Cyanide-free gold-imitating copper-zinc-tin alloy electroplating process for surface of carbon steel

An alloy electroplating, copper-zinc-tin technology is applied in the field of metal surface electroplating and cyanide-free imitation gold-copper-zinc-tin alloy plating process on carbon steel surface, which can solve the problem that the color stability and uniformity of the coating are difficult to control, and the cyanide-free imitation gold plating solution Not stable enough, unfavorable for mass production, etc., to achieve the effect of good anti-discoloration, short electroplating time, and maintenance cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

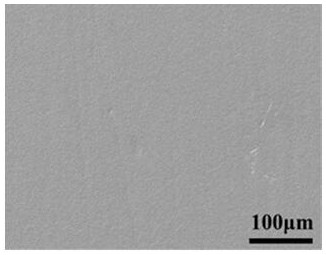

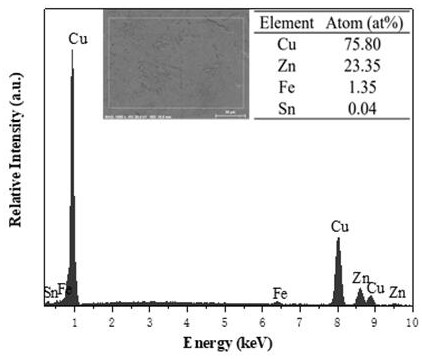

[0043] The concentration of each component of the cyanide-free copper-zinc-tin alloy electroplating solution of the present embodiment is: potassium pyrophosphate 250g / L, copper pyrophosphate 22g / L, zinc sulfate 40g / L, tin protophosphate 2.1g / L, hydroxyethylidene Diphosphonic acid 12g / L, additive (cationic quaternary ammonium salt) 0.05 g / L, sodium saccharin 0.3g / L, 1,4-butynediol 0.2g / L, sodium saccharin and 1,4-butynediol A compound brightener is formed, and the solvent is deionized water; the pH of the electroplating solution is adjusted to 8.6 by potassium pyrophosphate and potassium hydroxide.

[0044] The process steps of electroplating cyanide-free imitation gold copper-zinc-tin alloy on carbon steel surface are as follows:

[0045] (1) Polish the sample, and then perform ultrasonic degreasing, pickling and activation treatment in sequence. Degreasing fluid: sodium hydroxide (NaOH) 5g / L, sodium carbonate (NaOH) 2 CO 3 ) 15g / L, trisodium phosphate (Na 3 PO 4 12H 2 ...

Embodiment 2

[0050] The concentration of each component of the cyanide-free copper-zinc-tin alloy electroplating solution of the present embodiment is: potassium pyrophosphate 280g / L, copper pyrophosphate 24g / L, zinc sulfate 45g / L, tin protophosphate 2.5g / L, hydroxyethylidene Diphosphonic acid 18g / L, additive epichlorohydrin condensate 0.4 g / L, sodium saccharin 0.4g / L, 1,4-butynediol 0.3g / L, sodium saccharin and 1,4-butynediol A compound brightener is formed, and the solvent is deionized water; the pH of the electroplating solution is adjusted to 8.2 by potassium pyrophosphate and potassium hydroxide.

[0051] The process steps of electroplating cyanide-free imitation gold copper-zinc-tin alloy on carbon steel surface are as follows:

[0052] (1) Polish the sample, and then perform ultrasonic degreasing, pickling and activation treatment in sequence. Degreasing liquid: sodium hydroxide 10g / L, sodium carbonate 20g / L, trisodium phosphate 25g / L, sodium silicate 8g / L, sodium dodecylbenzenesul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com