One-component intumescent flame retardant with free radical quenching function and preparation method and application thereof

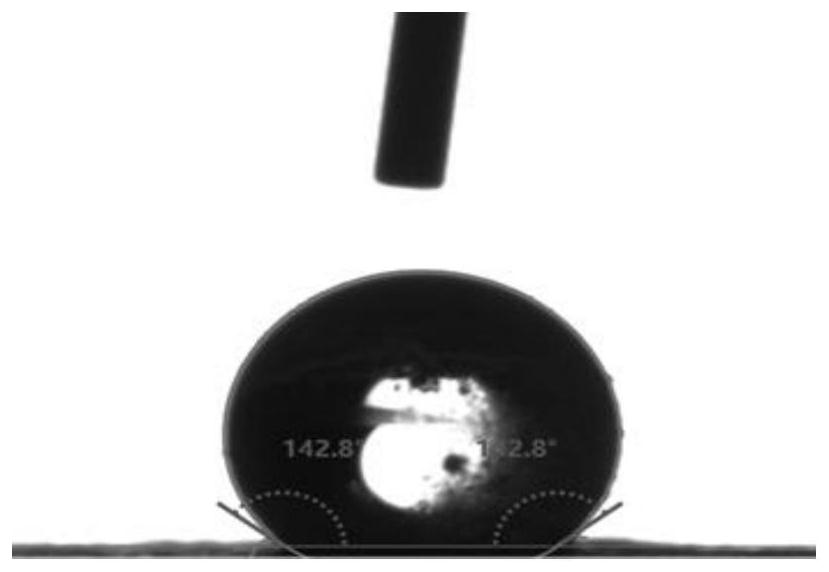

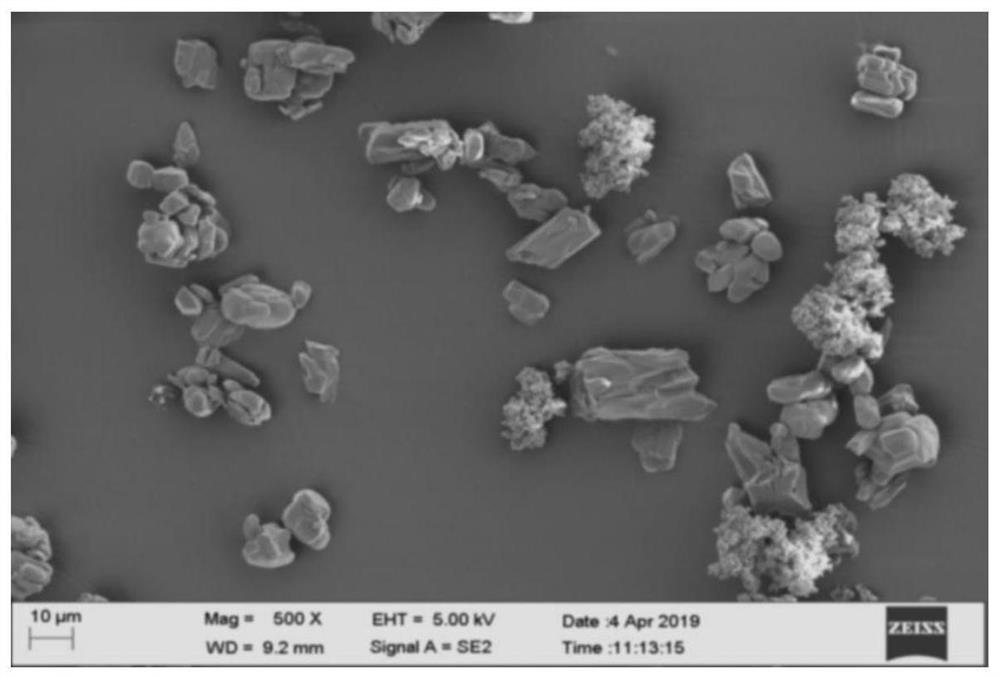

An intumescent flame retardant, one-component technology, used in the preparation and application of polymer halogen-free flame retardants, can solve the problems of high hygroscopicity, poor matrix compatibility, loss, etc., and achieve good compatibility, Excellent flame retardant performance, the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of macromolecule char-forming agent containing hindered amine structure

[0045] At 0°C, add 250mL of acetone and 18.8g (0.1mol) of cyanuric chloride into a 500mL four-neck flask, and stir at a uniform speed for 30 minutes; dissolve 22.3g (0.1mol) of 3-aminopropyltriethoxysilane In 10mL acetone, 0.076g (0.0001mol) 2,4-bis-[N-n-butyl-N-(1-cyclohexyloxy-2,2,6,6-tetramethyl-4-piperidinyl )amino]-6-(2-hydroxyethylamino)-1,3,5-triazine was dissolved in 10mL of acetone, and the two solutions were slowly added to the flask within 1h, and at the same time, 20mL of 5mol / L Sodium hydroxide aqueous solution, continue to react for 3 hours after dripping; then raise the temperature to 45°C, dissolve 3.1g (0.05mol) ethylenediamine and 4.0g (0.1mol) sodium hydroxide in 20mL deionized water to form a mixed solution, Slowly drop it into the flask within 1 hour, and then continue to react for 3 hours; after the reaction, filter the solution, wash the filter cake with dei...

Embodiment 2

[0051] (1) Preparation of macromolecule char-forming agent containing hindered amine structure

[0052] At 25°C, add 250mL of acetone and 18.8g (0.1mol) of cyanuric chloride to a 500mL four-neck flask, and stir at a uniform speed for 40 minutes; 38.2g (0.2mol) of γ-aminopropylmethyldiethoxy Dissolve silane in 10mL acetone, 0.076g (0.0001mol) 2,4-bis-[N-n-butyl-N-(1-cyclohexyloxy-2,2,6,6-tetramethyl-4-piper Pyridyl)amino]-6-(2-hydroxyethylamino)-1,3,5-triazine was dissolved in 10mL of acetone, and the two solutions were slowly added to the flask within 1h, and at the same time, 40mL of 5mol / L of sodium hydroxide aqueous solution, continue to react for 3 hours after dripping; then raise the temperature to 65°C, dissolve 3.1g (0.05mol) of ethylenediamine and 4.0g (0.1mol) of sodium hydroxide in 20mL of deionized water, and make a mixture The solution is slowly dropped into the flask within 1 hour, and the reaction is continued for 3 hours after the drop is completed; after the ...

Embodiment 3

[0058] (1) Preparation of macromolecule char-forming agent containing hindered amine structure

[0059] At 25°C, add 250mL of acetone and 18.8g (0.1mol) of cyanuric chloride into a 500mL four-neck flask, stir at a constant speed for 30min; dissolve 22.3g (0.1mol) of 3-aminopropyltriethoxysilane In 10mL acetone, 1.52g (0.002mol) 2,4-bis-[N-n-butyl-N-(1-cyclohexyloxy-2,2,6,6-tetramethyl-4-piperidinyl )amino]-6-(2-hydroxyethylamino)-1,3,5-triazine was dissolved in 10mL of acetone, and the two solutions were slowly added to the flask within 1h, and at the same time, 20mL of 5mol / L Sodium hydroxide aqueous solution, continue to react for 1h after dripping; then raise the temperature to 65°C, dissolve 3.1g (0.05mol) ethylenediamine and 4.0g (0.1mol) sodium hydroxide in 20mL deionized water to form a mixed solution, Slowly drop it into the flask within 1 hour, and then continue to react for 1 hour; after the reaction, filter the solution, wash the filter cake with deionized water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com