Ultra-fine grain rolling method for large-size high-temperature alloy bar

A high-temperature alloy and ultra-fine-grained technology, applied in metal rolling, metal rolling, rolling, etc., can solve the problems of high forming load of HPT, lack of loading capacity, and difficulty in realizing industrialization requirements, etc., to improve surface quality and deformation The effect of uniformity, reducing the number of repeated rolling, and strengthening the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Exemplary embodiments of the present invention will be described in detail below through specific examples. The following example takes the high-temperature alloy GH4169 rod with the specification of blank 3 as Φ84×400 as an example, however, the present invention is not limited thereto, and superalloy rods with other specifications can also be produced by the method of the present invention.

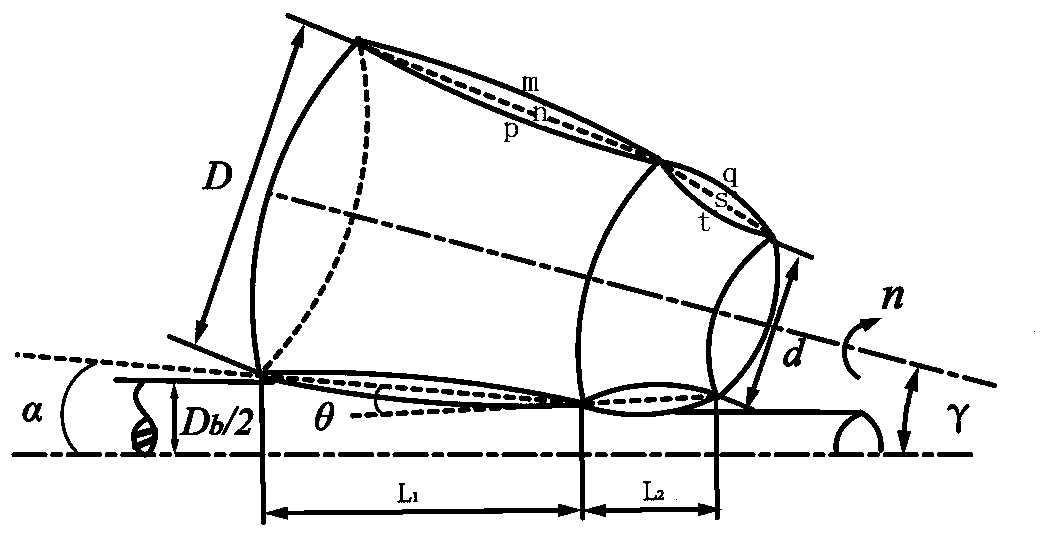

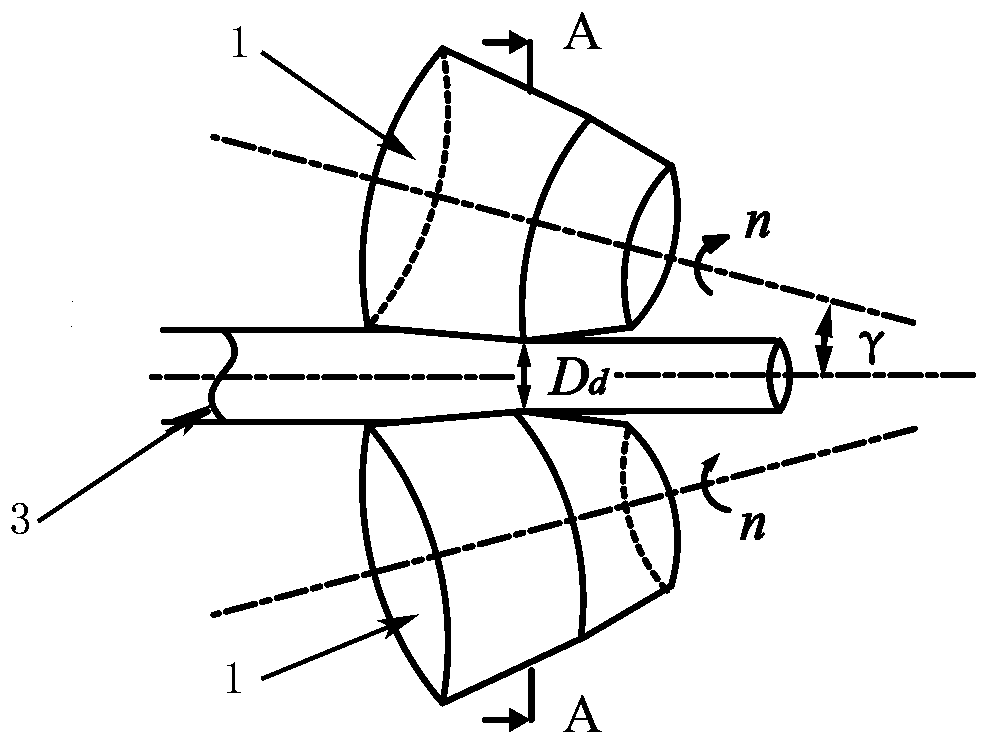

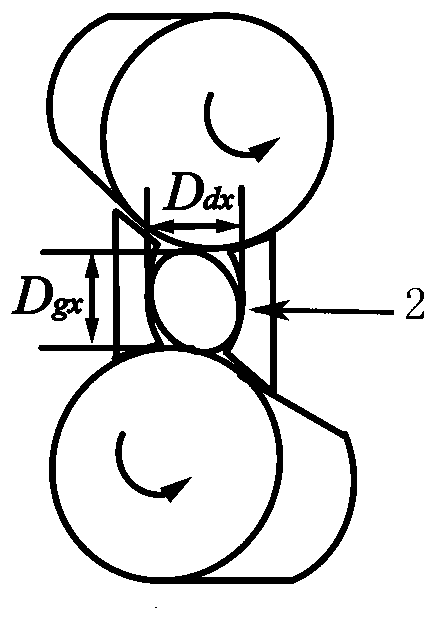

[0071] 1) Rolling tool design, specifically including roll 1 design and guide plate 2 design, roll 1 is set as hyperboloid truncated conical roll 1, specifically: the generatrix of roll 1 is formed by connecting two curves, such as figure 1 As shown, one of the curves is any curve between the curve m and the curve p, the connecting line between the two ends of the curve is the first middle line n, and the other curve is any curve between the curve q and the curve t, The connecting line between the two ends of the curve is the second center line s; one side of the guide plate 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com