Patents

Literature

51results about How to "Effective control ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

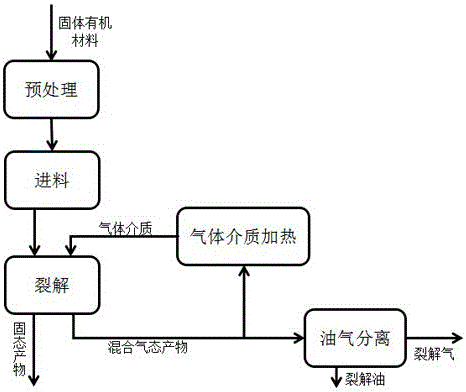

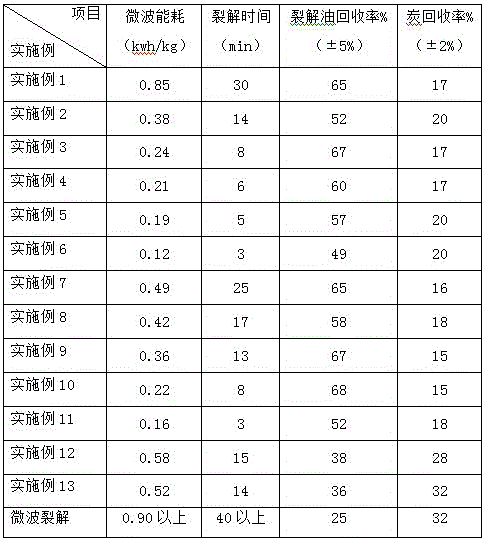

Tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves

ActiveCN105733644AStrong process controllabilityImproved microwave absorption propertiesProductsReagentsMicrowaveProduct gas

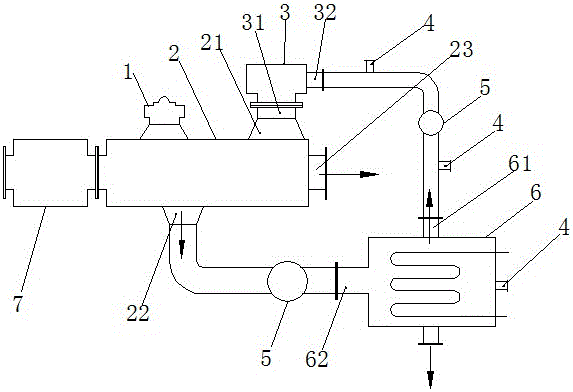

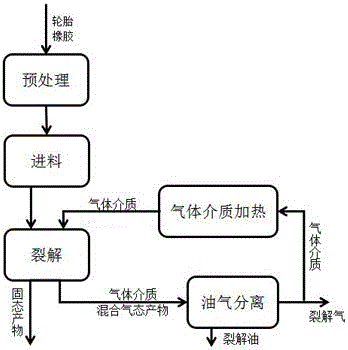

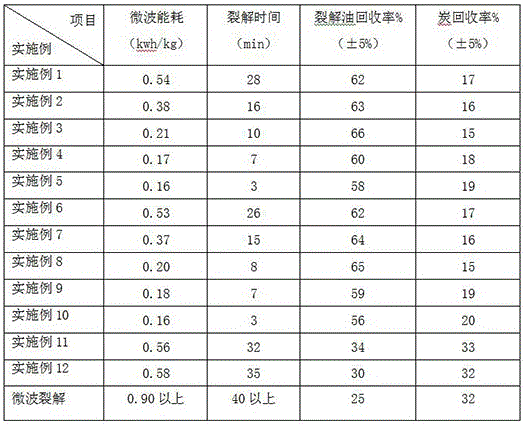

The invention provides a tire rubber pyrolysis method combining pyrolysis gas circulation heating and microwaves. The method includes the steps of A, preprocessing tire rubber; B, feeding the preprocessed tire rubber into a composite pyrolysis cavity; C, using a gas heating device to heat gas media to 350-700 DEG C; D, continuously feeding the heated gas into the composite pyrolysis cavity, and allowing the heated gas and the microwaves to jointly act on the tire rubber so as to perform pyrolysis to obtain solid products and mixed gas products; E, performing oil-gas separation on the mixed gas products to remove pyrolysis oil; F, partially feeding the gas obtained after the oil-gas separation in the step E into the gas heating device of the step C, and heating the gas to 350-700 DEG C for the circulation pyrolysis of the step D. By the tire rubber pyrolysis method, pyrolysis energy consumption and pyrolysis time can be reduced and cost is saved.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

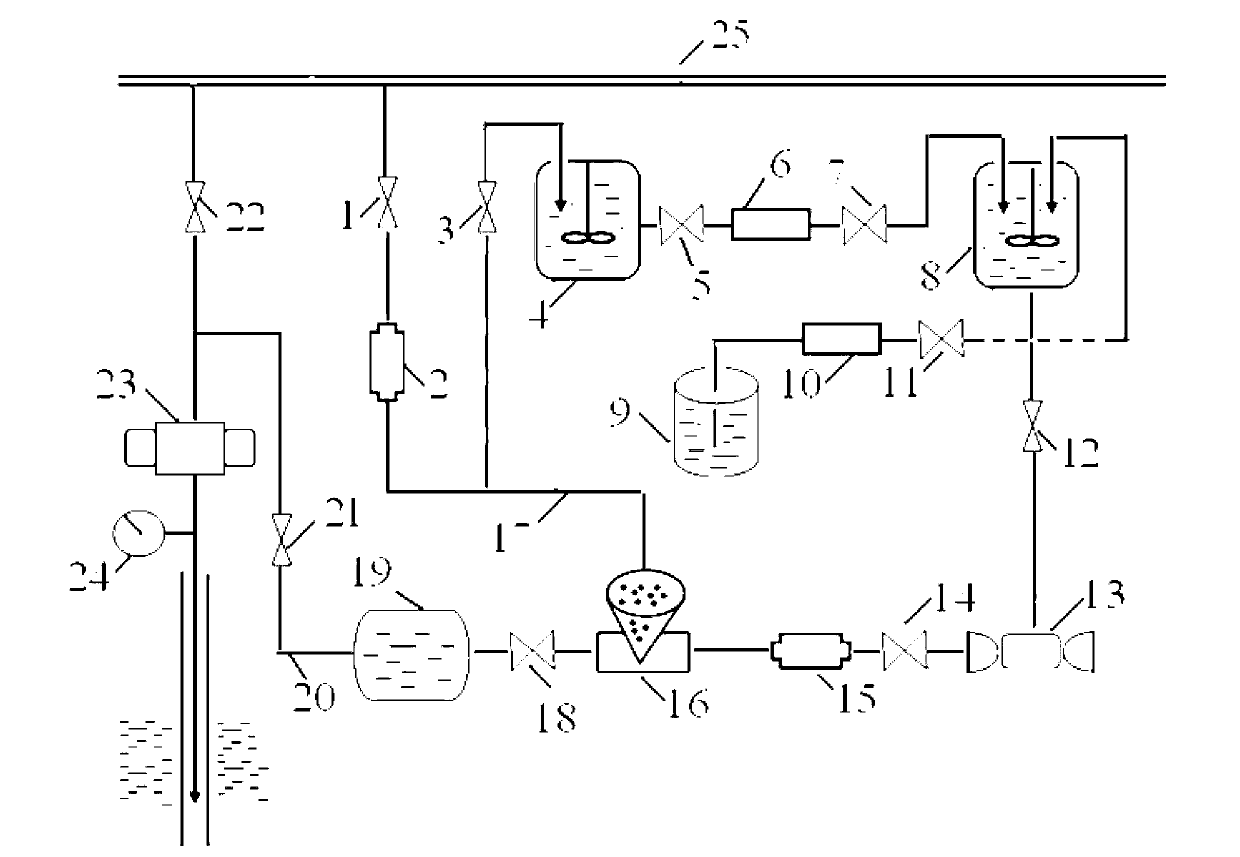

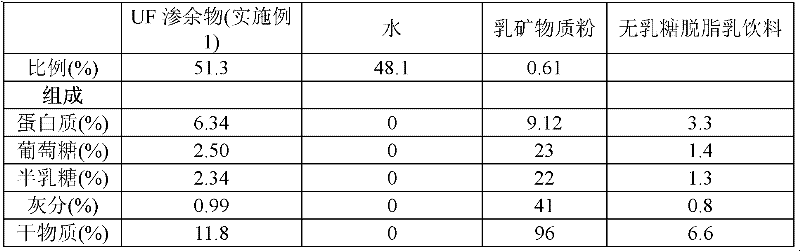

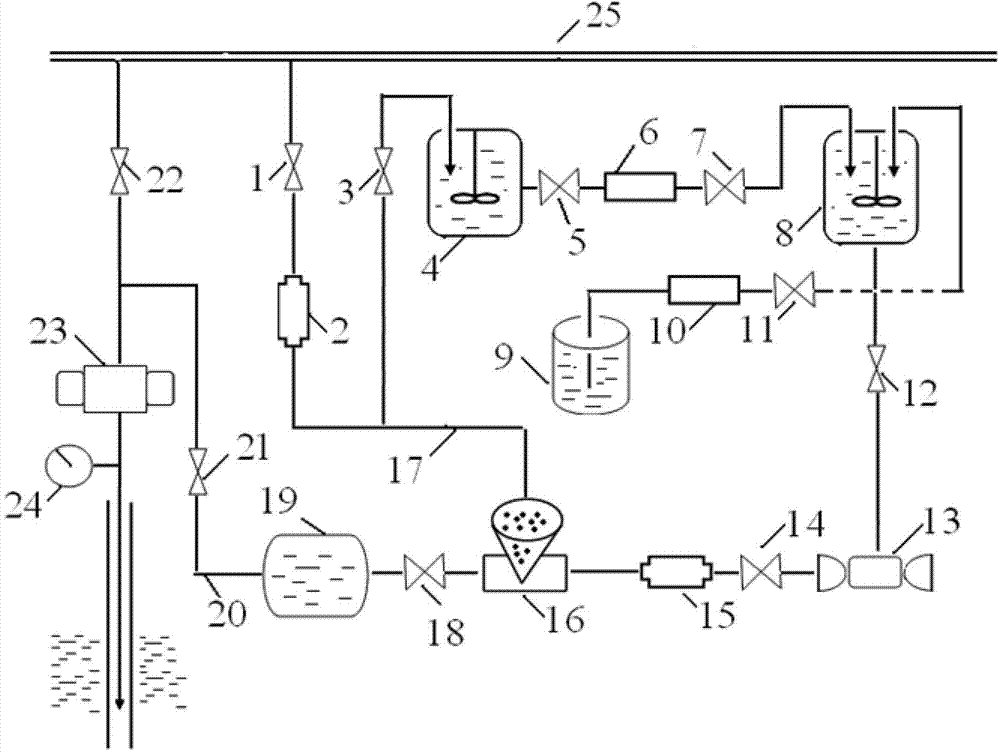

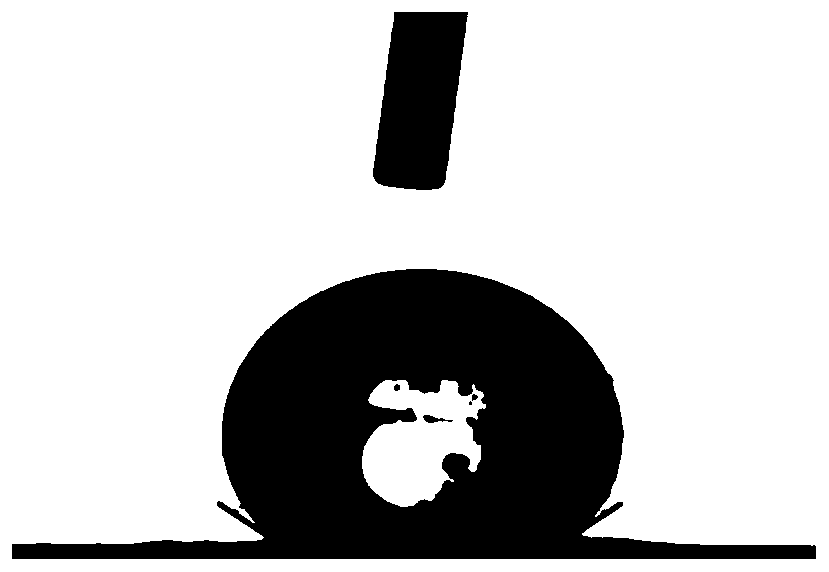

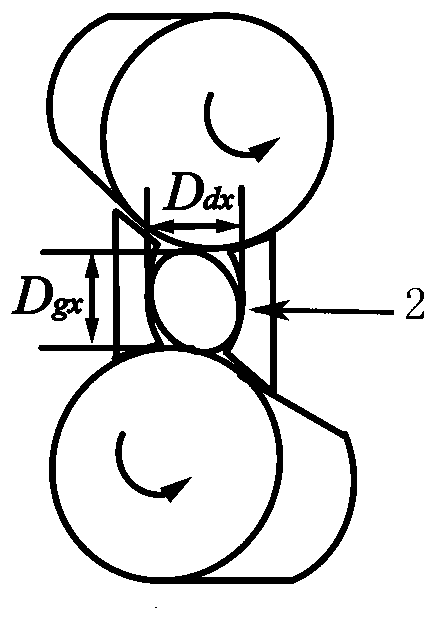

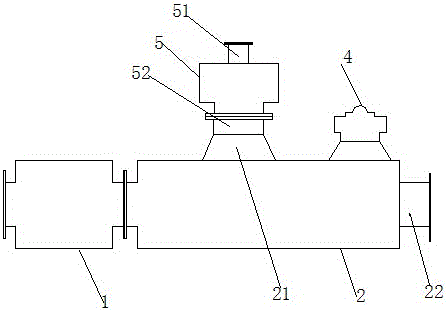

Online continuous production and injection integrating method and device for jelly dispersoid

ActiveCN102996106AShorten injection timeMeet the needs of continuous profile control (control and drive)Fluid removalBuffer tankColloid

The invention relates to an online continuous production and injection integrating method and device for a jelly dispersoid. The method comprises the following steps of: curing a polymer and preparing a jelly system; then, pumping the prepared jelly system into a colloid grinder through a flow meter, meanwhile, injecting water into the colloid grinder, and grinding by using the colloid grinder at the rotating speed of 1000-3000rpm for 3-5 minutes to prepare the jelly dispersoid; enabling the prepared jelly dispersoid to enter a buffer tank; and pumping the jelly dispersoid in the buffer tank into a water injection well through a high-pressure plunger pump. Production and injection integration of a profile control agent (profiling / flooding agent) is realized, the jelly system and the jelly dispersoid are prepared simultaneously while the jelly dispersoid is pumped into the water injection well, the production and the injection of the jelly dispersoid are continuously carried out on line, and production and injection are simultaneously carried out, so that the production and injection time of the jelly dispersoid is greatly shortened, and the large-dosage continuous profiling and flooding requirements of multiple well groups or blocks can be met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

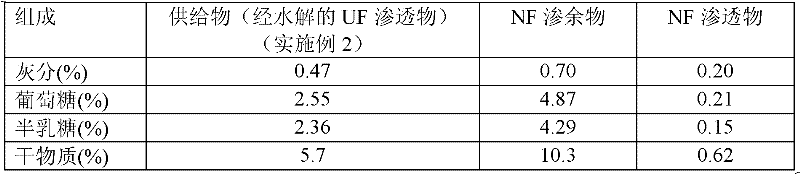

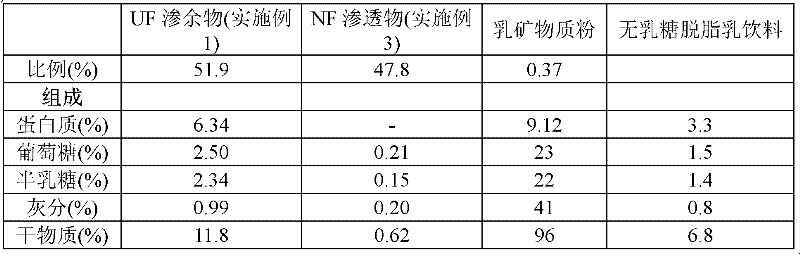

Low-lactose and lactose-free milk product and process for production thereof

The invention relates to a low-lactose and a lactose-free milk product and to a process for the production thereof. The lactose in the milk raw material is hy- drolyzed, proteins, minerals and sugars are separated into different fractions by the membrane technique, and a low-lactose or a lactose-free milk product is composed from the fractions. The invention provides a milk product the water therein originating from the original milk raw material. In addition, useful by-products are produced in the process.

Owner:VALIO LTD

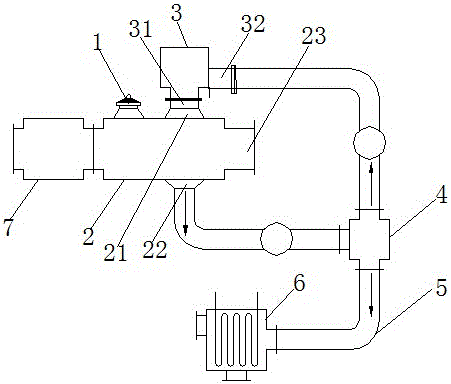

Solid organic material cracking method and system

ActiveCN106338066AImproved microwave absorption propertiesStrong process controllabilityProductsReagentsMicrowaveProduct gas

The invention provides a solid organic material cracking method and system. The method comprises the following steps of: A, pre-treating a solid organic material; B, sending the pre-treated solid organic material into a cracking device; C, heating a gas medium to 350-700 DEG C; D, continuously importing the heated gas medium into the cracking device to act on the solid organic material with microwave, so as to carry out cracking to obtain a solid product and a mixed gaseous product; and E, importing a part of the obtained mixed gaseous product into a gas heating device in the step C so as to heat the mixed gaseous product to 350-700 DEG C to be circularly used for the cracking in the step D. The process can effectively decrease the cracking energy consumption and the cracking time, and can save the cost.

Owner:成都德理克新材料科技有限公司

Online continuous production and injection integrating method and device for jelly dispersoid

The invention relates to an online continuous production and injection integrating method and device for a jelly dispersoid. The method comprises the following steps of: curing a polymer and preparing a jelly system; then, pumping the prepared jelly system into a colloid grinder through a flow meter, meanwhile, injecting water into the colloid grinder, and grinding by using the colloid grinder at the rotating speed of 1000-3000rpm for 3-5 minutes to prepare the jelly dispersoid; enabling the prepared jelly dispersoid to enter a buffer tank; and pumping the jelly dispersoid in the buffer tank into a water injection well through a high-pressure plunger pump. Production and injection integration of a profile control agent (profiling / flooding agent) is realized, the jelly system and the jelly dispersoid are prepared simultaneously while the jelly dispersoid is pumped into the water injection well, the production and the injection of the jelly dispersoid are continuously carried out on line, and production and injection are simultaneously carried out, so that the production and injection time of the jelly dispersoid is greatly shortened, and the large-dosage continuous profiling and flooding requirements of multiple well groups or blocks can be met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

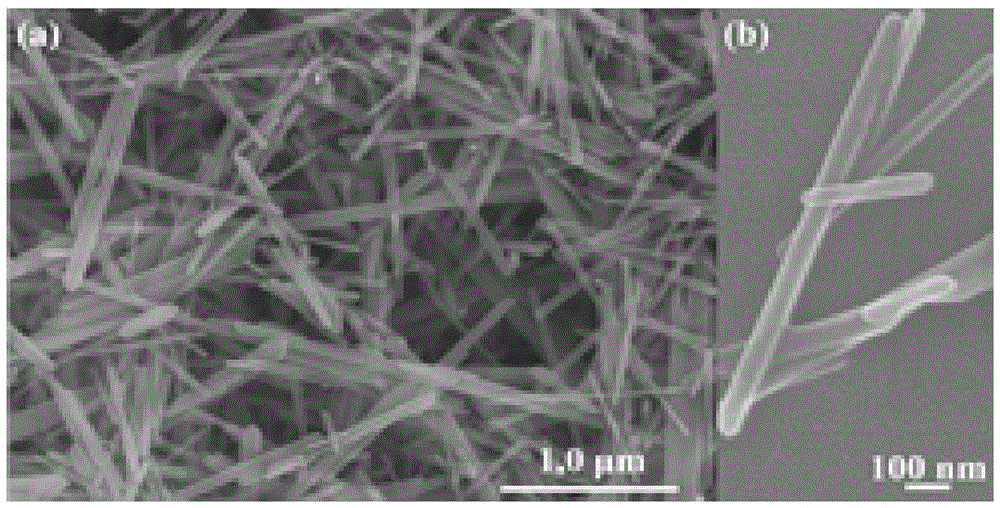

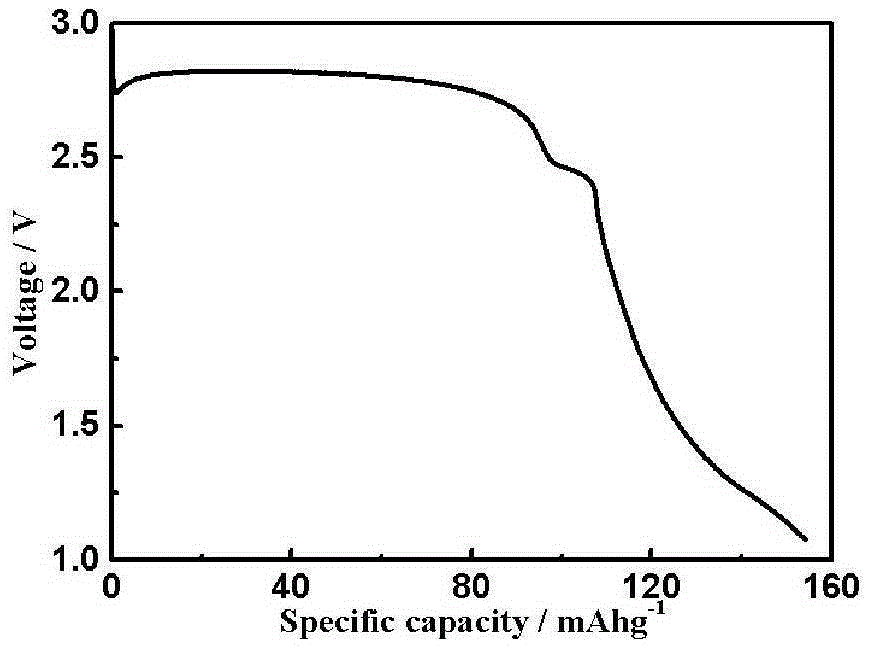

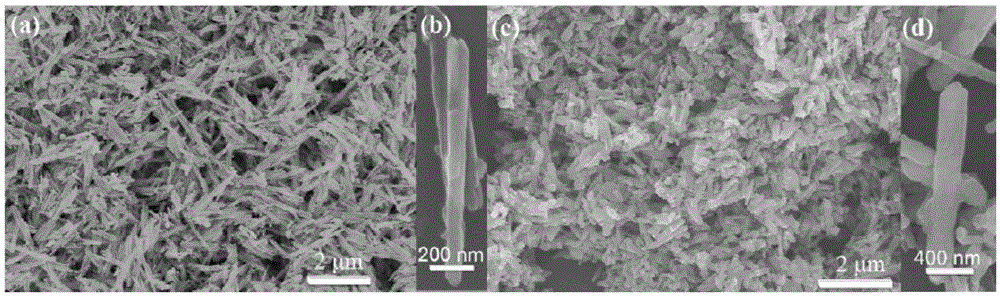

Lithium-containing metal oxide lithium electricity nanoelectrode materials and preparation method thereof

ActiveCN105304895AImprove electrochemical performanceElectrochemical performance regulationMaterial nanotechnologyCell electrodesHigh rateSolvent

The invention discloses lithium-containing metal oxide lithium electricity nanoelectrode materials and a preparation method thereof. Nanostructure metal oxide synthesized at low temperature through a water heating method, a solvent heating method, a sol-gel method and the like is subjected to pre-lithiation, and therefore the temperature at which a lithium-containing metal oxide crystal structure is formed and develops is effectively lowered, needed time is effectively shortened, the proportion and the mixed arranging degree of Li+ and transition metal ions in lithium-containing transition metal oxide can be effectively controlled, and the nanoscale and the structure of the metal oxide can be kept. Energy consumption in the material preparation process is greatly reduced, cost is reduced, meanwhile high-efficiency and high-rate lithium-containing transition metal oxide positive and negative materials can be obtained, and therefore the electrochemical pre-lithiation preparation method is an environment-friendly controlled preparation method of nano lithium-containing transition metal oxide nanostructure electrode materials.

Owner:NANJING UNIV OF POSTS & TELECOMM

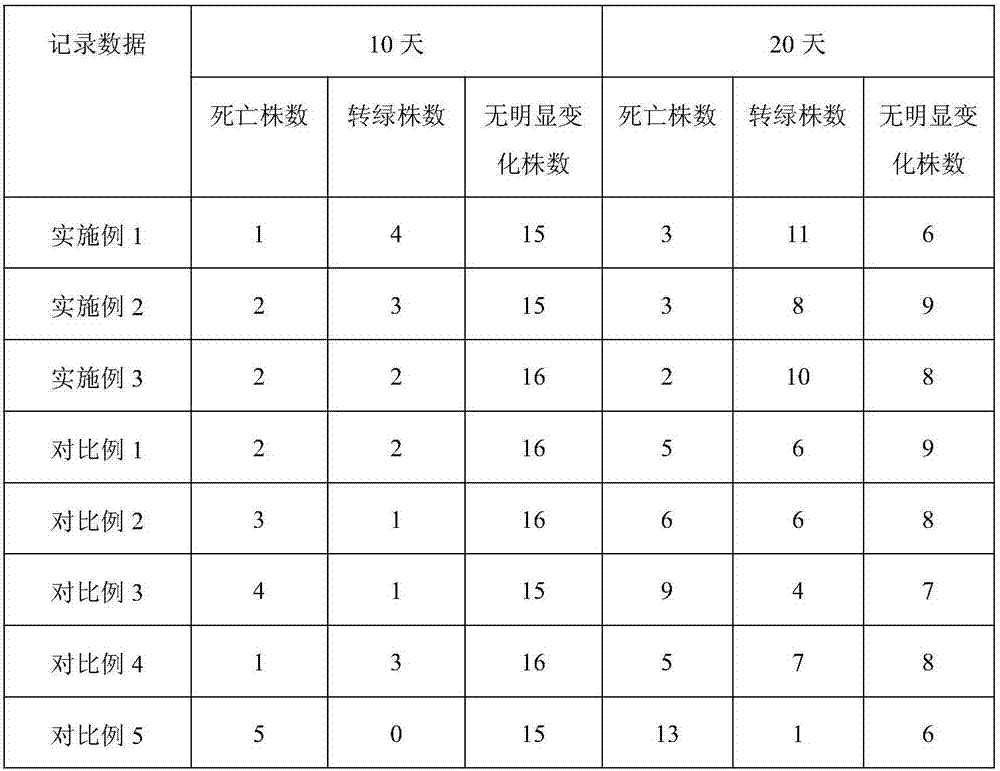

Special compound fertilizer for relieving citrus etiolation and preparation method thereof

InactiveCN107473861ASimple processSuitable for industrializationAlkali orthophosphate fertiliserExcrement fertilisersMicroorganismGeonoma congesta

The invention discloses a special compound fertilizer for relieving citrus etiolation and a preparation method thereof. The special compound fertilizer for relieving citrus etiolation is prepared from, by weight, 40-70 parts of organic fertilizer, 20-35 parts of plant ash, 10-25 parts of inorganic fertilizer, 0.1-0.5 part of rooting agent, 3-5 parts of humate and 2-5 parts of bacterial manure; the bacterial manure comprises bacillus mucilaginosus, trichoderma harzianum and saccharomycetes; the compound fertilizer can provide various nutrient elements required by the growth of citrus and can also improve the soil environment, reproduction of harmful bacteria is inhibited, the growth of beneficial bacteria is promoted, the compound fertilizer helps diseased or infected plants to absorb the nutrient elements, then citrus etiolation diseases are relived, and the recovery of the citrus diseased or infected plants is promoted.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

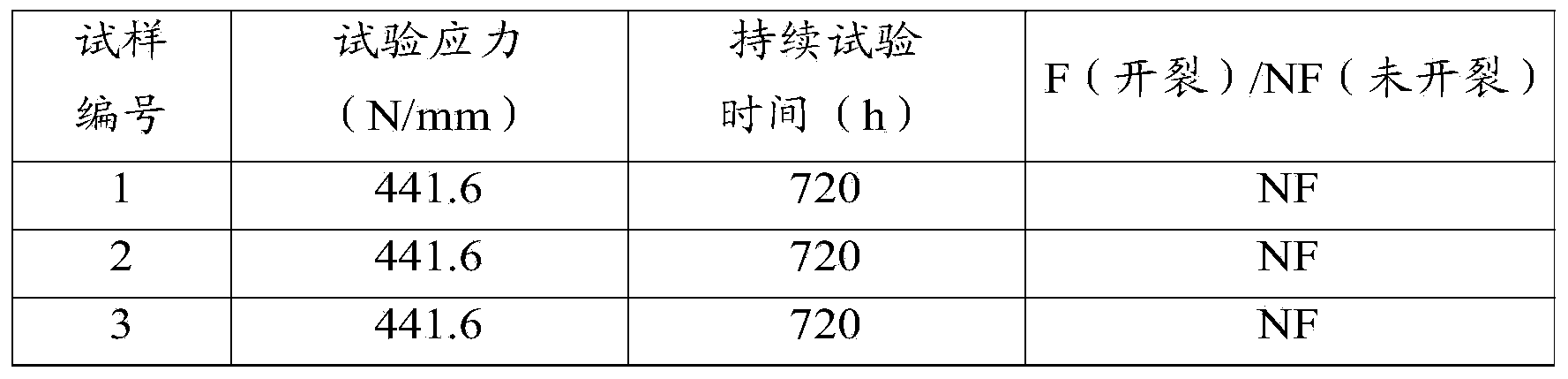

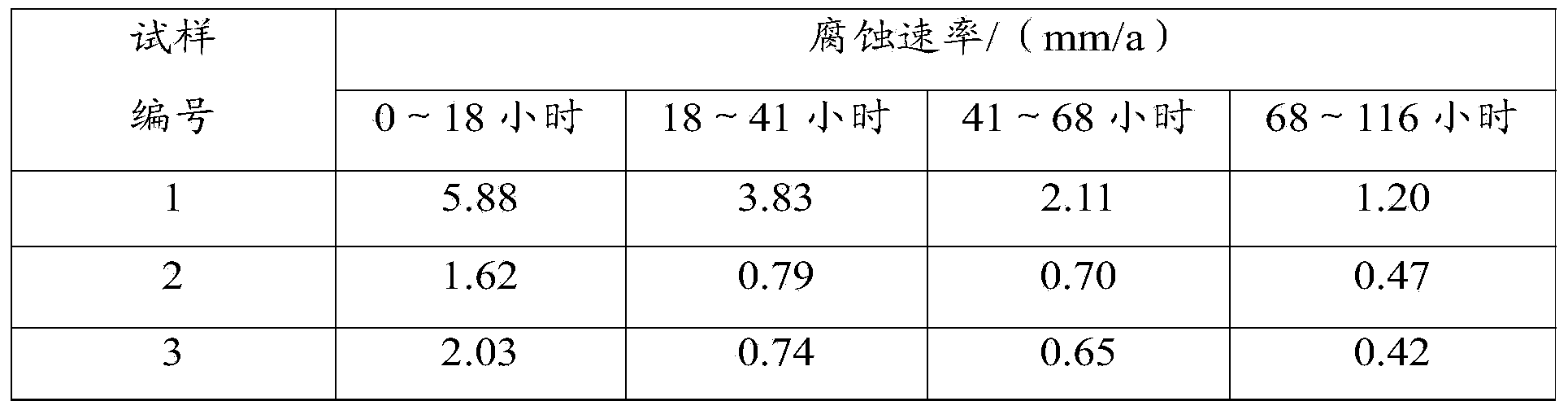

Method of improving corrosion resistance of oil tube

InactiveCN103834915AImprove corrosion resistanceImprove mechanical propertiesCorrosion preventionSolid state diffusion coatingNitrogenOxygen ions

The invention provides a method of improving corrosion resistance of an oil tube. The method comprises the following steps: (1) pre-cleaning; (2) card mounting; (3) pre-heating; (4) nitrogen-carbon-yttrium ion penetrating; (5) ion activating; (6) oxygen ion penetrating; (7) post-cleaning; (8) ion stabilizing, and (9) oil immersing. The method disclosed by the invention can carry out controllable ion penetrating (PIP) treatment on the oil tube to form multiple compound penetrating layers on the surface of the oil tube, so that good mechanical performance is achieved and service life of the oil tube is prolonged while the corrosion resistance is improved, and therefore, the method has good practical application effect.

Owner:四川中久红宇科技有限公司 +1

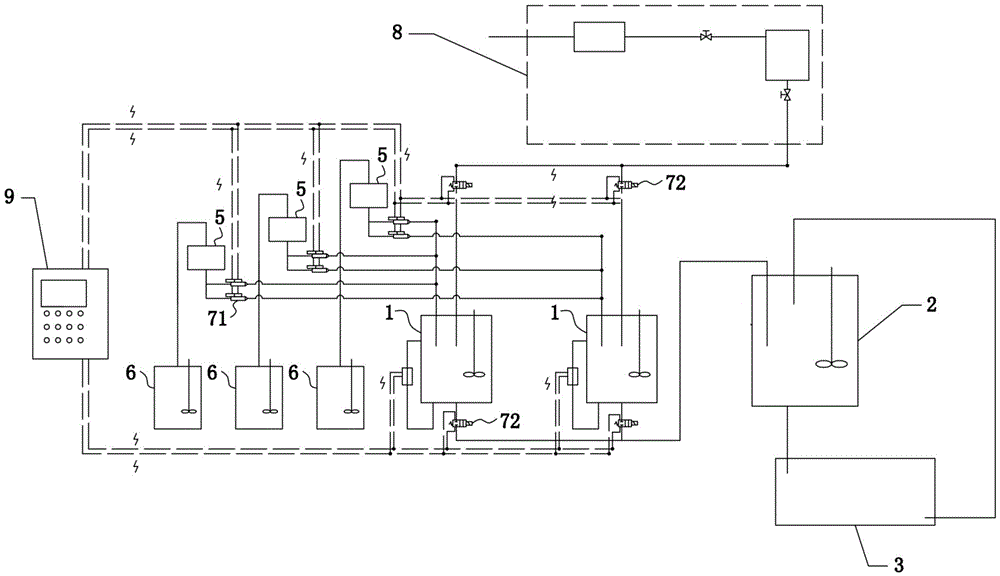

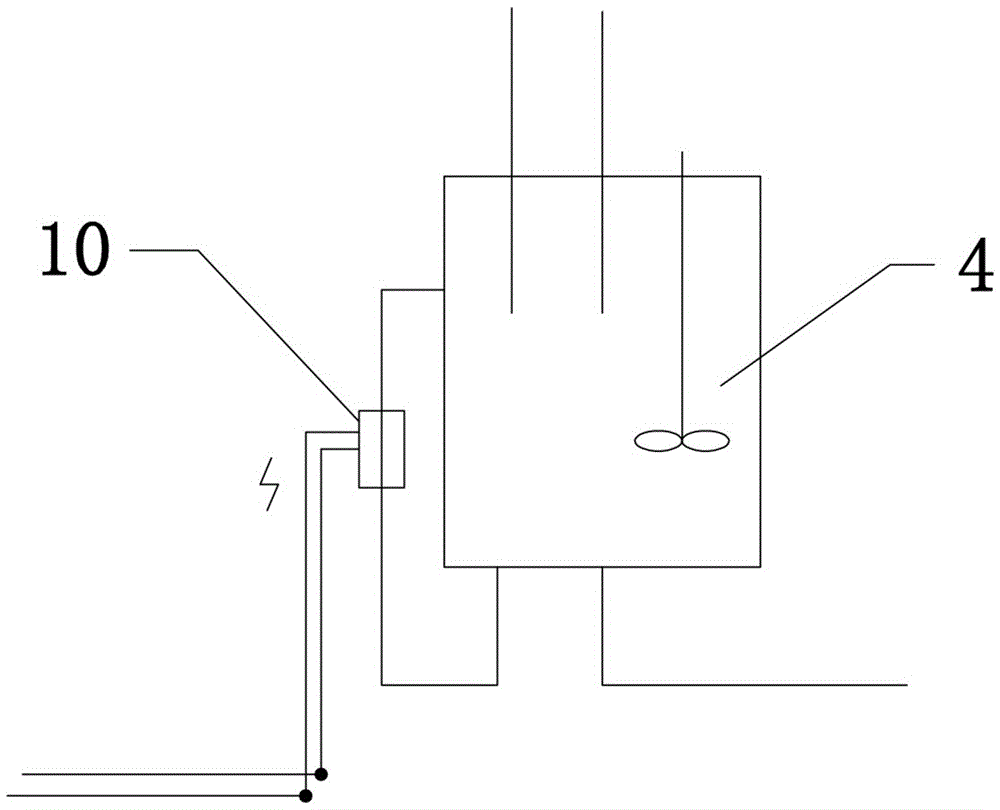

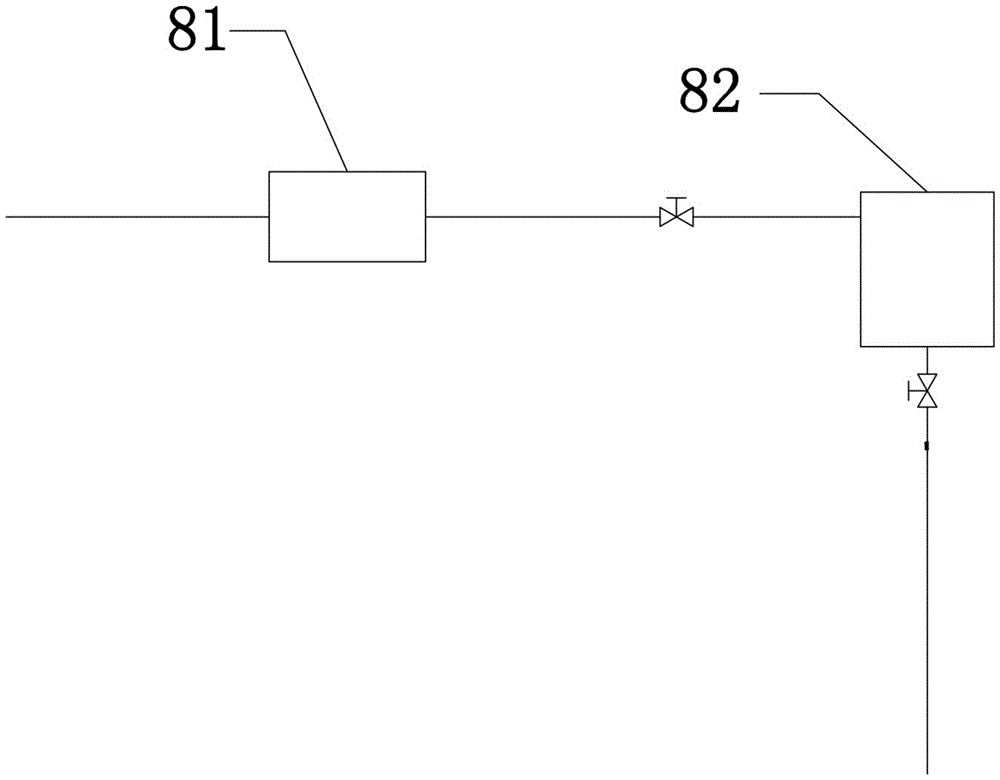

Nonwoven fabric liquid distribution system

InactiveCN105536602AUniform concentrationEffective control ratioRotary stirring mixersTransportation and packagingSolenoid valveDistribution system

The invention discloses a nonwoven fabric liquid distribution system. The nonwoven fabric liquid distribution system comprises a plurality of independent liquid distribution tanks, a liquid storage tank, N elevated tanks, N oil agent tanks and a liquid feeding device, a stirrer provided with a rotating shaft deviating from the axis center of a corresponding tank body is arranged in each of the liquid distribution tanks and the liquid storage tank, the water inlet of each of the liquid distribution tanks is connected with a soft water supply system through a liquid conveying pipeline provided with a solenoid valve, the output ports of the oil agent tanks correspond to the input ports of the elevated tanks one to one, the output ports of the elevated tanks are simultaneously connected with the input ports of the plurality of liquid distribution ports through liquid conveying pipelines provided with metering valves, the output port of each of the liquid distribution tank is connected with the input port of the liquid storage tank through a liquid conveying pipeline provided with a solenoid valve to realize alternate liquid conveying of the liquid distribution tanks to the liquid storage tank, and the liquid distribution tanks are in circulating connection with the liquid feeding device; and the nonwoven fabric liquid distribution system is also provided with a control center used for controlling the metering valves in order to adjust the flow amounts of all segments of the liquid conveying pipelines.

Owner:FOSHAN NAHAI BEAUTIFUL NONWOVEN CO LTD

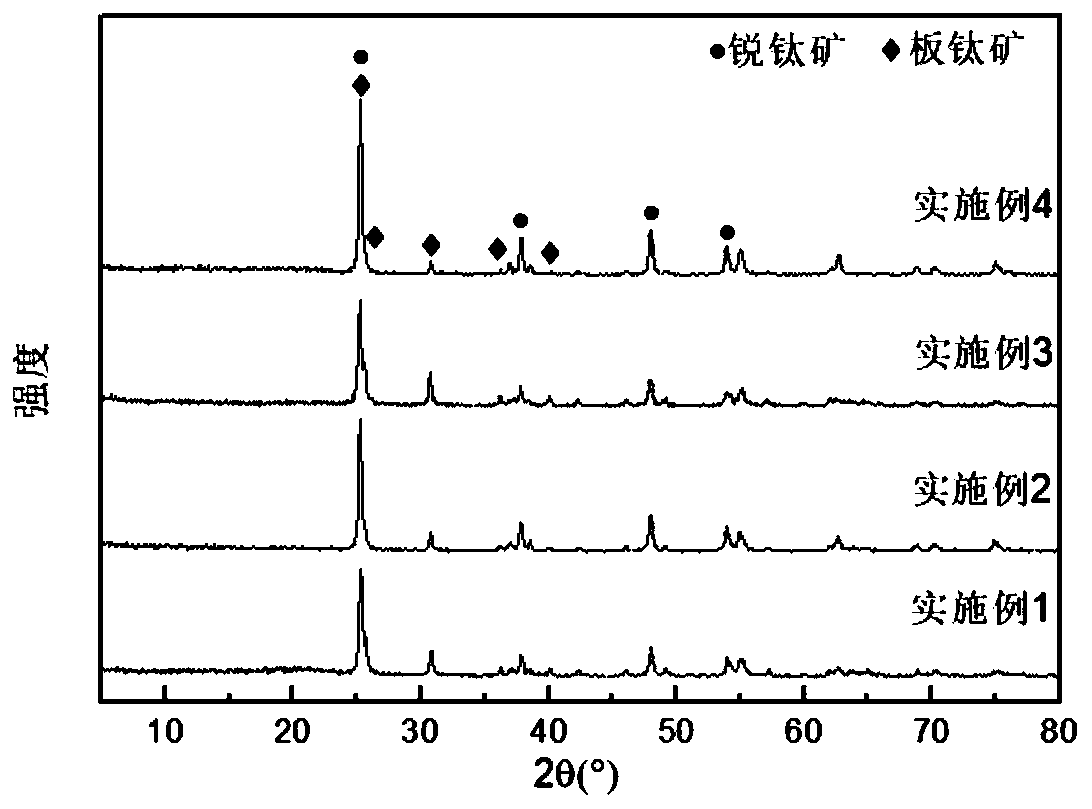

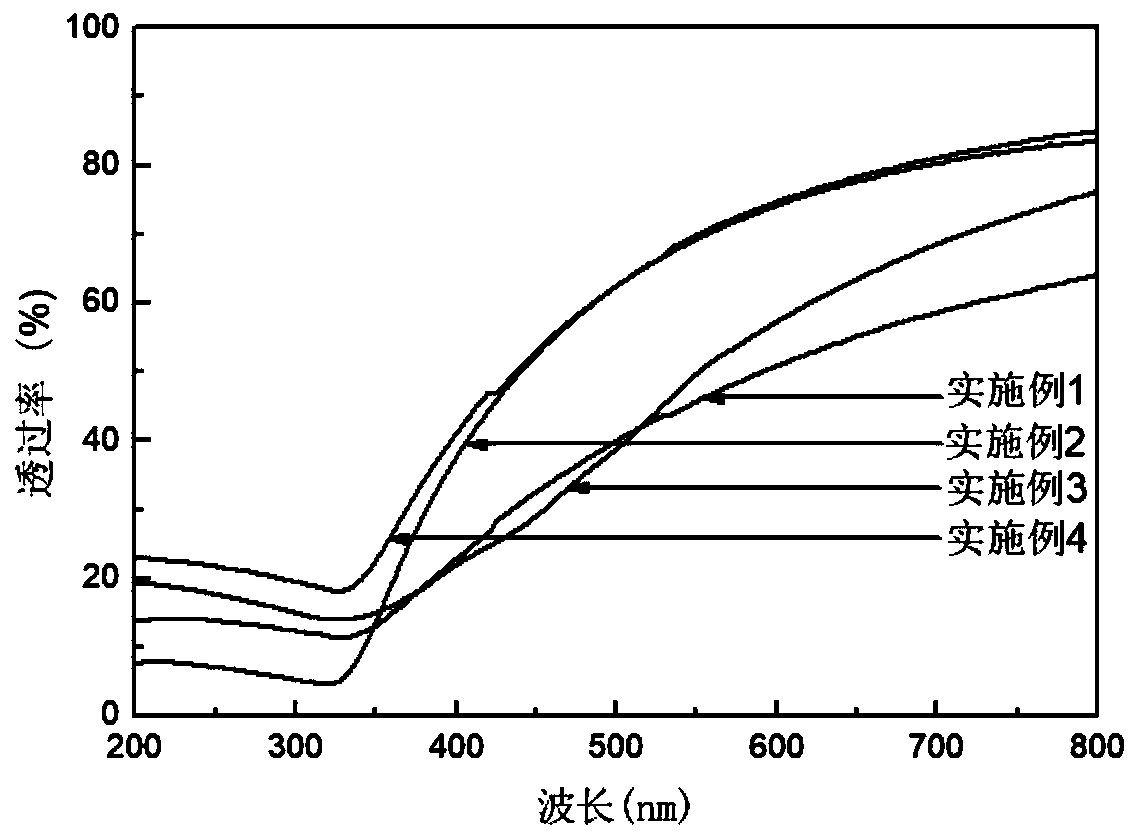

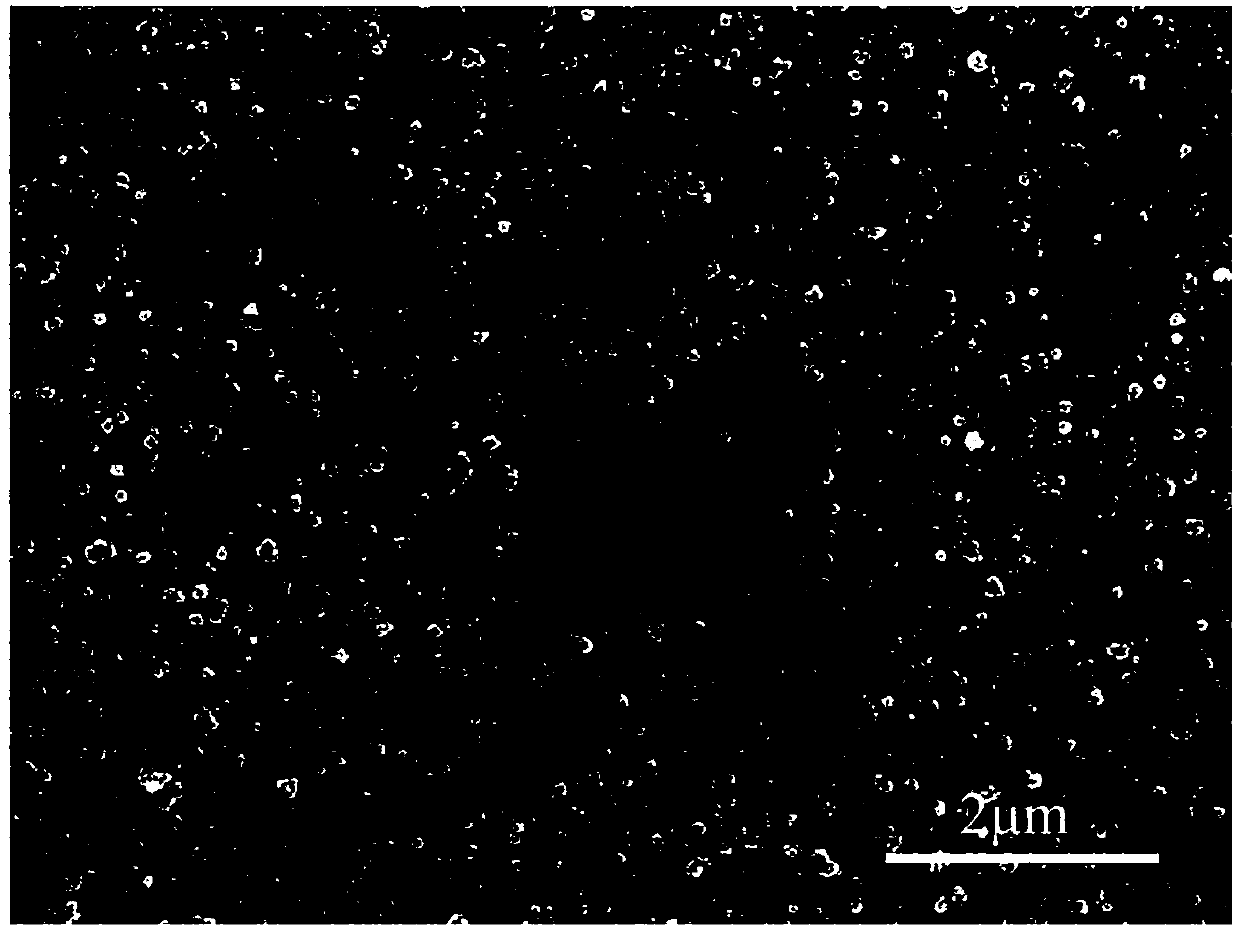

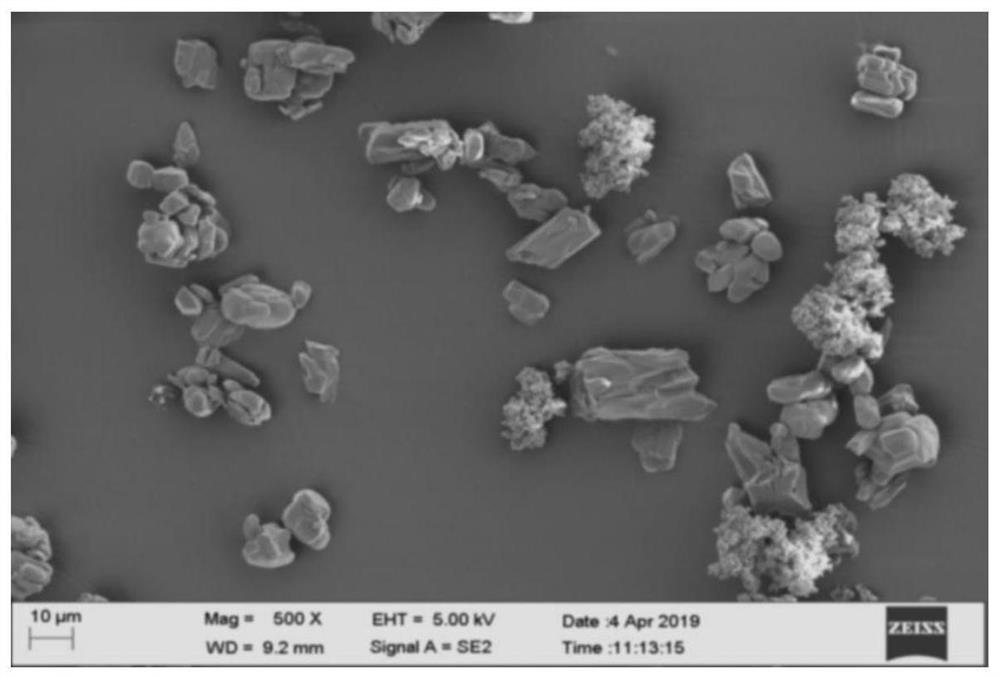

Anatase/brookite complex-phase titanium dioxide ultraviolet shielding agent and preparation method thereof

InactiveCN110697769AHigh whitenessHigh refractive indexMaterial nanotechnologyPhysical treatmentUltravioletMaterials science

The invention relates to an anatase / brookite complex-phase titanium dioxide ultraviolet shielding agent and a preparation method thereof, and belongs to the technical field of novel inorganic materials. According to the invention, the ultraviolet shielding performances of different phases of titanium dioxide are fully utilized, and in a hydrothermal synthesis system of titanium alkoxide, the anatase / brookite complex-phase titanium dioxide ultraviolet shielding material is prepared by using cheap inorganic sodium salt as a crystal form guiding agent, so that the defects of poor light scatteringand poor reflection of the anatase type titanium dioxide ultraviolet region are overcome, and the visible light transmission effect of the composite shielding agent is guaranteed; with the method, the ratio of the anatase type TiO2 to the brookite type TiO2 in the complex-phase shielding agent can be controlled by adjusting the dosage of the crystal form guiding agent, so that the working performances of the shielding agent in UVA and UVB sections can be adjusted as required; and the grain growth of TiO2 can be inhibited by utilizing the interaction between different crystalline phase grainsof the complex-phase TiO2 so as to successfully achieve the nanocrystallization control of TiO2, so that the excellent performance of the obtained ultraviolet shielding agent is guaranteed.

Owner:JILIN UNIV

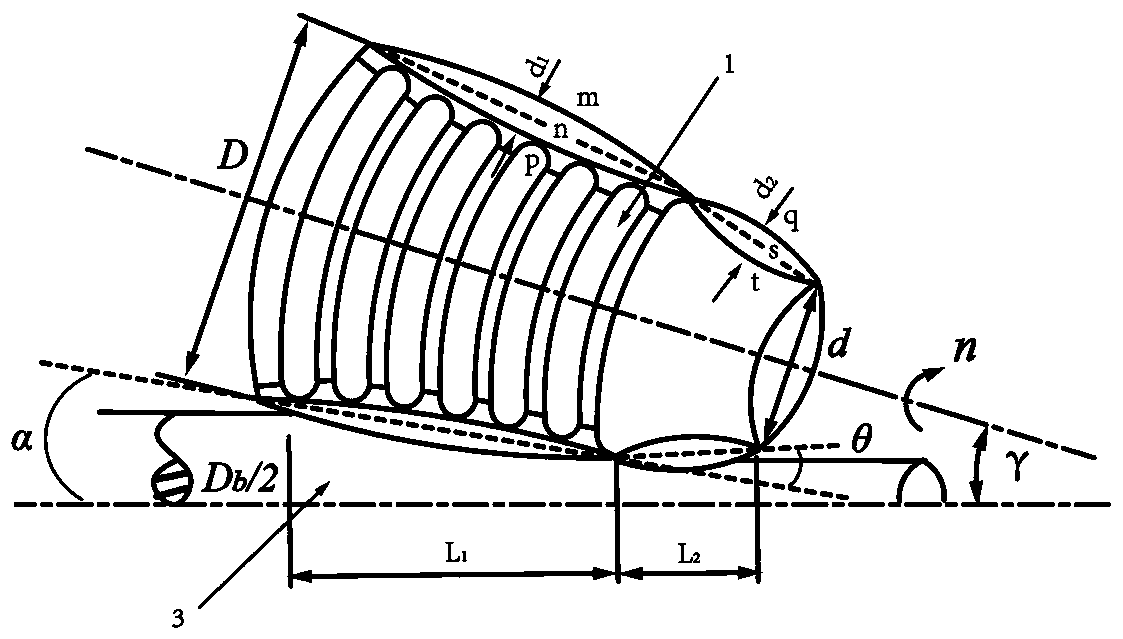

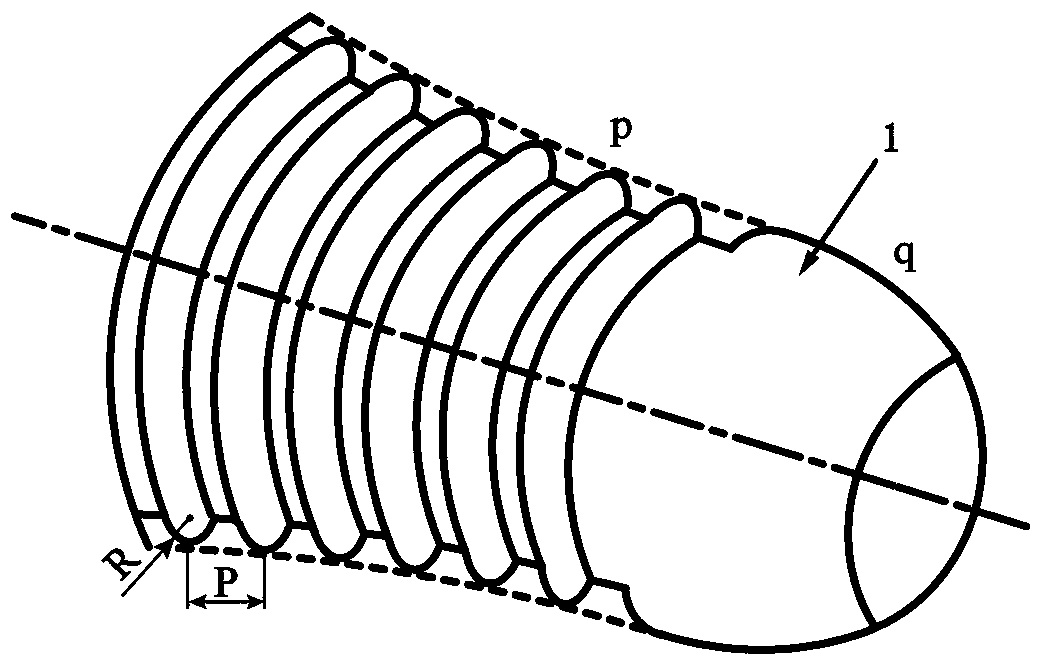

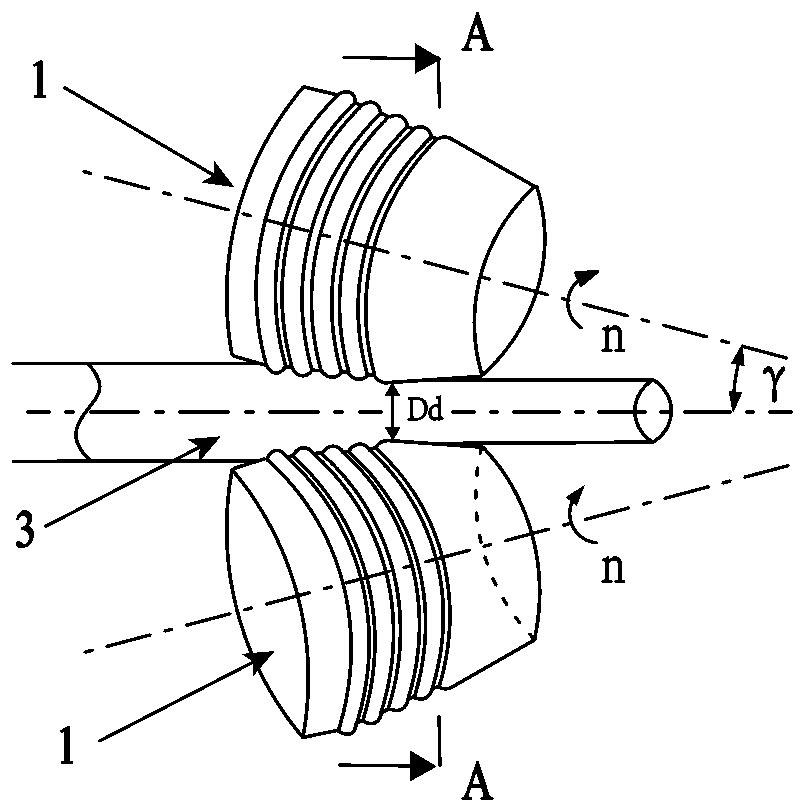

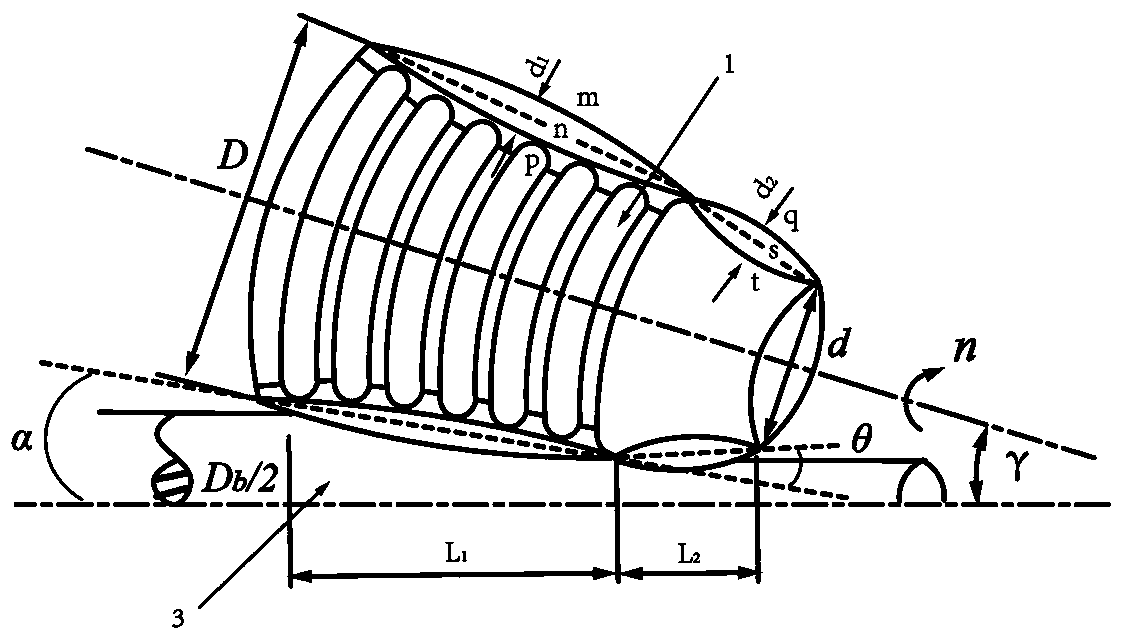

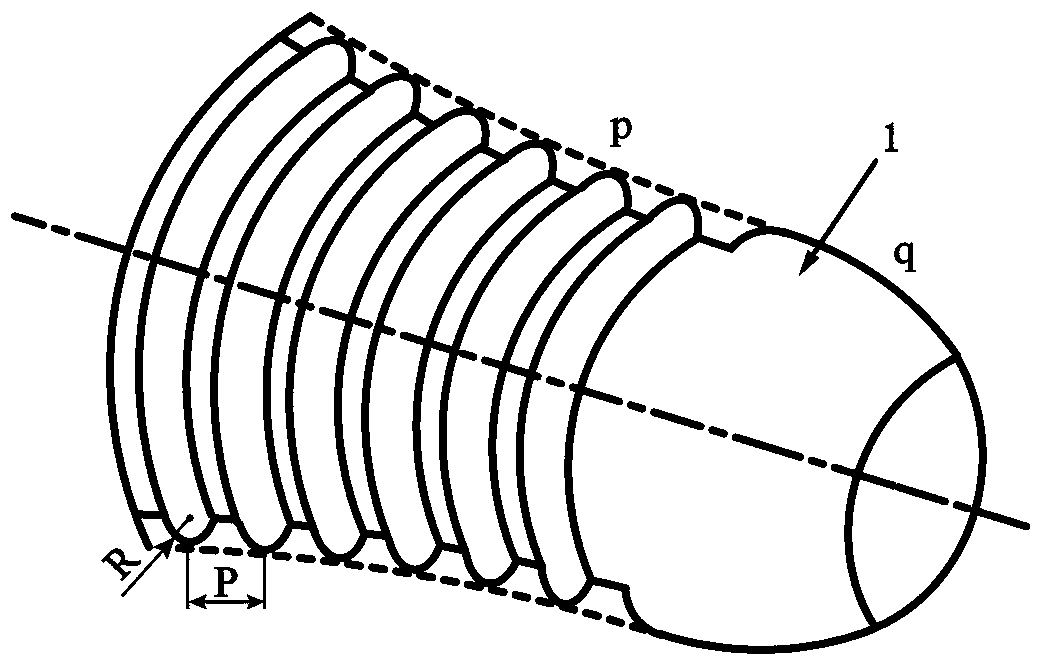

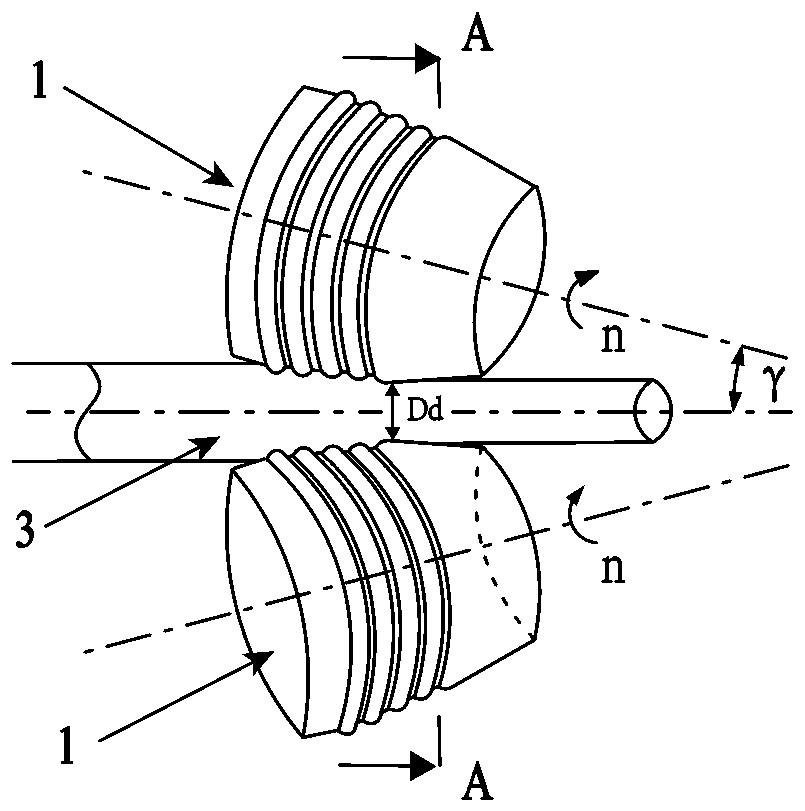

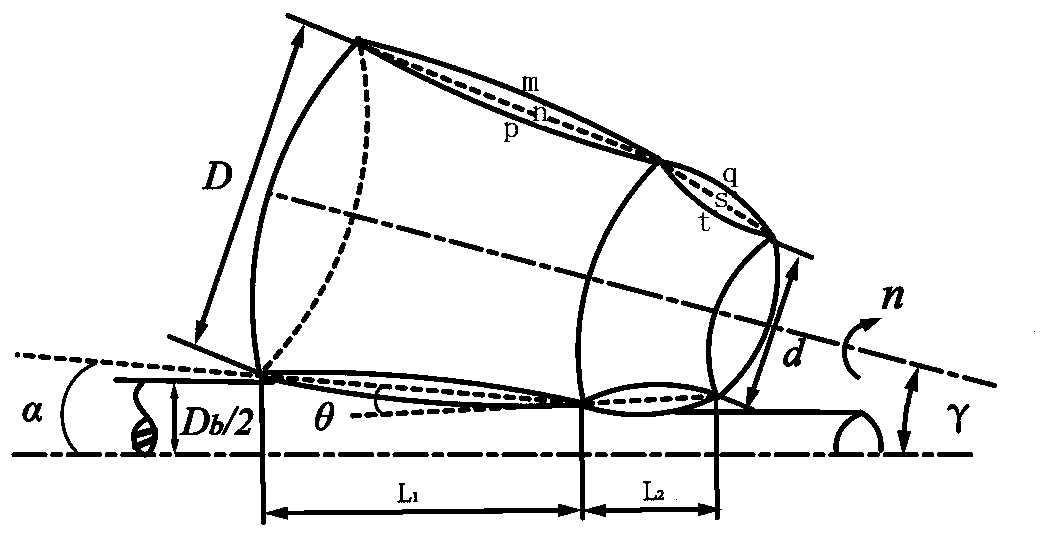

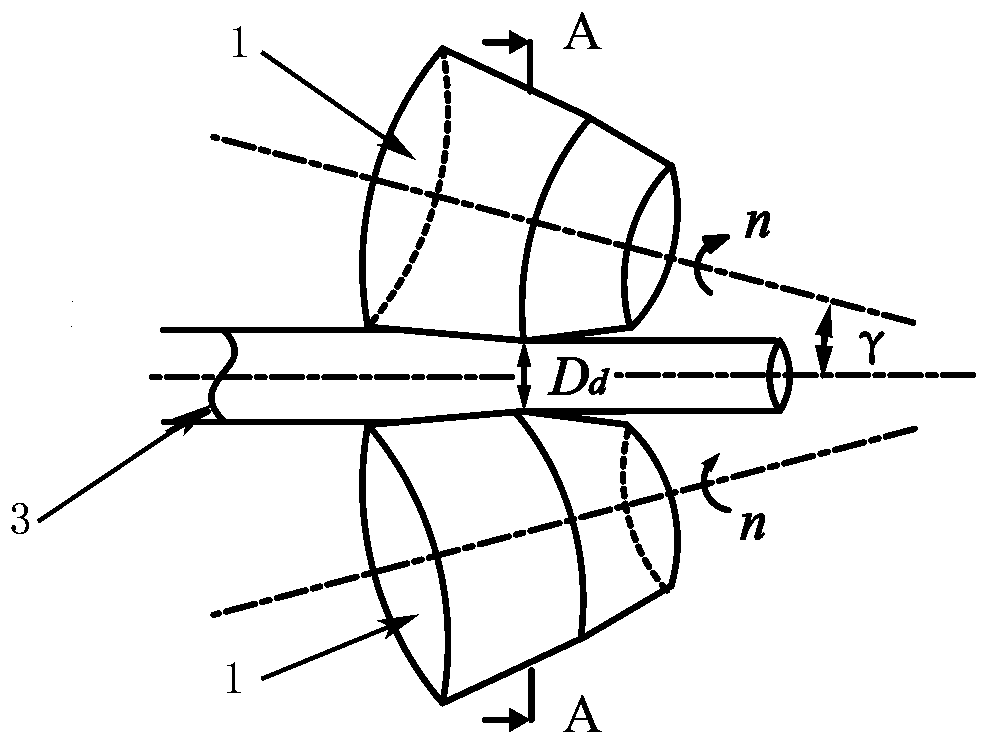

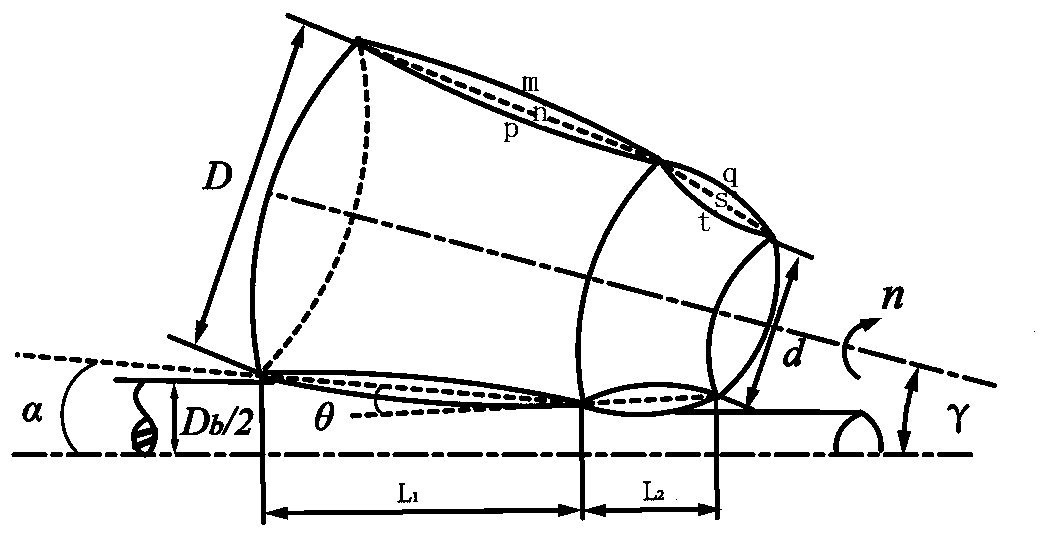

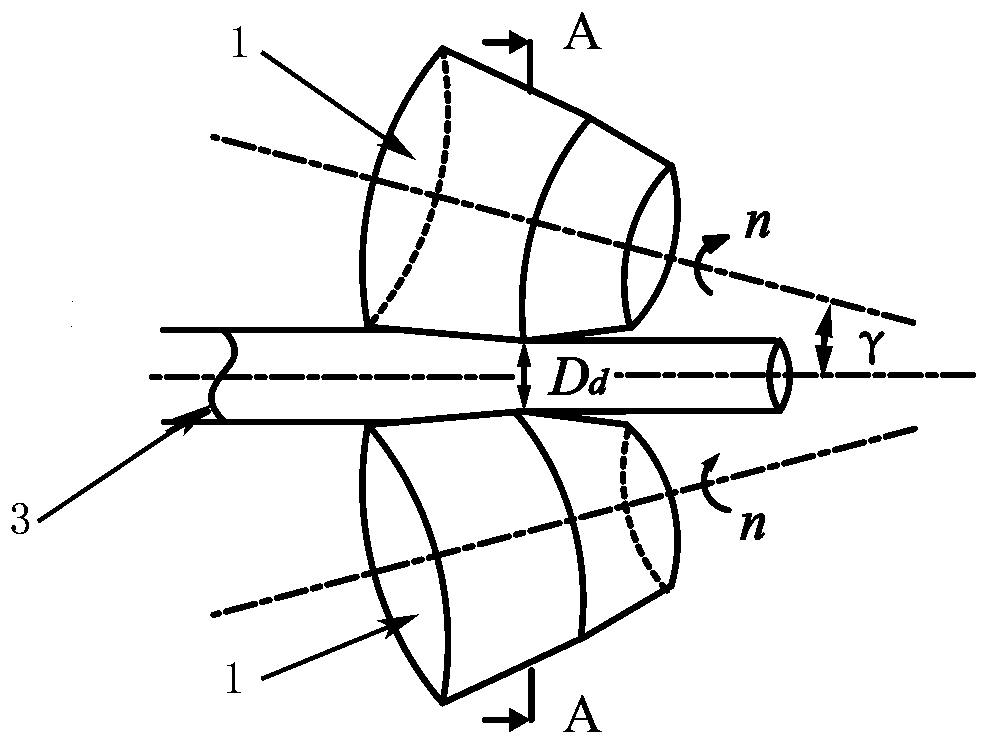

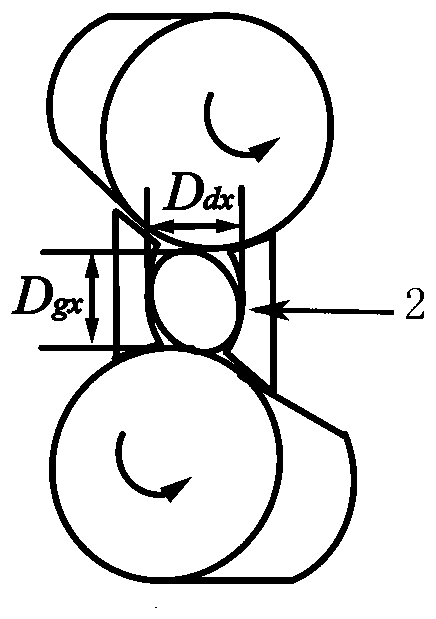

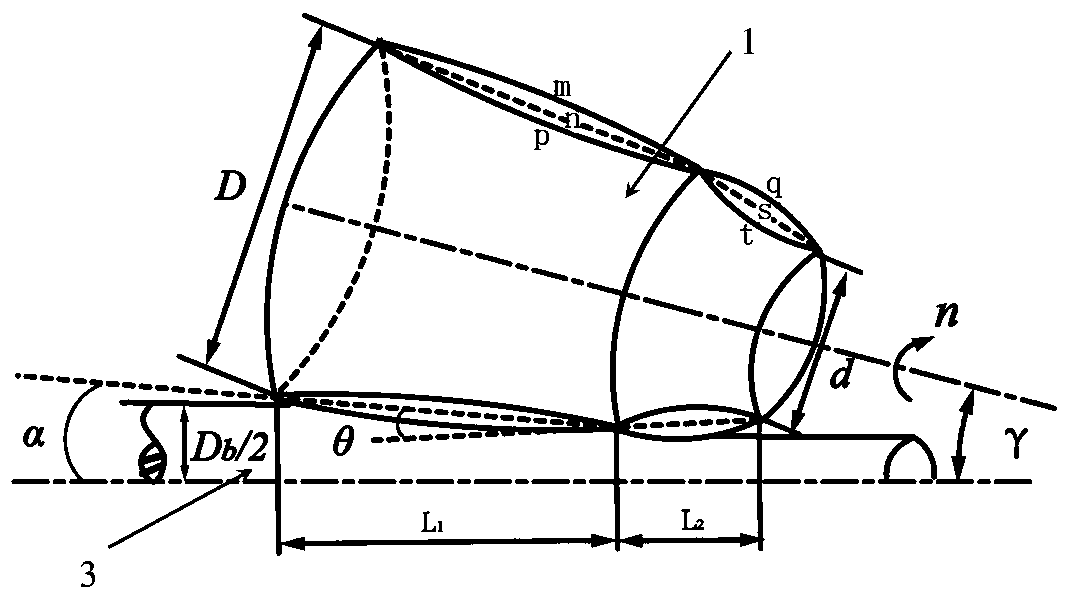

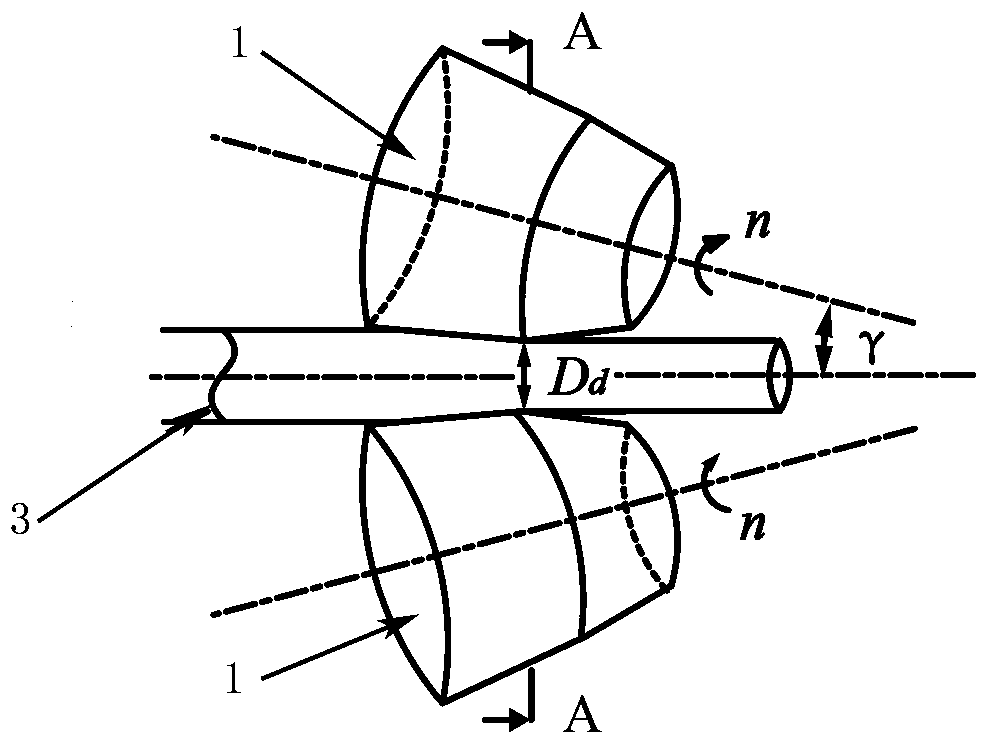

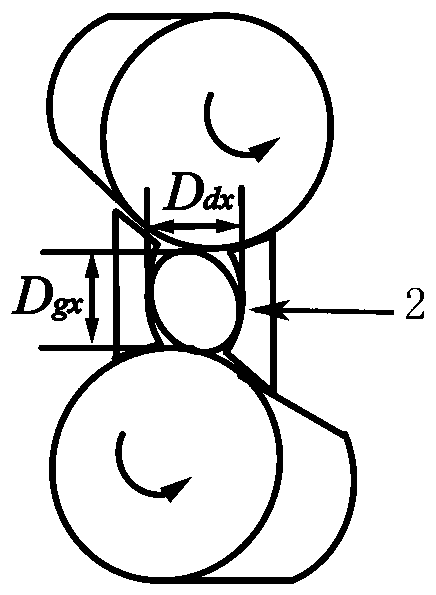

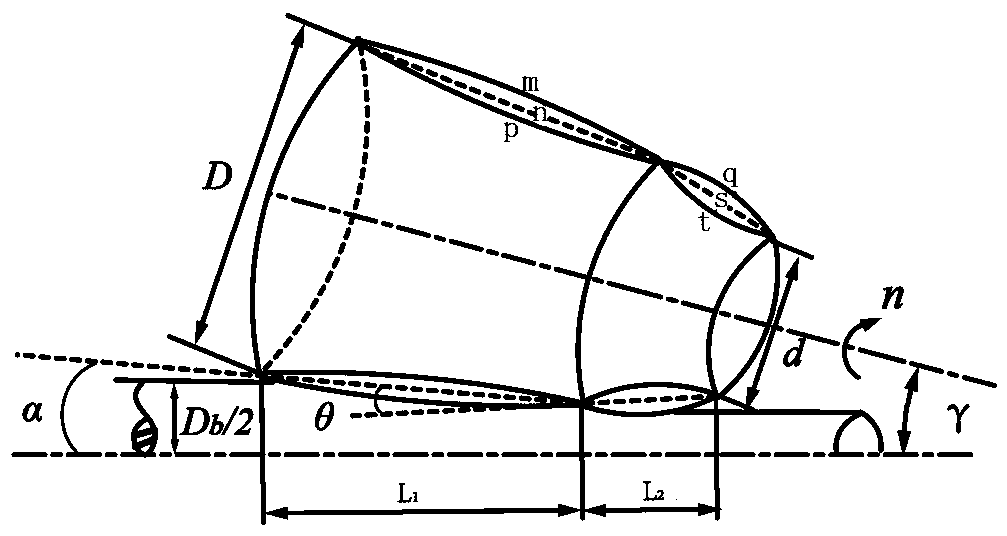

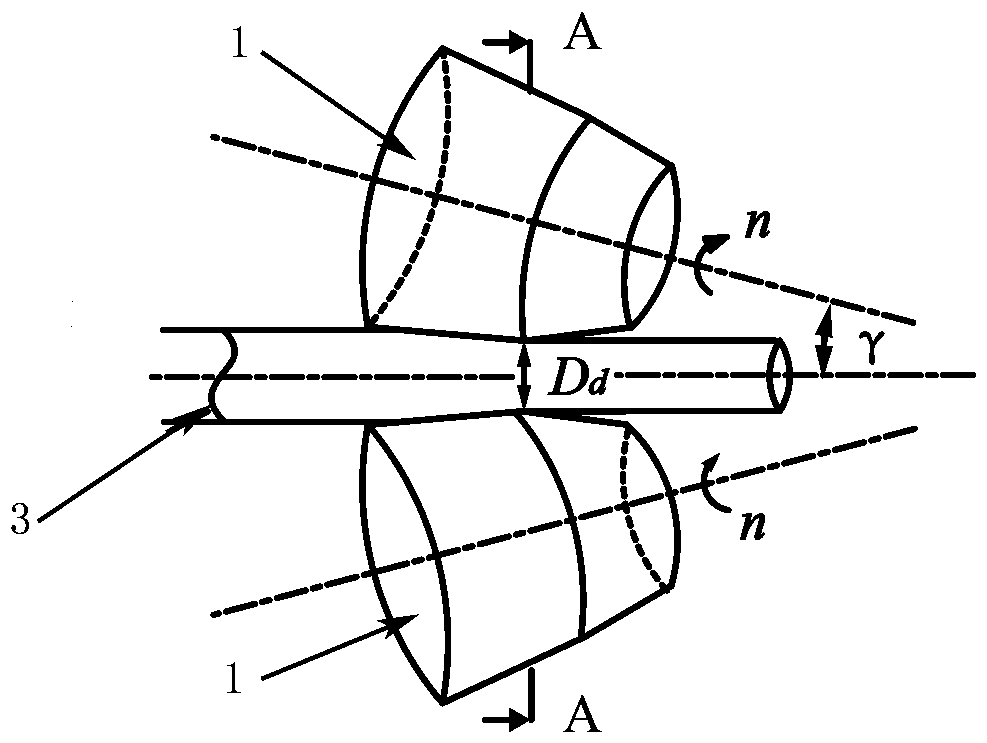

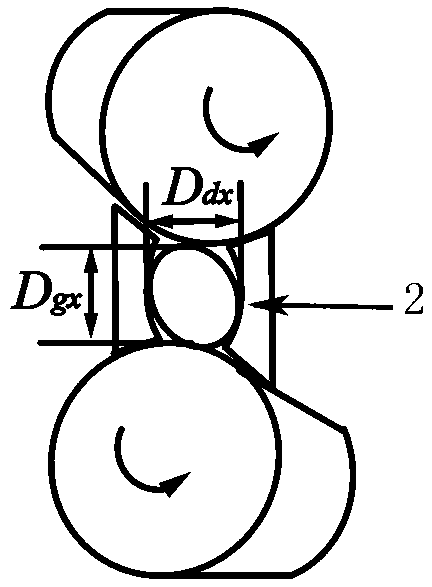

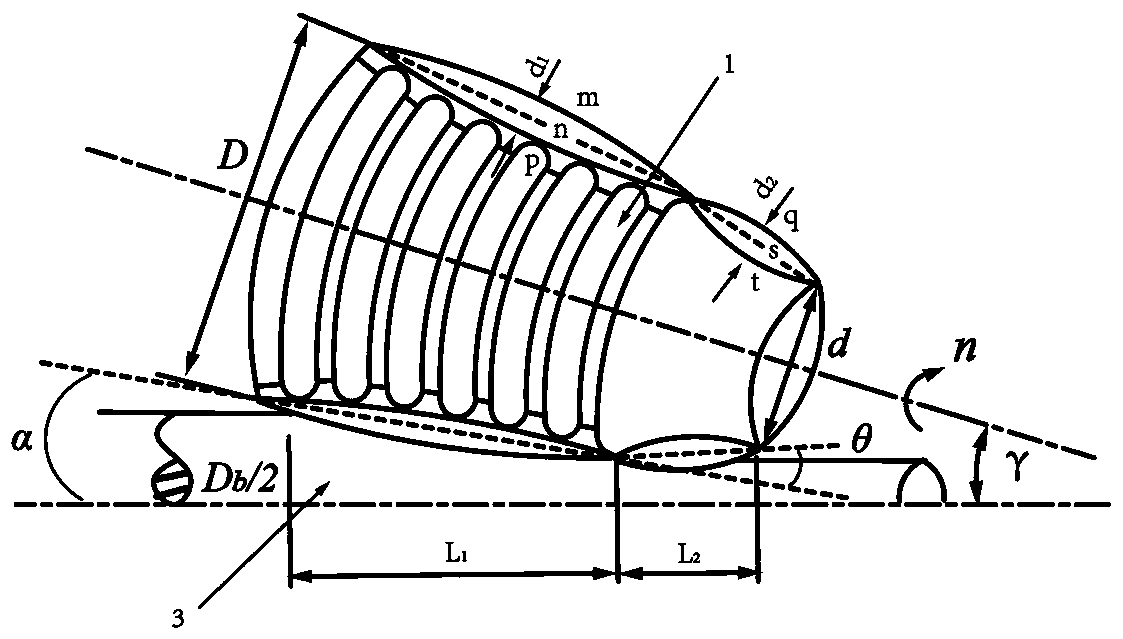

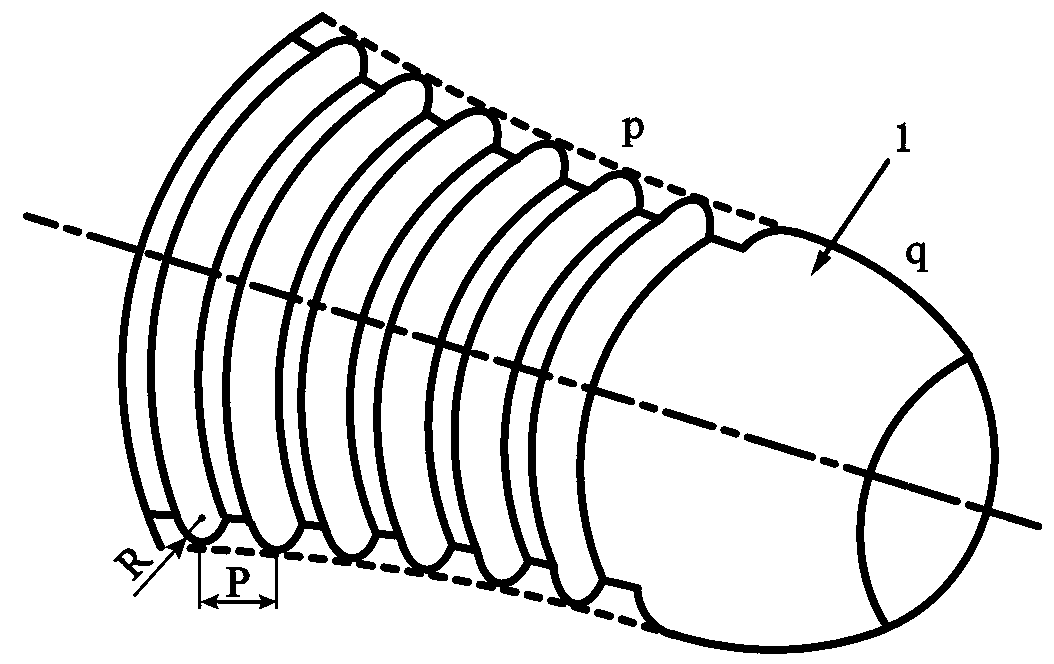

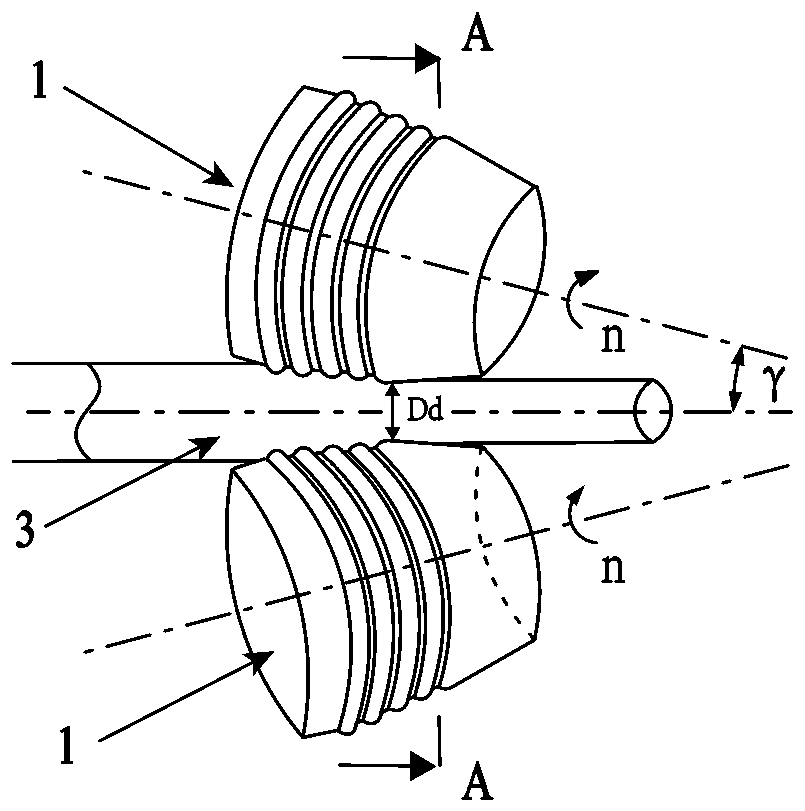

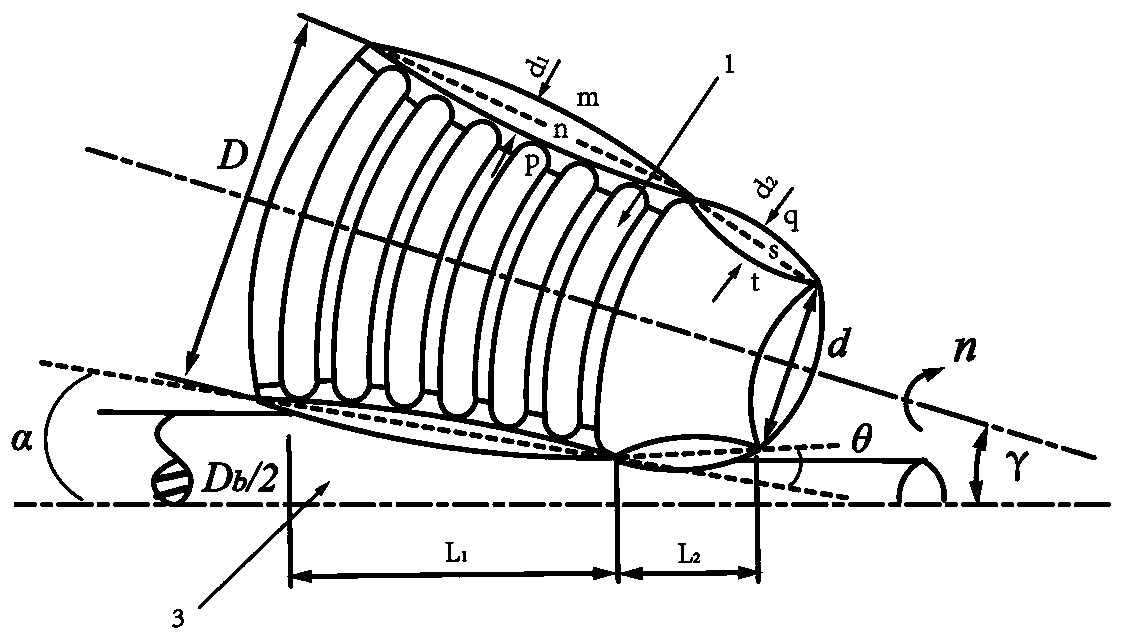

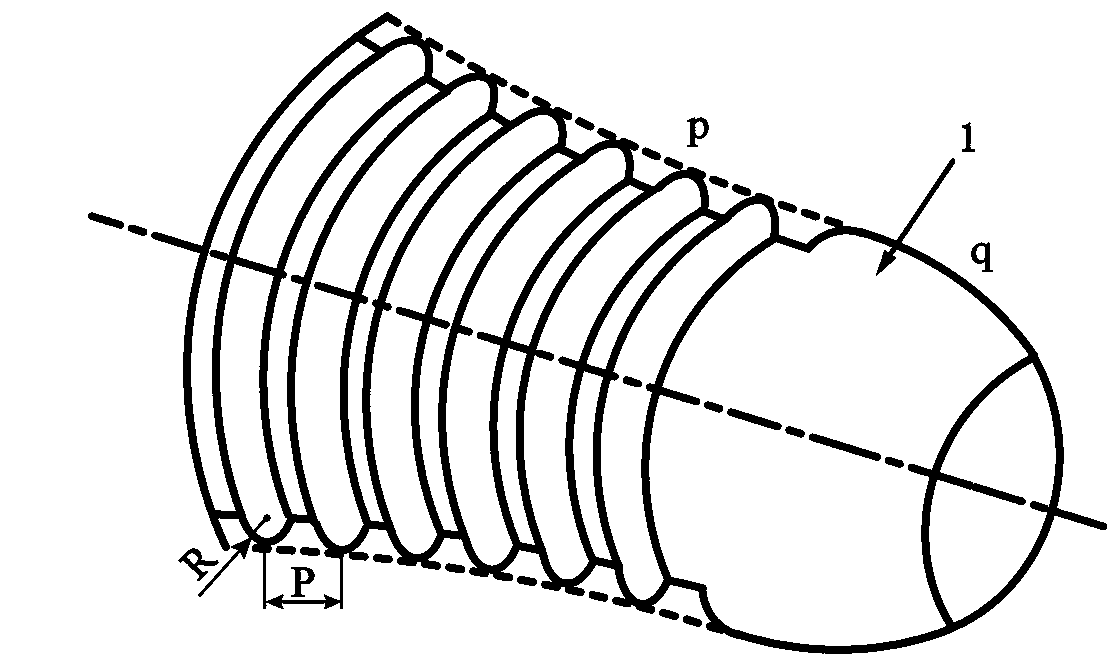

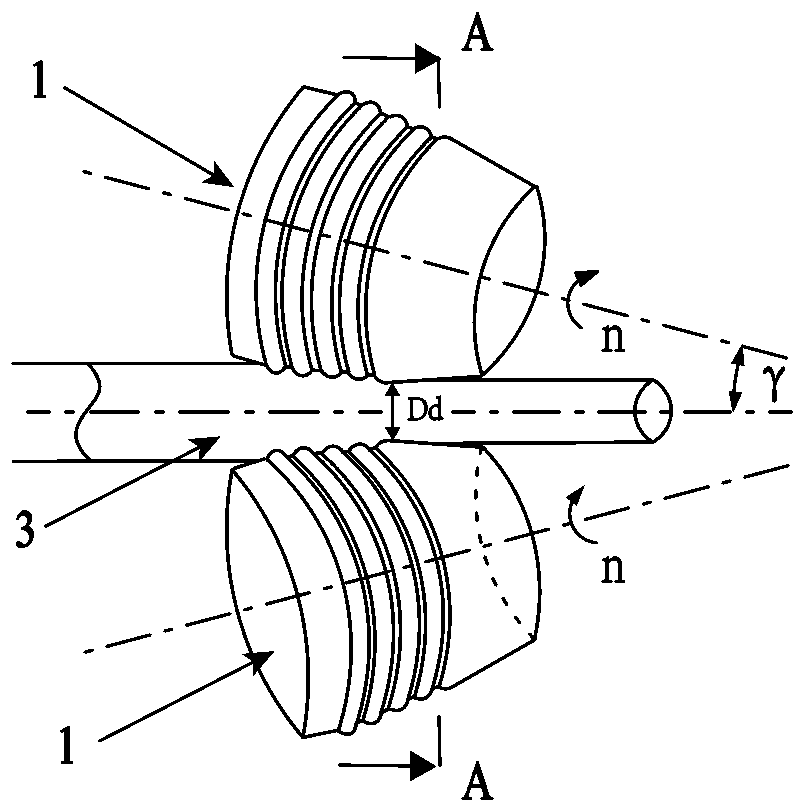

Reversed cone spiral roller ultra-fine grain rolling method of large-sized titanium alloy bar

ActiveCN109909296AReduce the number of repeated rollingReduce tensile stressRollsMetal rolling arrangementsHyperboloidUltra fine

The invention relates to the field of machining, in particular to a reversed cone spiral roller ultra-fine grain rolling method of a large-sized titanium alloy bar. The reversed cone spiral roller ultra-fine grain rolling method of the large-sized titanium alloy bar comprises the following steps that of designing a rolling tool, wherein roller design and guide plate design are involved specifically, and each roller is arranged to be a hyperboloid circular-truncated-cone-like spiral roller; forming a deformation area, wherein the curved faces of the two guide plates are oppositely arranged, thetwo rollers are placed between the two guide plates, and the area defined by the two guide plates and the two rollers is the deformation area; forming a constant-ovality deformation area, wherein theovality in the deformation area is kept constant; and selecting a rolling feeding manner, wherein inverted feeding type rolling manner is adopted. By the adoption of the reversed cone spiral roller ultra-fine grain rolling method of the large-sized titanium alloy bar, by designing the hyperboloid circular-truncated-cone-like spiral rollers and the curved-face guide plates and forming the constant-ovality deformation area, severe plastic deformation can be generated on the premise of remarkably restraining the Mannesmann effect of the core portion.

Owner:安徽东耘智能设备制造有限责任公司

Single-component intumescent flame retardant with free radical quenching function, preparation method and applications thereof

The invention discloses a single-component intumescent flame retardant with free radical quenching function, a preparation method and applications thereof. The preparation method comprises: carrying out a reaction by using cyanuric chloride, alkoxy silane, a hindered amine monomer and a diamine monomer as raw materials sequentially at 0-25 DEG C and 45-65 DEG C to obtain an intermediate product; and carrying out ion exchange and nucleophilic substitution reaction on the intermediate product, a nitrogen-phosphorus flame retardant and a diamine monomer at 80-120 DEG C to prepare the single-component intumescent flame retardant with free radical quenching function, wherein the single-component intumescent flame retardant is used in polypropylene fire retardation. Compared with the flame retardant in the prior art, the single-component intumescent flame retardant of the invention has the easily controlled phosphorus-nitrogen ration, easily achieves the efficient coupling of free radical quenching and intumescent charring, has high flame-retardant efficiency, can achieve efficient flame-retardant effect only at a small adding amount, further has outstanding water resistance, and is widely applied to the fields of electronic and electrical appliances, architectural decoration, automobile parts and the like.

Owner:SOUTH CHINA UNIV OF TECH

Chinese medicinal wine for treating hemiplegia and preparation method thereof

InactiveCN104208212ASmall toxicityGreat tasteNervous disorderAnthropod material medical ingredientsCentipedeMedicinal herbs

The invention discloses a Chinese medicinal wine for treating hemiplegia and a preparation method thereof. The Chinese medicinal wine is prepared from the following raw materials of, by weight, 1 part of aconite roots, 1 part of aconitine, 1 part of fructus chaenomelis, 1 part of honeysuckle, 1 part of radix cyathulae, 1 part of Chinese angelica, 1 part of radix stephaniae tetrandrae, 1 part of dark plum fruit, 1 part of radix gentianae macrophyllae, 1 part of scorpion, 1-2 parts of centipede, 18-22 parts of crystal sugar, and 170-199 parts of white spirits, wherein the weight ratio of the aconite roots, the bighead atractylodes rhizome, to eucommia barks is 9: 13: 13, the volume of the white spirits in the Chinese medicinal wine ranges from 42%(V / V) to 56%(V / V), and the raw materials are placed in a wine jar. According to the Chinese medicinal wine for treating hemiplegia, natural Chinese herbal medicine is used according to compatibility mechanisms of a monarch, a minister, an assistant and a guide, the Chinese medicinal wine is capable of promoting blood circulation to remove blood stasis, eliminating evil, promoting inner mechanisms of the bodies, and effectively treating hemiplegia, complications of hemiplegia, and sequelae, and the Chinese medicinal wine is innovative medicine for treating hemiplegia.

Owner:刘建忠

Reverse conical spiral roller ultra-fine grain rolling method of large-size 45 steel bar

ActiveCN109807174AReduce the number of repeated rollingReduce tensile stressTemperature control deviceMetal rolling stand detailsRound tableSteel bar

The invention discloses a reverse conical spiral roller ultra-fine grain rolling method of a large-size 45 steel bar, and relates to the field of machining. The method comprises the following steps that a rolling tool is designed, wherein design specifically comprises roller design and guide plate design, and rollers are designed to be dual-curve-face round-table-shaped spiral rollers; a deformingarea is constructed, wherein curve faces of two guide plates are oppositely placed, the two rollers are placed between the guide plates, and the area defined by the guide plates and the rollers is the deforming area; an equal ovality deforming area is constructed, wherein ovality in the deforming area is kept unchangeable; and the inverted feeding manner is selected, wherein the pouring-in type rolling manner is adopted. According to the reverse conical spiral roller ultra-fine grain rolling method of the large-size 45 steel bar, through design of the dual-curve-face round-table-shaped spiralrollers and the curve guide plates, the equal ovality deforming area is constructed, and the violent plastic deforming is generated on the premise of obviously restraining the heart Mannesmann effect.

Owner:安徽东耘智能设备制造有限责任公司

Ultra-fine grain rolling method for large-size high-temperature alloy bar

ActiveCN109772890AReduced lateral stretch deformationReduce tensile stressRollsMetal rolling arrangementsOvalityUltra fine

The invention relates to the field of mechanical processing, in particular to an ultra-fine grain rolling method for a large-size high-temperature alloy bar. The ultra-fine grain rolling method comprises the following steps that rolling tool design is carried out and specifically comprises a roller design and a guide plate design, wherein each roller is set as a hyperboloid circular truncated cone-shaped roller, and specifically, the generatrix of each roller is formed by connecting two curves; and one side of each guide plate is set as a curved surface; a deformation region is constructed, wherein the curved surfaces of the two guide plates are oppositely arranged, the two rollers are arranged between the guide plates, and the region enclosed by the two guide plates and the two rollers isthe deformation region; a deformation region with equal ovality is constructed, wherein the ovality in the deformation region remains unchanged; and a rolling feeding mode is selected, wherein a reverse rolling mode is adopted. According to the ultra-fine grain rolling method for the large-size high-temperature alloy bar, by designing the hyperboloid circular truncated cone-shaped rollers and thecurved guide plates and constructing the deformation region with equal ovality, severe plastic deformation can be generated on the premise of remarkably inhibiting the Mannesmann effect at the center.

Owner:重庆两航金属材料有限公司

Cracking technology and system of solid organic material

InactiveCN106334704AImproved microwave absorption propertiesStrong process controllabilityTransportation and packagingSolid waste disposalMicrowaveWater vapor

The invention provides a cracking technology of a solid organic material. The technology comprises the following steps: heating a gas medium to 200-800 DEG C, continuously introducing the heated gas medium to a cracking device, and cracking the solid organic material under the common action of the heated gaseous medium and microwaves, wherein the gas medium is anyone or a combination comprising above one of nitrogen, water vapor, carbon dioxide and inert gas. The technology aims at the particularity of the solid organic material, innovatively combines treatment of gas obtained after cracking of the solid organic material with microwave cracking, and improves the controllability of the cracking treatment process through adopting specific technologic steps and parameters to substantively reduce the energy consumption and substantively improve the cracking efficiency.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

A method for ultra-fine grain rolling of large size 45 steel bars

ActiveCN109807176BInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsTectonic deformationMachining

The invention discloses an ultrafine grain rolling method of a large-size 45 steel bar, and relates to the field of machining, particularly to the ultrafine grain rolling method of the large-size 45 steel bar. The ultrafine grain rolling method comprises the following steps of design of rolling tools, specifically comprising design of rollers and design of guide plates: setting the rollers as double-curved surface circular table rollers, specifically, forming generatrices of the rollers through connecting two curves, and setting one surfaces of the guide plates as curved surfaces; constructionof a deformation zone: oppositely placing the curved surfaces of the two guide plates, placing the two rollers between the guide plates, and setting a region refined by the two guide plates and the two rollers as the deformation zone; and selection of rolling feeding manner: selecting reverse feeding rolling manner, and constructing an even-ovality deformation zone. According to the ultrafine grain rolling method of the large-size 45 steel bar provided by the invention, the double-curved surface circular table rollers and the curved surface guide plates are designed, the even-ovality deformation zone is constructed, and severe plastic deformation under the precondition of the Mannesmann effect of a central part can be remarkably inhibited.

Owner:安徽东耘智能设备制造有限责任公司

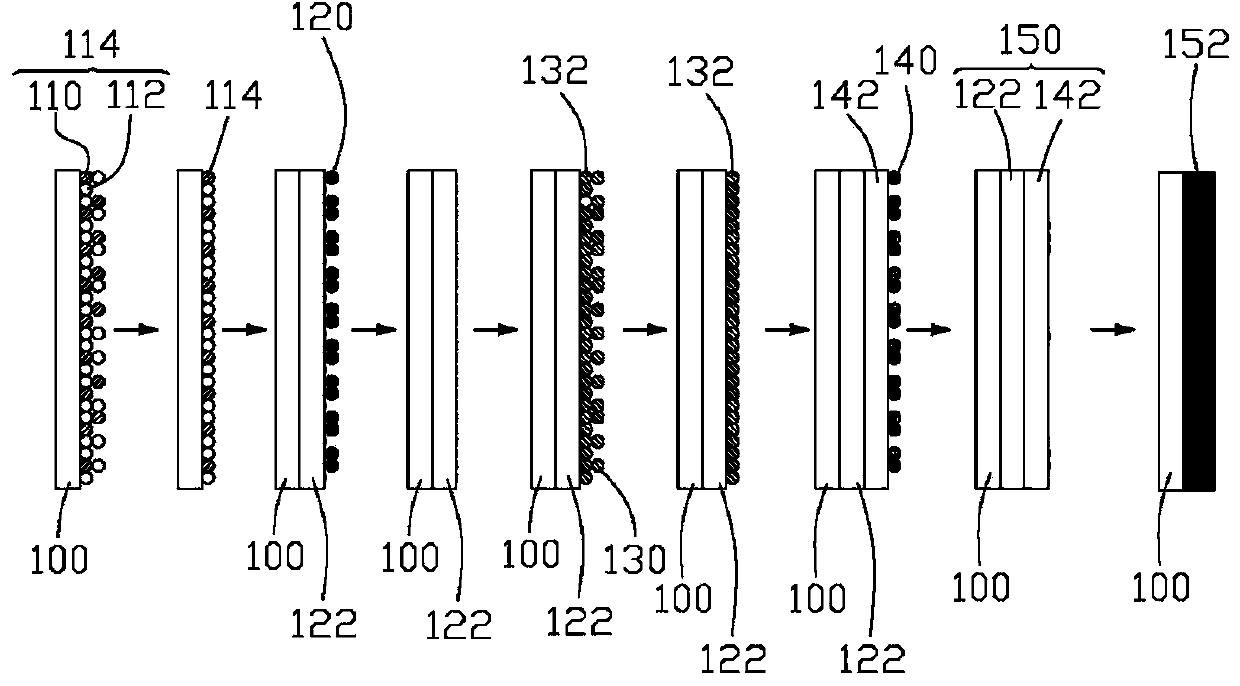

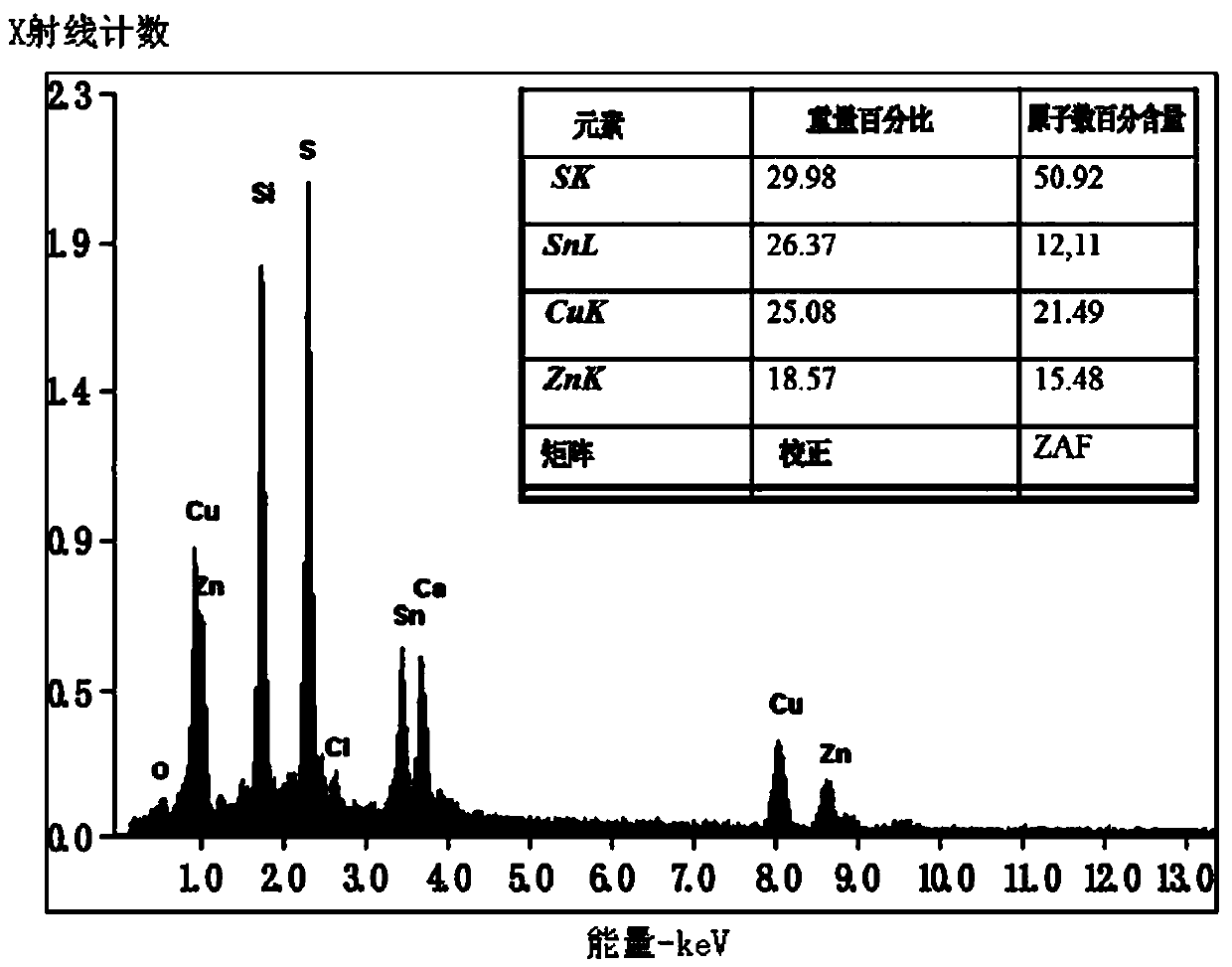

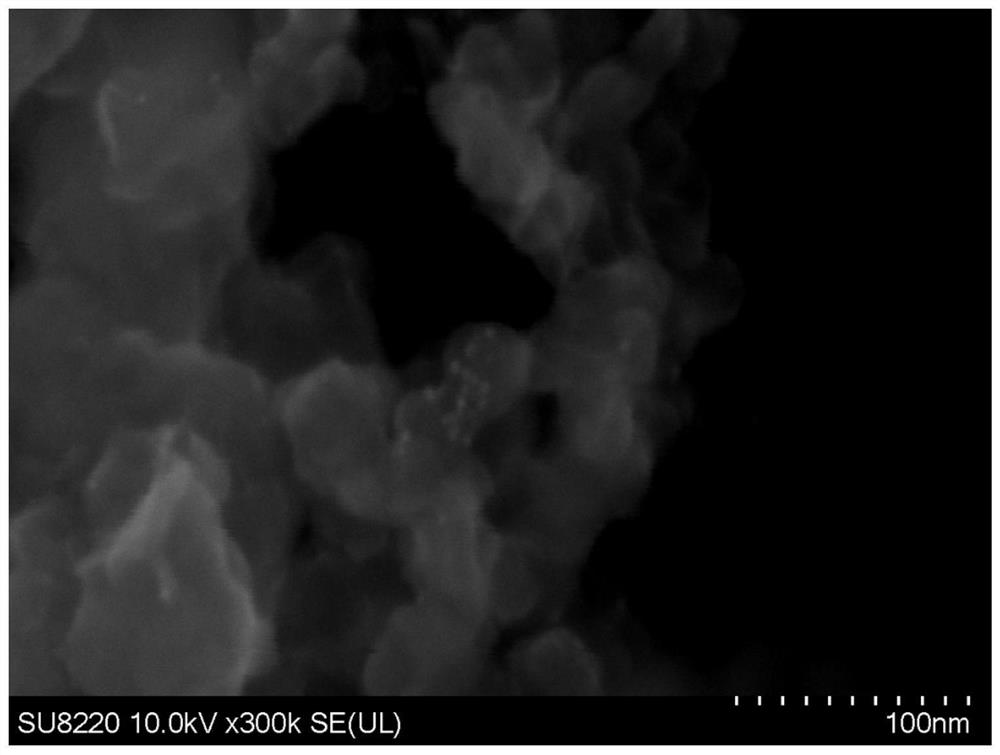

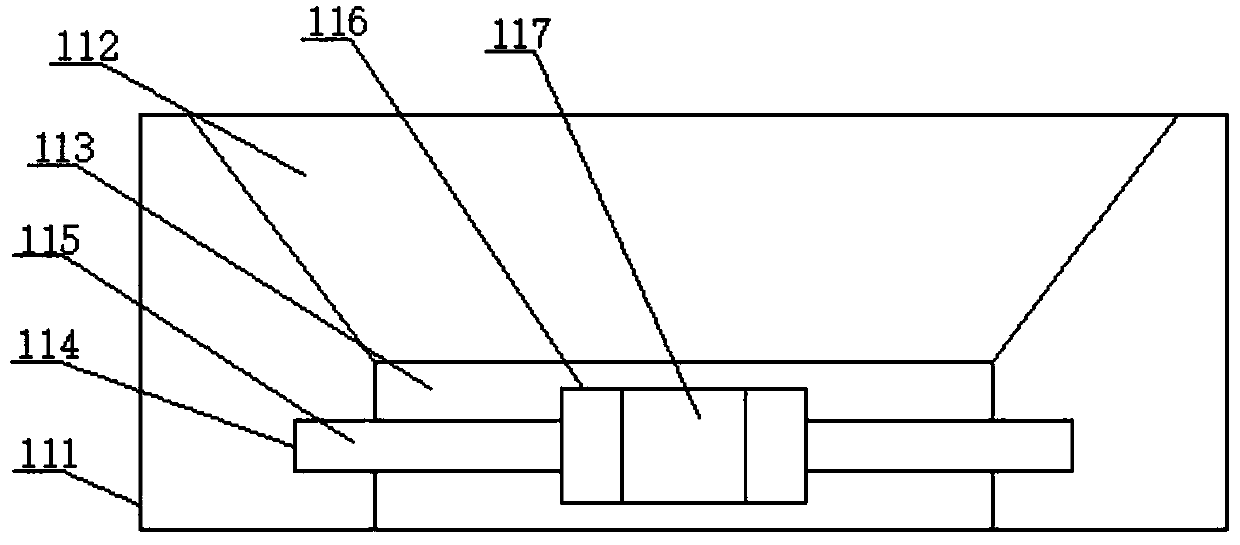

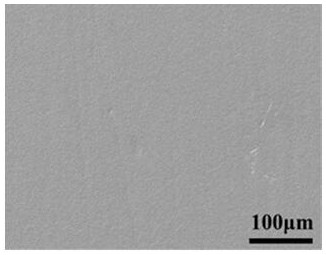

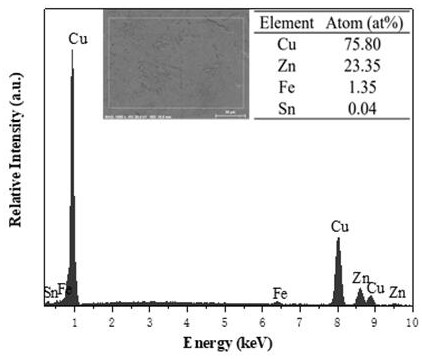

Copper-zinc-tin sulfide thin film preparation method

InactiveCN104201236AAvoid unevennessEffective control ratioFinal product manufacturePhotovoltaic energy generationSulfurZinc ion

The invention relates to a copper-zinc-tin sulfide thin film preparation method. The preparation method includes the deposition of a copper ion and tin ion thin film compound on the surface of a substrate through a successive ion layer adsorption reaction method, the deposition of a zinc ion thin film compound and final high temperature sulfuration treatment for obtaining a zinc tin sulfide thin film. According to the preparation method, the problem of uneven film components due to ion competition in a copper ion, tin ion and zinc ion co-adsorption process can be solved, and the proportion of every component in the copper-zinc-tin sulfide thin film can be effectively controlled for the preparation of the single-phase copper-zinc-tin sulfide thin film.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

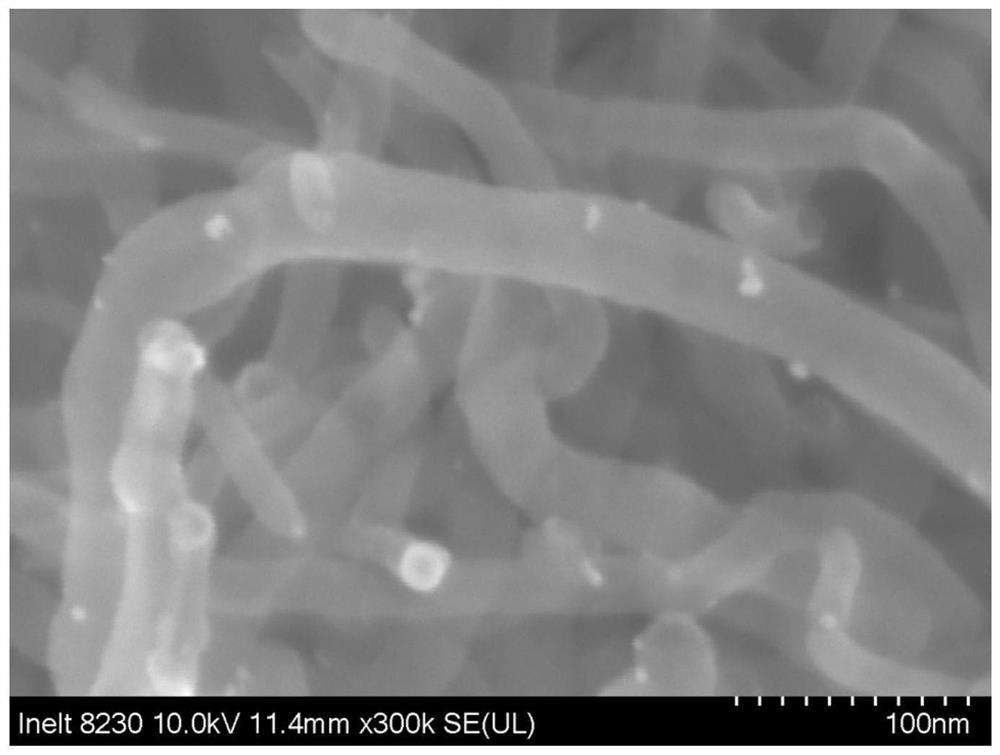

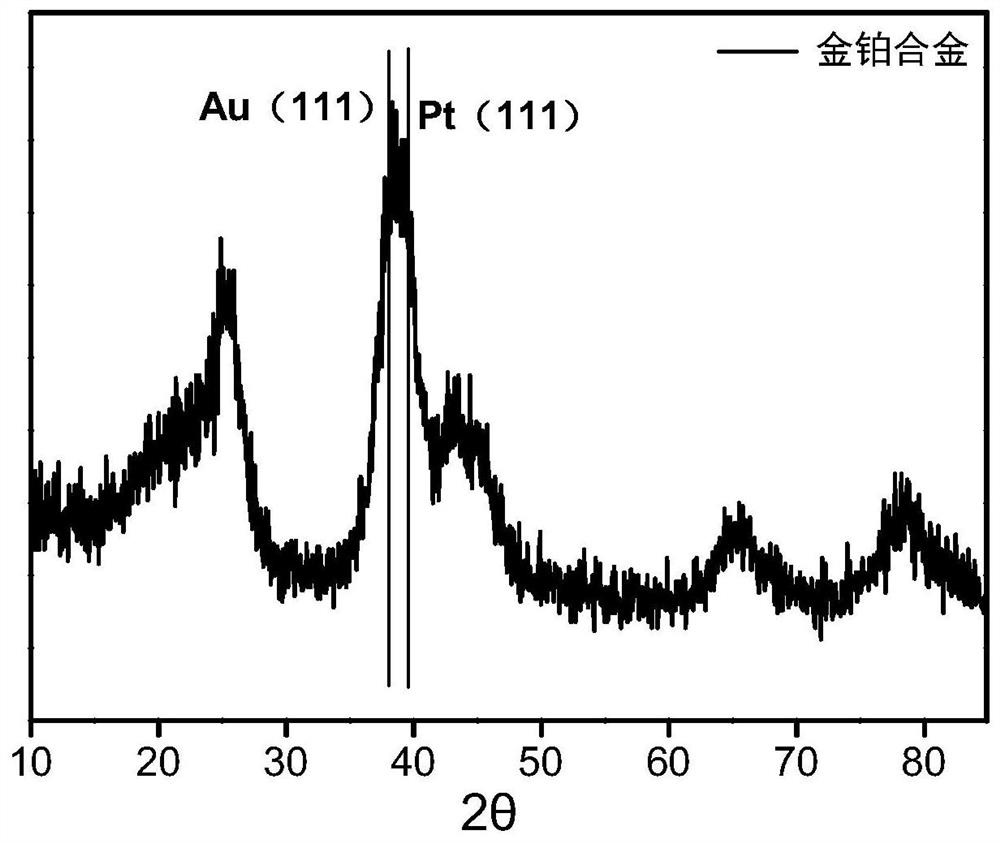

Supported gold-platinum alloy electrode for electrocatalytic reduction of CO2 and preparation method thereof

ActiveCN112442706AOptimize binding energyImprove stabilityElectrolytic organic productionElectrodesPtru catalystCarbon nanotube

The invention provides a supported gold-platinum alloy electrode for electrocatalytic reduction of CO2 and a preparation method thereof. The preparation method comprises the steps: enabling Vulcan XC-72R carbon black or carbon nanotubes to be subjected to hydrophilic treatment, using oleylamine as a stabilizer, chloroauric acid and chloroplatinic acid as precursors, and a borane tert-butylamine complex as a reducing agent, and adding the treated carbon black or carbon nanotubes; and carrying out mechanical stirring, centrifugal washing and vacuum drying to obtain supported gold-platinum alloy,preparing an ink solution, and coating and drying the prepared alloy catalyst material to obtain the supported gold-platinum alloy electrode. The prepared supported gold-platinum alloy electrode hashigh catalytic activity, high stability and good performance of electrochemical catalytic reduction of CO2. The preparation process is simple, has low requirements on equipment, and has a good industrial prospect.

Owner:SICHUAN UNIV

A method for ultra-fine grain rolling of large-size titanium alloy rods

ActiveCN109807175BInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsTitanium alloyMachining

The invention discloses an ultra-fine grain rolling method of a large titanium alloy bar and relates to the field of machining, in particular to the ultra-fine grain rolling method of the large titanium alloy bar. The ultra-fine grain rolling method of the large titanium alloy bar comprises the following steps that rolling tools are designed, roller design and guide plate design are included, eachroller is designed into a double-curved face type circular truncated cone roller, and specifically, a bus of each roller is formed by connecting two curves, and one face of each guide plate is designed into a curved face; a deformation zone is configured, wherein the curved faces of the two guide plates are oppositely arranged, the two rollers are arranged between the guide plates, and a regiondefined by the two guide plates and the two rollers is the deformation zone; an equal ovality deformation zone is configured, wherein ovality in the deformation zone is kept unchangeable; and a rolling feeding manner is selected, wherein a backward advancing rolling manner is adopted. According to the ultra-fine grain rolling method of the large titanium alloy bar, by designing the double-curved face type circular truncated cone rollers and the curved face-shaped guide plates and configuring the equal ovality deformation zone, intensive plastic deformation can be generated on the promise of remarkably restraining a Mannesmann effect of the heart.

Owner:安徽东耘智能设备制造有限责任公司

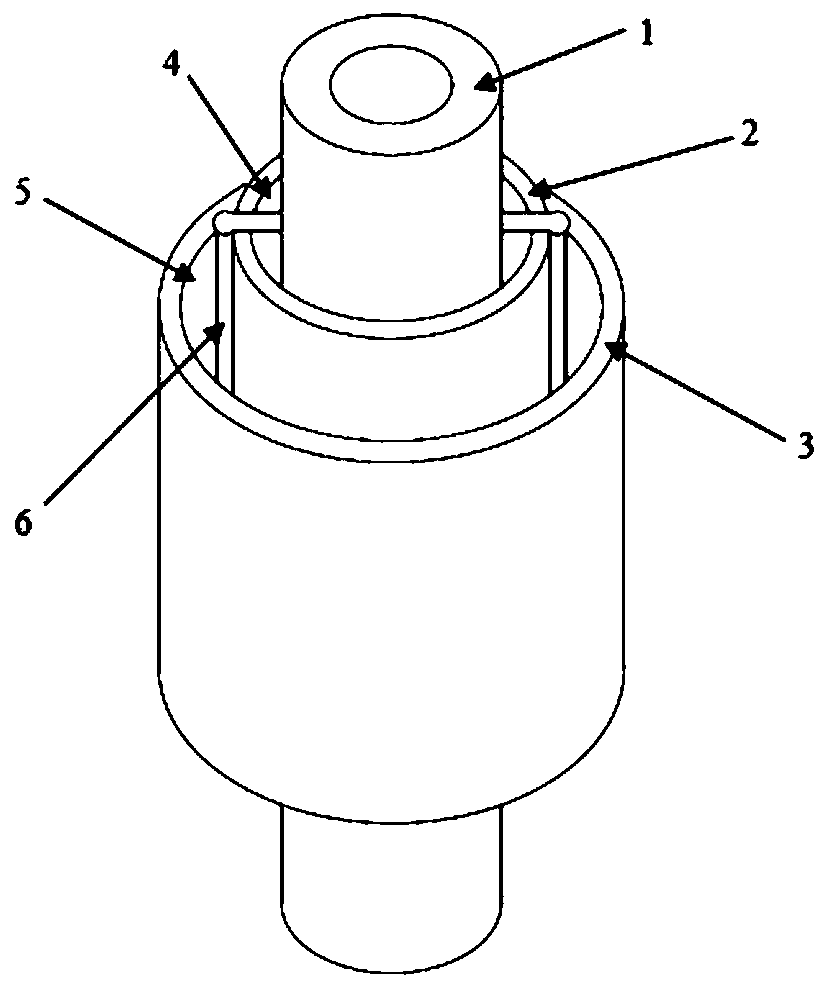

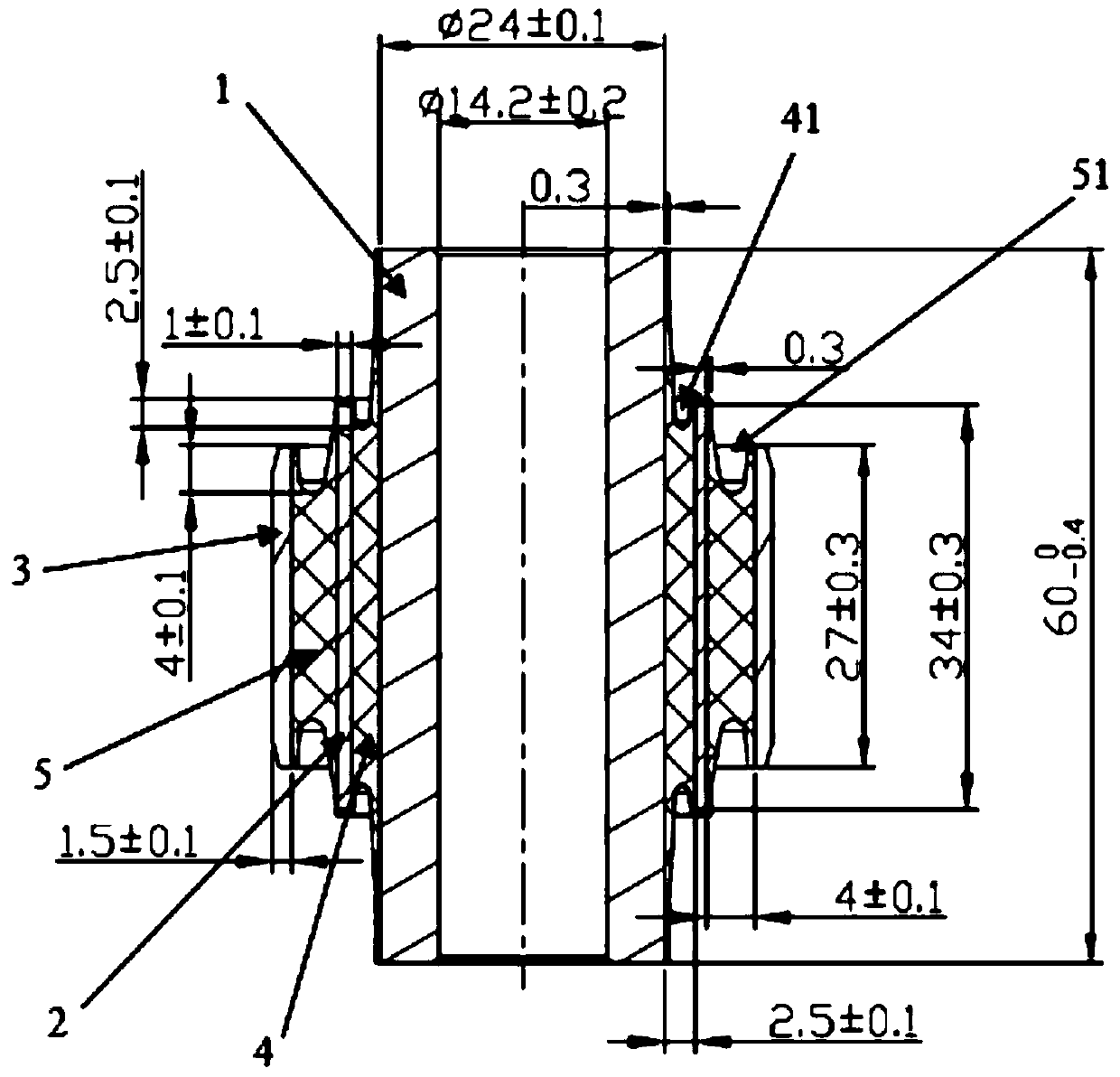

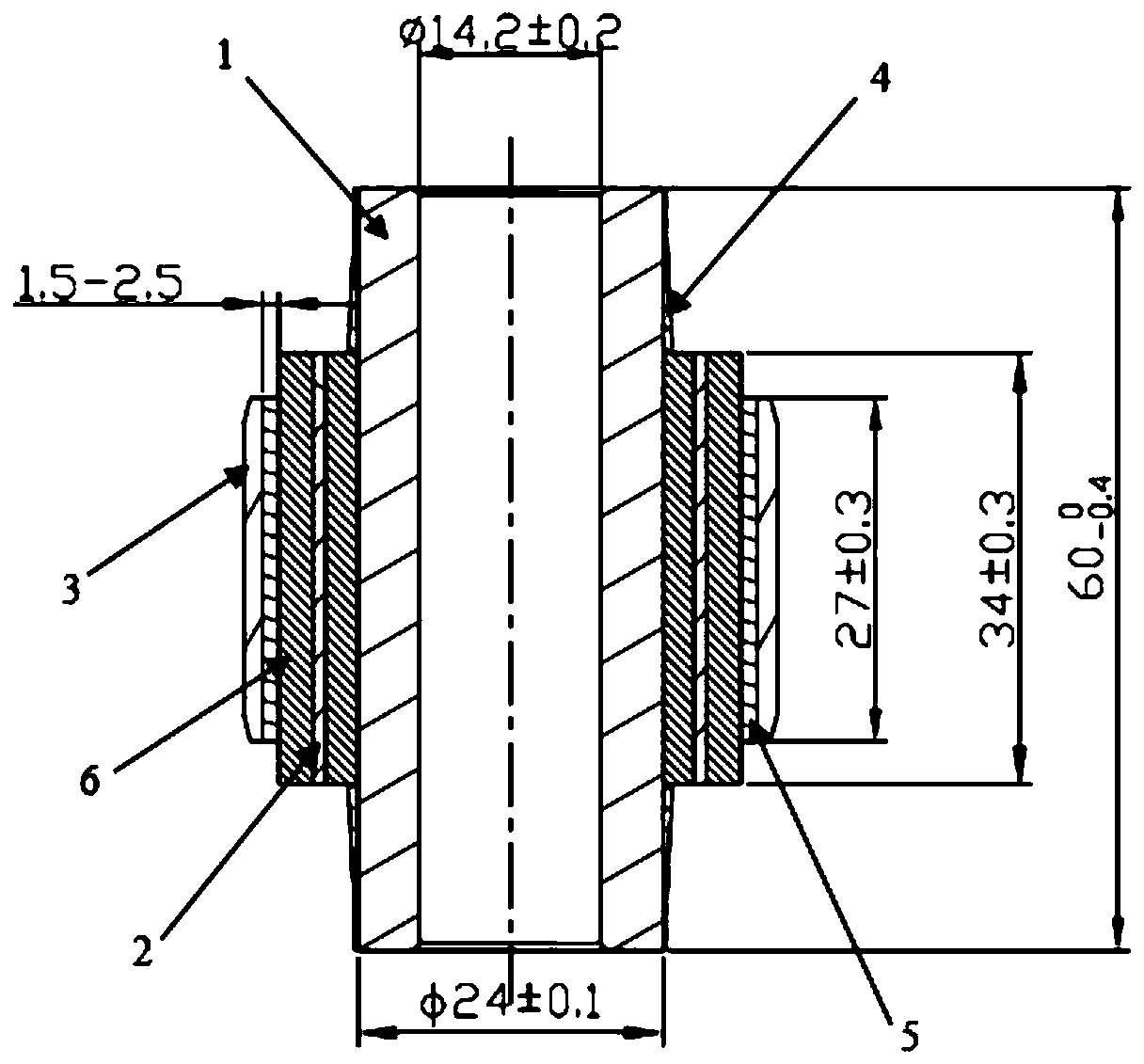

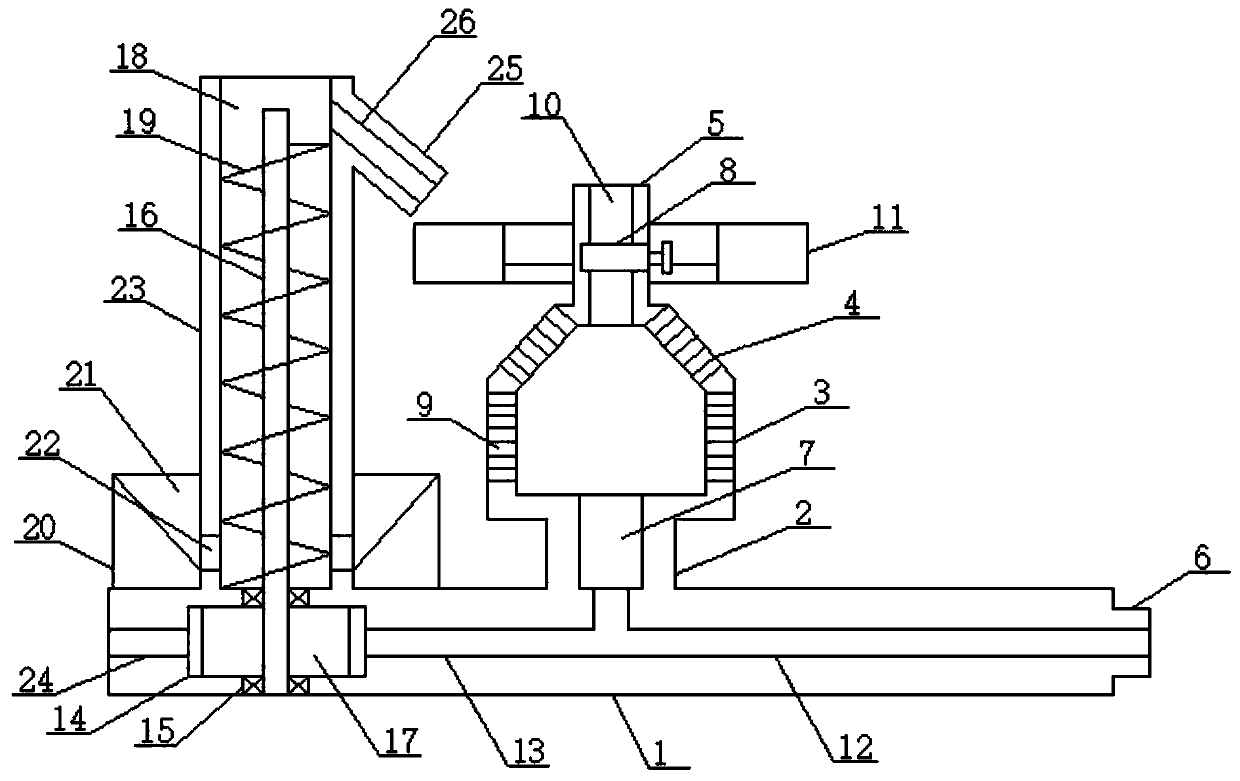

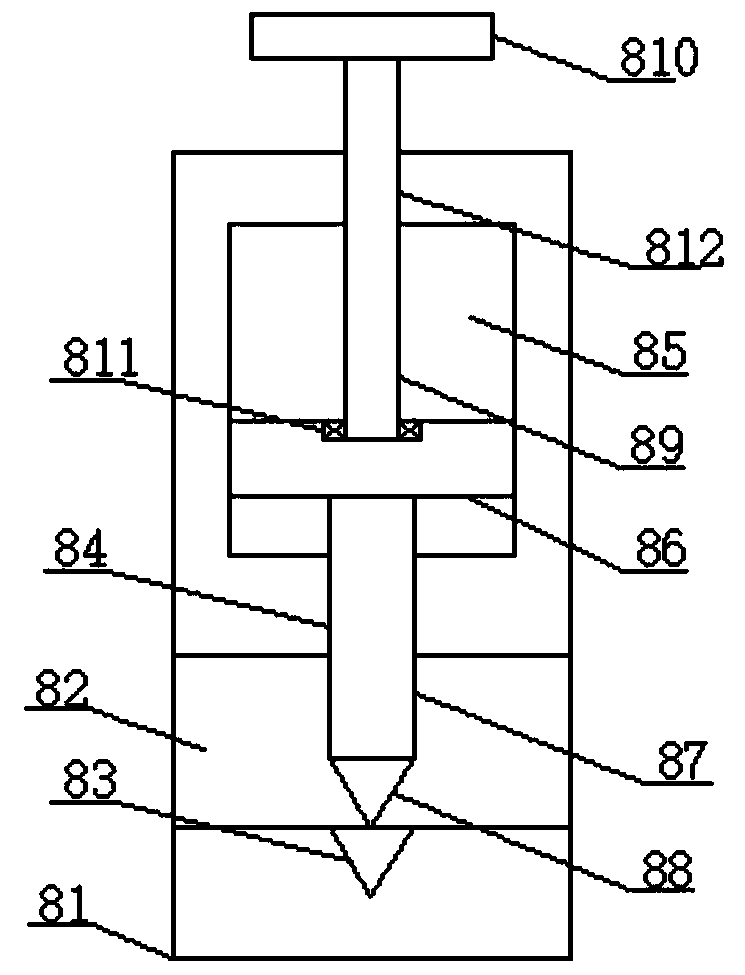

High-radial low-torsion multi-framework easy-to-control rubber bushing

InactiveCN110329024AGuaranteed comfort and safetyExtended service lifePivoted suspension armsEngineeringControllability

The invention provides a high-radial low-torsion multi-framework easy-to-control rubber bushing. The high-radial low-torsion multi-framework easy-to-control rubber bushing is composed of an inner framework (1), a middle framework (2), an outer framework (3), super-elastic rubber A (4) and super-elastic rubber B (5), wherein the heights of the inner framework (1), the middle framework (2) and the outer framework (3) are in a stair shape and gradually decreases towards the radial center line; and strip-shaped bosses (6) are arranged on the positions, with the same heights as the middle framework(2), of the outer wall of the left side and the outer wall of the right side of the inner framework (2), each strip-shaped boss (6) is connected to the outer wall of the inner framework (1), penetrates through the middle framework (2) and is close to but not in contact with the outer framework (3), and the height of each strip-shaped boss (6) is always equal to that of the middle framework (2). According to the rubber bushing, the combination of controllability and comfort is realized; and meanwhile, the super-elastic rubber is prevented from being cracked due to impact force in the running process, and the safety of the automobile is ensured.

Owner:重庆恒伟林汽车零部件有限公司

Wind power driven type particle dust raising device

InactiveCN111282816AEfficient dust raisingRealize the transport functionGas current separationMachines/enginesPhysicsRotational axis

The invention discloses a wind power driven type particle dust raising device which comprises a bottom mounting base plate. The device carries out driving by means of powerful wind power generated byan air blower. The wind power can achieve upward wind power blowing for raising dust and also can drive the part of a spiral blade, so that the particles fall into a wind power range from bottom to top under the action of gravity, and therefore, efficient dust raising action is exerted. Furthermore, the device is provide with a thread structure moving pipe mounting type ventilating speed effectivecontrol mechanism which can control the proportion of effective air quantity and ineffective air quantity effectively, so that effective regulating action is exerted. In addition, the device is provided with a pipeline top mounting type particle falling guiding falling mechanism, so that the device can be mounted around a pipeline. Meanwhile, the device guides the above particles to move toward ablowing port in a falling direction. In addition, the device is provided with a wind power driven turbine type rotary shaft rotating state driving mechanism.

Owner:泉州昀康工业设计服务有限公司

Cyanide-free gold-imitating copper-zinc-tin alloy electroplating process for surface of carbon steel

The invention discloses a cyanide-free gold-imitating copper-zinc-tin alloy electroplating process for the surface of carbon steel. The process comprises the following steps of: immersing pretreated carbon steel to be electroplated into an electroplating bath filled with a pre-plating solution, and electroplating at room temperature to obtain carbon steel with a pre-plated copper layer, wherein the pre-plating solution is prepared by dissolving copper sulfate, potassium hydroxide, carboxylate, a sulfur-containing grain refiner and an amine-containing brightener in deionized water; and immersing the carbon steel with a pre-plated copper layer into an electroplating bath filled with an electroplating solution, and electroplating at room temperature to obtain the carbon steel of which the surface contains a gold-imitating plating layer containing three elements of copper, tin and zinc, wherein the electroplating solution is prepared by dissolving potassium pyrophosphate, copper pyrophosphate, zinc sulfate, stannous pyrophosphate, hydroxyethylidene-1, 1-diphosphonic acid, an additive and a brightener in deionized water. The obtained plating layer is high in quality, golden and uniform in color and good in discoloration resistance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Ultrafine grain rolling method of large-size 45 steel bar

ActiveCN109807176AInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsSteel barLarge size

The invention discloses an ultrafine grain rolling method of a large-size 45 steel bar, and relates to the field of machining, particularly to the ultrafine grain rolling method of the large-size 45 steel bar. The ultrafine grain rolling method comprises the following steps of design of rolling tools, specifically comprising design of rollers and design of guide plates: setting the rollers as double-curved surface circular table rollers, specifically, forming generatrices of the rollers through connecting two curves, and setting one surfaces of the guide plates as curved surfaces; constructionof a deformation zone: oppositely placing the curved surfaces of the two guide plates, placing the two rollers between the guide plates, and setting a region refined by the two guide plates and the two rollers as the deformation zone; and selection of rolling feeding manner: selecting reverse feeding rolling manner, and constructing an even-ovality deformation zone. According to the ultrafine grain rolling method of the large-size 45 steel bar provided by the invention, the double-curved surface circular table rollers and the curved surface guide plates are designed, the even-ovality deformation zone is constructed, and severe plastic deformation under the precondition of the Mannesmann effect of a central part can be remarkably inhibited.

Owner:安徽东耘智能设备制造有限责任公司

One-component intumescent flame retardant with free radical quenching function and preparation method and application thereof

The invention discloses a single-component intumescent flame retardant with free radical quenching function, a preparation method and applications thereof. The preparation method comprises: carrying out a reaction by using cyanuric chloride, alkoxy silane, a hindered amine monomer and a diamine monomer as raw materials sequentially at 0-25 DEG C and 45-65 DEG C to obtain an intermediate product; and carrying out ion exchange and nucleophilic substitution reaction on the intermediate product, a nitrogen-phosphorus flame retardant and a diamine monomer at 80-120 DEG C to prepare the single-component intumescent flame retardant with free radical quenching function, wherein the single-component intumescent flame retardant is used in polypropylene fire retardation. Compared with the flame retardant in the prior art, the single-component intumescent flame retardant of the invention has the easily controlled phosphorus-nitrogen ration, easily achieves the efficient coupling of free radical quenching and intumescent charring, has high flame-retardant efficiency, can achieve efficient flame-retardant effect only at a small adding amount, further has outstanding water resistance, and is widely applied to the fields of electronic and electrical appliances, architectural decoration, automobile parts and the like.

Owner:SOUTH CHINA UNIV OF TECH

A method for ultra-fine grain rolling of large-size aluminum alloy rods with reverse-cone helical rolls

ActiveCN109772891BReduce the number of repeated rollingReduce tensile stressRollsMetal rolling arrangementsMachiningFine grain

The invention relates to a reverse cone spiral roller ultra-fine grain rolling method of a large-size aluminum alloy bar, and relates to the field of mechanical processing. The method includes the following steps that a rolling tool is designed, wherein roll design and guide plate design are specifically included, and rollers are arranged to be double curved surface type circular-table-shaped spiral rollers; a deformation zone is constructed, wherein the curved surfaces of two guide plates are oppositely arranged, the two rollers are placed between the guide plates, and an area defined by thetwo guide plates and the two rollers is the deformation zone; an equal-ovality deformation zone is constructed, wherein the ovality in the deformation zone remains unchanged; and a rolling feeding mode is selected, wherein a reverse rolling mode is adopted. According to the reverse cone spiral roller ultra-fine grain rolling method of the large-size aluminum alloy bar, the double curved surface type circular-table-shaped spiral rollers and the curved surface guide plates are designed, the equal-ovality deformation zone is constructed, and acute plastic deformation is generated on the premise that the heart Mannesmann effect is significantly suppressed.

Owner:安徽汉正轴承科技有限公司

A method for ultra-fine grain rolling of large-size superalloy rods with reverse-cone helical rolls

ActiveCN109909297BReduce the number of repeated rollingReduce tensile stressRollsMetal rolling arrangementsTectonic deformationEngineering

The invention relates to the field of machining, in particular to a reverse conical spiral roller ultra-fine grain rolling method of large high-temperature alloy bars. The method includes the following steps that design of rolling tools specifically includes roller design and guiding plate design, and rollers are set to be double-curved-surface type truncated-cone-shaped spiral rollers; a deformation zone is constructed as follows: curved surfaces of two guiding plates are placed oppositely, the two rollers are placed between the guiding plates, and the zone defined by the two guiding plates and the two rollers is the deformation zone; an equal-ellipticity deformation zone is constructed as follows: the ellipticity is unchanged in the deformation zone; the rolling feeding manner is selected as follows: the back feeding type rolling manner is selected. According to the method, the double-curved-surface type truncated-cone-shaped spiral rollers and the curved guiding plates are designed,and the equal-ellipticity deformation zone is constructed, so that severe plastic deformation can be produced on the premise that the core Mannesmann effect can be suppressed remarkably.

Owner:安徽东耘智能设备制造有限责任公司

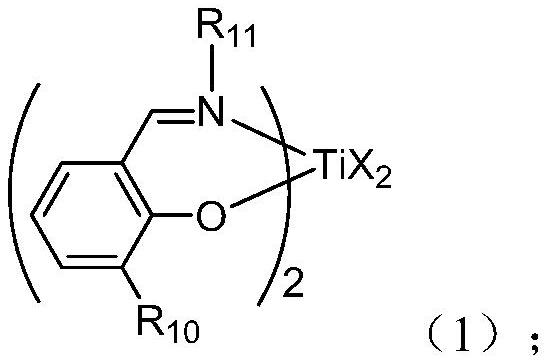

Catalytic cycloolefin copolymer composition and preparation method thereof

The invention relates to C08F, in particular to a catalytic cycloolefin copolymer composition and a preparation method thereof. The preparation raw materials of the composition comprise a chain-shaped vinyl monomer a, a cyclic vinyl monomer and a catalyst e, the copolymer provided by the invention can be used for the reaction of copolymers with different cyclic vinyl monomer contents by selecting the proper catalyst e and controlling the types of the raw materials, and has good tolerance even if a polar cyclic monomer is added, so that the copolymer can be applied to the reaction of the copolymers with different cyclic vinyl monomer contents. According to the present invention, the influence on the catalytic activity is avoided, such that the probability of the copolymerization and the insertion of the cyclic ethylene is improved so as to obtain the copolymerization with different cyclic vinyl unit contents from low to high, the high molecular weight polymer can be obtained in the short time and the short temperature, the cost is reduced, and the energy consumption is reduced.

Owner:广东新华粤石化集团股份公司 +1

Method for preparing dimethyl succinate

ActiveCN106674004AEliminate the effects ofExtended service lifeOrganic compound preparationChemical industrySorbentSuccinic acid

The invention discloses a method for preparing dimethyl succinate. The method comprises the following steps: carrying out an autocatalytic mono-esterification reaction on biological process succinic acid and methanol, and allowing the obtained autocatalytic mono-esterification reaction product to go through a catalytic rectification reaction device provided with an ion exchange resin catalyst and modified active carbon used as an adsorbent and undergo a double esterification reaction in order to generate dimethyl succinate, wherein the ion exchange resin and the modified active carbon are added in a grading manner according to a certain volume ratio, and reaction product flow sequentially goes through a modified active carbon bed A, an ion exchange resin catalyst bed and a modified active carbon bed B. The method has the advantages of effective elimination of influences of ammonia nitrogen in the biological process succinic acid raw material on the dimethyl succinate product and the catalyst, high esterification efficiency, and stable activity and long-time cycle running of the catalyst.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

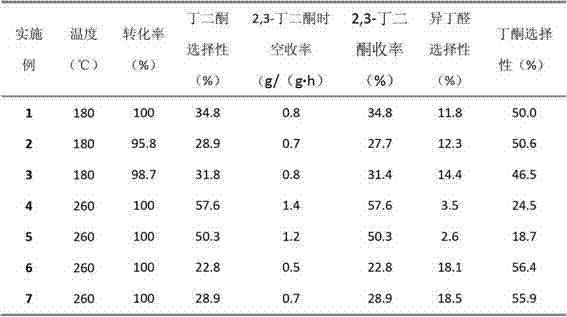

Production technique for preparing 2,3-butanedione from 2,3-butanediol by one-step oxidization and heterogeneous catalyst used by same

InactiveCN102962093AWide variety of sourcesSource GreenMolecular sieve catalystsOrganic compound preparationChemistryMetal

The invention discloses a production technique for preparing 2,3-butanedione from 2,3-butanediol by one-step oxidization and a heterogeneous catalyst used by the same. The technique comprises the following steps: reacting 2,3-butanediol or water solution thereof in a fixed bed tubular reactor at 140-300 DEG C under atmospheric pressure at the liquid hourly space velocity of 0.6-6h<-1>, thereby converting the 2,3-butanediol into a liquid-phase product mainly composed of butanone and butanedione under the action of the heterogeneous catalyst. The heterogeneous catalyst is composed of 2-50 wt% of active metal constituent, 0-10 wt% of non-metal boron or phosphorus and HZSM-5 with the silica-alumina ratio of 100-500. By using the technique and catalyst disclosed by the invention, under optimized conditions, the conversion rate of the 2,3-butanediol is 100%, the yield of the 2,3-butanediol is greater than 57%, and the space-time yield is greater than 1.3g / (g.h).

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com