Copper-aluminum-silicon alloy nano cathode material of lithium battery and preparation method thereof

A negative electrode material, silicon alloy technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of short cycle life, low first cycle efficiency, long charge and discharge time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

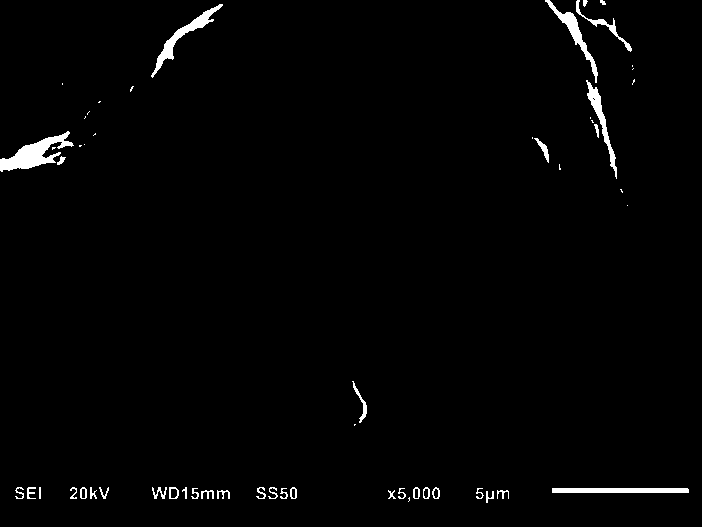

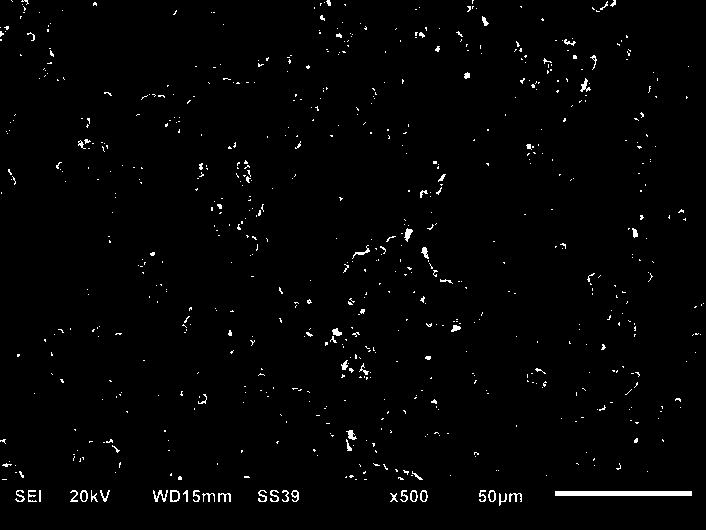

Embodiment 1

[0036] Embodiment 1, a copper-aluminum-silicon alloy nano negative electrode material for a lithium battery, consists of the following raw materials in parts by weight: 42-46 parts of silicon, 50-58 parts of copper, 5-15 parts of aluminum, and 0-3 parts of impurities. The alloy nano-anode material described as a whole includes: pores, shrinkage cavities, shrinkage porosity, dislocations, vacancies and cavities with a multi-defect organizational structure, and the particle size is ≤ 80 μm.

[0037] The present embodiment is prepared according to the following steps:

[0038] (1) Ingredients of Cu-Al-Si alloy:

[0039]Cut pure copper into φ50mm×100mm rods, pre-treat with pickling and vacuum drying before use, and control the drying temperature at 110±5°C; cut pure aluminum into 50mm×50mm×30mm small aluminum plates, and use acid before use Washing plus vacuum drying pretreatment, the drying temperature is controlled at 200±5°C; the block size of metal silicon is controlled at 5-...

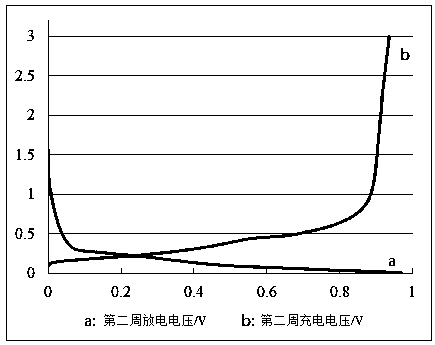

Embodiment 2

[0058] Embodiment 2: a copper-aluminum-silicon alloy nano negative electrode material for a lithium battery, consisting of the following raw materials in parts by weight: 42 parts of silicon, 50 parts of copper, 5 parts of aluminum, and 0.5 part of impurities; its preparation method is as follows:

[0059] (1) Ingredients of Cu-Al-Si alloy:

[0060] Cut pure copper into φ50mm×100mm rods, pre-treat with pickling and vacuum drying before use, and control the drying temperature at 110±5°C; cut pure aluminum into 50mm×50mm×30mm small aluminum plates, and use acid before use Washing plus vacuum drying pretreatment, the drying temperature is controlled at 200±5°C; the block size of metal silicon is controlled at 5-30mm, pickling before use to remove surface impurities, and then vacuum drying, the drying temperature is controlled at 180± 5°C. The total weight of ingredients is 20Kg, including 42 parts of silicon, 50 parts of copper, 5 parts of aluminum, and 0.5 parts of impurities (...

Embodiment 3

[0073] Embodiment 3: a copper-aluminum-silicon alloy nano negative electrode material for a lithium battery, consisting of the following raw materials in parts by weight: 46 parts of silicon, 58 parts of copper, 15 parts of aluminum, and 3 parts of impurities; its preparation method is as follows:

[0074] (1) Ingredients of Cu-Al-Si alloy:

[0075] Cut pure copper into φ50mm×100mm rods, pre-treat with pickling and vacuum drying before use, and control the drying temperature at 110±5°C; cut pure aluminum into 50mm×50mm×30mm small aluminum plates, and use acid before use Washing plus vacuum drying pretreatment, the drying temperature is controlled at 200±5°C; the block size of metal silicon is controlled at 5-30mm, pickling before use to remove surface impurities, and then vacuum drying, the drying temperature is controlled at 180± 5°C. The total weight of ingredients is 20Kg, including: 46 parts of silicon, 58 parts of copper, 15 parts of aluminum, and 3 parts of impurities (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com