Patents

Literature

46results about How to "Promote Nanoization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

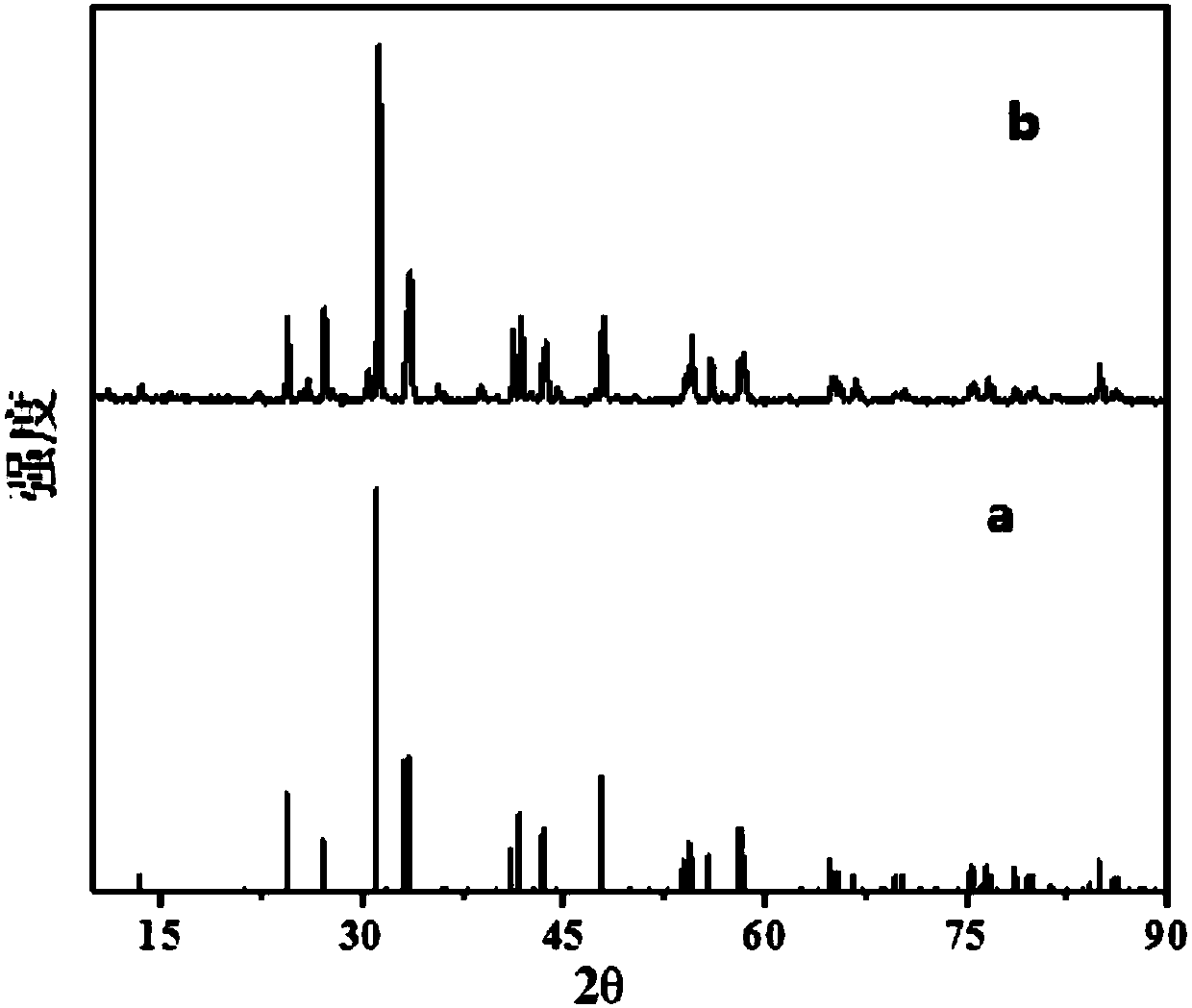

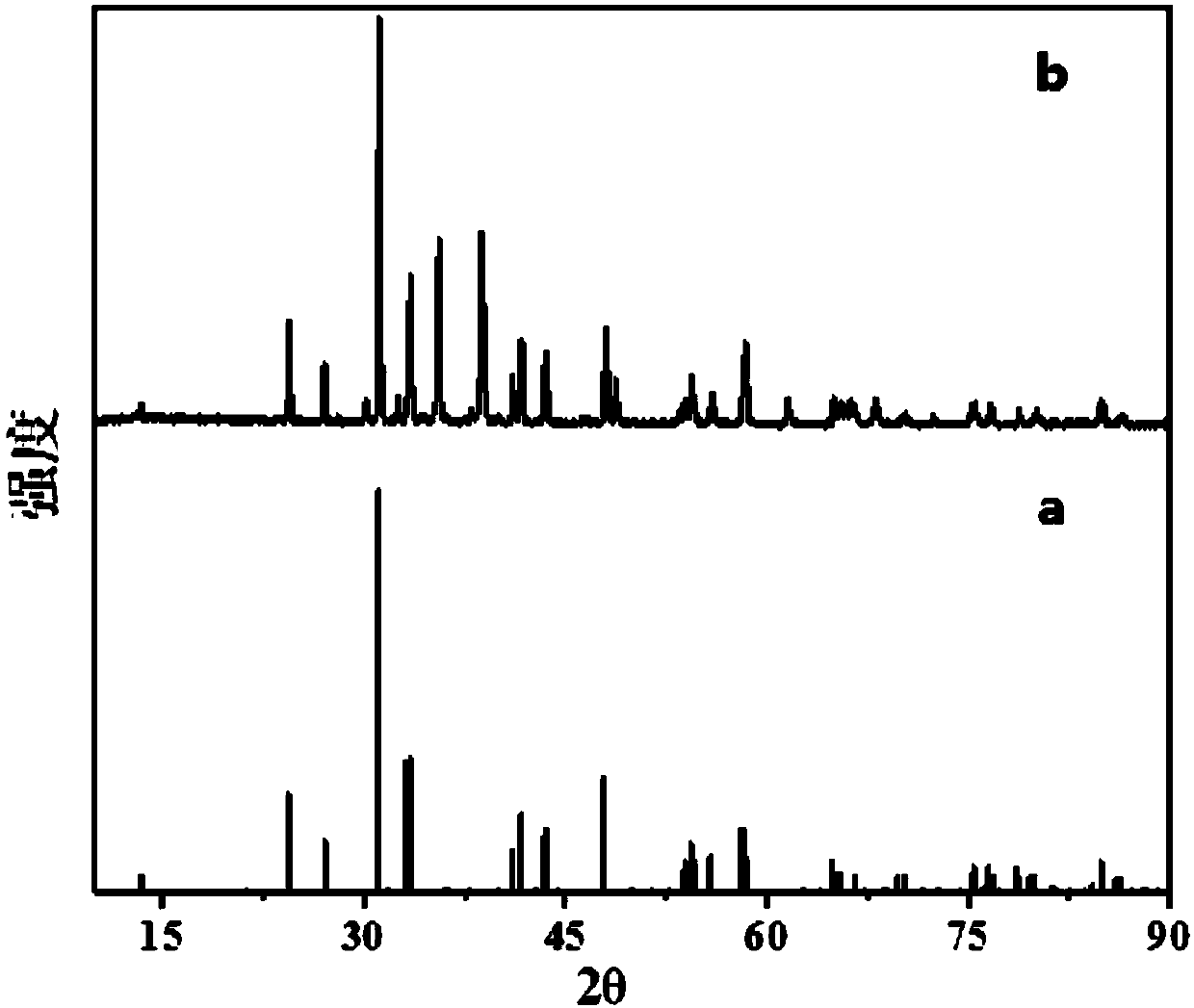

Open framework fluorine-based solid-state electrolyte material and preparation method of open framework fluorine-based solid-state electrolyte material

ActiveCN106887639AImprove conductivityReduce performanceFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteOpen framework

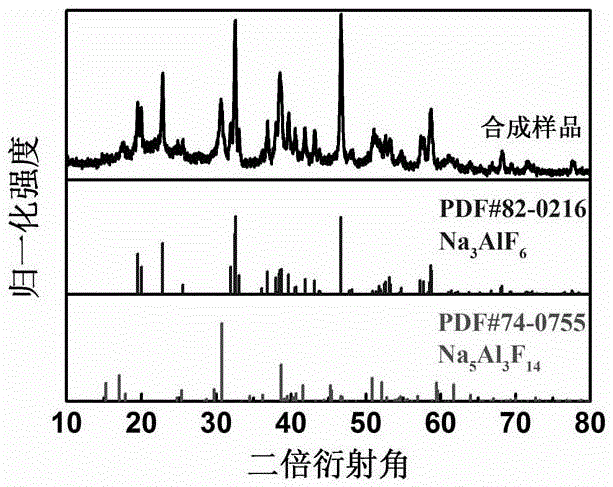

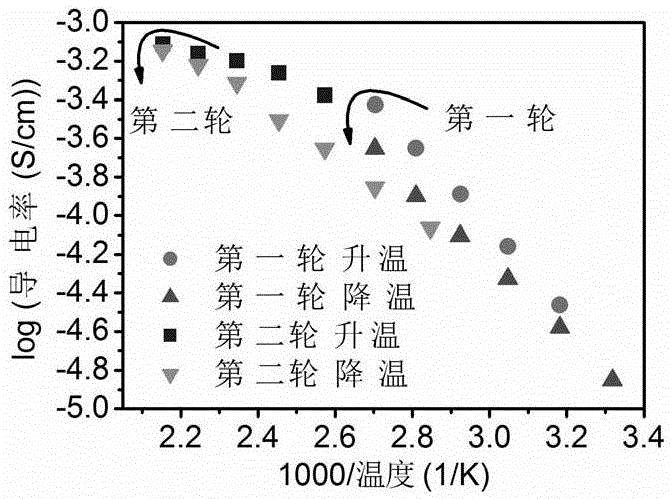

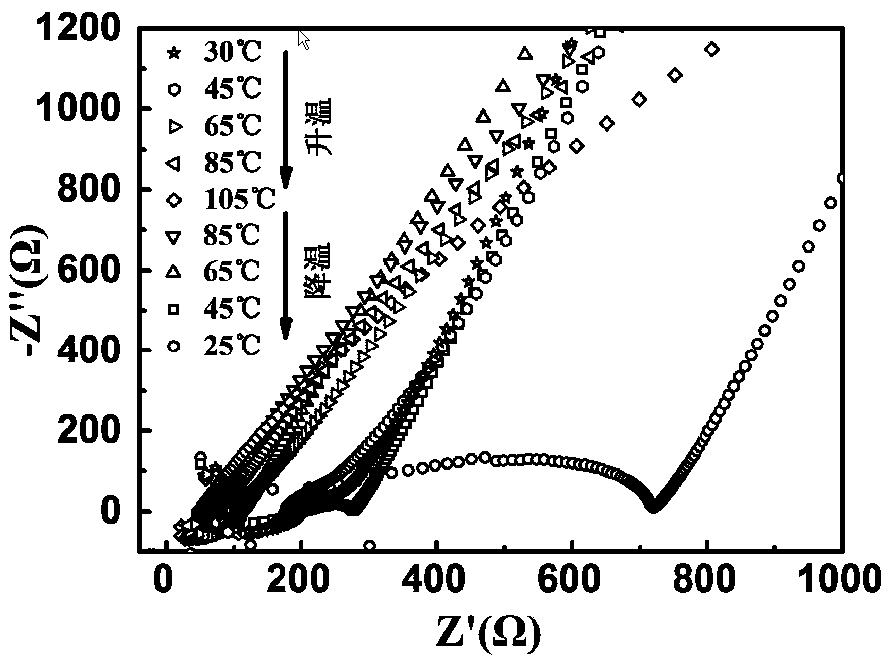

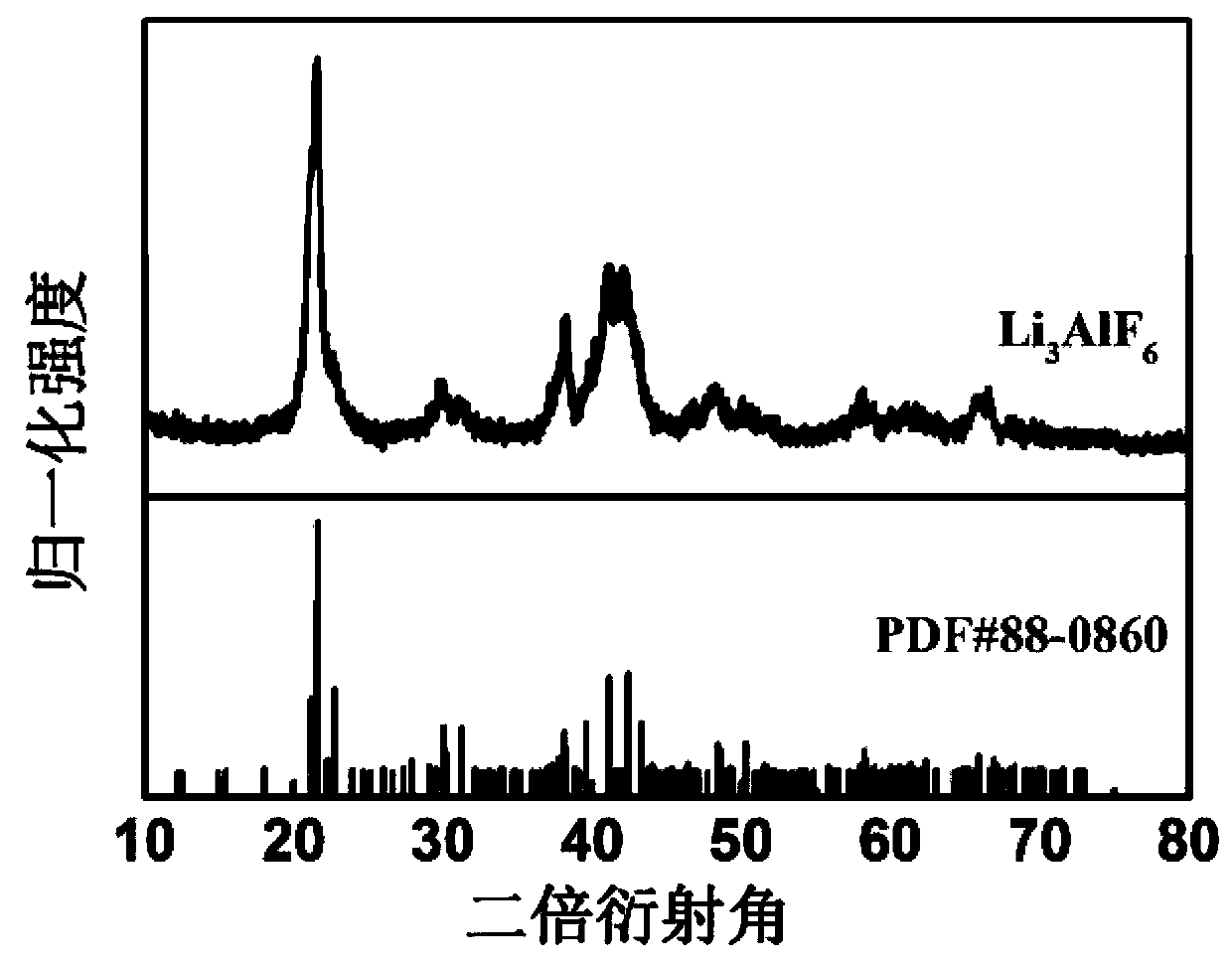

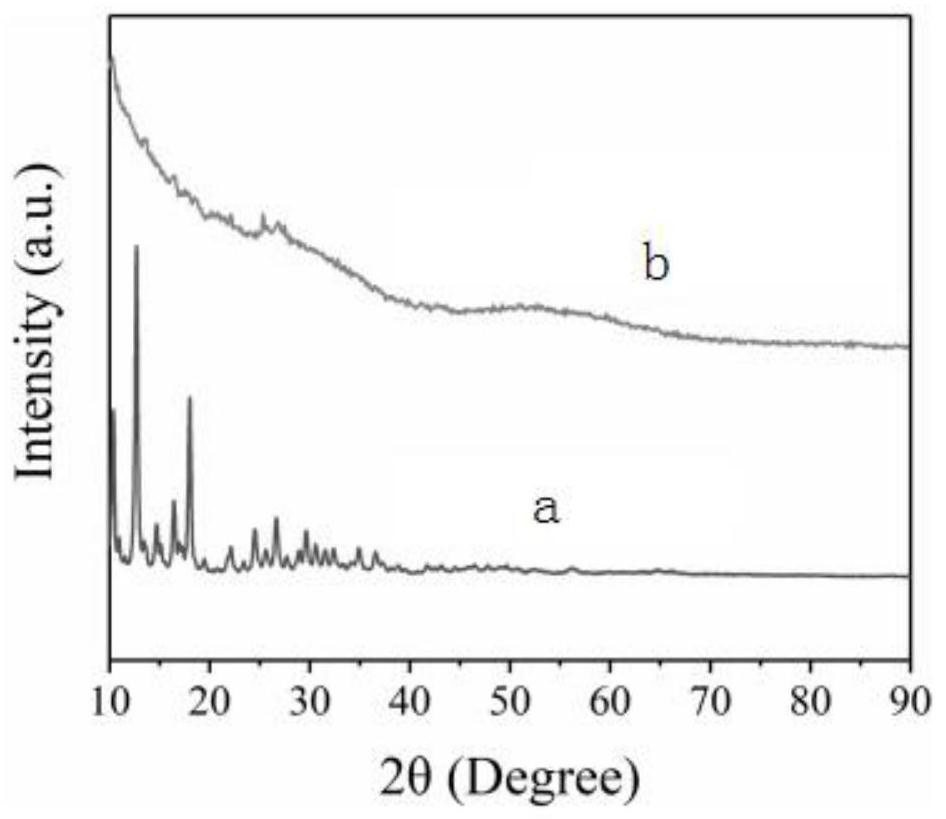

The invention relates to an open framework fluorine-based solid-state electrolyte material and a preparation method of the open framework fluorine-based solid-state electrolyte material. A chemical formula of the electrolyte material is as follows: AxMyFx+3y, wherein x is more than 0 and less than or equal to 6, y is more than 0 and less than or equal to 3, A is Na and / or Li and M is Al and / or Ga. The open framework fluorine-based solid-state electrolyte material AxMyFx+3y provided by the invention is lithium-enriched or sodium-enriched phase aluminum-based or gallium-based fluoride; the invention provides application of a novel open framework structural prototype to fluoride solid-state electrolyte for the first time; meanwhile, lithium enriching or sodium enriching is realized; the concentration of transferable alkali metal ions is increased so that the intrinsic ionic conductivity is easy to improve; the electrical conductivity of a bulk phase and a particle boundary can be improved through means of nanocrystallization, disordering, surface modification and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

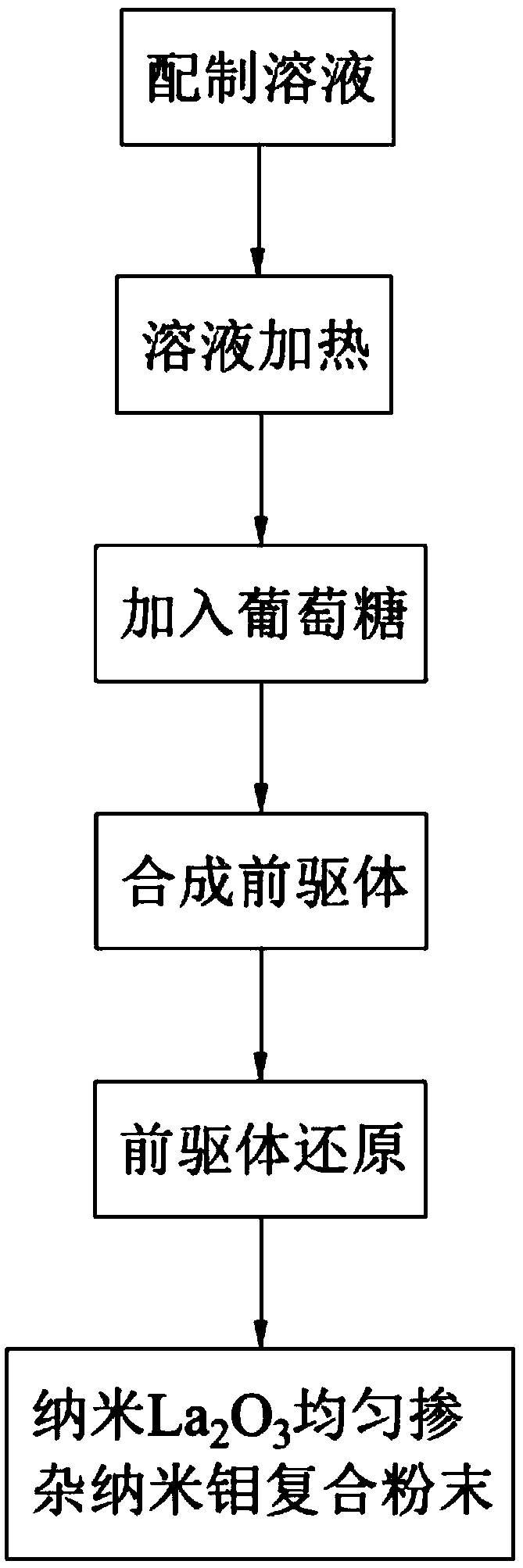

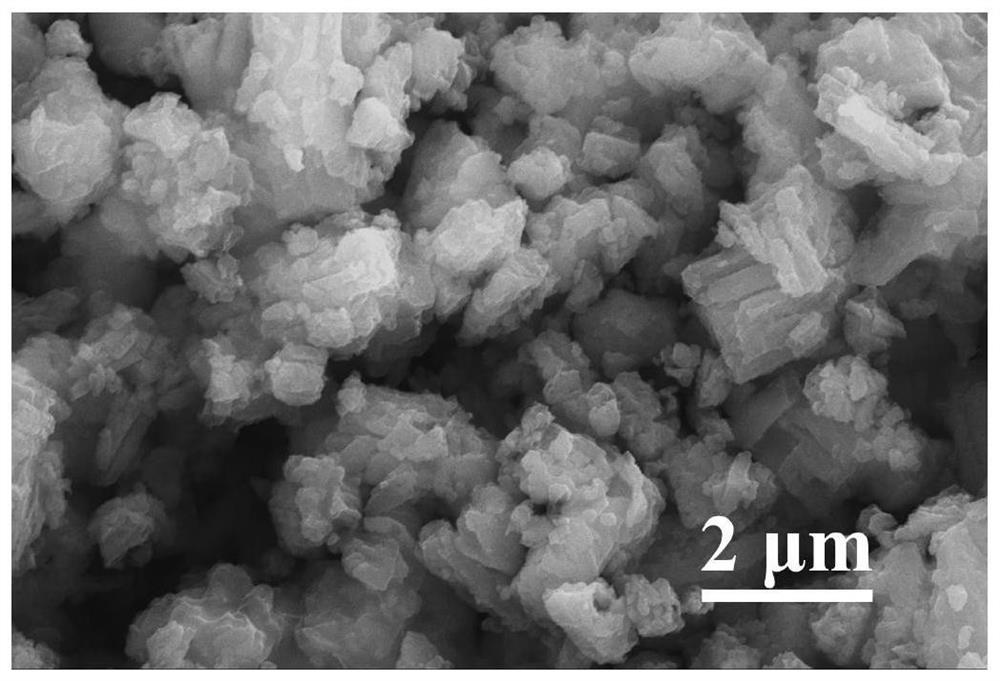

Composite powder formed by uniformly doping nano-La2O3 in nano-Mo and preparation method thereof

ActiveCN106363166AEvenly dispersedEvenly dopedMaterial nanotechnologyTransportation and packagingNanoparticleLanthanum compounds

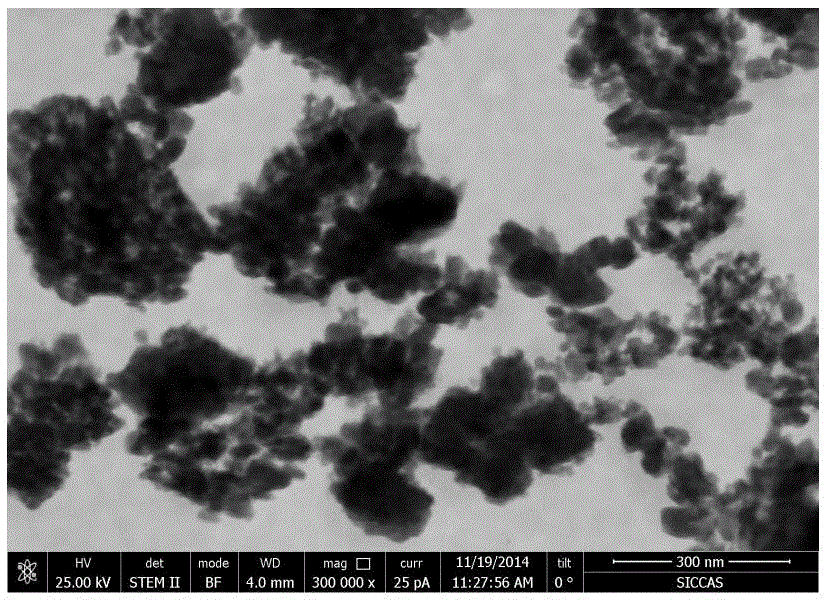

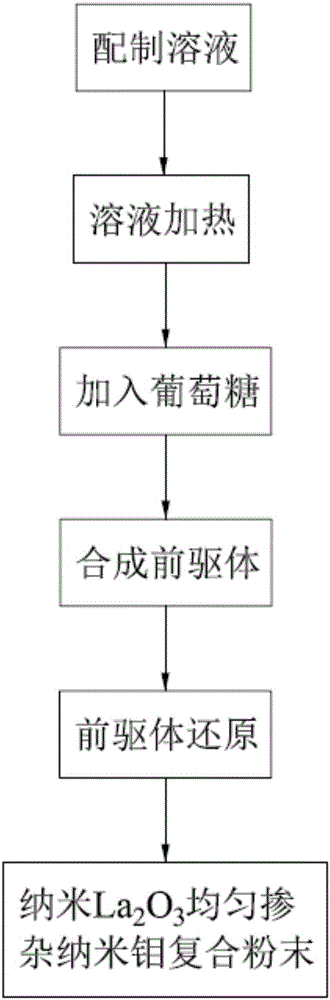

The invention discloses composite powder formed by uniformly doping nano-La2O3 in nano-Mo. The size of the La2O3 and Mo composite powder is 30-100 nm, and the La2O3 content is 0.5-5.0wt.%. The invention further discloses a preparation method of the composite powder. The method includes the technological processes of solution preparing, solution heating, glucose adding, precursor synthesizing, precursor reduction and forming of the composite powder through uniformly doping of the nano-La2O3 in the nano-Mo. According to the composite powder formed by uniformly doping the nano-La2O3 in the nano-Mo and the preparation method thereof, uniform dispersion and stability of nano-particles are guaranteed, and moreover, the powder size can be effectively adjusted and controlled; and meanwhile, the precursor reaction synthesis temperature is low, the reaction time is short, the efficiency is high, energy saving is achieved, and operation is simple.

Owner:XIAMEN UNIV OF TECH

Aviation titanium alloy 3D printing enhancement process

PendingCN112453426AImprove fatigue fracture strengthHigh mechanical strengthAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedLaser scanning

The invention discloses an aviation titanium alloy 3D printing enhancement process, which comprises the following steps: S1, outputting a to-be-laid powder raw material through a mixer, and flatly laying the to-be-laid powder raw material on a powder bed through a scraper strip and a powder leaking groove; S2, performing laser scanning on metal powder on the powder bed for the first time until thetemperature of the metal powder laid on the powder bed rises to a preset temperature; S3, planning a scanning path for a preheated metal powder layer according to a set scanning strategy, and performing laser scanning for the second time; S4, cooling and molding to obtain a solidified metal sheet; S5, performing laser scanning on the solidified metal sheet for the third time to obtain a semi-finished product; and S6, performing laser scanning on the surface of a metal cutting layer of a finished product for the fourth time, and then the aviation titanium alloy 3D printing enhancement processis completed. The process provided by the invention can reduce cracks and bubbles in the finished product, and the finished product is high in mechanical strength, dimensional precision and compactness and low in surface roughness Ra value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Nanometer fibre loading transition metallic catalyst

InactiveCN1990107AEase of conditionsAvoid metal lossOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventChemistry

The invention relates to a nano-fiber loading transition metal catalyst, styrene - acrylonitrile copolymer dissolved by adding solvents reactor for mixing, heating, joining Rh, Pt or Pd chloride for the Coordination in an inert gas protection, formation high polymer and Rh, Pt or Pd complexes solution then vacuum distillation, put into the containers with a nozzle and connected with high-voltage electrostatic generator output terminal, screening the metal receive polymers and Rh, Pt or Pd complexes nanowires, nanowires hot pressing in the glass fiber fabric, crank out nanofibers supported transition metal catalysts, it has the advantages and effect of hydrogenation, oxidation reactions are normal temperature and pressure, prevent metal erosion and catalyst poisoning phenomenon occurred, high activity, does not produce harmful gases and easy separation and recovery, will not cause environmental pollution, can greatly simplify the process.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Anatase/brookite complex-phase titanium dioxide ultraviolet shielding agent and preparation method thereof

InactiveCN110697769AHigh whitenessHigh refractive indexMaterial nanotechnologyPhysical treatmentUltravioletMaterials science

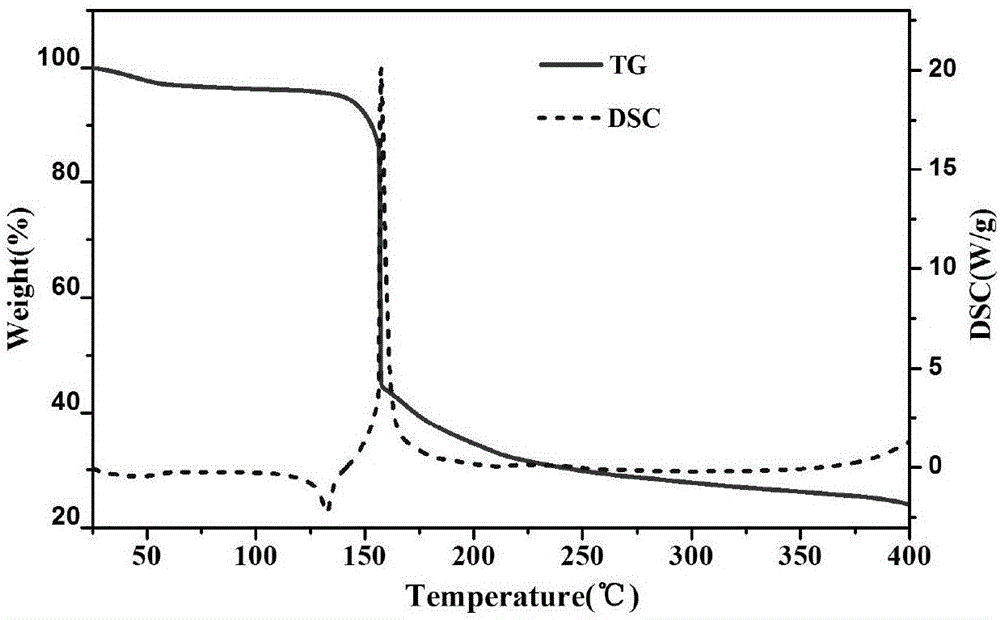

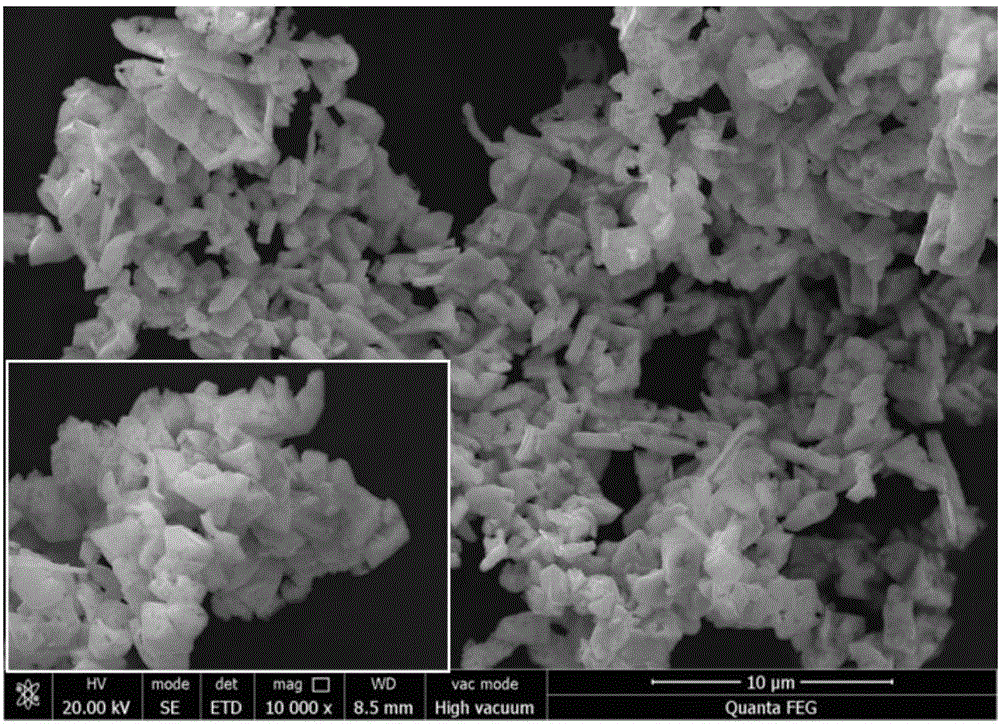

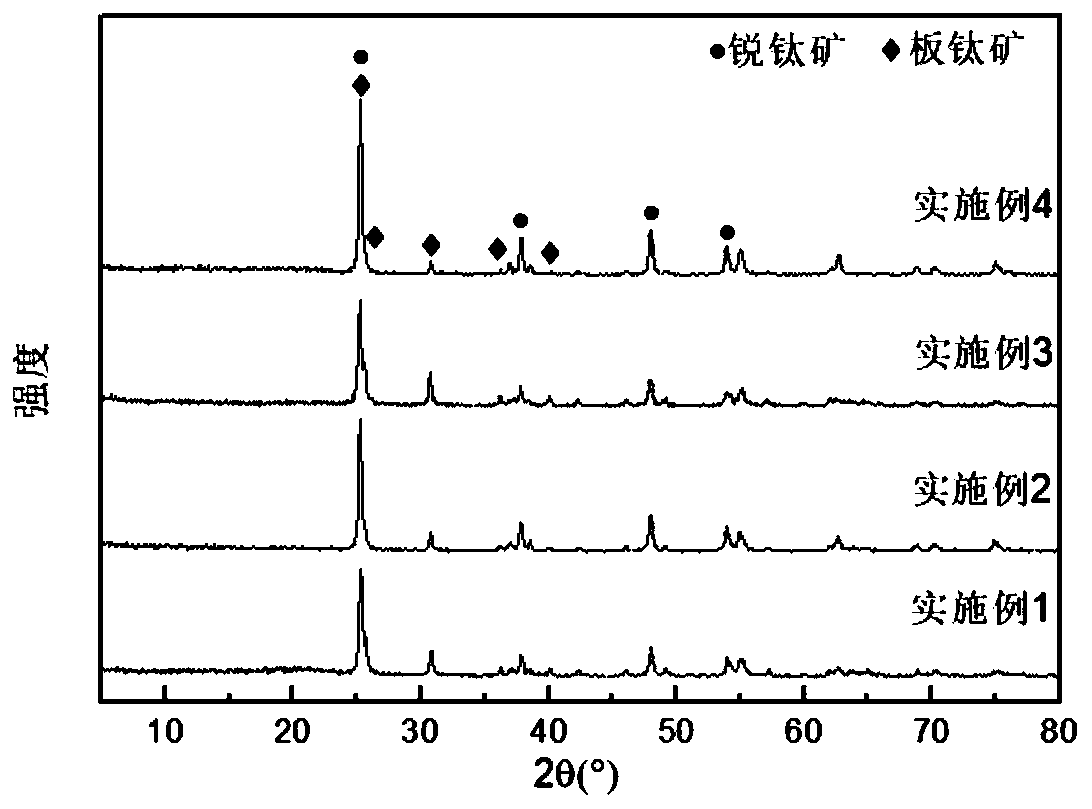

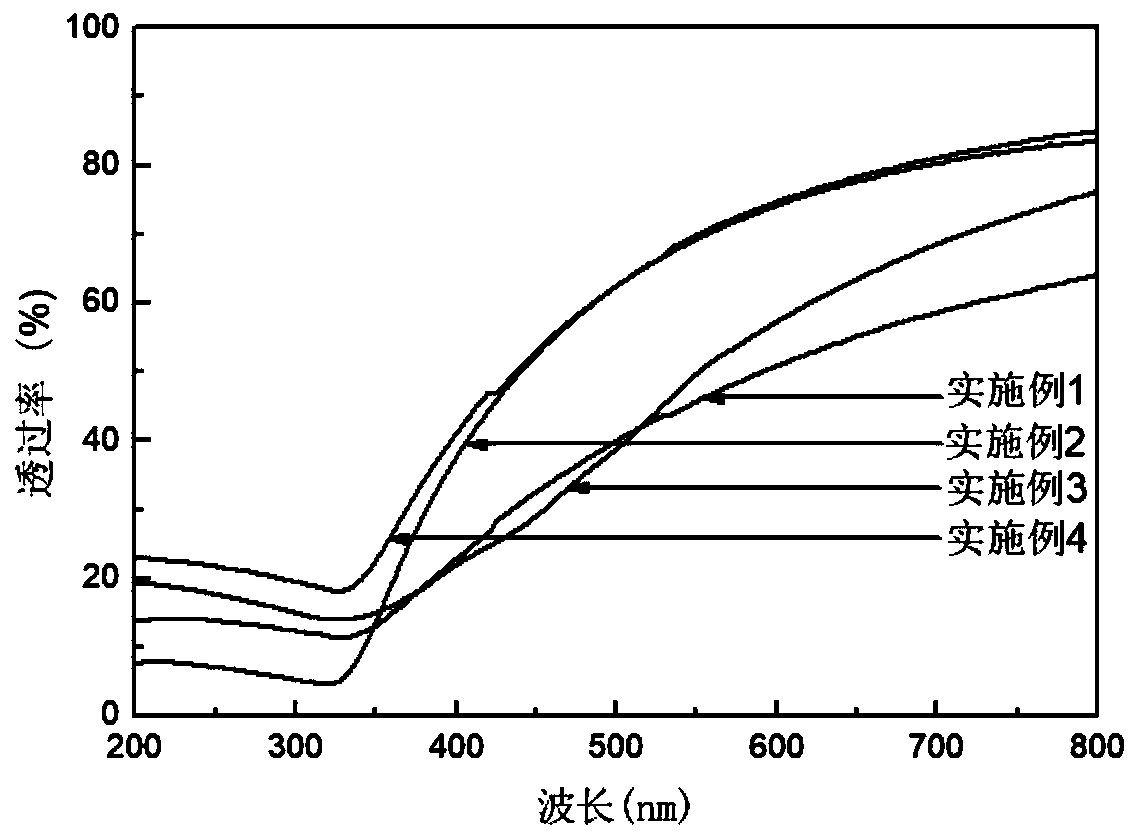

The invention relates to an anatase / brookite complex-phase titanium dioxide ultraviolet shielding agent and a preparation method thereof, and belongs to the technical field of novel inorganic materials. According to the invention, the ultraviolet shielding performances of different phases of titanium dioxide are fully utilized, and in a hydrothermal synthesis system of titanium alkoxide, the anatase / brookite complex-phase titanium dioxide ultraviolet shielding material is prepared by using cheap inorganic sodium salt as a crystal form guiding agent, so that the defects of poor light scatteringand poor reflection of the anatase type titanium dioxide ultraviolet region are overcome, and the visible light transmission effect of the composite shielding agent is guaranteed; with the method, the ratio of the anatase type TiO2 to the brookite type TiO2 in the complex-phase shielding agent can be controlled by adjusting the dosage of the crystal form guiding agent, so that the working performances of the shielding agent in UVA and UVB sections can be adjusted as required; and the grain growth of TiO2 can be inhibited by utilizing the interaction between different crystalline phase grainsof the complex-phase TiO2 so as to successfully achieve the nanocrystallization control of TiO2, so that the excellent performance of the obtained ultraviolet shielding agent is guaranteed.

Owner:JILIN UNIV

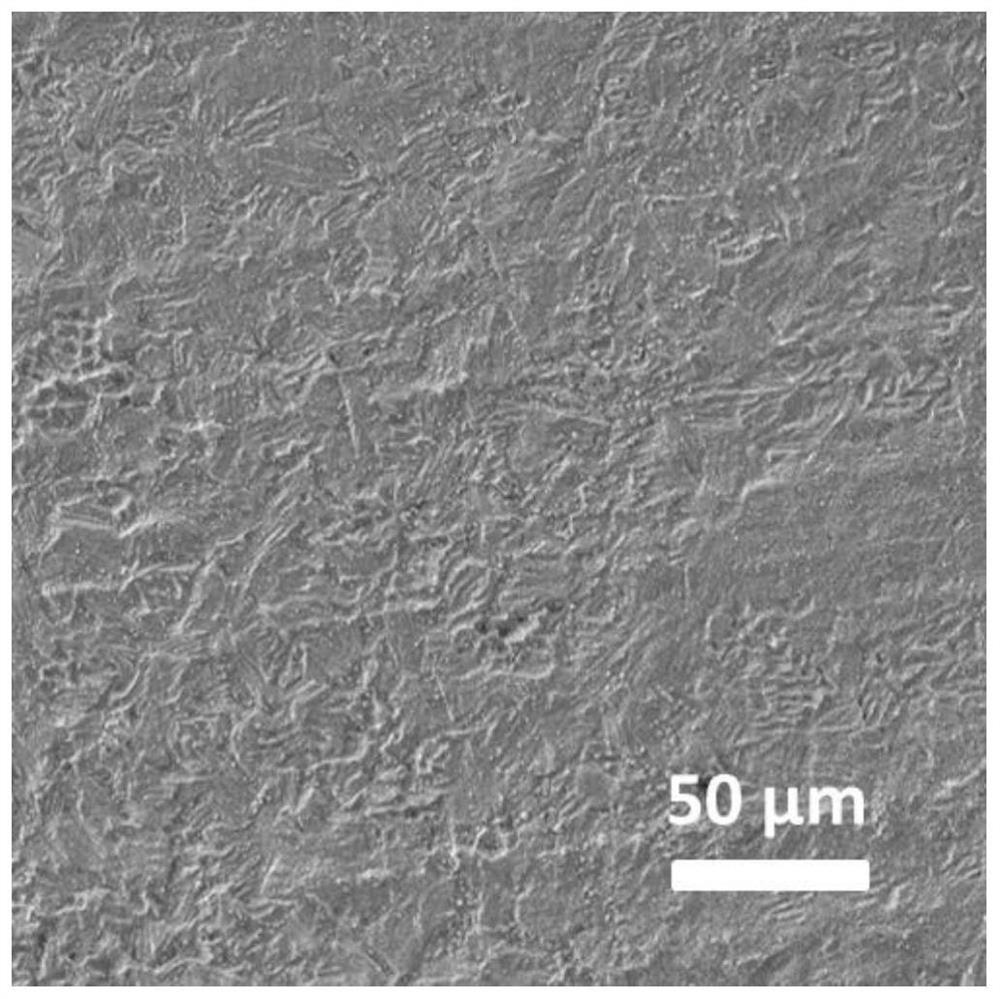

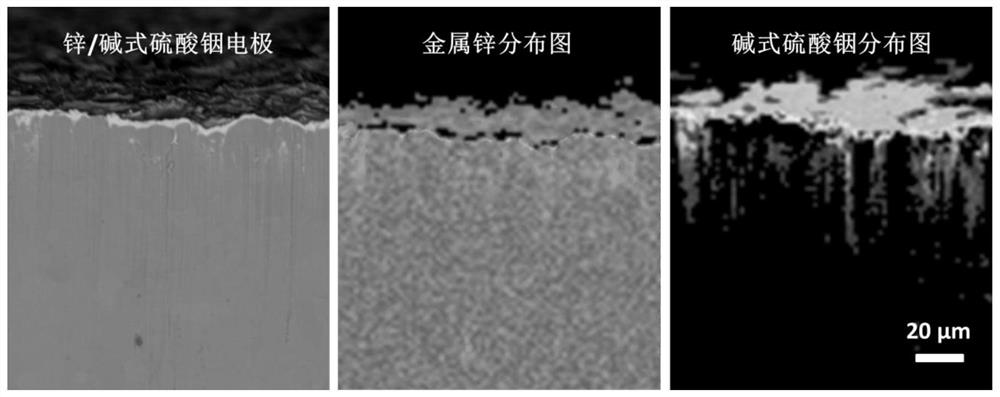

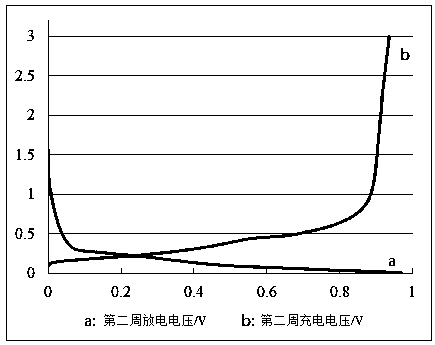

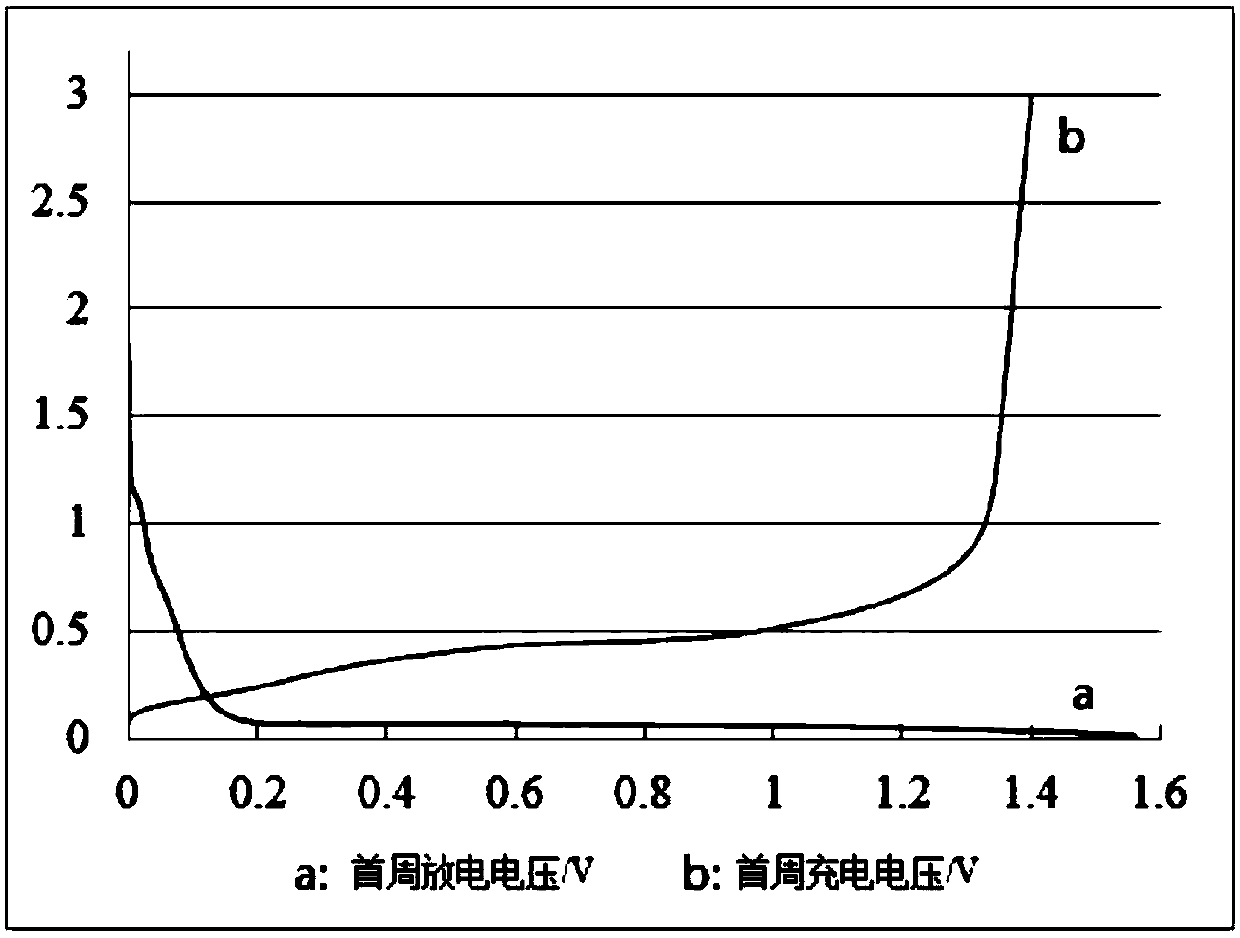

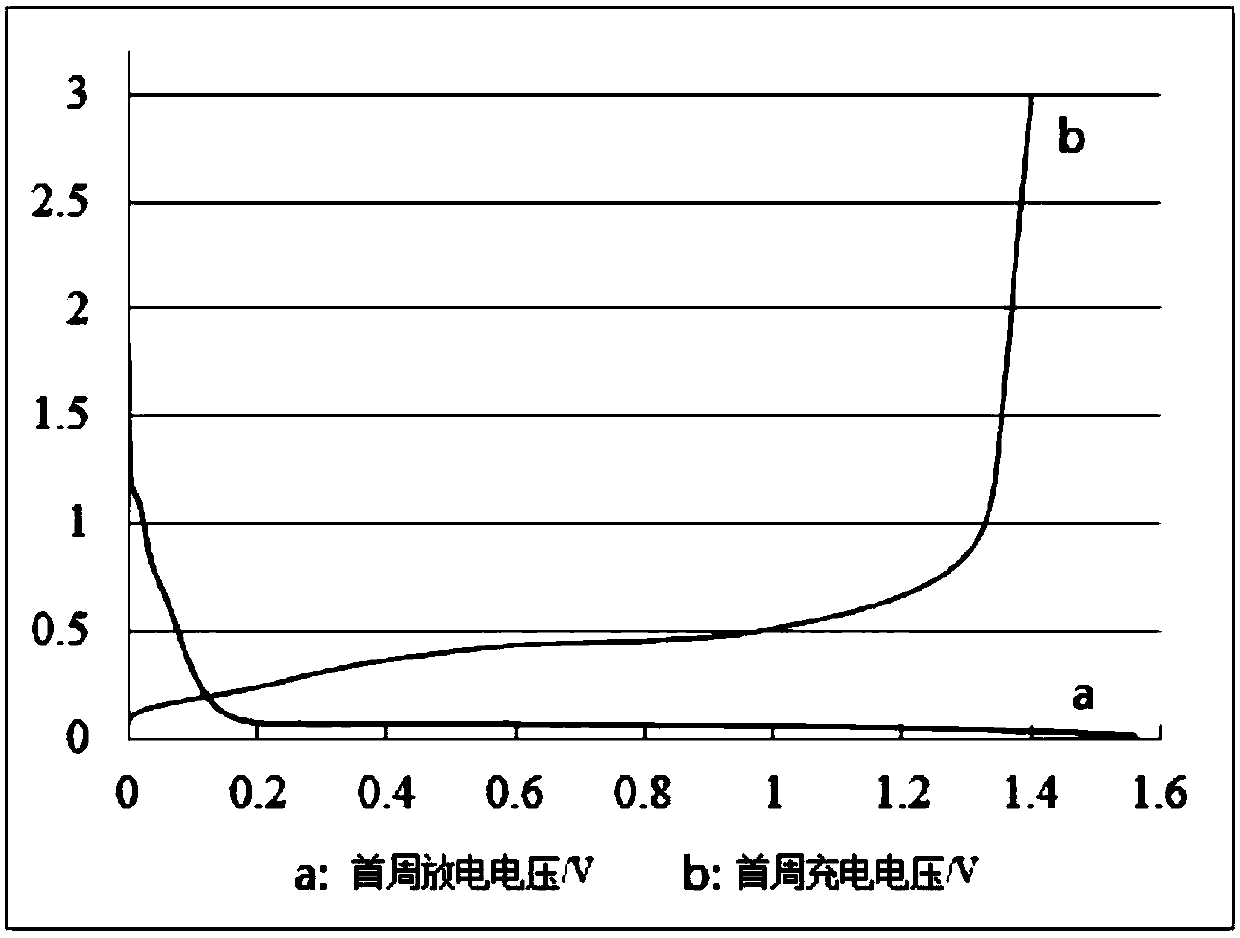

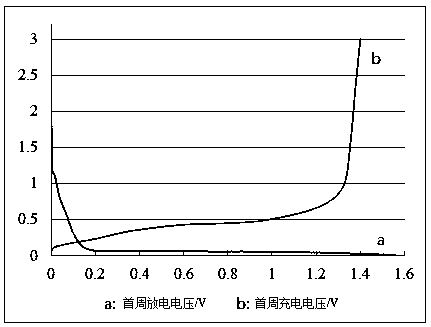

Long-cycle-life aqueous zinc secondary battery negative electrode and preparation and application thereof

InactiveCN112331933AImprove Coulombic efficiencyInhibition of dendrite growthFinal product manufactureZinc-halogen accumulatorsSolid state electrolyteElectrolytic agent

The invention discloses a preparation method of a long-cycle-life aqueous zinc secondary battery negative electrode, and belongs to the technical field of zinc secondary batteries. The preparation method comprises the following steps: firstly, carrying out chemical replacement reaction on zinc and metal salt to deposit a metal simple substance on the zinc metal surface and further to obtain a zincmetal surface covered solid electrolyte precursor; covering a solid electrolyte precursor on the surface of zinc metal to serve as a negative electrode to assemble a battery; and after the solid electrolyte precursor material is subjected to in-situ electrochemical cycle activation, generating solid electrolyteon the surface of zinc metal in situ, and obtaining the zinc secondary battery negativeelectrode material. The obtained zinc / solid electrolyte electrode has a large actual electrochemical active area and high mechanical stability, and meanwhile, the solid electrolyte isolates zinc metal from liquid electrolyte, so that the defects of active metal corrosion, surface passivation, dendritic crystal growth and the like of a traditional zinc metal electrode are inhibited, and the cycling stability of an electrode material is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Copper-aluminum-silicon alloy nano cathode material of lithium battery and preparation method thereof

ActiveCN107790712AUnique structureImprove conductivityMaterial nanotechnologyTransportation and packagingSilicon alloyNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nano cathode material of a lithium battery and a preparation method thereof, and belongs to the technical field of cathode materials of the lithium battery. The adopted technical scheme is that the copper-aluminum-silicon alloy nano cathode material of the lithium battery comprises the following raw materials in parts by weight: 42 to 46 parts of silicon, 50 to 58 parts of copper, 5 to 15 parts of aluminum and 0 to 3 parts of impurities; the copper-aluminum-silicon alloy nano cathode material integrally comprises a multi-defect structurewith pores, shrinkage cavities, shrinkage porosities, dislocation, vacancy and holes; and the particle size is smaller than or equal to 80 <mu>m. The copper-aluminum-silicon alloy nano cathode material can be applied to the technical field of cathode materials of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Method for filling and synthetizing full waterborne polyurethane base leather through nano attapulgite

InactiveCN104727156ARich sourcesImprove mechanical propertiesTextiles and paperWoven fabricPolymer chemistry

The invention discloses a method for filling and synthetizing full waterborne polyurethane base leather through nano attapulgite. The method includes adopting non woven fabrics as the base fabric, and soaking the non woven fabric in NaCl water solution; drying and ironing the soaked base fabric, and calendering the surface; adopting attapulgite as raw material, smashing, soaking in water, extruding through opposite rollers, aging and adding anionic waterborne polyurethane for high speed pre-dispersion; adding foaming agent, foam stabilizing agent and aqueous colorant sequentially, mixing at high speed, and obtaining waterborne polyurethane synthesis leather slurry; soaking the pretreated base fabric in the waterborne polyurethane synthesis leather slurry, scraping the surface, drying, and obtaining the waterborne polyurethane base leather. The attapulgite filler is low in cost and easy to prepare, the synergistic reinforcement effect of fibrillar attapulgite and associated minerals is played completely, the mechanical property of the synthesis base leather is improved effectively, organic solvent is omitted during production, safety and environment protection can be achieved, the process is easy and simple to implement, and large-scale production is easy to implement.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

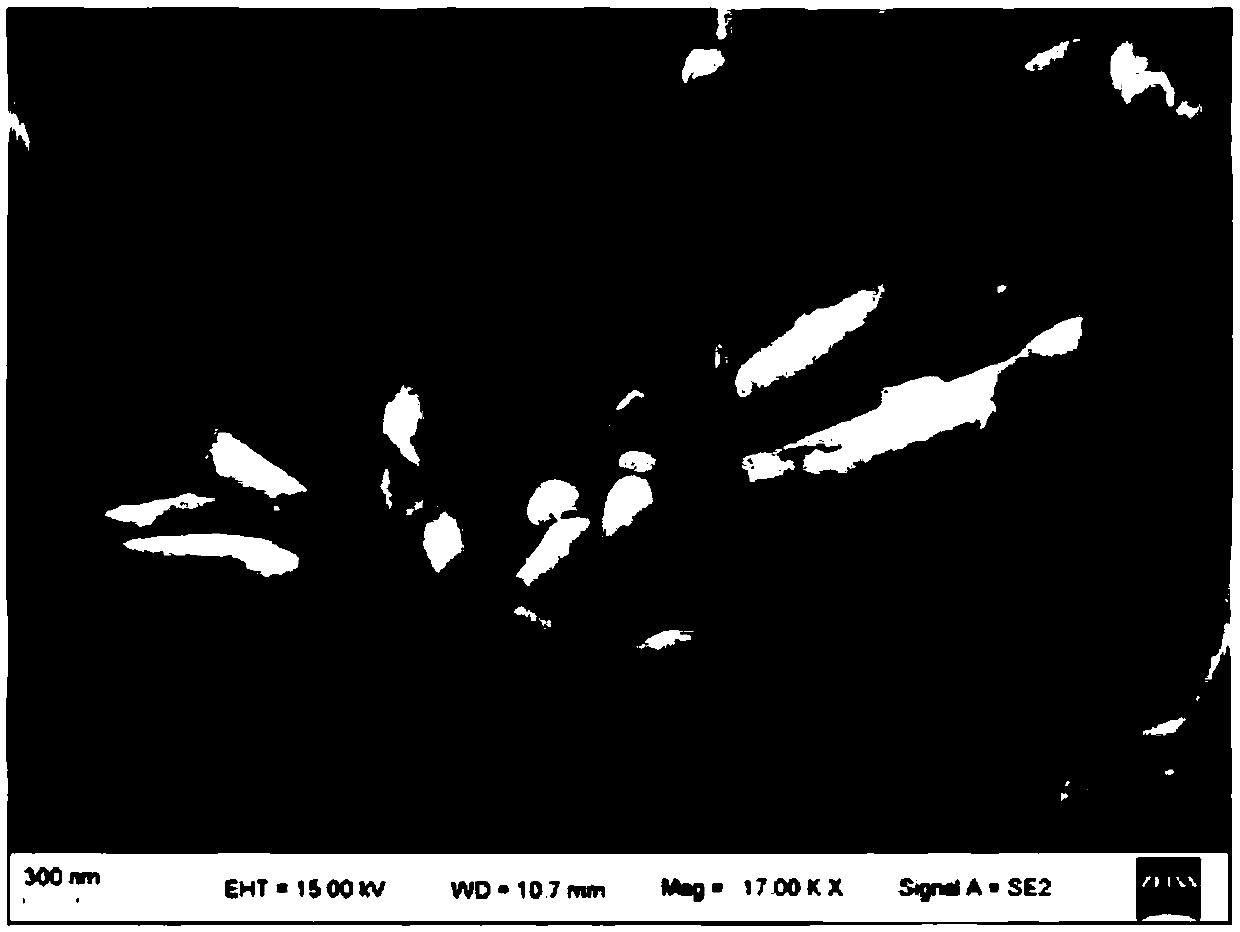

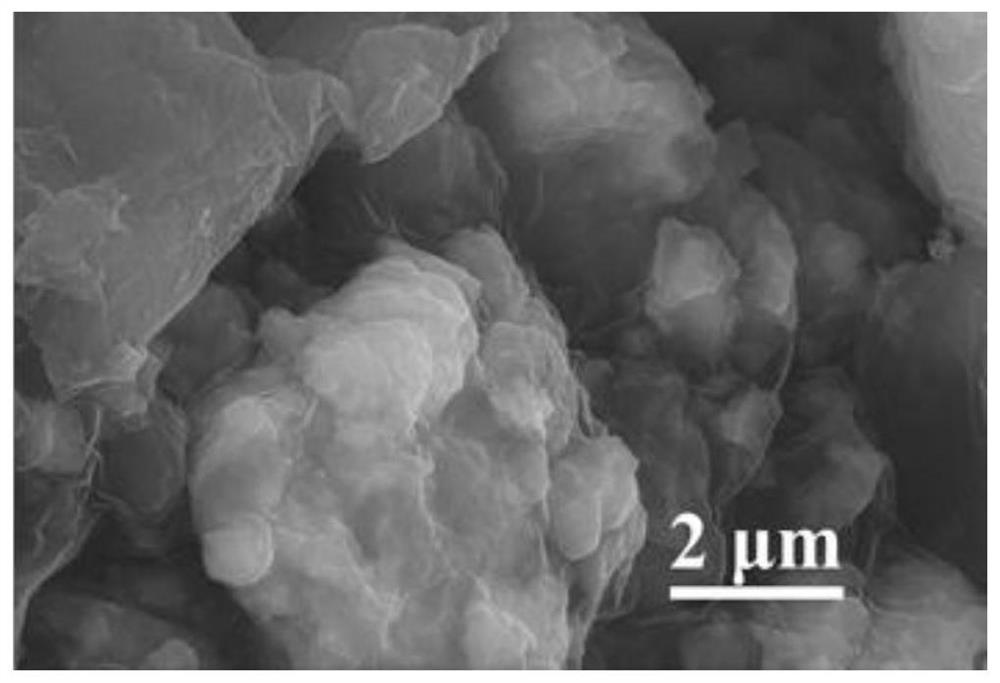

Preparation method of lanthanum cuprate nano adsorption material

ActiveCN107857289AGood catalytic effectLarge aspect ratio and specific surface areaOther chemical processesWater contaminantsElectrospinningChemistry

The invention relates to the technical field of preparation of copper-based rare earth materials, specifically to a preparation method of a lanthanum cuprate nano adsorption material. The powder preparation is performed in combination with an improved electrostatic spinning method and a chemical synthesis method. Lanthanum cuprate La2CuO4 nano power prepared according to the method provided by theinvention is high in purity, good in appearance, small in grain size and strong in adsorption property for malachite green. The preparation method provided by the invention is economic, efficient, simple to operate, low in requirements for equipment conditions and capable of realizing the controllable preparation of La2CuO4; the prepared lanthanum cuprate power has a nanometer scale, so that theapplication range of the lanthanum cuprate power is greatly enlarged, and the suitability for industrial production is realized.

Owner:NORTHEASTERN UNIV

Preparation method and application of Ce-containing visible light catalytic nanomaterial

ActiveCN107930636AEffective dispersionShort reaction timeMaterial nanotechnologyWater/sewage treatment by irradiationChemical synthesisPhoto catalysis

The invention belongs to the technical field of nanomaterials and photocatalytic materials, and particularly relates to a preparation method and application of a rare earth and transition metal composite visible light catalytic material, in particular to a preparation method and application of a Ce-containing visible light catalytic nanomaterial. The invention adopts a method of combining simple chemical synthesis with an external electric field; the method has the characteristics of short reaction time, energy reservation, no possibility of producing industrial wastes, less pollution and suitability for mass production; meanwhile, by controlling the external electric field, the morphology and related properties of prepared Cu-Ce nano-powder are changed and the controllability is good. According to the preparation method and the application disclosed by the invention, the applied electric field is improved, and cross control over a direct-current electric field and an alternating current electric field is adopted.

Owner:东北大学秦皇岛分校

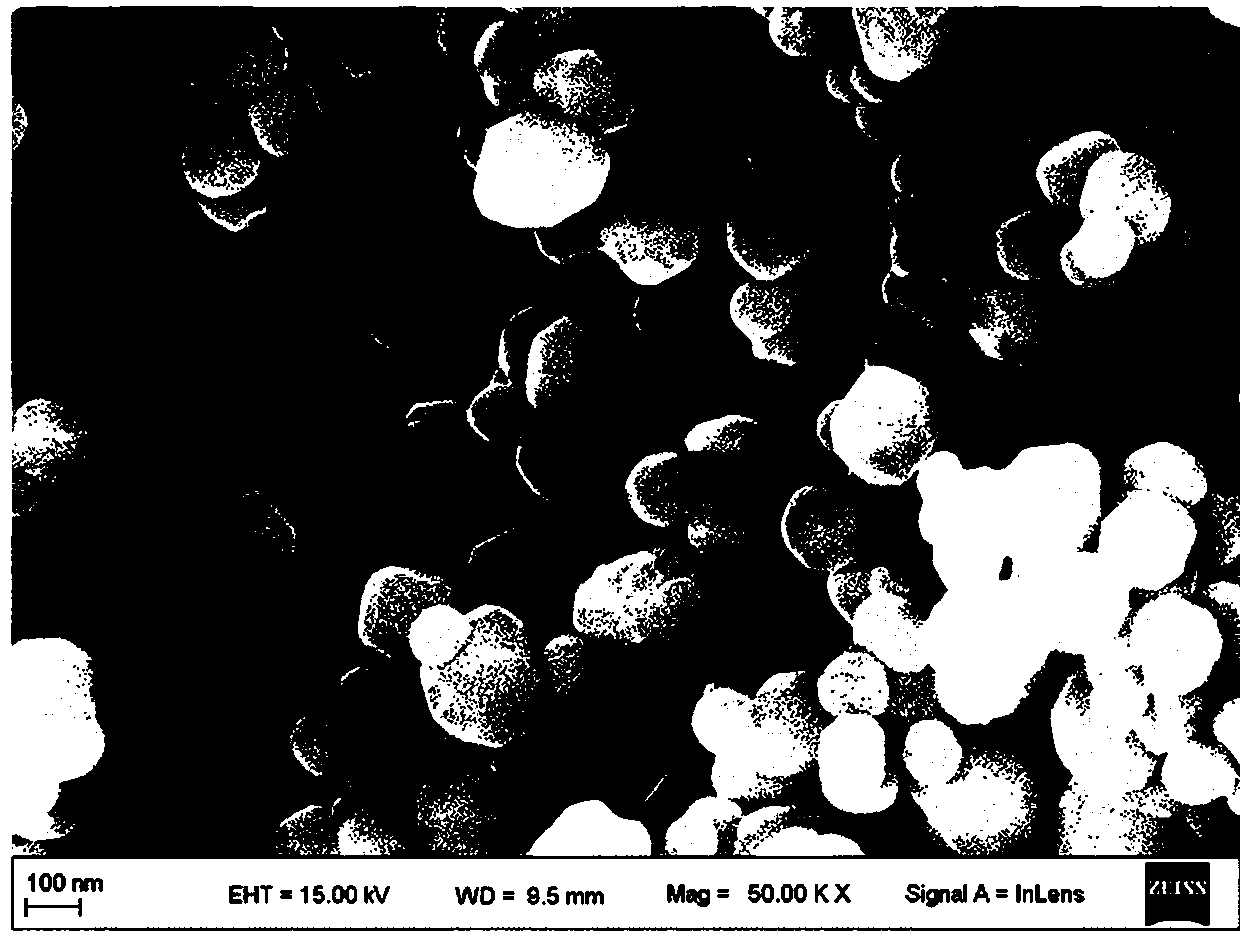

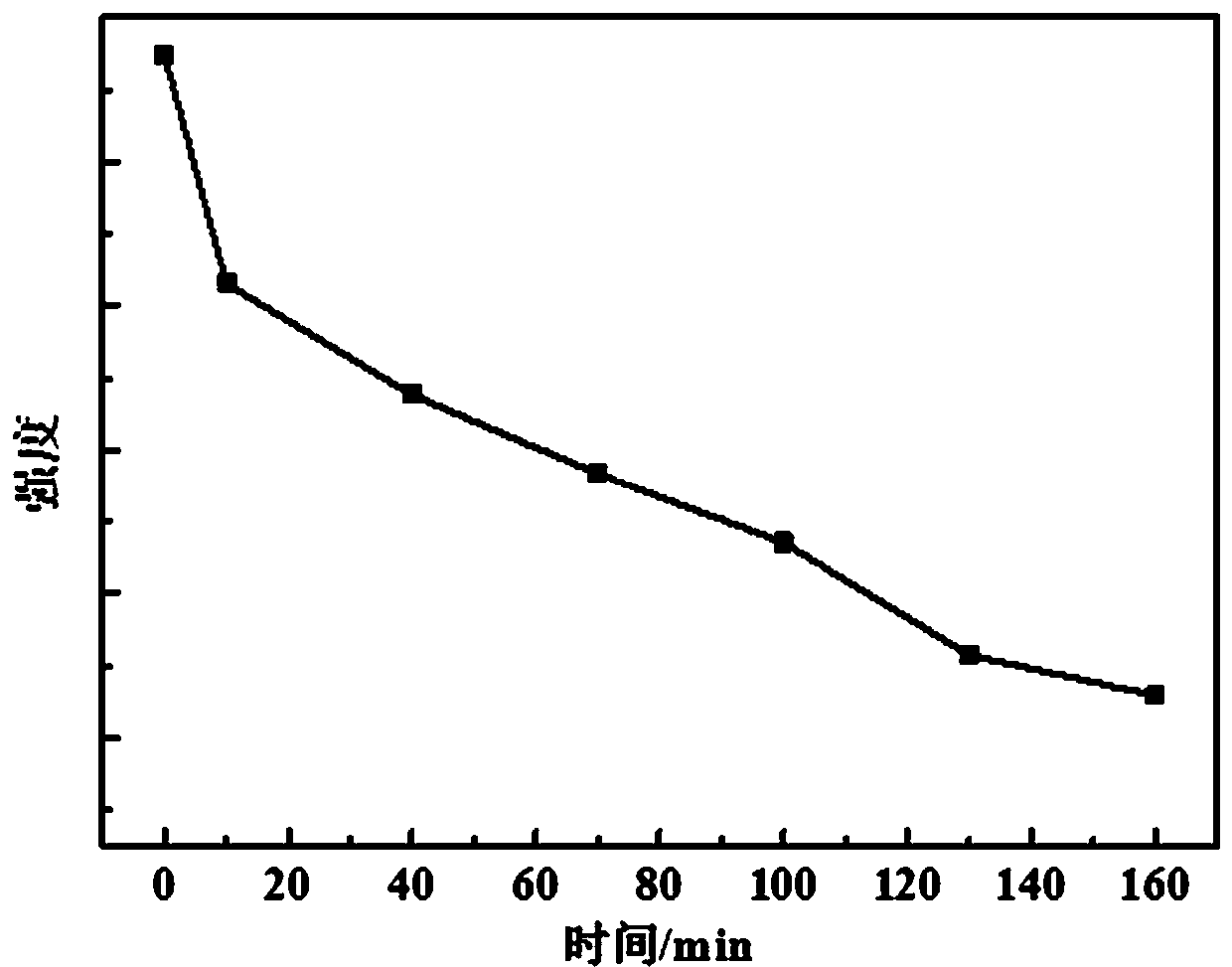

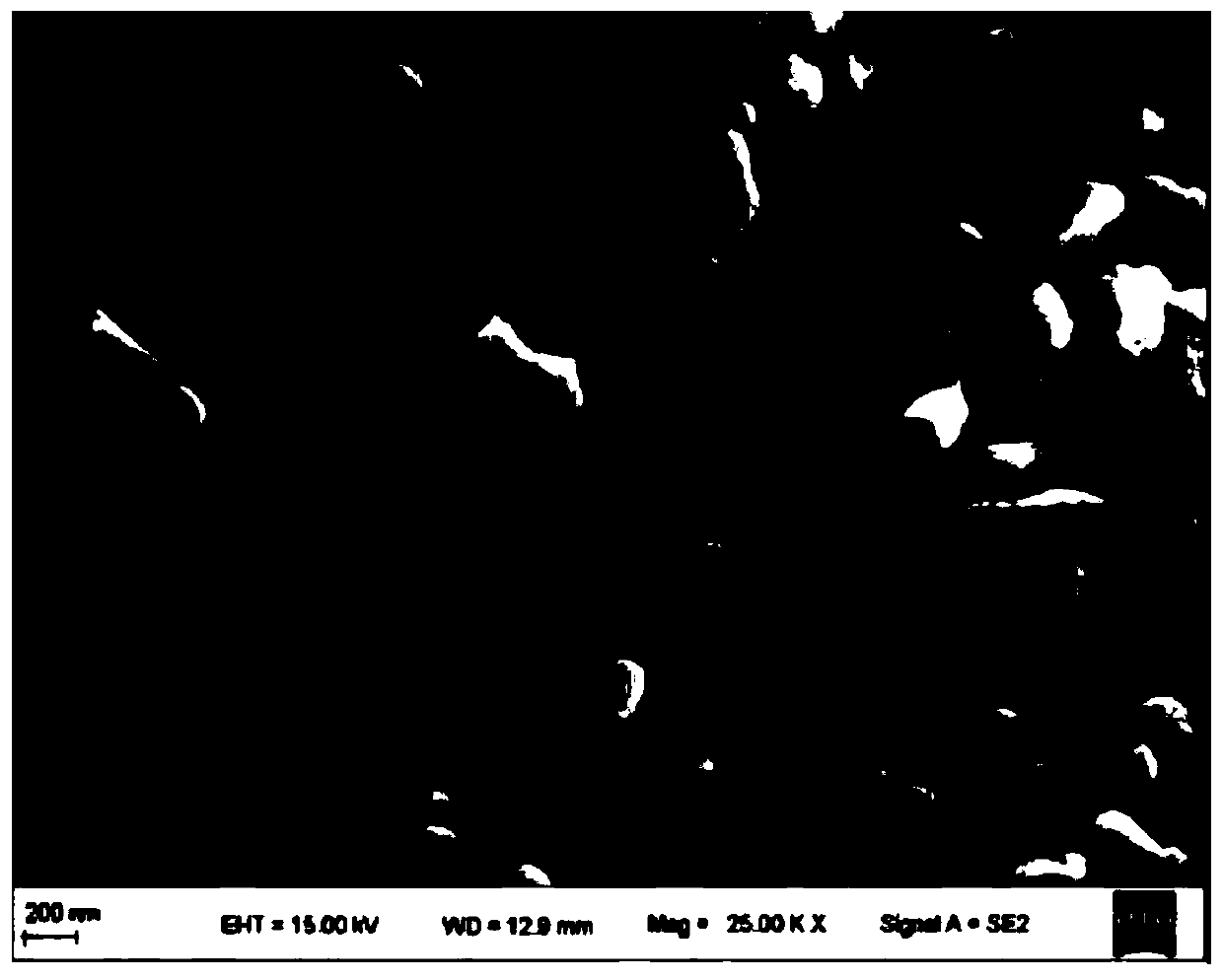

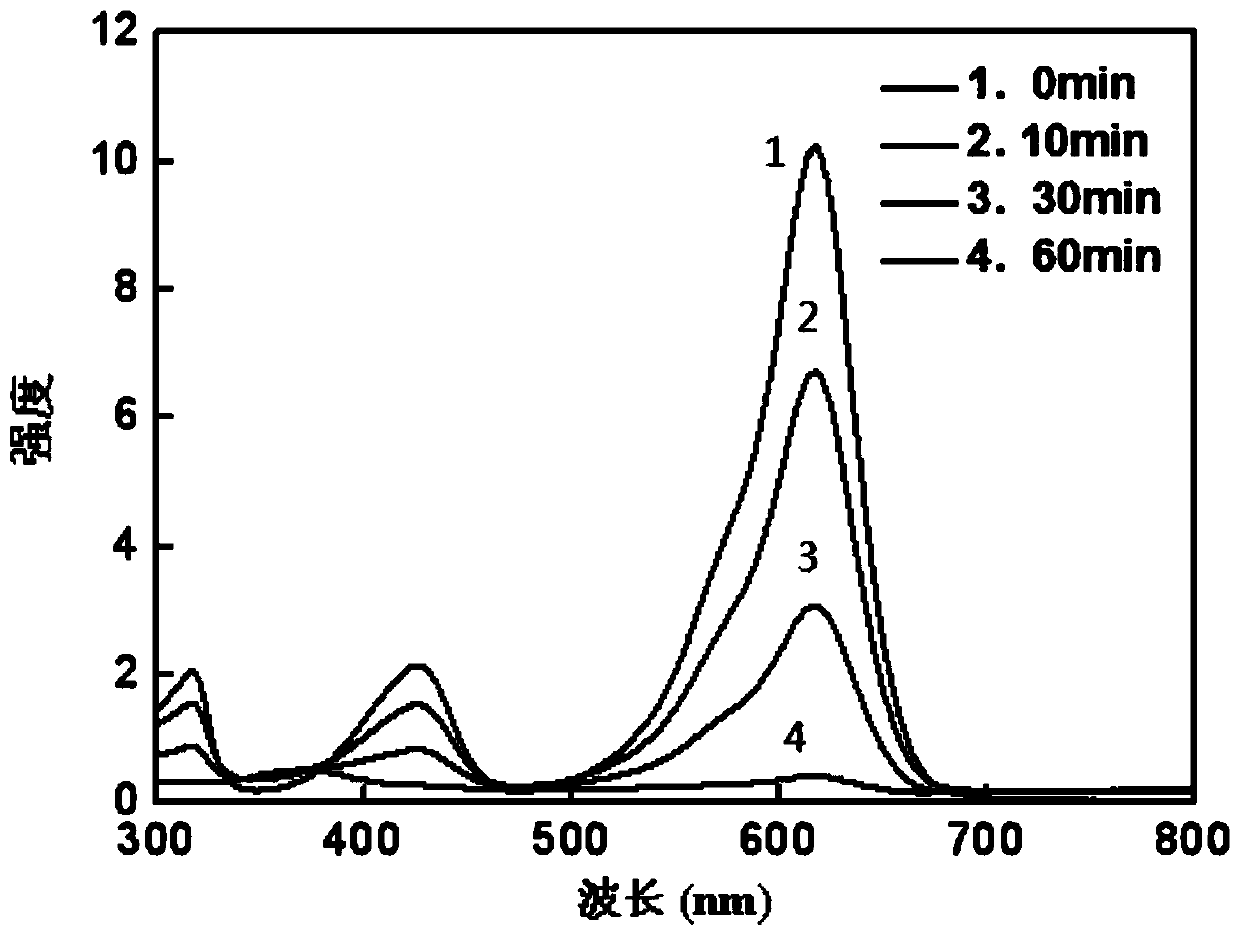

Preparation method and application of samarium cuprate nano-photocatalytic powder

ActiveCN107758723AShort reaction timeEnergy savingWater/sewage treatment by irradiationWater contaminantsIonElectrospinning

The invention relates to the technical field of photocatalysis and discloses a preparation method and application of samarium cuprate nano-photocatalytic powder. Preparation is performed by adopting an improved electrostatic spinning method and an electric field. The method is low in sintering temperature, and the samarium cuprate (Sm2CuO4) nano-powder is high in purity, uniform in particle size and large in specific surface area and has excellent photocatalytic performance on malachite green. The preparation method provided by the invention is easy to operate and low in cost; the preparationconditions are mild, and the condition that impurities are introduced or losses of metallic materials are caused is avoided; and the stoichiometric ratio of metal ions in precipitates can be ensured,and the method can be popularized and applied to industrial production. The prepared samarium cuprate nano-photocatalytic powder can serve as a photocatalyst and is applied to treatment of malachite green containing industrial and dye wastewater.

Owner:NORTHEASTERN UNIV

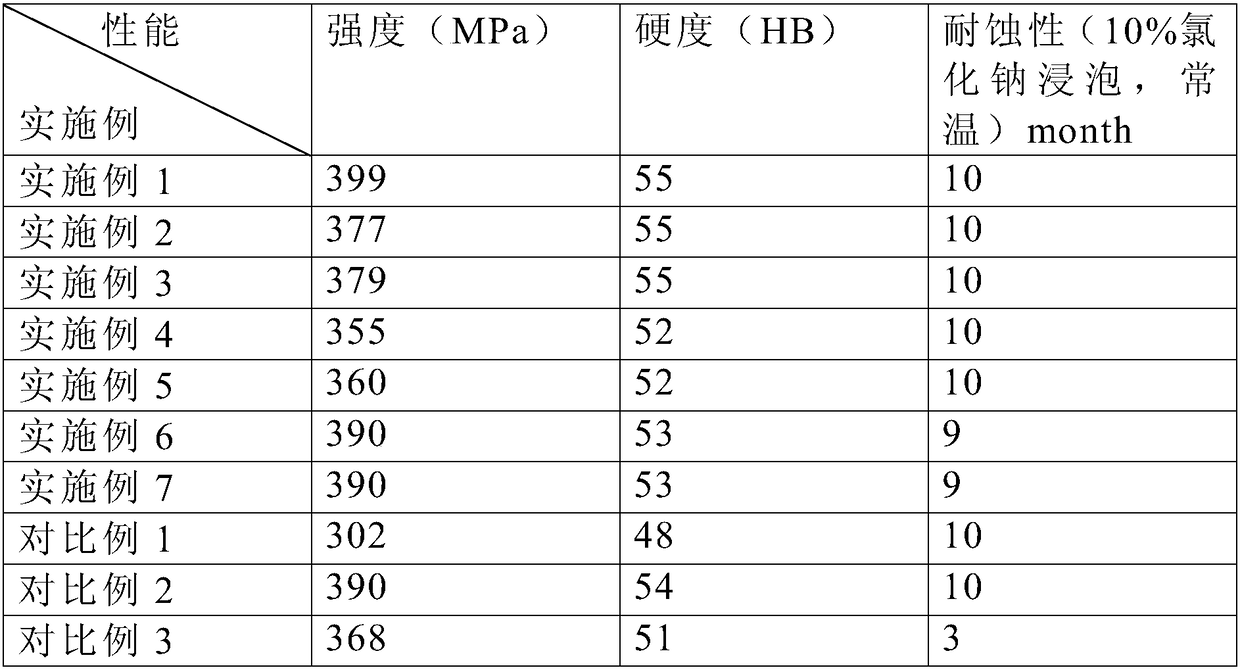

Robot big cover plate and preparation process thereof

The invention discloses a robot big cover plate and a preparation process thereof, and belongs to the technical field of a metal material. The big cover plate is prepared from the following raw material ingredients in percentage: 0.4 to 0.8 percent of Fe, 0.5 to 0.7 percent of Si, 0.02 to 0.04 percent of Ti, 0.05 to 0.09 percent of Mg, 0.01 to 0.03 percent of Be and the balance of Al and impurities. The Be in the raw materials is an excellent metal additive, has low density and has the intensity being 4 times of that of steel. The light weight and high intensity of the Be are used, so that thealuminum alloy has good physical performance; the mechanical performance of the aluminum alloy is enhanced; meanwhile, the oxygen affinity of the Be is used for reducing impurity oxygen in the aluminum alloy. The chemical properties of the Ti per se is stable; the embrittlement increase risk of the Fe on the alloy is eliminated; meanwhile, the preferential solidification characteristics of the Feare utilized so that a solidification core is formed; the mechanical property of the aluminum alloy is enhanced. Meanwhile, crystal grains are refined through the progressive normalizing processing and the uniform annealing process; the ingredient aliquation in the alloy can be eliminated. In addition, a nanometer stage carbon film is formed on the surface of the alloy; the intensity is high; theanti-corrosion performance of the aluminum alloy is greatly enhanced.

Owner:NINGBO HUAYUAN JINGTE METAL PROD CO LTD

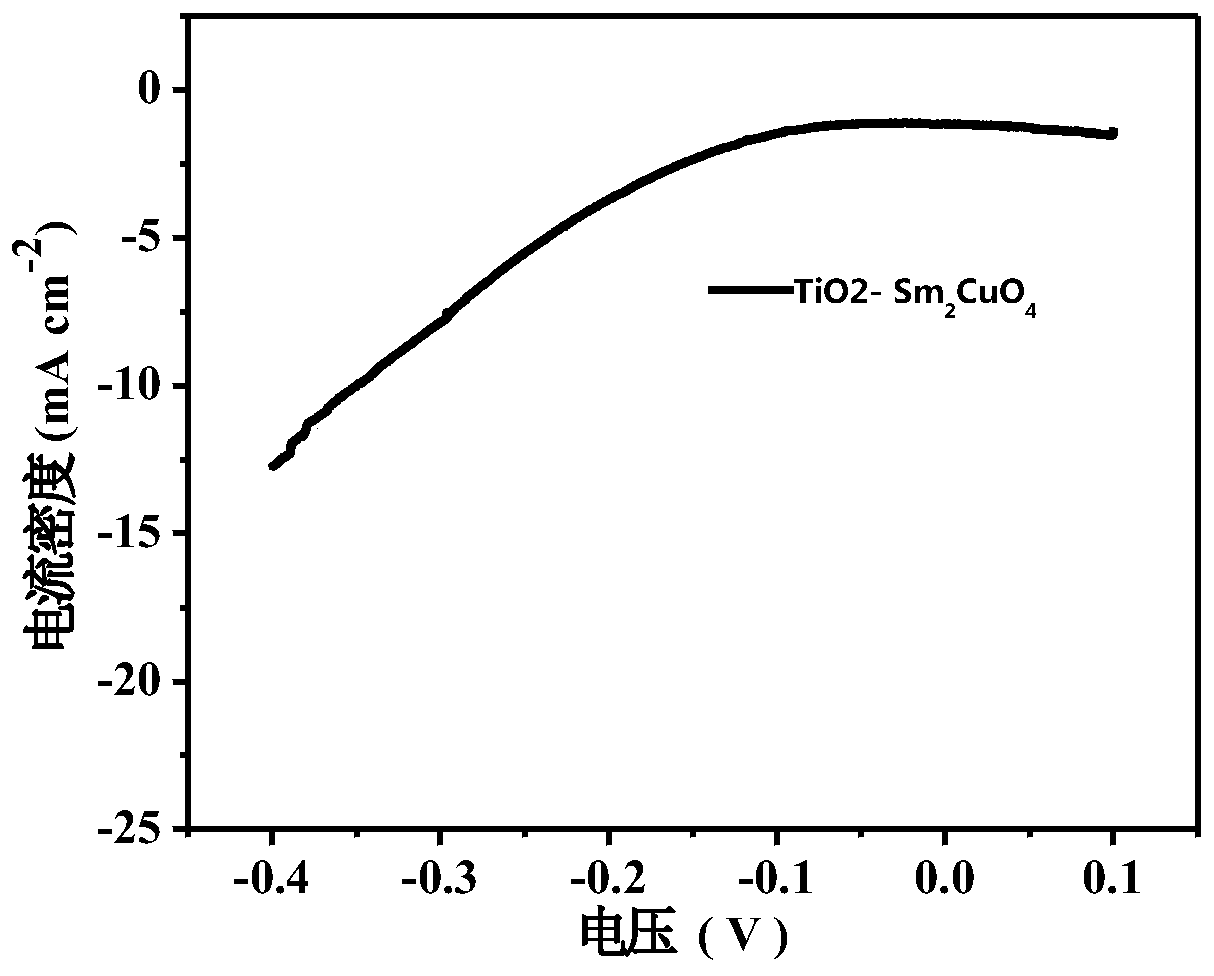

Preparation method of TiO2-samarium cuprate nano photocatalysis and electrocatalysis powder

ActiveCN110681384ANo wasteImprove matchMaterial nanotechnologyWater/sewage treatment by irradiationMalachite greenMalachite green stain

The invention belongs to the technical field of photocatalysis and electrocatalysis, and particularly relates to a preparation method of a TiO2-samarium cuprate nano photocatalysis and an electrocatalysis powder. The prepared powder has a relatively strong catalytic effect in visible light region and ultraviolet light region at the same time, is high in purity, uniform in granularity, good in controllability and excellent in performance, can be used as a photocatalyst, and is applied to malachite green-containing industry and dye wastewater treatment.

Owner:东北大学秦皇岛分校

Method for preparing copper-aluminum-silicon alloy powder by water atomization and application of method

ActiveCN107732190AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesMolten stateSilicon alloy

The invention relates to a method for preparing copper-aluminum-silicon alloy powder by water atomization and application of the method, and belongs to the technical field of preparation of a lithiumbattery negative electrode material. The invention provides a high-performance lithium battery copper-aluminum-silicon alloy nanometer negative electrode material prepared by employing a water atomization method and application of the copper-aluminum-silicon alloy nanometer negative electrode material. The method comprises the steps of 1, starting a tundish system of an atomization system, whereinthe inner diameter of a tundish nozzle selects 6-14 millimeters; 2, adjusting a tapping temperature of molten-state copper-aluminum-silicon alloy to be 1,300-1,700 DEG C; and 3, pouring liquid-statemetal to a tundish, adjusting water atomization pressure to be 300-450Mpa, and performing water atomization powder preparation, wherein the copper-aluminum-silicon alloy comprises the constituents based on parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of other impurity. The method can be widely applied to the field of preparation of the lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

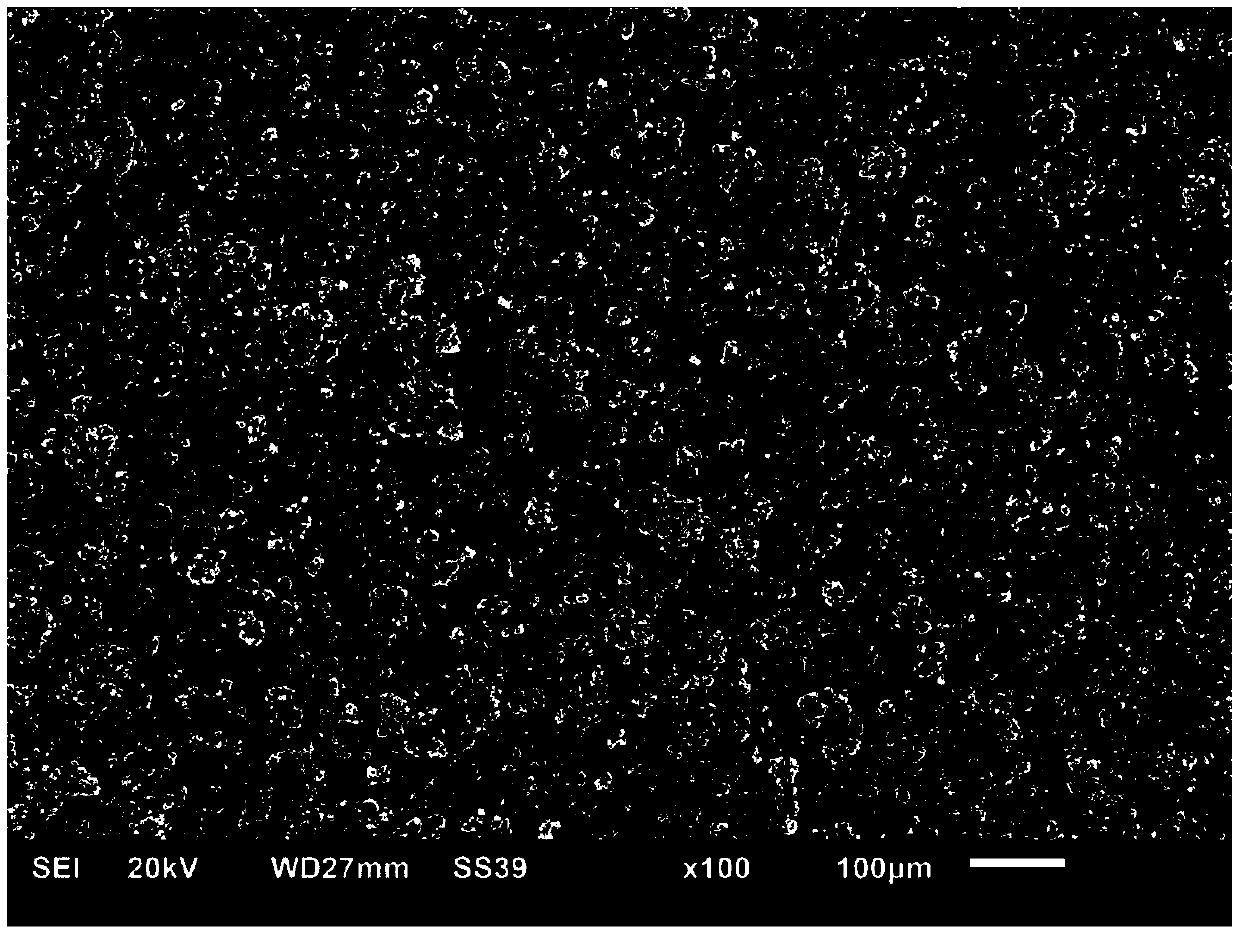

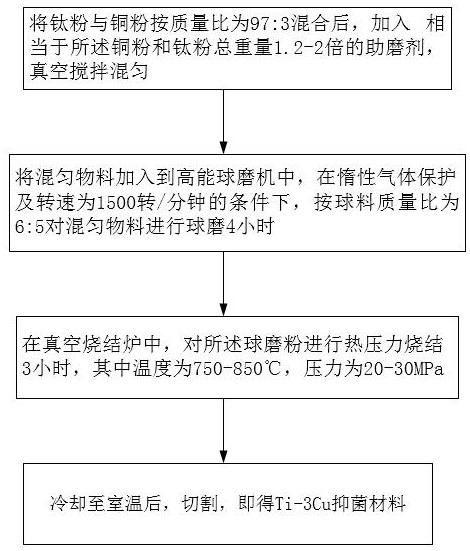

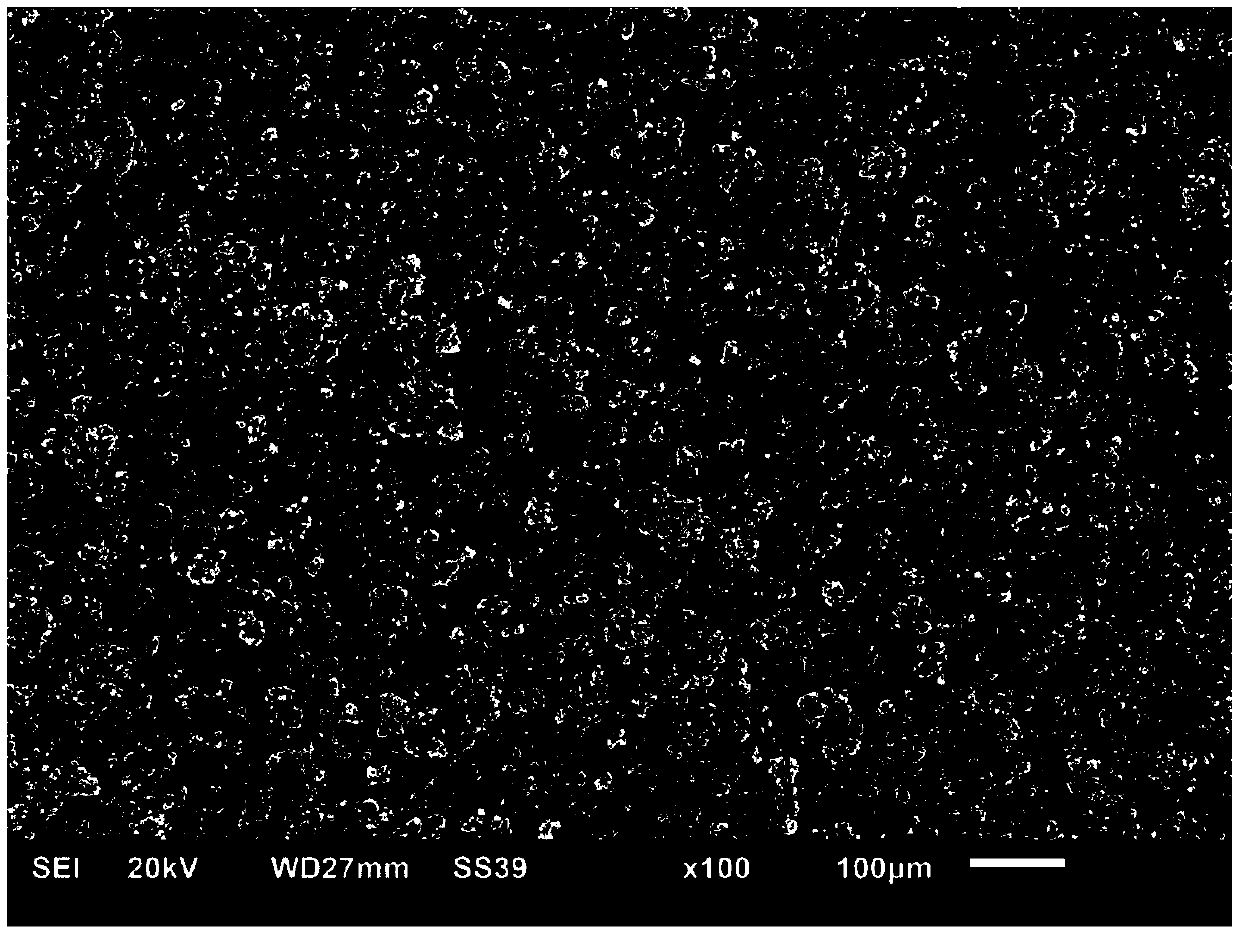

Preparation method for antibacterial material

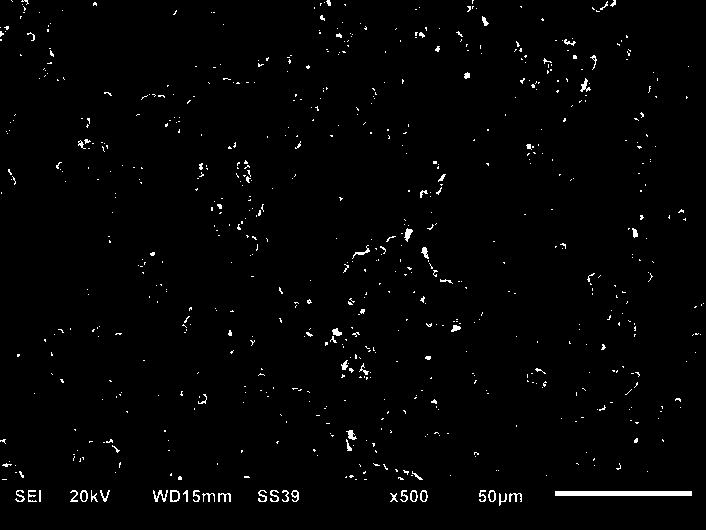

InactiveCN112831677APromote NanoizationUniform and stable dispersionBiocideAnimal repellantsTitanium alloyTitanium powder

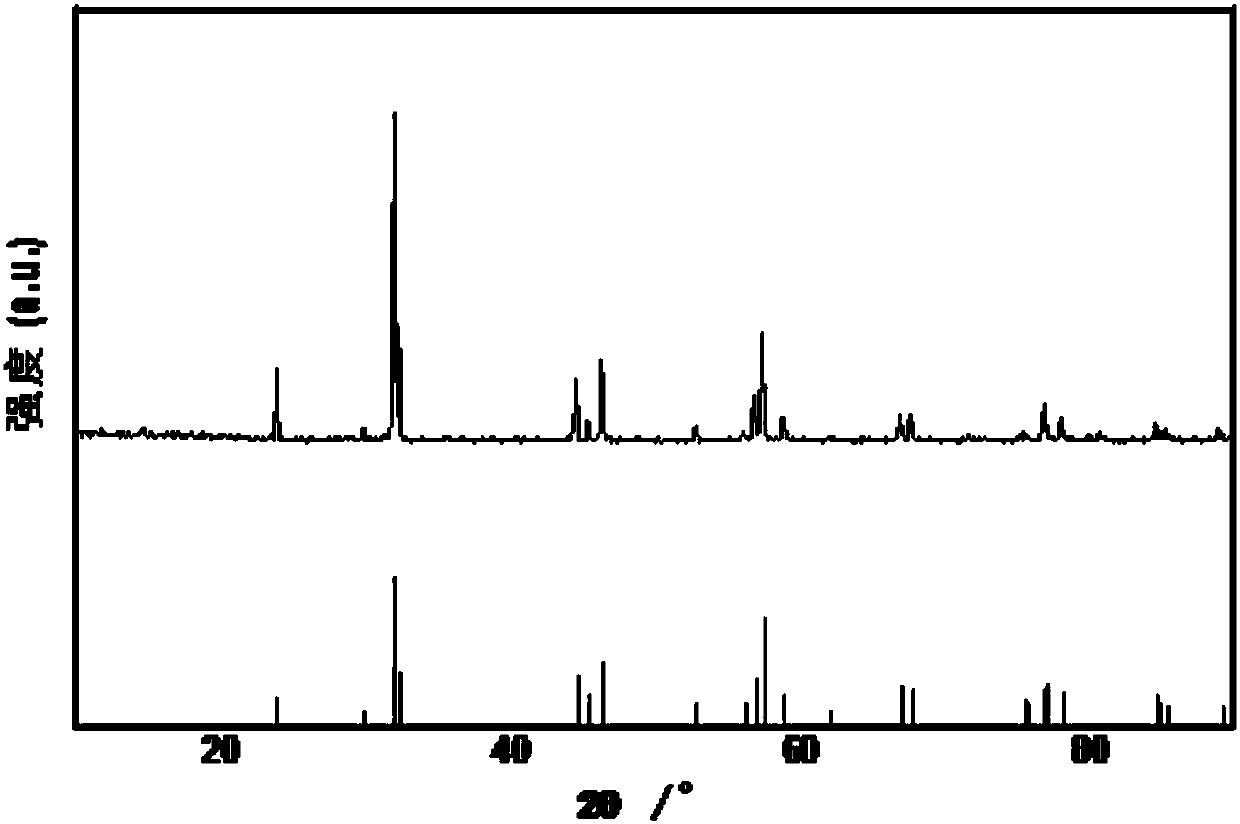

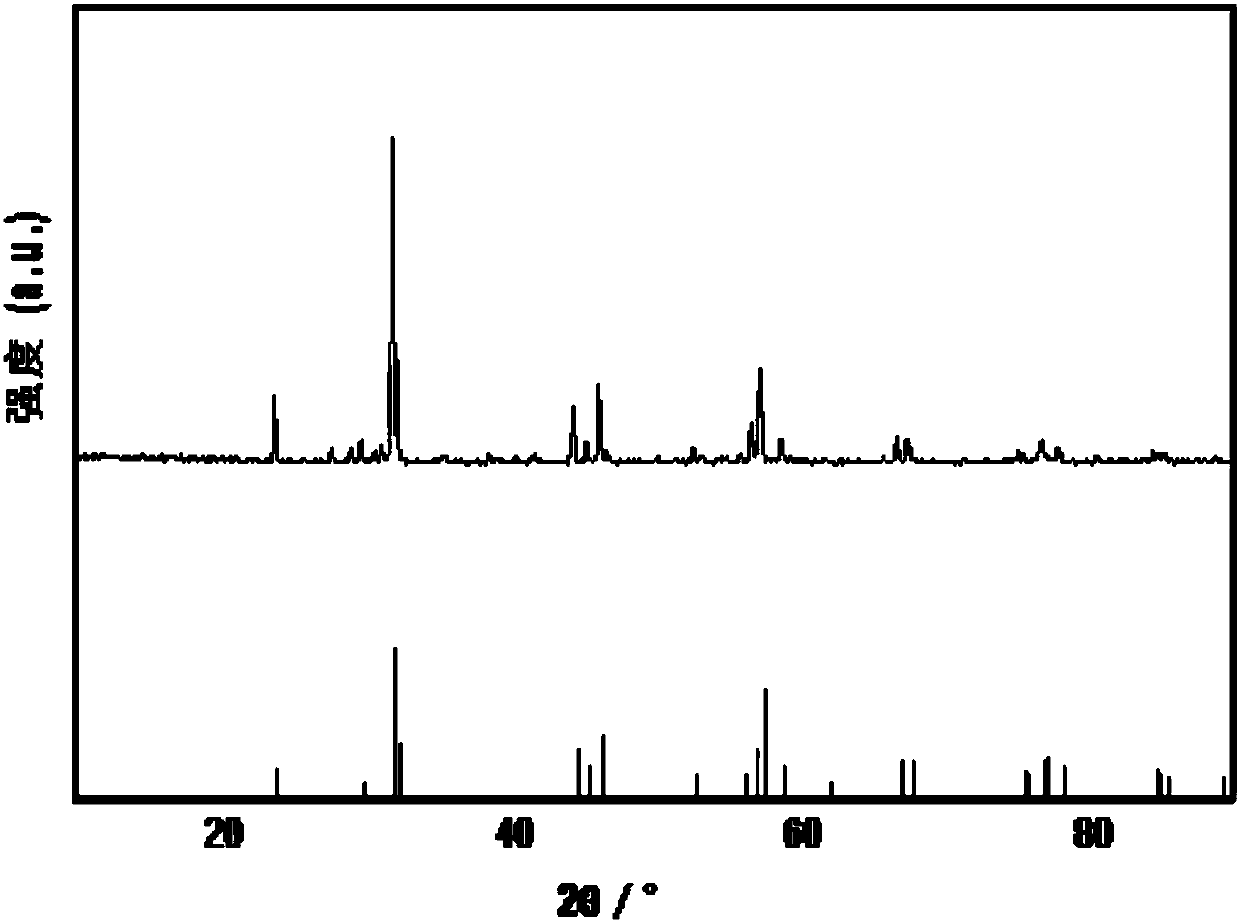

The invention discloses a preparation method for an antibacterial material, and relates to the field of titanium alloy material preparation. The preparation method comprises the steps that titanium powder and copper powder are mixed according to the mass ratio of 97: 3, then a grinding aid with the weight of 1.2-2 times of the total weight of the titanium powder and the copper powder is added, and vacuum stirring and uniform mixing are carried out; a uniformly mixed material is added into a high-energy ball mill, and ball milling is carried out on the uniformly mixed material for 4 hours according to the mass ratio of balls to the material of 6: 5 under the conditions of inert gas protection and the rotating speed of 1500 revolutions per minute; in a vacuum sintering furnace, ball-milled powder is subjected to hot pressure sintering treatment for 3 hours, wherein the temperature is 750-850 DEG C, and the pressure is 20-30 MPa; and cooling is carried out to room temperature, and cutting is carried out to obtain the antibacterial material. According to the preparation method for the antibacterial material, the surfaces of the titanium powder and the copper powder can be modified, the "agglomeration" phenomenon of the titanium powder and the copper powder is avoided, grain structures of the titanium powder and the copper powder can be changed, nanocrystallization of the copper powder and the titanium powder is facilitated, and therefore the copper powder is uniformly and stably dispersed on the surface of the titanium powder, and the stability of the antibacterial performance of Ti-3Cu alloy is improved.

Owner:西安庄信新材料科技有限公司

A kind of nano la2o3 evenly doped nano molybdenum composite powder and its preparation method

ActiveCN106363166BEvenly dispersedEvenly dopedMaterial nanotechnologyTransportation and packagingNanoparticleChemistry

The invention discloses a nano La 2 o 3 Uniformly doped nanomolybdenum composite powder La 2 o 3 The size of the composite powder with Mo is 30~100nm, La 2 o 3 The content is 0.5~5.0wt.%. It is also disclosed that its preparation process is: preparation of solution→solution heating→adding glucose→synthesis of precursor→precursor reduction→nanometer La 2 o 3 Uniformly doped nano molybdenum composite powder. The invention not only ensures the uniform dispersion and stability of the nanoparticles, but also can effectively control the size of the powder. At the same time, the reaction synthesis temperature of the precursor is low, the reaction time is short, the efficiency is high, the energy is saved and the operation is simple.

Owner:XIAMEN UNIV OF TECH

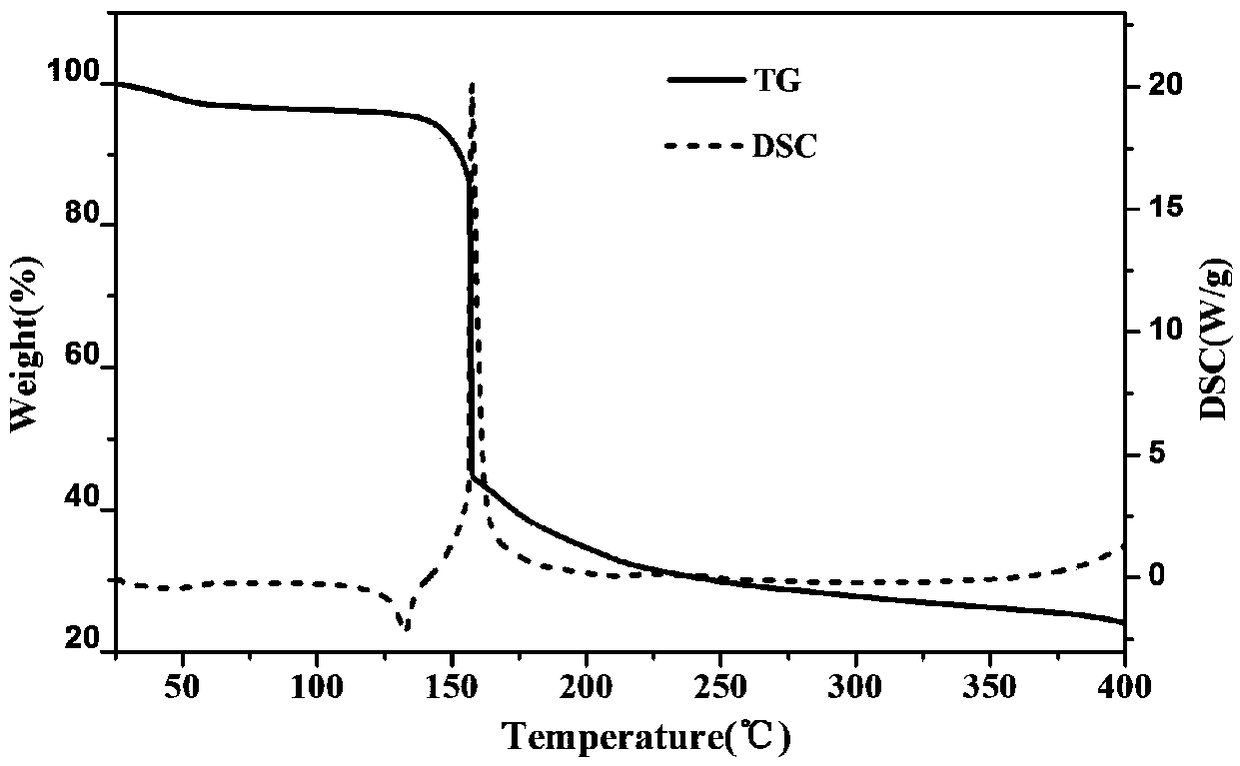

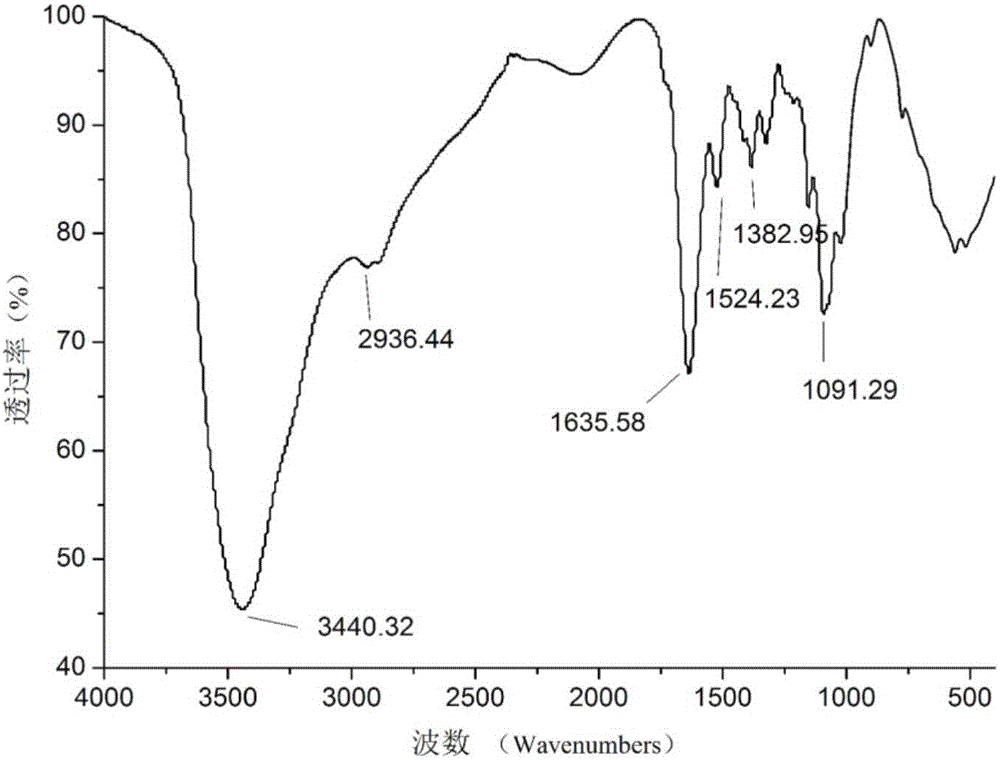

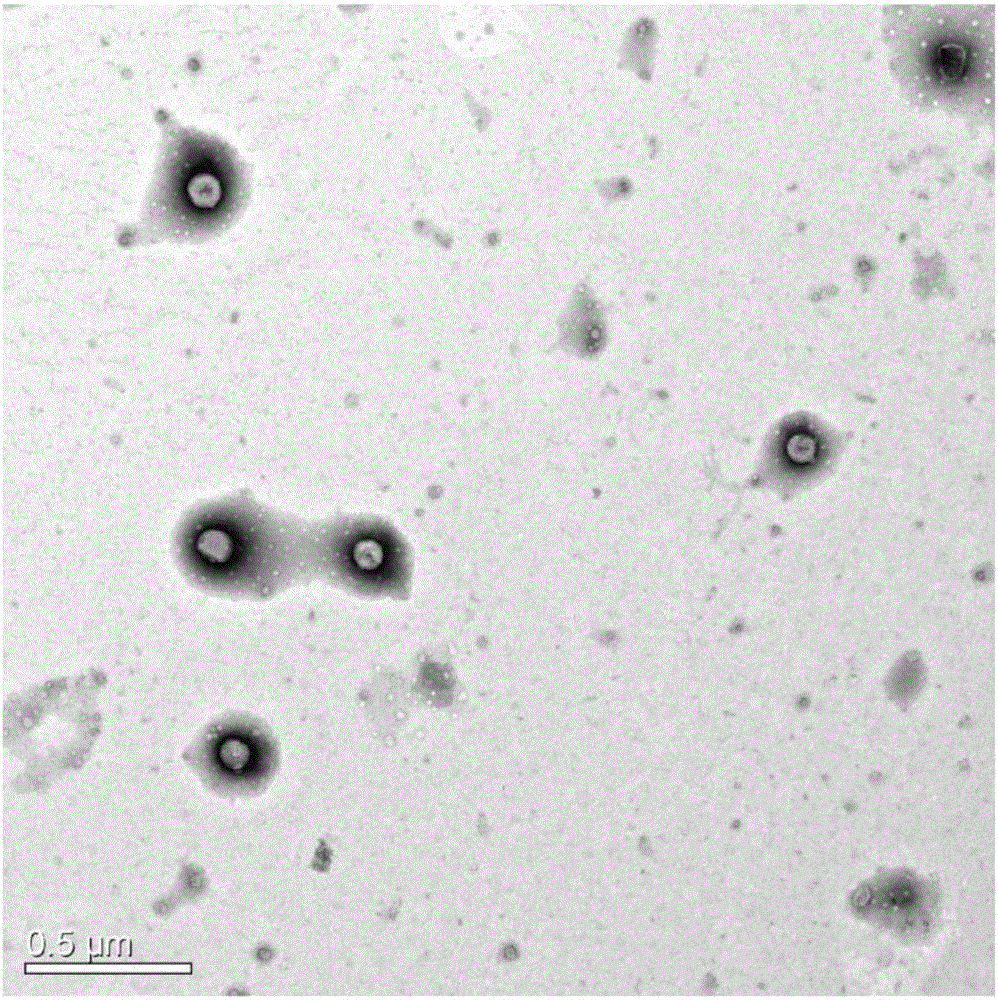

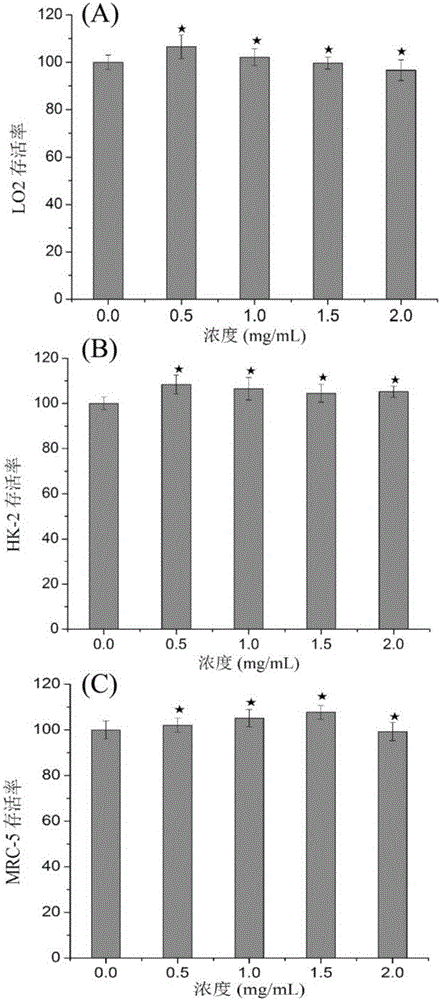

EGCG (Epigallocatechin Gallate) functionalized chitosan derivative as well as EGCG functionalized chitosan derivative carried honokiol nano particle and preparation methods of EGCG functionalized chitosan derivative and EGCG functionalized chitosan derivative carried honokiol nano particle

InactiveCN106420634APromote NanoizationGood biocompatibilityAntibacterial agentsPowder deliveryNanoparticleStructural formula

The invention provides an EGCG (Epigallocatechin Gallate) functionalized chitosan derivative, an EGCG functionalized chitosan derivative carried honokiol nano particle and preparation methods of the EGCG functionalized chitosan derivative and the EGCG functionalized chitosan derivative carried honokiol nano particle. The structural formula of the EGCG functionalized chitosan derivative is as shown in the description; in the structural formula, the content of EGCG is 10 to 60 percent; the deacetylation degree is 50 to 98 percent; the content of amino is 50 to 98 percent. According to the EGCG functionalized chitosan derivative carried honokiol nano particle, the nano particle is prepared from the EGCG functionalized chitosan derivative and honokiol; the honokiol and the EGCG functionalized chitosan derivative form the nano particle through charge action; the honokiol is encapsulated inside the nano particle.

Owner:SICHUAN UNIV

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of negative electrode material

InactiveCN107732196AUnique microstructureReasonable particle size distributionMaterial nanotechnologyCell electrodesDislocationNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the negative electrode material, and belongs to the technical field of the negative electrode material of the lithium battery. According to the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the negative electrode material provided by the invention, a technical scheme is adopted as follows: the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials in parts by weight: 27.5-32 parts of silicon, 58-63 parts of copper, 9-11 parts of aluminum and 0-5 parts of impurities; and the overall alloy nanomaterial comprises a multi-defect organization structure of air pores, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain diameter is less than or equal to 80[mu]m. The inventioncan be applied to the technical field of the negative electrode material of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of negative electrode material

InactiveCN107732197AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesSilicon alloyNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the negative electrode material, and belongs to the technical field of the negative electrode material of the lithium battery. According to the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the negative electrode material provided by the invention, a technical scheme is adopted as follows: the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials in parts by weight: 37-42 parts of silicon, 55-62 parts of copper, 4-15 parts of aluminum and 0-3 parts of impurities; and the overall alloy nanomaterial comprises a multi-defect organization structure of air pores, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain diameter is less than or equal to 80[mu]m. The invention can be applied to the technical field of the negative electrode material of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

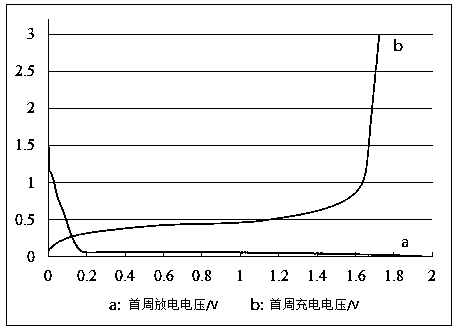

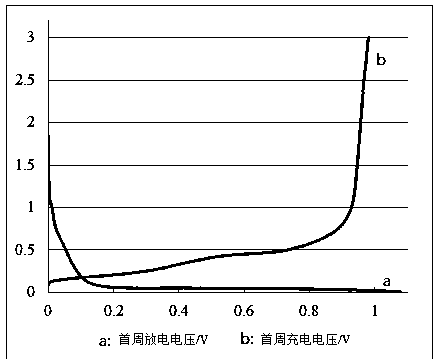

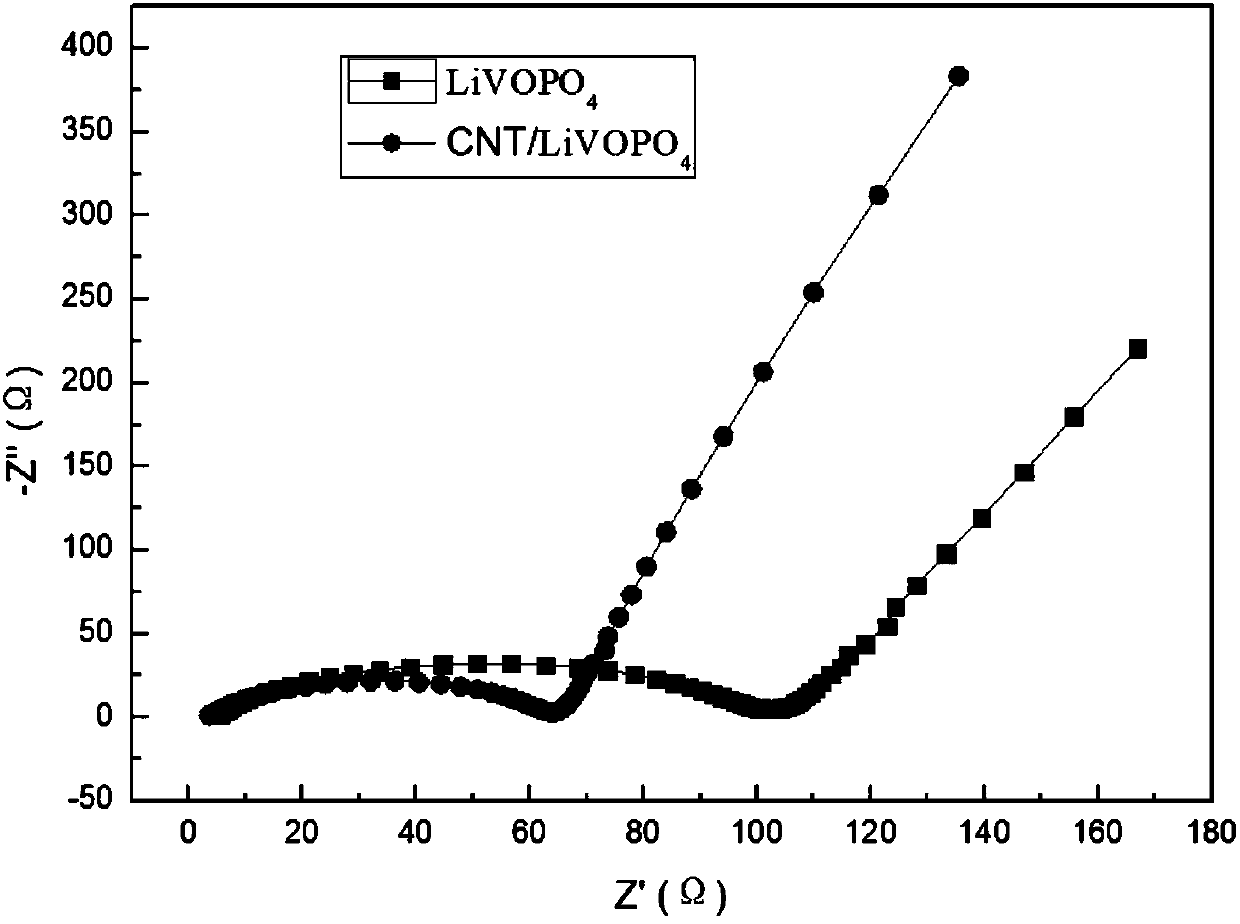

Nanometer lithium vanadium phosphate positive electrode material, preparation method thereof and lithium ion battery

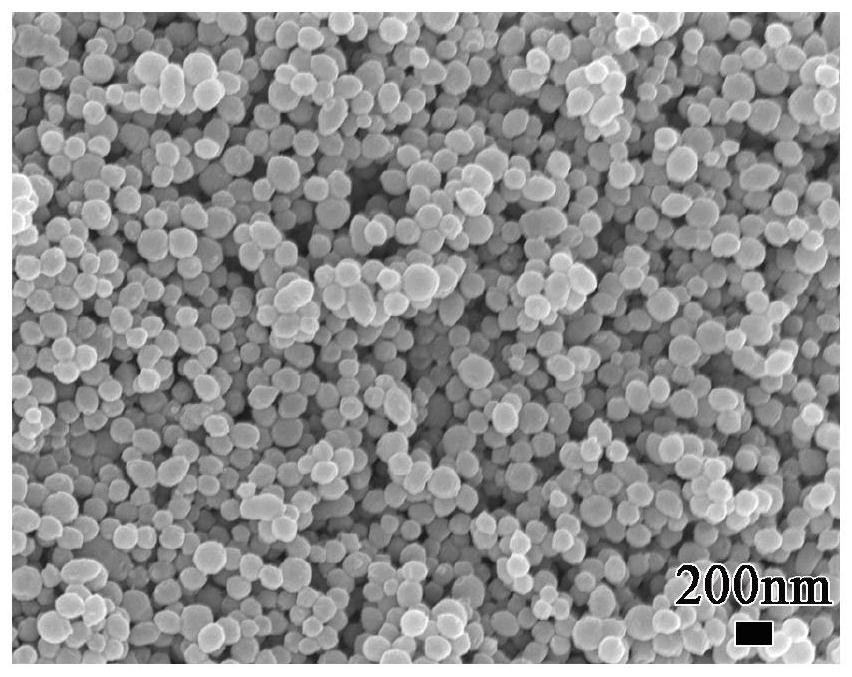

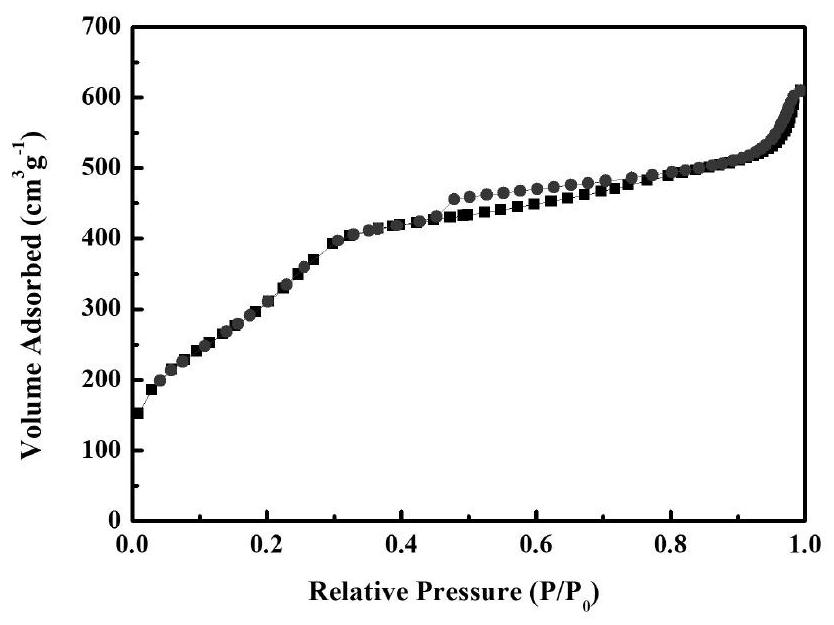

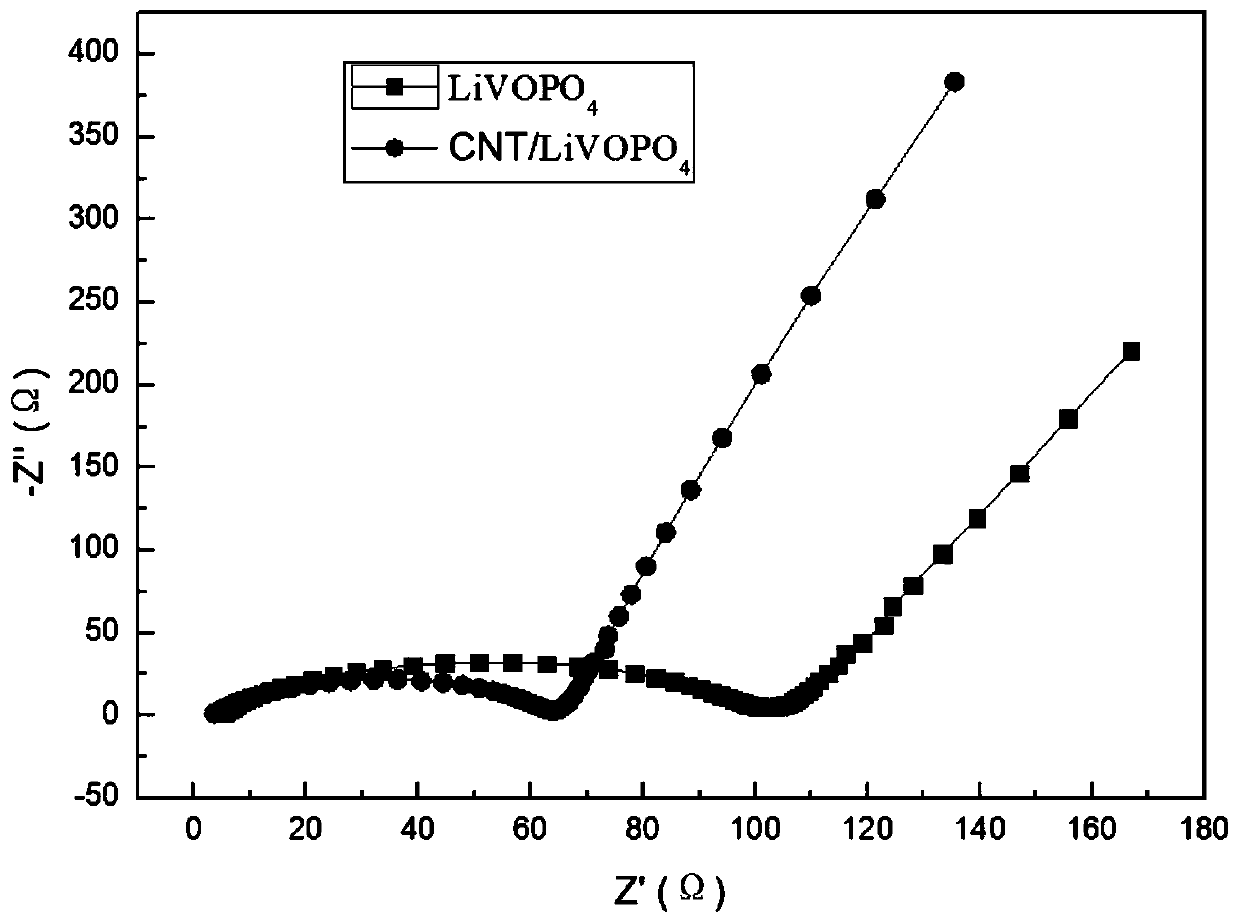

ActiveCN107845783AImprove conductivityIncrease migration rateMaterial nanotechnologyCell electrodesLithium vanadium phosphate batteryCarbon nanotube

The invention provides a nanometer lithium vanadium phosphate positive electrode material. The nanometer lithium vanadium phosphate positive electrode material comprises a carbon nanotube and nanometer lithium vanadium phosphate, wherein the grain of the nanometer lithium vanadium phosphate is 40-200 nanometers, and the mass ratio of the carbon nanotube and the nanometer lithium vanadium phosphateis (0.2-1):(99-99.8). The invention also provides a preparation method of the nanometer lithium vanadium phosphate positive electrode material. The preparation method comprises the following steps ofproviding a lithium source, a vanadium source, a phosphate source and a polyacrylic acid complexing agent, performing uniform mixing in a solvent, and adjusting pH to 3-6 to obtain a gel mixture; drying and crushing the gel mixture to obtain a lithium vanadium phosphate precursor; and providing the carbon nanotube and a dispersing agent, mixing and grinding the lithium vanadium phosphate precursor, the carbon nanotube and the dispersing agent, performing sintering in an inert atmosphere, and performing crushing and sieving to obtain the nanometer lithium vanadium phosphate positive electrodematerial.

Owner:SHENZHEN DYNANONIC

An open-frame fluorine-based solid-state electrolyte material and its preparation method

ActiveCN106887639BImprove conductivityEasy surface modificationFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteChemical groups

The present invention involves a frame -based fluorine solid electrolytic material and its preparation method. The chemical group of the electrolyte material has become: x M y F x+3y Among them, 0 <x ≤6, 0 <y ≤ 3, A is na and / or li, M is al and / or ga.The opening frame of the invention fluorine -based solid state electrolyte A x M y F x+3y It is the application of lithium -enriched or sodium -rich aluminum -based aluminum -based or cymbal fluoride. The present invention proposes the application of a new type of open -frame structure prototype in fluoride solid electrolytes, and at the same time realize its lithium rich or sodium rich.The concentration of alkaline metal ions is conducive to increasing its ionic conductivity. Through nanomacization, disorder, surface modification and other means, the conductivity of the body and granular boundaries can be improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

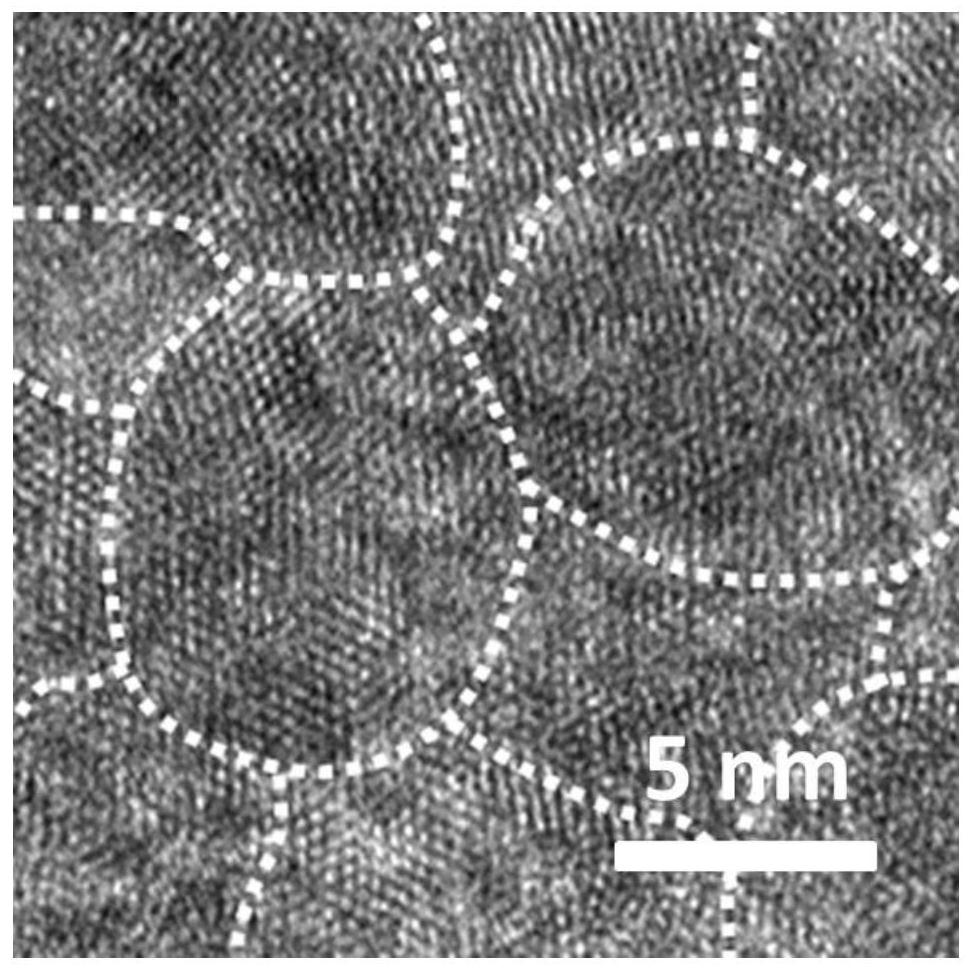

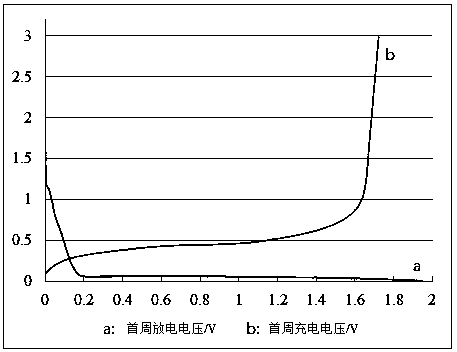

Method for preparing ultra-small oxide and carbon compounded lithium battery negative electrode material by microwave method

PendingCN113666411AAlleviate volume expansionImprove conductivityNegative electrodesSecondary cellsMicrowave methodLithium electrode

The invention relates to a method for preparing an ultra-small oxide and carbon compounded lithium battery negative electrode material by a microwave method. The invention belongs to the field of preparation of lithium ion battery negative electrode materials. The invention aims to solve the technical problems that the existing lithium ion battery is low in comprehensive performance such as capacity and conductivity, the preparation process is relatively complicated, and the cost is relatively high. The method comprises the following steps: 1, preparing a salt solution to enable metal ions to permeate into a metal-organic framework (MOF) material; separating the ion-permeated MOF material from the solution by suction filtration, and drying to obtain an ion-permeated MOF material; 2, mixing the ion-permeated MOF material and graphene, grinding, and then carrying out microwave short-time heating; and 3, washing and removing impurities from the product to obtain the ultra-small oxide and carbon compounded lithium battery negative electrode material. The nano-particle size of the product is 2-10nm, and the product can have high capacity under low oxide loading.

Owner:HARBIN INST OF TECH

Vibration aging treatment method of copper-aluminum-silicon nano alloy material and application of vibration aging treatment method

InactiveCN107760921AStress reliefImprove performance consistencySecondary cellsNegative electrodesAlloyCopper

The invention discloses a vibration aging treatment method of a copper-aluminum-silicon nano alloy material and application of the vibration aging treatment method, and belongs to the technical fieldof lithium battery cathode material preparation. To overcome defects of the prior art, the invention provides the vibration aging treatment method of the copper-aluminum-silicon nano alloy material and application of the vibration aging treatment method. According to the technical scheme, the vibration aging treatment method is implemented after a step of vacuum drying after steps of blending, smelting, powdering, separation and screening, dried copper-aluminum-silicon nano alloy powder is subjected to vibration aging treatment, an electromagnetic vibration aging instrument is adopted, the electromagnetic vibration efficiency is 3000-5000Hz, and the vibration time is 24-150 hours; a copper-aluminum-silicon nano alloy comprises the following components in parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurities, and the particle size of the alloy is less than or equal to 80mu m. The vibration aging treatment method can be widely applied to the field of lithium battery cathode materials.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of copper-aluminum-silicon alloy nanometer negative electrode material

InactiveCN107706386AUnique structureImprove conductivityCell electrodesSilicon alloyNickel–lithium battery

The invention relates to a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material, and belongs to the technical field of a lithium battery negative electrode material. The invention provides a high-performance copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and a preparation method of the high-performance copper-aluminum-silicon alloy nanometer negative electrode material. The copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials based on parts by weight: 32-39 parts of silicon, 54-59 parts of copper, 1-8 parts of aluminum and 0-5 parts of impurity, the whole alloy nanometer material comprises a multi-defect tissue structure of air holes, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain is smaller than orequal to 80 micrometers. The copper-aluminum-silicon alloy nanometer negative electrode material can be applied to the technical field of a lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of copper-aluminum-silicon alloy nanometer negative electrode material

InactiveCN107732189AUnique structureImprove conductivityCell electrodesDislocationNickel–lithium battery

The invention relates to a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material, and belongs to the technical field of a lithium battery negative electrode material. The invention provides a high-performance copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material. The copper-aluminum-silicon alloy nanometer negative electrodematerial of the lithium battery comprises the following raw materials based on parts by weight: 50-70 parts of silicon, 20-40 parts of copper, 0.5-10 parts of aluminum and 0-5 parts of impurity, thealloy nanometer material integratedly comprises a multi-defect tissue structure of air holes, shrinkage holes, shrinkage porosity, dislocation, vacancies and holes, and the grain size is smaller thanor equal to 80 micrometers. The copper-aluminum-silicon alloy nanometer negative electrode material can be applied to the technical field of the lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

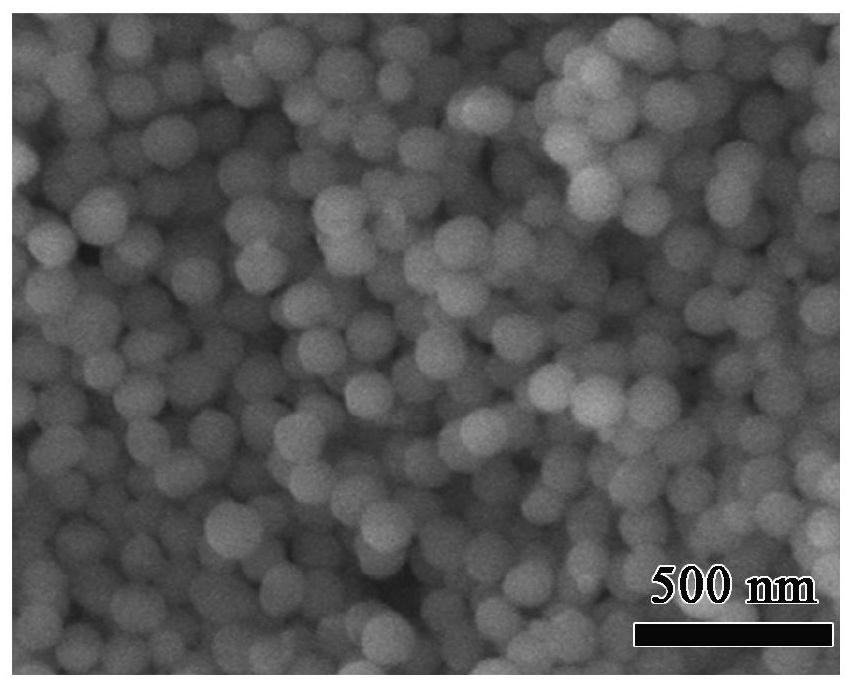

Mesoporous silica nanosphere and its preparation method and application in drug loading

ActiveCN109896528BReduce usageAvoid secondary pollutionOrganic active ingredientsSilicaActive agentMesoporous silica

The invention discloses a mesoporous silica nanosphere, its preparation method and its application in drug loading. The preparation method comprises: adding a silicon source solution composed of an organic silicon source and a diluent into In the mixed aqueous solution in the diluent, stir and react, filter, wash and then calcined; the particle size of the prepared sample is 40-200nm, and the specific surface area is 1050-1350m 2 / g, with a pore size of 1.8‑2.4nm; it can be applied to the loading of hydrophobic drugs to realize nanonization of drugs and enhance their water solubility and dissolution rate. The method provided by the invention can avoid the use of organic templates of traditional mesoporous silica nanospheres; the raw materials are easy to obtain, the equipment is simple, and the efficiency is high; the pore wall particles are introduced into the mesoporous structure, which is beneficial to drug diffusion and loading, and reduces the weight. Crystallization, so that the in vitro dissolution rate is almost 100%, and its bioavailability is significantly higher than that of commercially available drugs, which is of great practical significance.

Owner:HUAZHONG UNIV OF SCI & TECH

Nanoscale lithium vanadyl phosphate positive electrode material and preparation method thereof, lithium ion battery

ActiveCN107845783BImprove conductivityIncrease migration rateMaterial nanotechnologyCell electrodesPhysical chemistryCarbon nanotube

The invention provides a nanometer lithium vanadium phosphate positive electrode material. The nanometer lithium vanadium phosphate positive electrode material comprises a carbon nanotube and nanometer lithium vanadium phosphate, wherein the grain of the nanometer lithium vanadium phosphate is 40-200 nanometers, and the mass ratio of the carbon nanotube and the nanometer lithium vanadium phosphateis (0.2-1):(99-99.8). The invention also provides a preparation method of the nanometer lithium vanadium phosphate positive electrode material. The preparation method comprises the following steps ofproviding a lithium source, a vanadium source, a phosphate source and a polyacrylic acid complexing agent, performing uniform mixing in a solvent, and adjusting pH to 3-6 to obtain a gel mixture; drying and crushing the gel mixture to obtain a lithium vanadium phosphate precursor; and providing the carbon nanotube and a dispersing agent, mixing and grinding the lithium vanadium phosphate precursor, the carbon nanotube and the dispersing agent, performing sintering in an inert atmosphere, and performing crushing and sieving to obtain the nanometer lithium vanadium phosphate positive electrodematerial.

Owner:SHENZHEN DYNANONIC

Carbon coating treatment method for copper-aluminum-silicon nano alloy material and application of carbon coating treatment method

InactiveCN107732198AUnique structureReasonable particle size distributionCell electrodesCarbon coatingSilicon alloy

The invention provides a carbon coating treatment method for a copper-aluminum-silicon nano alloy material and an application of the carbon coating treatment method, belongs to the technical field ofpreparation of negative electrode materials for lithium batteries, and provides a carbon coating treatment method for treating a copper-aluminum-silicon nano alloy material and an application of the carbon coating treatment method to overcome the disadvantages of the prior art. According to the adopted technical scheme, the carbon coating treatment method is carried out through vacuum drying afterthe steps of burdening, smelting, milling, separating and screening, and comprises the steps of firstly preparing dried copper-aluminum-silicon alloy powder, a carbonaceous material and water at theratio in parts by weight of (80-100):(1-2):(8-11); stirring the raw materials evenly, putting the mixture into a vacuum heat treatment furnace, carrying out heat preservation at 600-800 for 2-4h and carrying out carbon coating treatment, wherein the vacuum degree is smaller than or equal to 0.02Pa; and finally carrying out furnace cooling to below 80 DEG C and drawing a charge. The copper-aluminum-silicon nano alloy is prepared from the following components in parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurities; and the particlesizes are smaller than or equal to 80 microns. The carbon coating treatment method can be widely applied to the field of the negative electrode materials for the lithium batteries.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

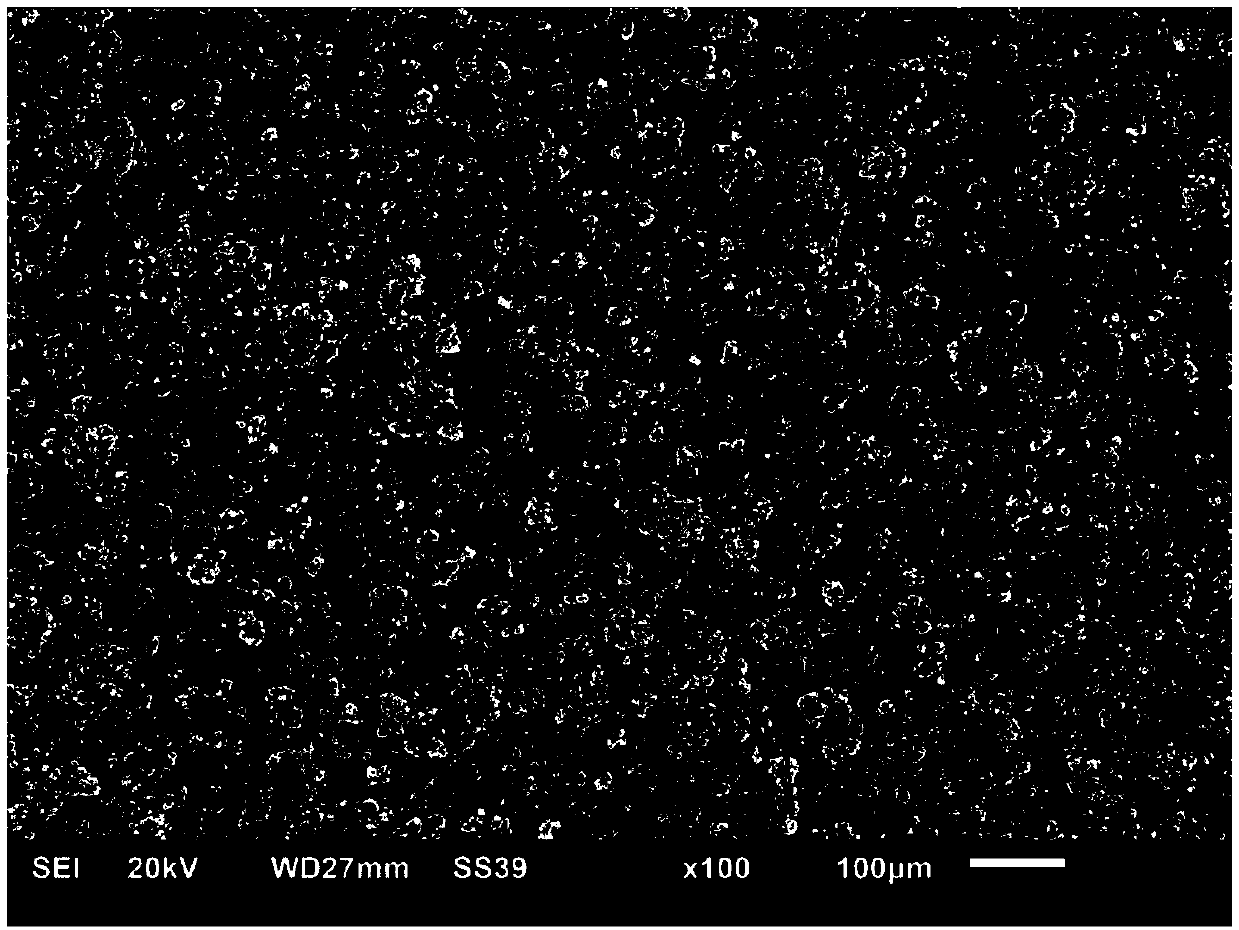

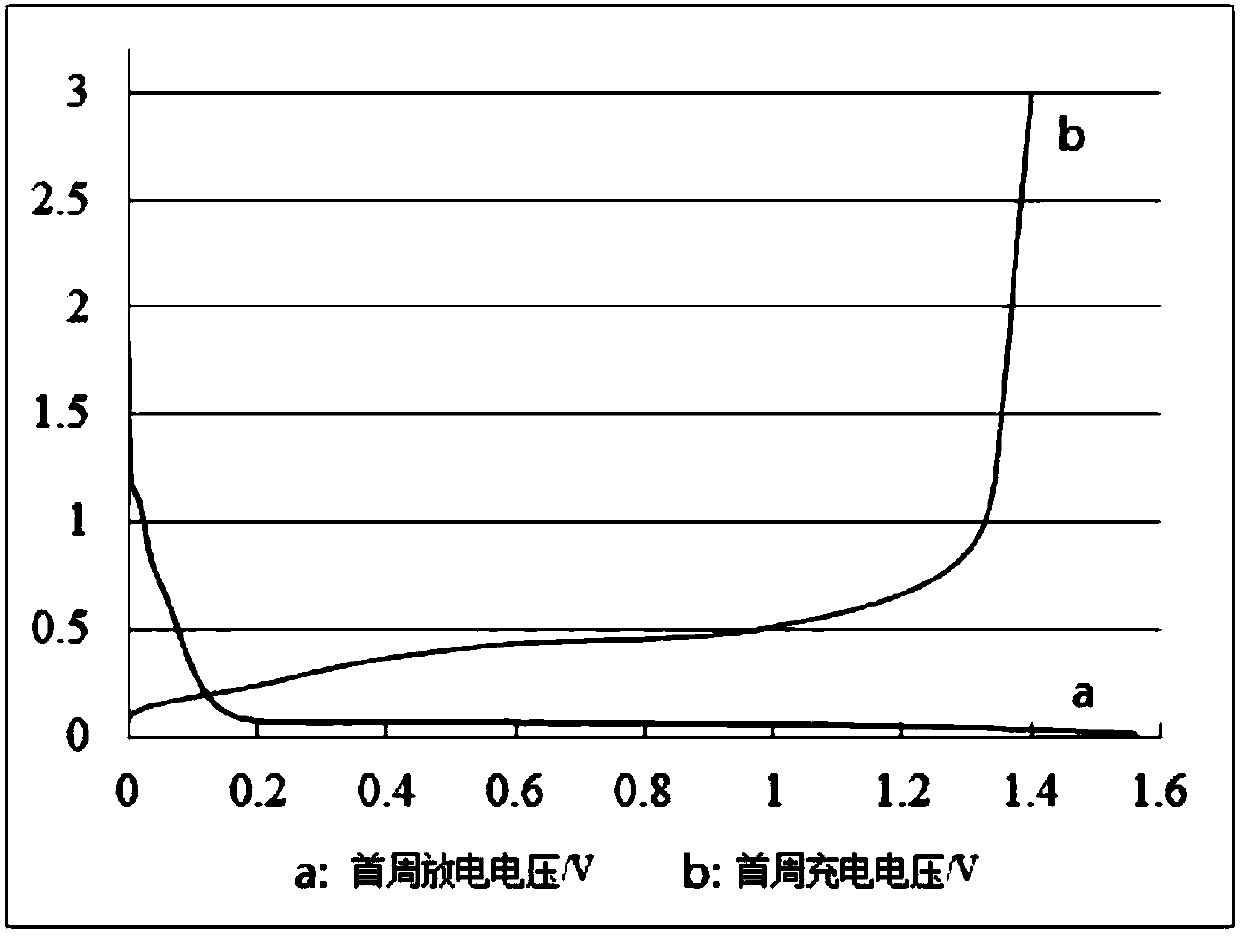

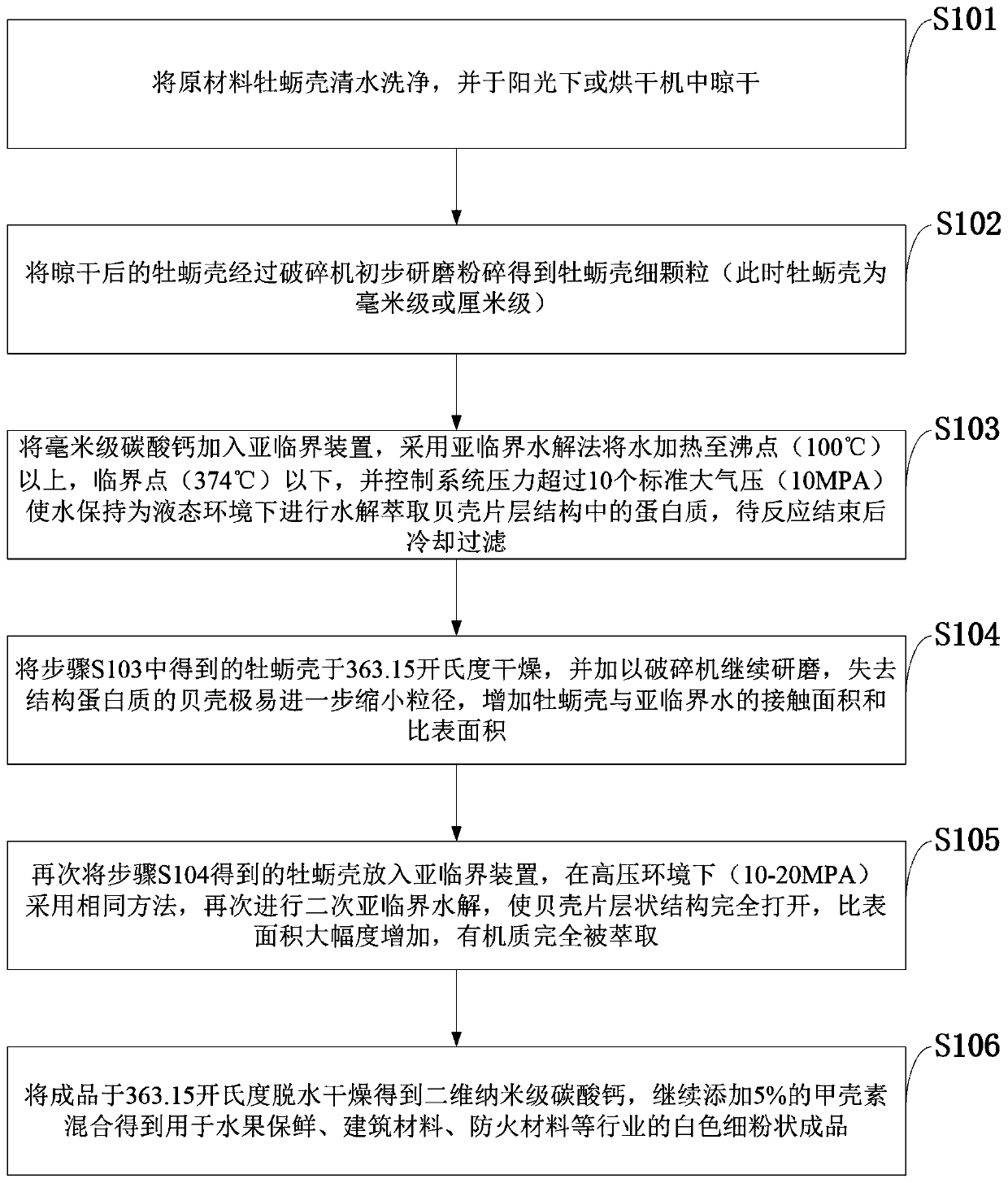

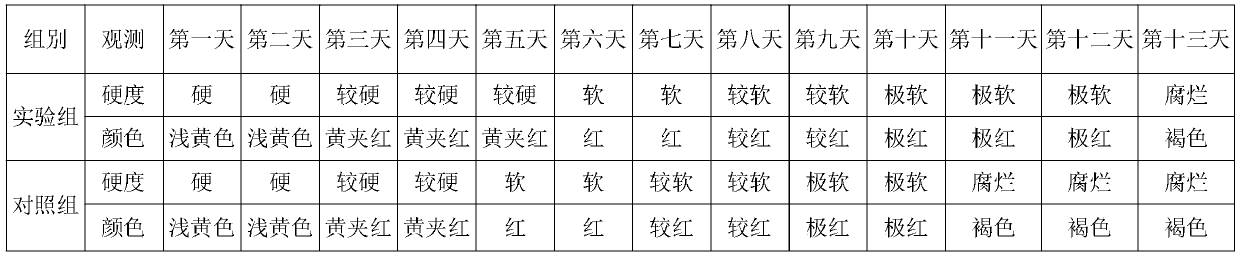

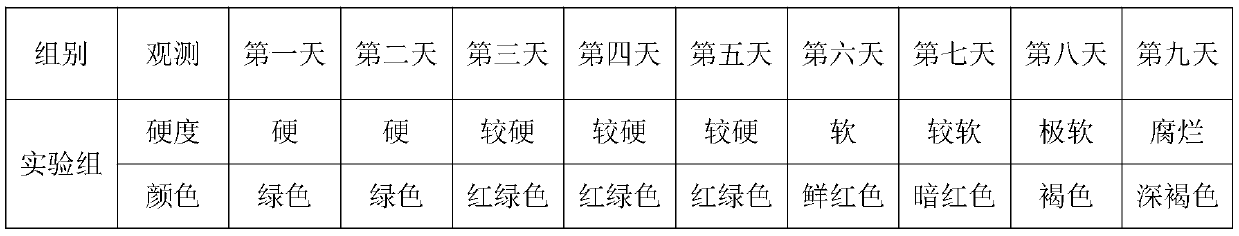

A method for preparing nano-calcium carbonate based on subcritical hydrolysis

ActiveCN110203957BReduce energy consumptionIncrease profitCalcium/strontium/barium carbonatesFruit and vegetables preservationPhysical chemistryNano carbon

Owner:水恣意(厦门)科技有限公司

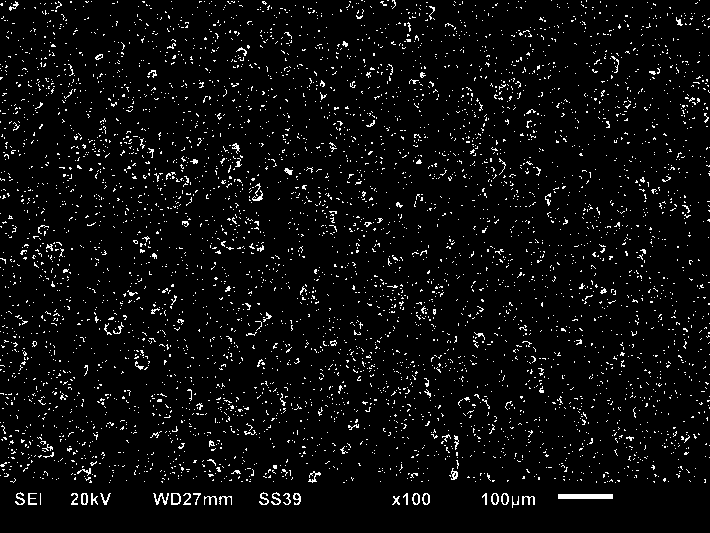

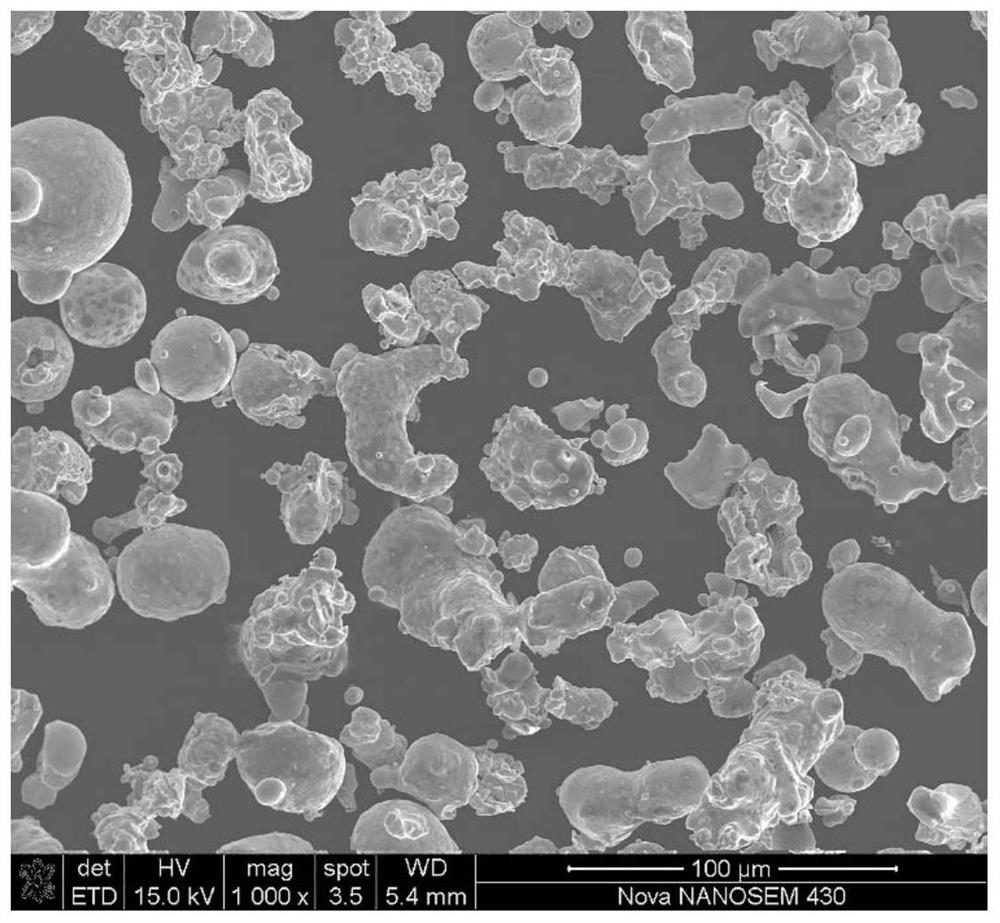

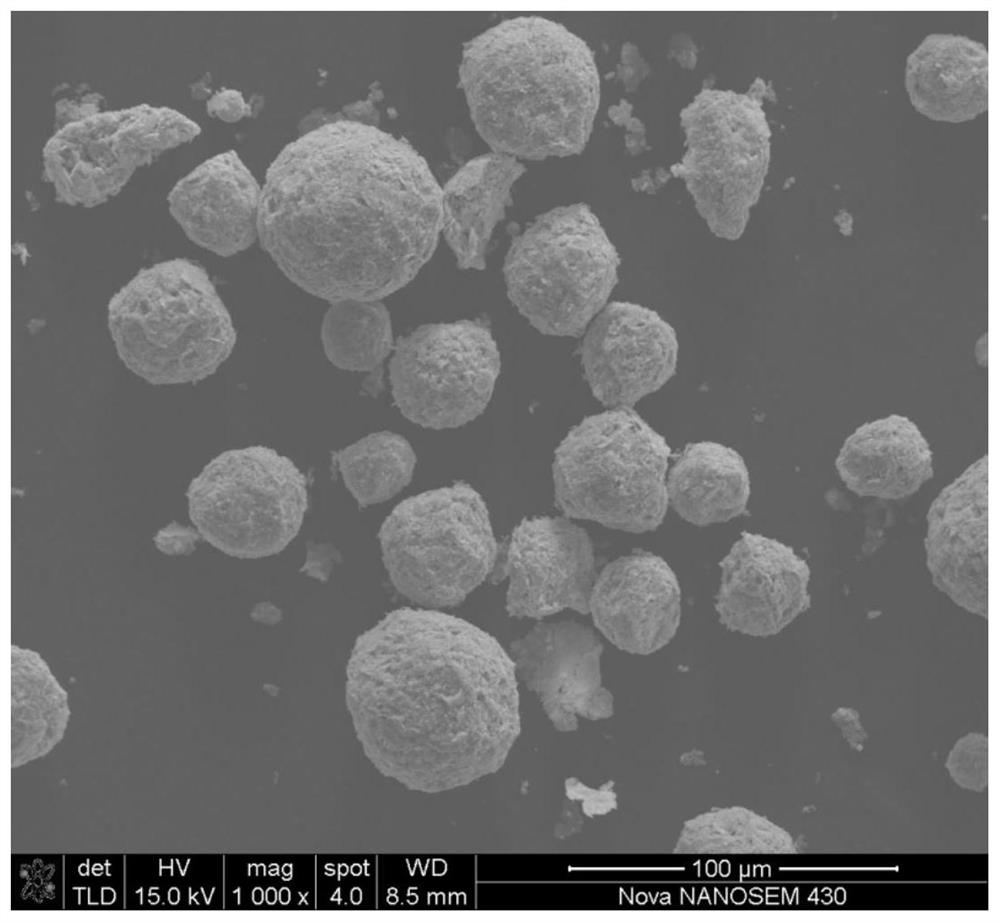

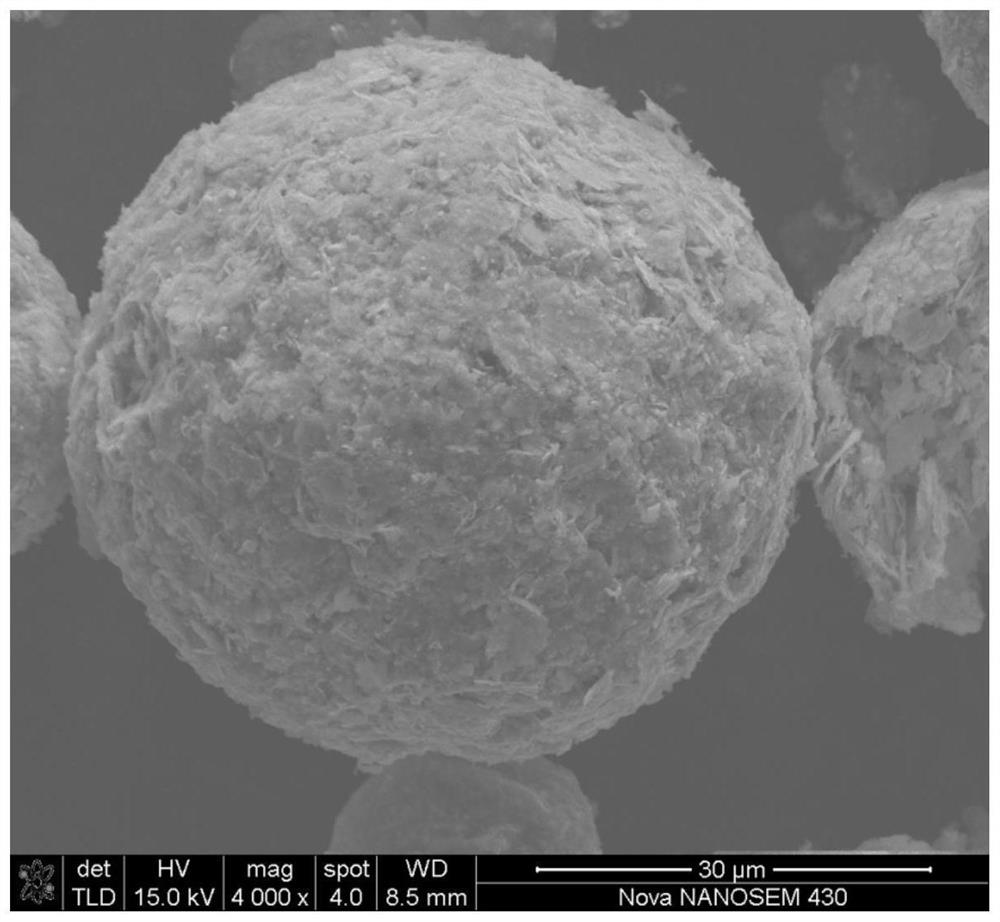

A kind of high sphericity nanostructure stainless steel powder and preparation method thereof

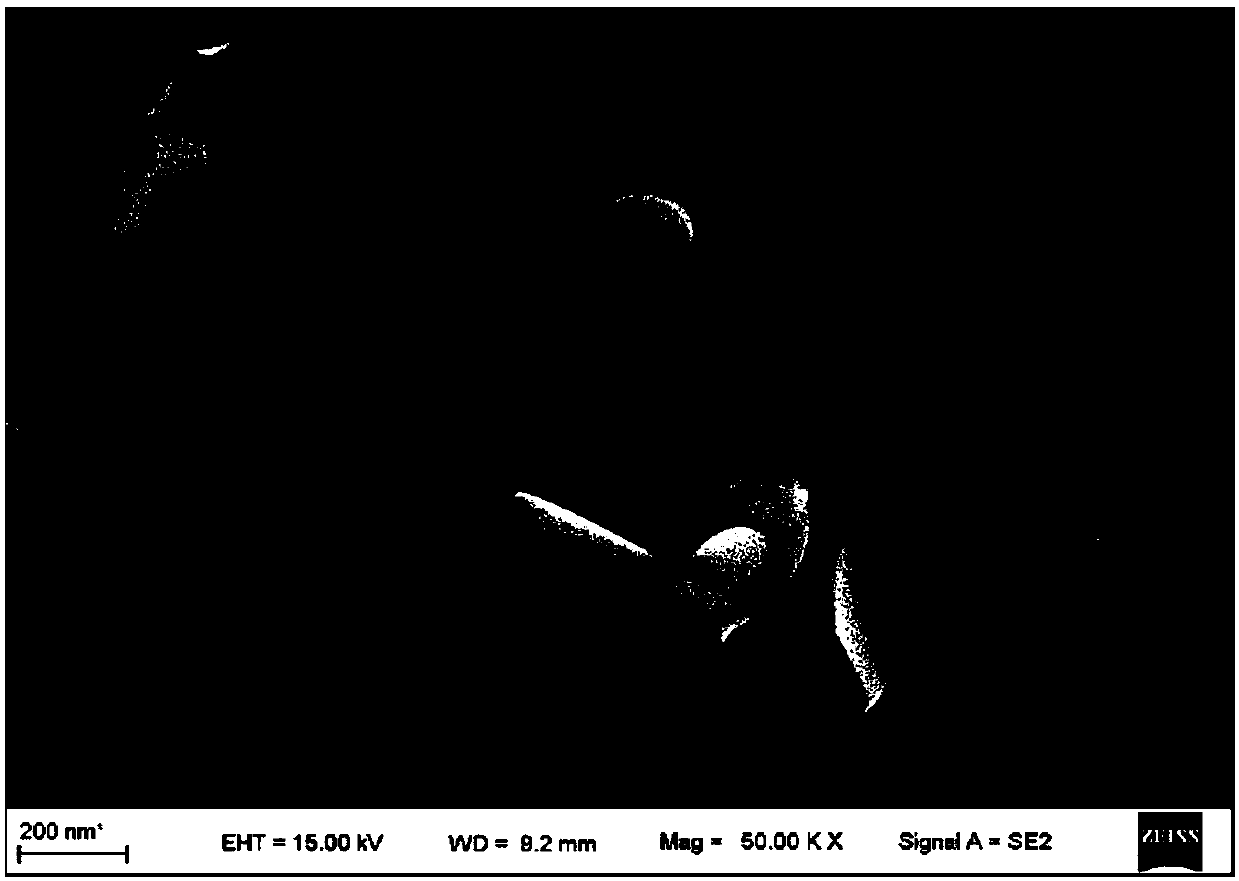

ActiveCN110405218BWith nanostructureSmooth and dense surfaceMaterial nanotechnologyTransportation and packagingSpray GranulationNano structuring

The invention discloses a preparation method of high-sphericity nano-structure stainless steel powder. The invention adopts spray granulation to obtain larger composite particles formed by agglomeration of nano stainless steel powder, and then uses a plasma spheroidization process to obtain nano-structured stainless steel powder. Structure, smooth and dense surface, high sphericity stainless steel powder. Through the combination of spray granulation and plasma spheroidization, the obtained stainless steel has extremely high sphericity, and is smooth and dense, which meets the requirements of 3D printing equipment for powder properties. The method of the invention is simple in operation, high in production efficiency, capable of mass production, has no pollution to the environment, and is an efficient and feasible powder preparation method.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com