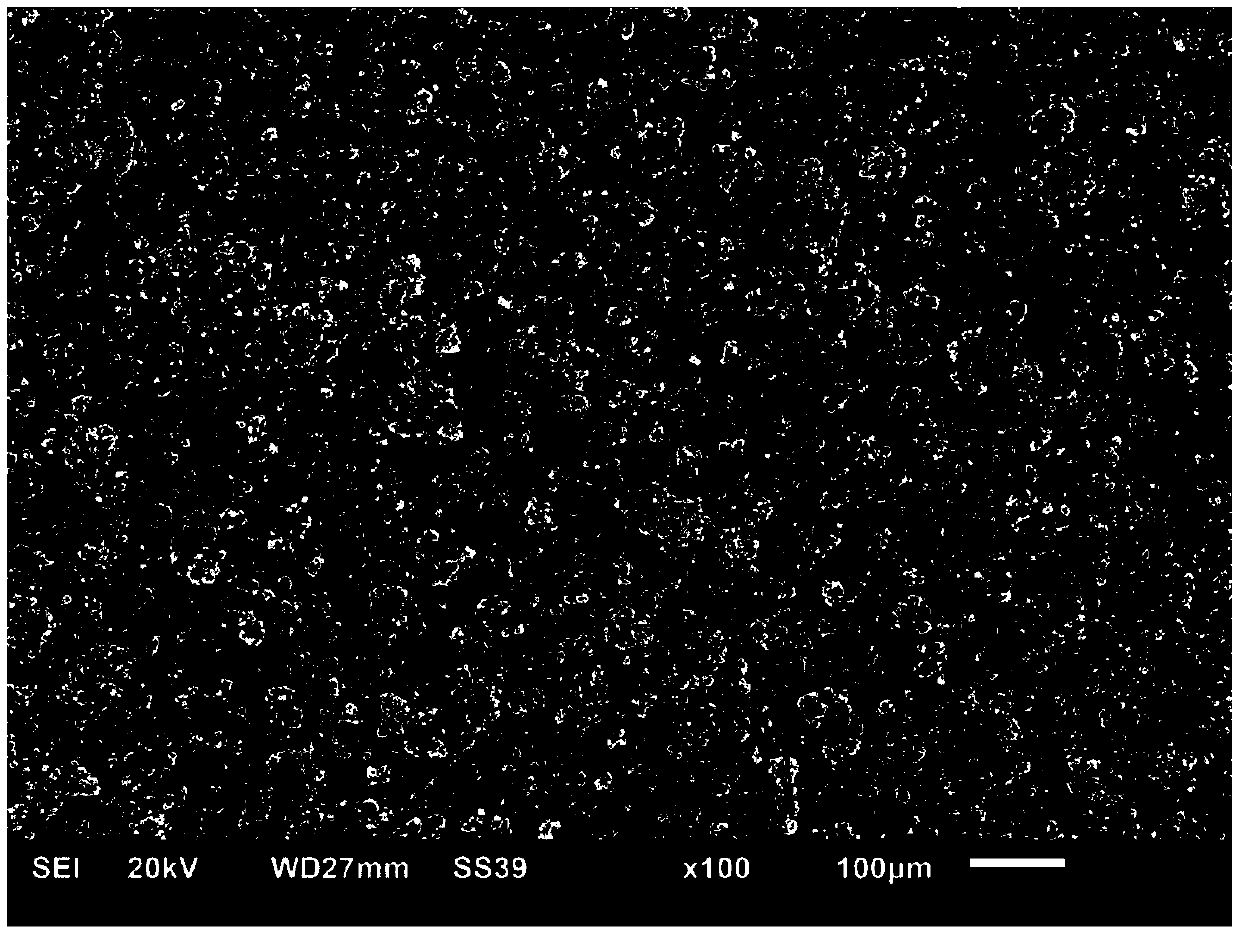

Embodiment 1

[0057] (1) Ingredients of Cu-Al-Si alloy,

[0058] Cut pure copper into φ50mm×100mm rods, pre-treat with pickling and vacuum drying before use, and control the drying temperature at 110±5°C; cut pure aluminum into 50mm×50mm×30mm small aluminum plates, and use acid before use Washing plus vacuum drying pretreatment, the drying temperature is controlled at 200±5°C; the block size of metal silicon is controlled at 5-30mm, pickling before use to remove surface impurities, and then vacuum drying, the drying temperature is controlled at 180± 5°C. The total weight of ingredients is 20Kg, of which by weight: 22-27.5 parts of silicon, 60-70 parts of copper, 0.5-10 parts of aluminum, 0-5 parts of impurities, impurities include: titanium, cobalt, nickel, manganese, iron, boron , phosphorus, carbon, etc., first add part of the silicon, then add copper and aluminum, then add the remaining silicon, and start heating.

[0059] (2) Smelting of Cu-Al-Si alloy:

[0060] Select the technical ...

Embodiment 2

[0081] Example 2, the composition of the copper-aluminum-silicon alloy is by weight: 27.5-32 parts of silicon, 58-63 parts of copper, 1-11 parts of aluminum, 0-5 parts of other impurities, molten copper - The temperature of the aluminum-silicon alloy is 1550±50°C, other steps and methods are basically similar to those in Example 1, Figure 6-10 Shown, the performance of the final product of this embodiment and embodiment 1 is basically the same.

Embodiment 3

[0082] Example 3, the composition of the copper-aluminum-silicon alloy is by weight: 32-39 parts of silicon, 54-59 parts of copper, 1-8 parts of aluminum, 0-5 parts of impurities, molten copper- The temperature of the aluminum-silicon alloy is 1650 ± 50 ° C, and other steps and methods are basically similar to those in Example 1, Figure 11-20 Shown, the performance of the final product of this embodiment and embodiment 1 is basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com