Anatase/brookite complex-phase titanium dioxide ultraviolet shielding agent and preparation method thereof

An ultraviolet shielding agent, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of different crystal TiO2 ultraviolet shielding performance reports, insufficient ultraviolet absorption capacity, large amount of organic solvent, etc. Excellent UV shielding effect, achieving nanometer control, and the effect of no calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

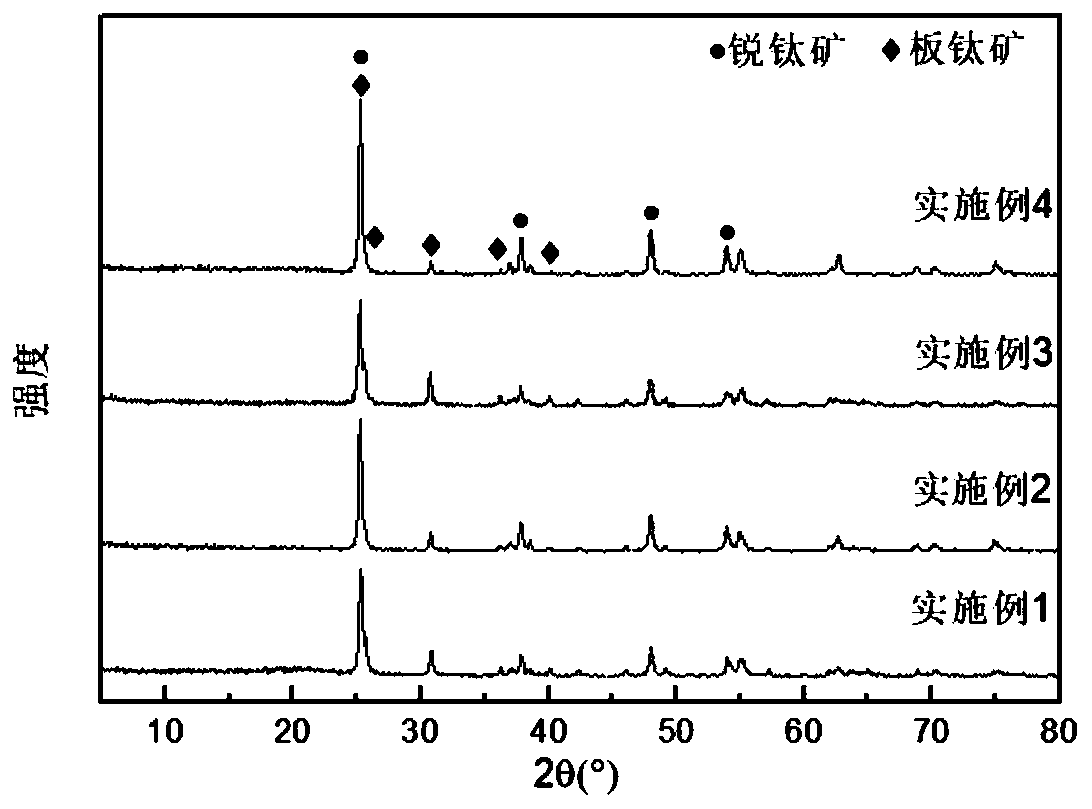

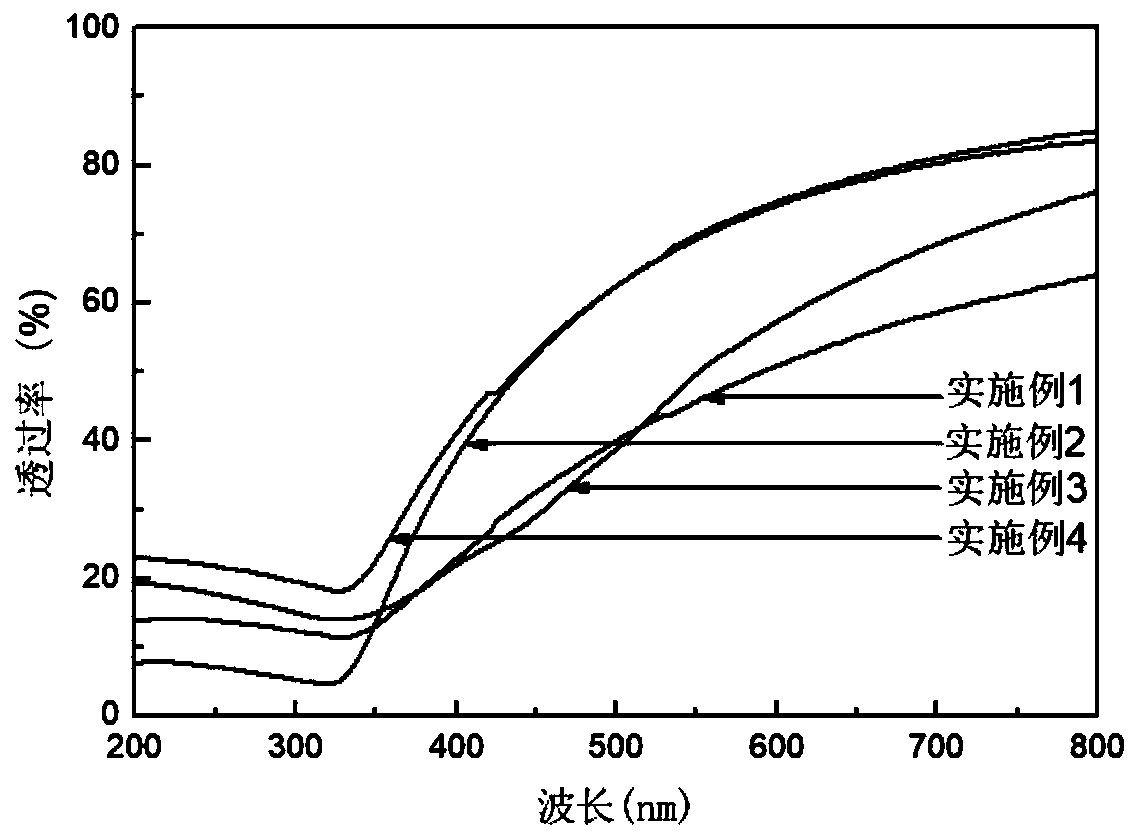

Embodiment 1

[0020] Weigh 10ml of butyl titanate, add 16ml of triethanolamine solvent to it, fully stir on a magnetic stirrer for 30 minutes to make it fully dispersed, then weigh 1.17g of NaCl and add it to 100ml of distilled water to prepare 0.2mol / l NaCl The solution was stirred for 30 minutes on a magnetic stirrer. Slowly add the dispersed 25ml NaCl solution into the prepared butyl titanate organic solvent system, so that Ti 4+ The concentration is about 1mol / L. After being fully dispersed on a magnetic stirrer for 1 hour, the prepared solution was added to a polytetrafluoroethylene reaction kettle, subjected to hydrothermal reaction at 160°C for 24 hours, and centrifuged and washed after the sample was cooled. Dry the centrifuged product at 100°C. Finally, after grinding for 3 minutes with a mortar, an anatase / brookite titanium dioxide inorganic ultraviolet shielding agent was obtained. The UV-Vis transmission spectrum analysis of the sample shows that it can shield 70% of UVA and ...

Embodiment 2

[0022] Weigh 10ml of butyl titanate, add 8ml of triethanolamine solvent to it, fully stir on a magnetic stirrer for 30ml minutes to make it fully dispersed, then weigh 5.85g of NaCl and add it to 100ml of distilled water to prepare a 1mol / l NaCl solution After stirring for 30 min on a magnetic stirrer. Slowly add the dispersed 50ml NaCl solution into the prepared butyl titanate organic solvent system, so that Ti 4+ The concentration is around 0.5mol / L. After being fully dispersed on a magnetic stirrer for 1 hour, the prepared solution was added to a polytetrafluoroethylene reactor, and subjected to a hydrothermal reaction at 180°C for 24 hours. After the sample was cooled, it was centrifuged and washed. Dry the centrifuged product at 100°C. Finally, after grinding for 3 minutes with a mortar, an anatase / brookite titanium dioxide inorganic ultraviolet shielding agent was obtained. The content of brookite reaches 30%. The UV-Vis transmission spectrum analysis of the sample s...

Embodiment 3

[0024] Weigh 10ml of butyl titanate, add 2ml of triethanolamine solvent to it, fully stir for 30ml on a magnetic stirrer to fully disperse it, and then weigh 21.25g of NaNO 3 Add to 100ml distilled water to prepare 2.5mol / l NaNO 3 The solution was stirred for 30 minutes on a magnetic stirrer. The dispersed 100mlNaNO 3 The solution was slowly added to the prepared butyl titanate organic solvent system, so that Ti 4+ The concentration is around 0.25mol / L. After being fully dispersed on a magnetic stirrer for 1 hour, the prepared solution was added to a polytetrafluoroethylene reactor, and hydrothermally reacted at 160°C for 30 hours. After the sample was cooled, it was centrifuged and washed. Dry the centrifuged product at 100°C. Finally, after grinding for 3 minutes with a mortar, an anatase / brookite titanium dioxide inorganic ultraviolet shielding agent was obtained. An anatase / brookite titanium dioxide inorganic UV shielding agent was obtained. Then carry out UV-Vis tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com