Patents

Literature

39results about How to "Short plating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-free black tin cobalt alloy plating solution and electroplating technology by using same

The invention relates to a nickel-free black tin cobalt alloy plating solution and an electroplating technology by using same. The parameters and contents of all components of the plating solution are as follows: the content of tin ions in a tin salt is 0.05-6g / L; the content of cobalt ions in a cobalt salt is 0.05-0.8g / L; the content of third metallic ions is 0.02-50g / L; the content of a complexing agent is 0.1-180g / L; the content of a blacking agent is 0.1-50g / L; the content of a PH buffer is 5-300g / L; the baume degree of the plating solution is 6-250; the temperature is 20-55 DEG C; and PH is 9-13. According to the technology provided by the invention, tin is taken as a main alloy layer and few cobalt and third and fourth metal ions are added in tin to form a ternary or quaternary alloy system; the cobalt content in the common black tin cobalt alloy plating solution excesses 8g / L, but the cobalt content is reduced to 0.05g / L according to the new electroplating technology provided by the invention; the special biodegradable or non-biodegradable stabilizing complexing agent and PH buffer are used, so that the production cost is lowered; and the nickel-free black tin cobalt alloy plating solution meets the limitation requirement on CO in the European Union Rosh standard, Germany LMBG standard, Mattel children toy standard, European Oeko-Tex Standard 100 standard and the like.

Owner:杜强

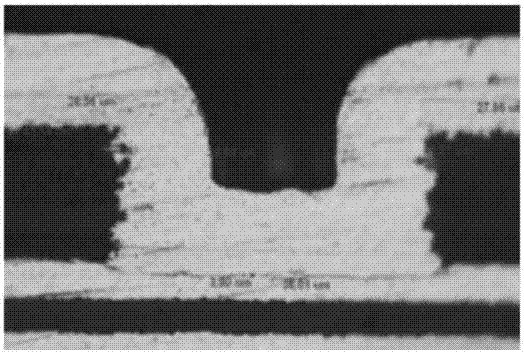

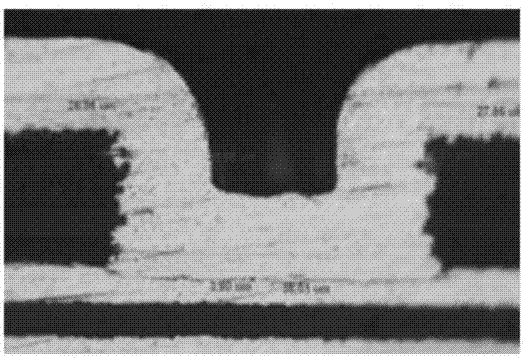

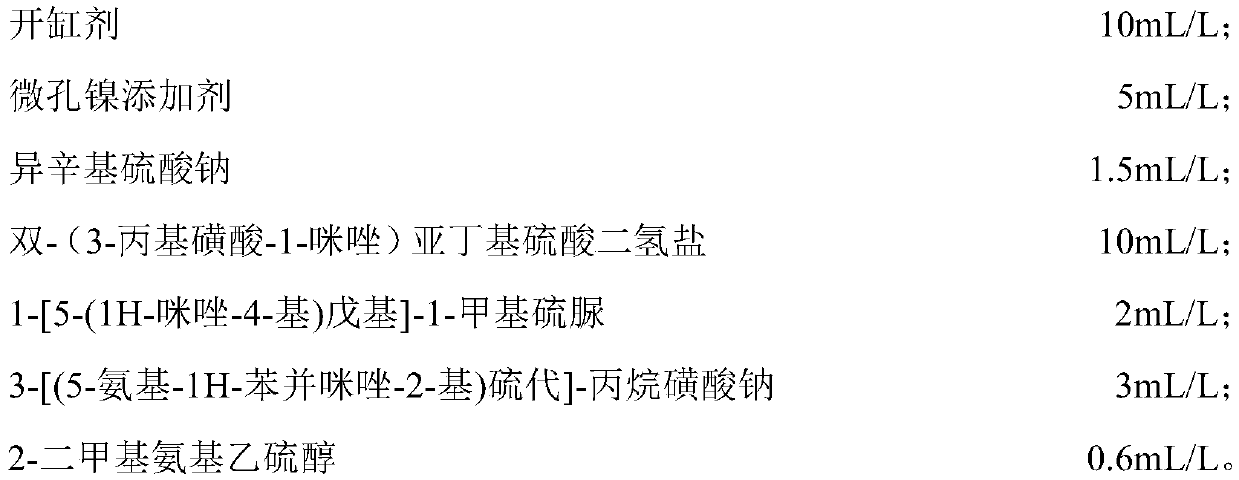

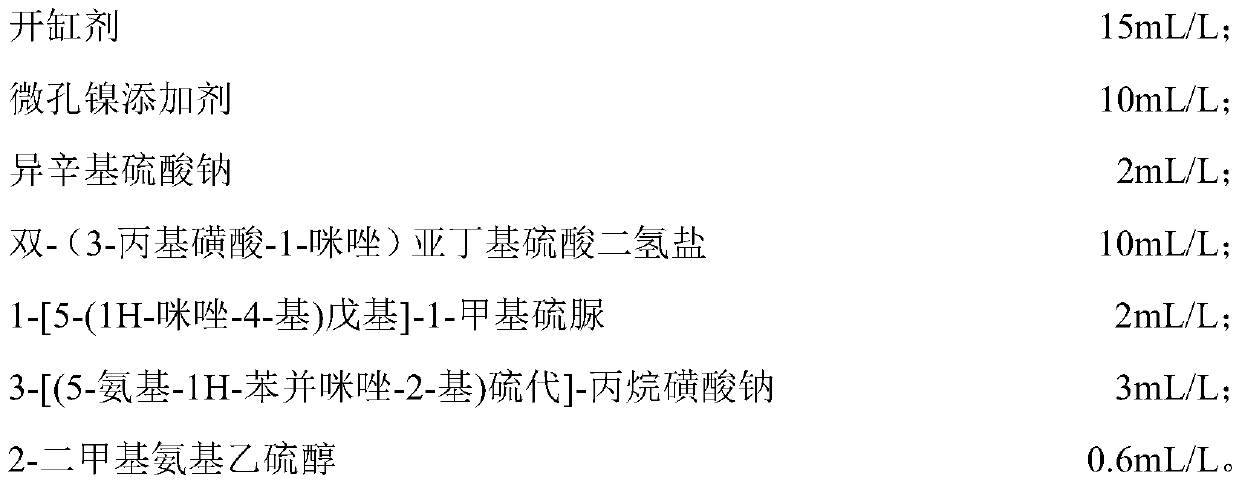

Electroplate liquid for jointly plating through hole and blind hole and electroplating method

InactiveCN107313081AImprove ductilityImprove reliabilityPrinted element electric connection formationSulfonateCopper

The invention provides a co-plating electroplating solution and an electroplating method for through-blind holes. In the through-blind hole co-plating electroplating solution of the present invention, the electroplating solution comprises A-D components, wherein the A component is anhydrous copper sulfate; the B component is sulfuric acid; the C component is chlorine compound; the D component is selected from sodium polydithiodipropanesulfonate, sodium 3-mercaptopropanesulfonate, sodium N,N-dimethyldithiocarbonylpropanesulfonate, internal salt of isothioureapropanesulfonate and 3-(benzothiazole-2-mercapto)-sodium propanesulfonate or a mixture of at least two of them. The total organic carbon content of the through-blind hole co-plating electroplating solution of the present invention is low, the ductility and thermal shock reliability of electroplated copper are high, the electroplating time is short, the process is simple, the electroplating efficiency is high, and the through hole and blind hole are effectively improved. plating reliability.

Owner:SUZHOU TIANCHENG CHEM

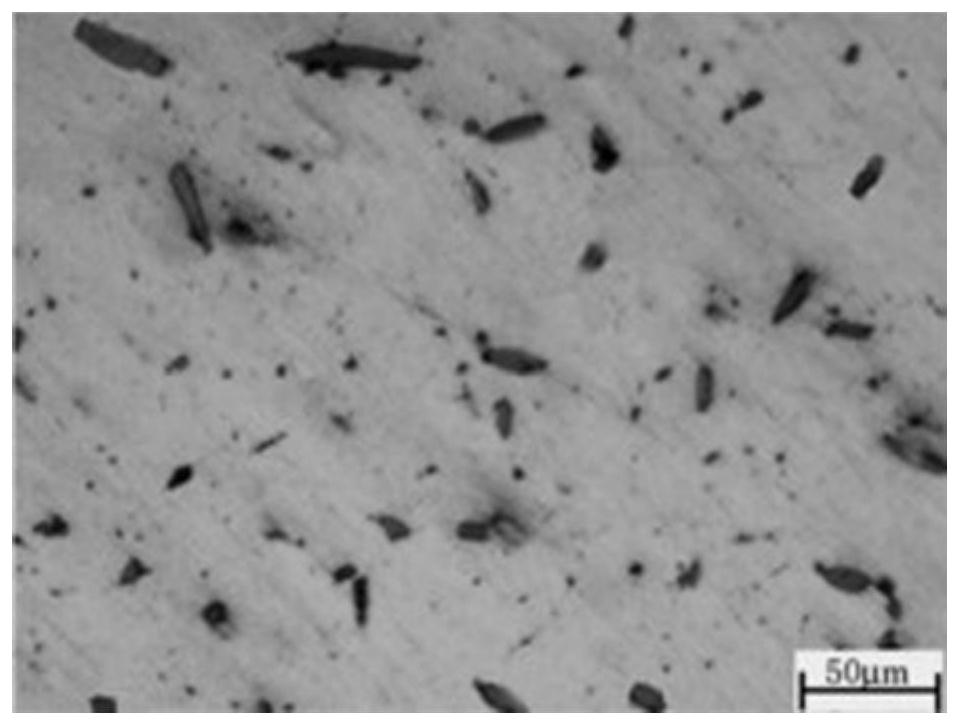

Method of coating metal layer on roller surface of biroller thin belt continuous casting machine

InactiveCN1693538AImprove wear resistanceImprove thermal fatigue resistanceElectrolytic coatingsNanoparticleMetal

Owner:CHONGQING UNIV

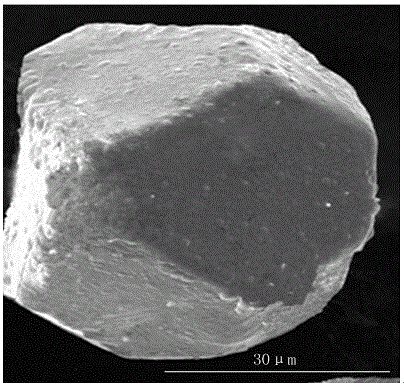

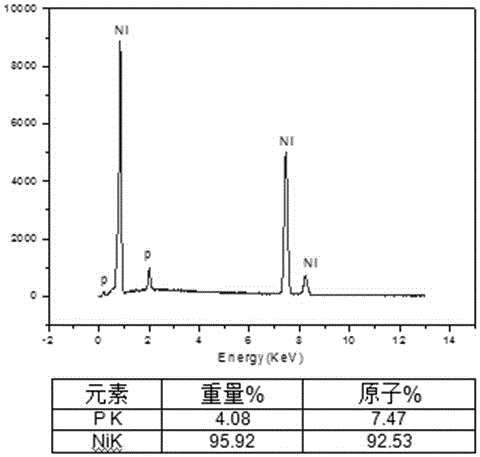

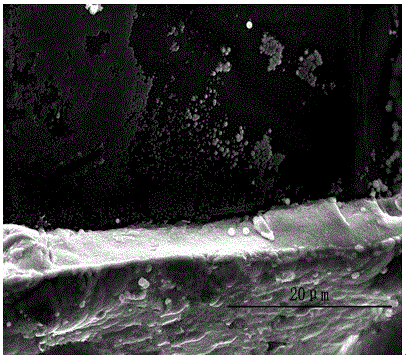

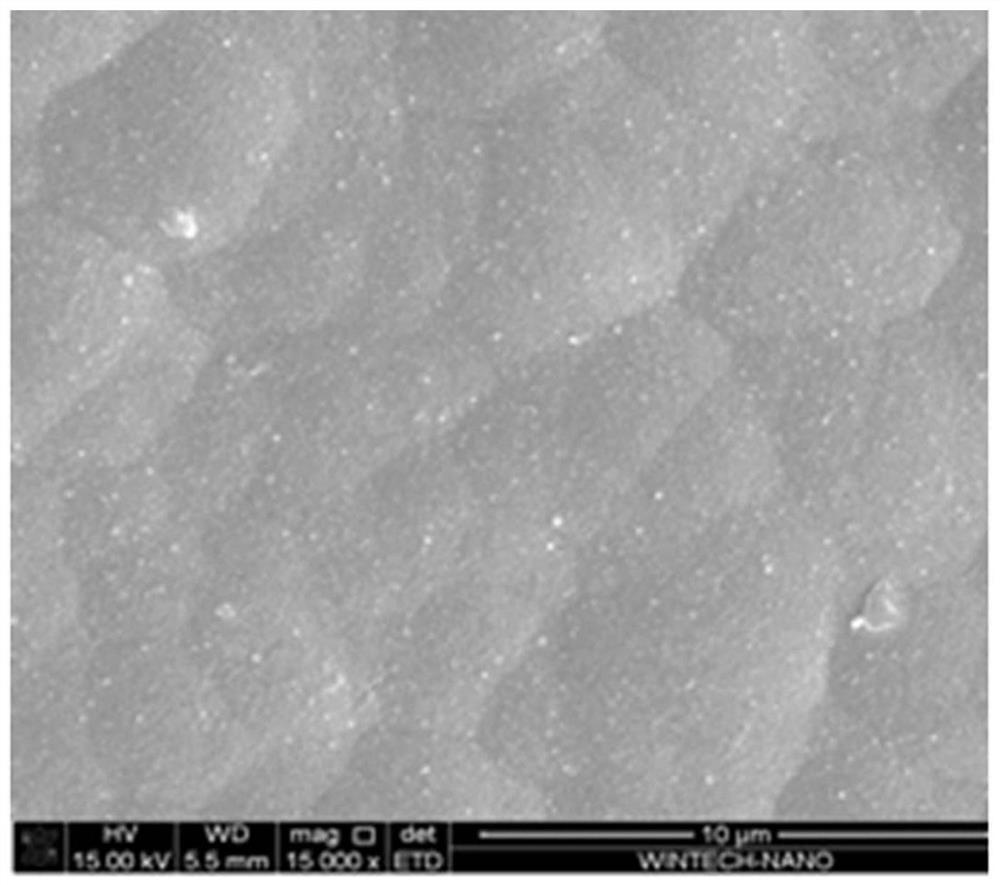

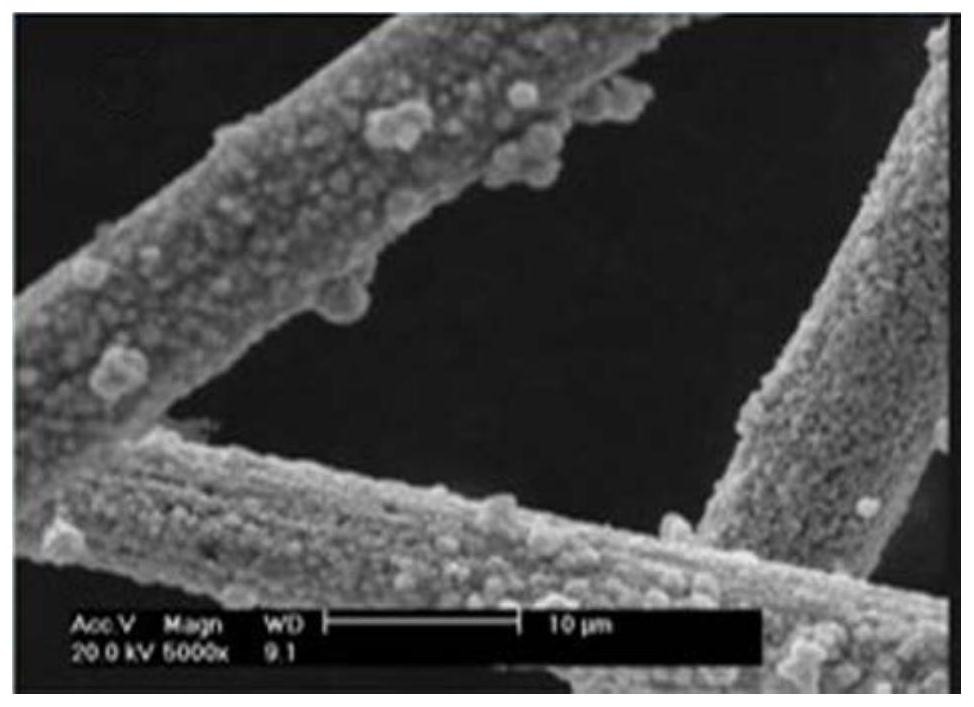

Method for chemically plating surface of diamond with Ni and P in microwave-ultrasound combined mode

InactiveCN105112891AReduce dosageLow costLiquid/solution decomposition chemical coatingChemical platingMicroparticle

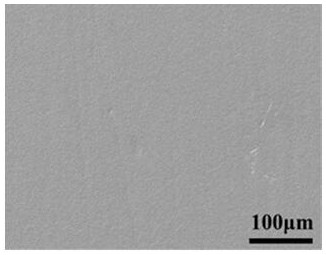

The invention relates to a method for chemically plating the surface of diamond with Ni and P in a microwave-ultrasound combined mode and belongs to the technical field of diamond composites. The method includes the steps that firstly, grease and dirt of diamond particles are removed after the diamond particles are boiled in a NaOH solution, and then the surfaces of the diamond particles are roughened after the diamond particles are boiled in a dilute HNO3 solution; the diamond particles obtained after surface roughening are placed in a base colloid palladium solution for sensitization-activation; the diamond particles obtained after sensitization-activation are added into a sodium hypophosphite-water(1 / 2) solution with the concentration of 30 g / L for surface Pd2+ reduction of the diamond particles; and the diamond particles obtained after surface Pd2+ reduction are added into a chemical plating solution, are plated for 1-1.5 h under the microwave irradiation and ultrasound stirring conditions and stand still after being plated, and the diamond particles plated with Ni-P on the lower layer are washed with distilled water for vacuum drying. According to the method, the microwave irradiation heating technology and the ultrasound technology are combined to be applied to the Ni-P chemical plating process of the surface of the diamond, the quality of a coating is improved, and the coating is flat, smooth, dense, uniform and high in binding capacity and corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

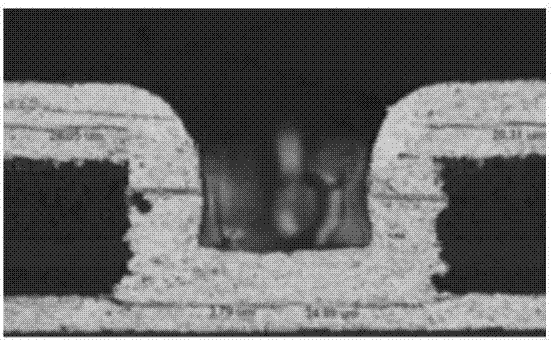

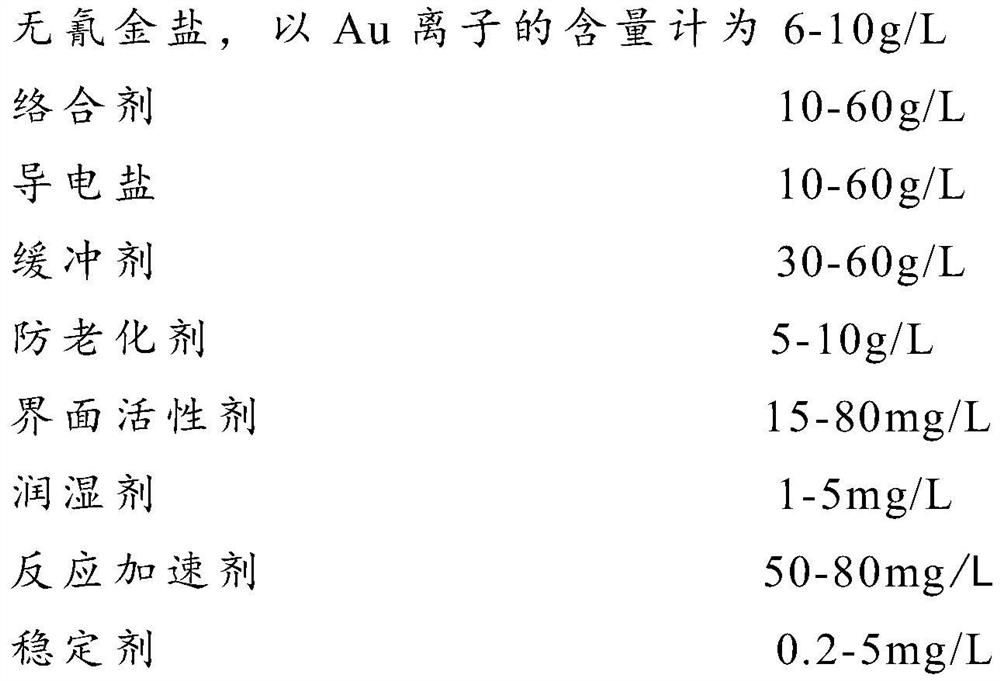

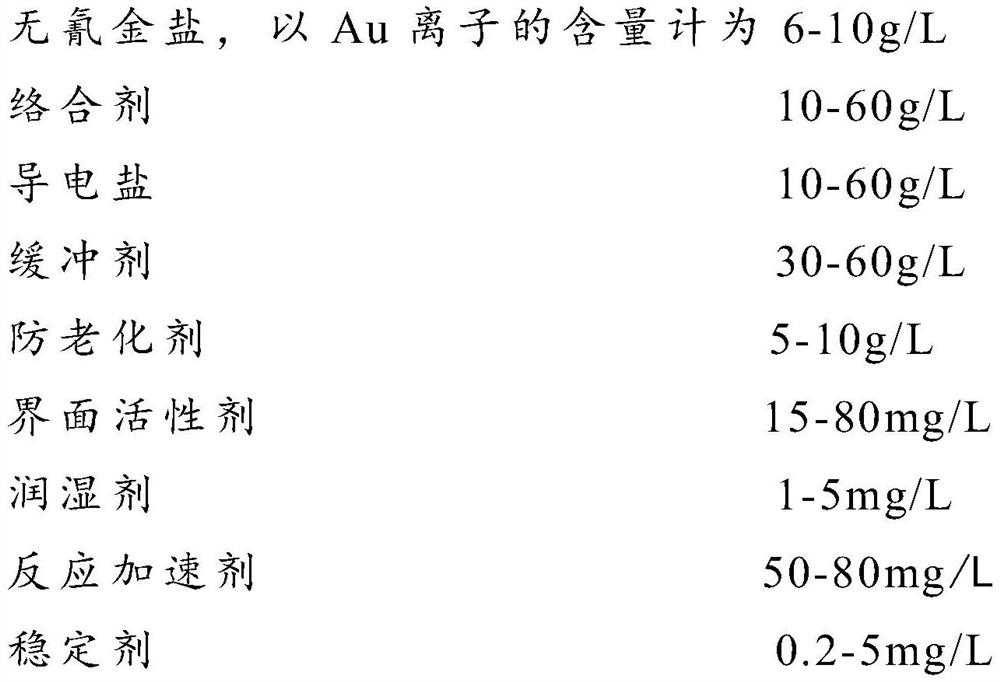

Cyanide-free chemical gold plating solution applied to advanced wafer packaging field and gold plating process thereof

ActiveCN113026068AAvoid narrow operating rangesSpeed up the activation reactionCellsSemiconductor devicesCyanideActive agent

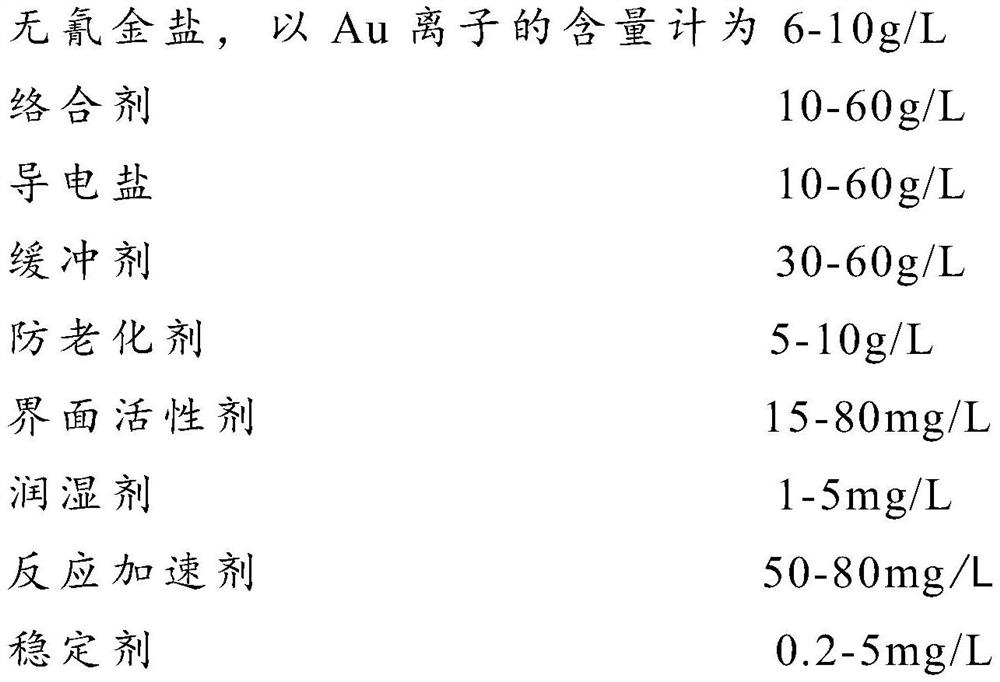

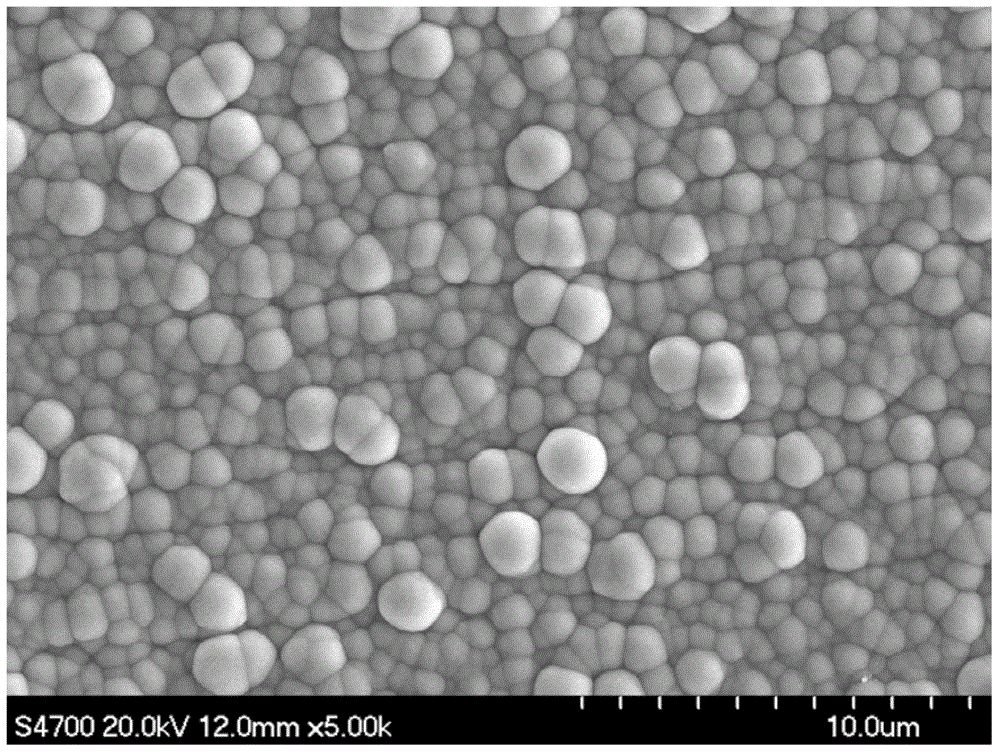

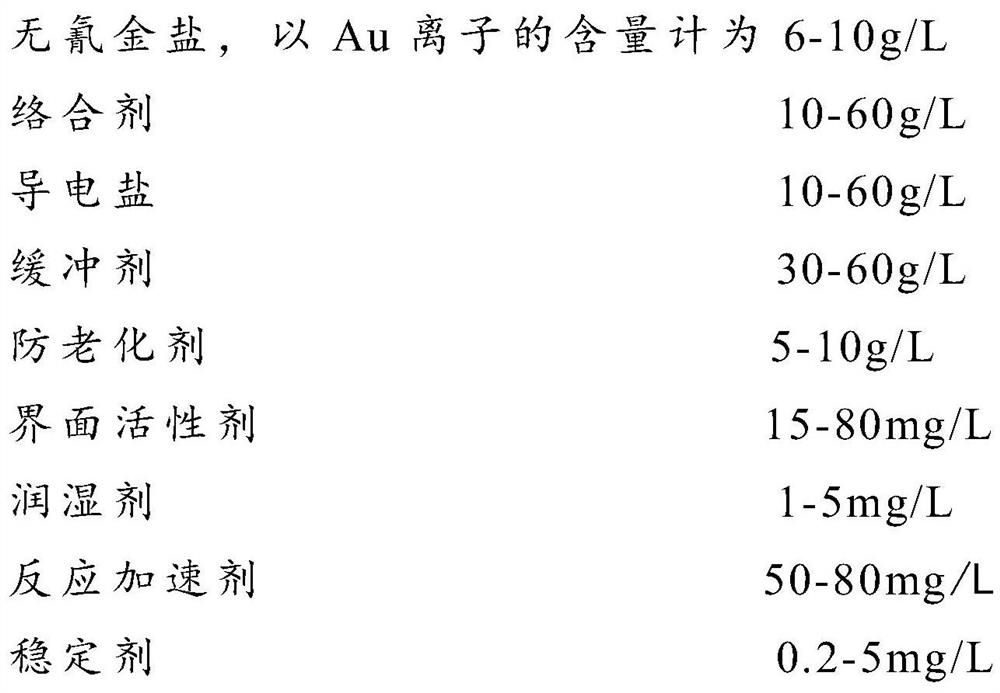

The invention discloses a cyanide-free chemical gold plating solution applied to the advanced wafer packaging field and a gold plating process thereof. The cyanide-free chemical gold plating solution is prepared from the following components: cyanide-free gold salt with the content of Au ions being 6-10 g / L, 10-60 g / L of a complexing agent, 10-60 g / L of conductive salt, 30-60 g / L of a buffer agent, 5-10 g / L of an anti-aging agent, 15-80 mg / L of an interfacial agent, 1-5 mg / L of a wetting agent, 50-80 mg / L of a reaction accelerator, and 0.2-5 mg / L of a stabilizer, wherein the reaction accelerator is a compound of 2,6-diaminopyridine and 3-pyridine methanol, and the mass concentration ratio of the 2,6-diaminopyridine to the 3-pyridine methanol is 2:1. The solution not only ensures the stability of the plating solution, but also enables a plated part to be easily spread on the surface of an electrode so as to achieve the purpose of uniform plating, and therefore the effect of void-free and seamless filling of wafer packaging micropores is further achieved.

Owner:SHENZHEN CHENGGONG CHEM

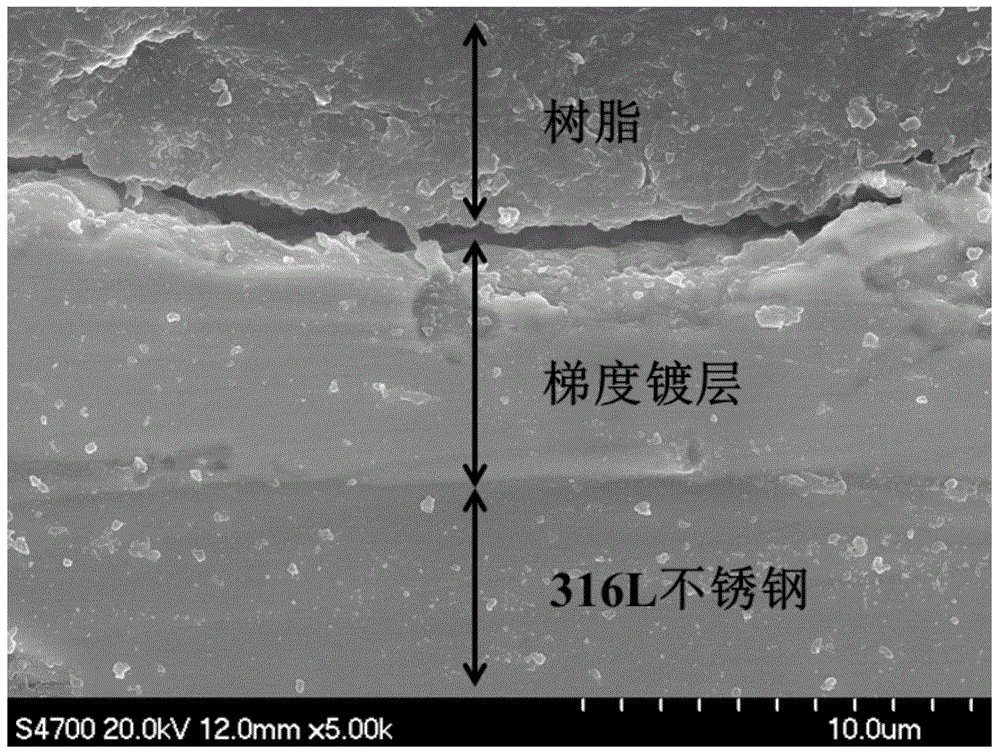

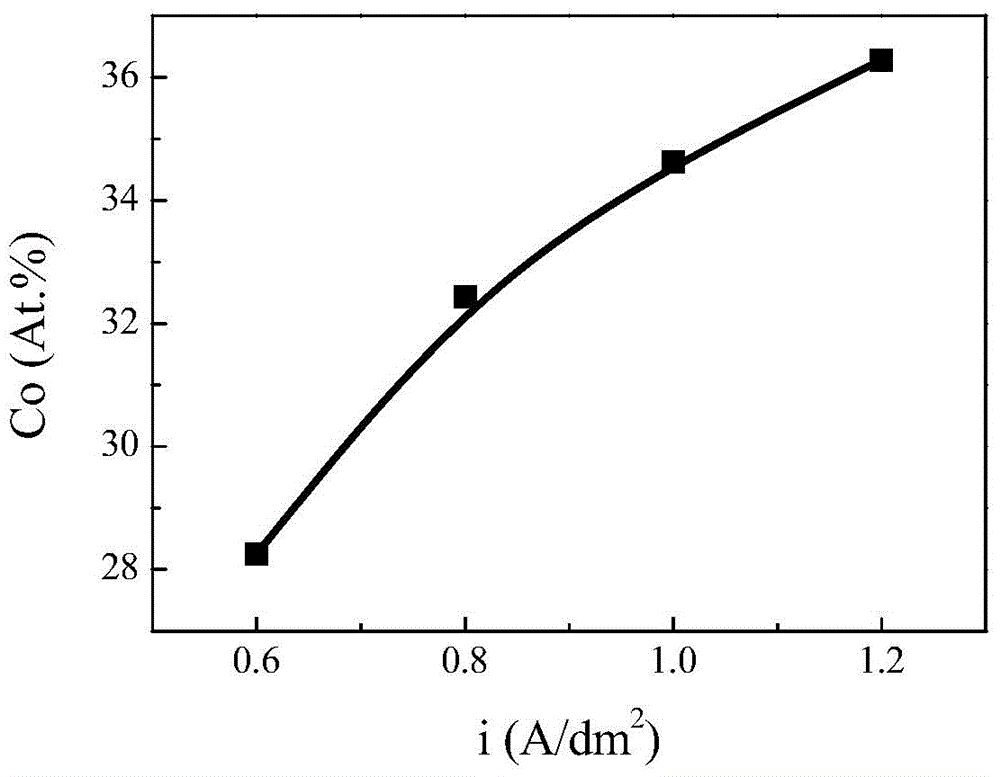

Electroplating process of high-abrasion resistance corrosion-resistance Pd-Co gradient alloy for stainless steel surface

The invention relates to an electroplating process of a high-abrasion resistance corrosion-resistance Pd-Co gradient alloy for a stainless steel surface. The electroplating process comprises a surface pre-treating step and an electroplating step, and is characterized in that an electroplating solution used in the electroplating step is composed of 5-12 g / L of palladium salt Pd (NH3)4Cl2 (measured by the mass of Pd), 50-125 g / L of NH4Cl, 50-100 ml / L of NH3.H2O with the mass percent concentration of 28%, 16-50 g / L of CoCl2.6H2O, 50-100 g / L of C2H5O2N, 1-5 g / L of saccharin and the balance of water, wherein the pH value is 7-8, and the temperature is 30-50 DEG C. In the electroplating step, electroplating is sequentially carried out for 2-3 min by adopting the current density of (0.5-0.6), (0.8-0.9), (1.0-1.1) and (1.2-1.4) A / dm<2>. The electroplating process is simple, and realizes the preparation of a gradient coating in a single trough; the obtained coating is excellent in washing resistance, excellent in corrosion resistance and capable of exerting the good protection effect on stainless steel in a solid-liquid two-phase scoured high-temperature non-oxidizing medium.

Owner:BEIJING UNIV OF CHEM TECH

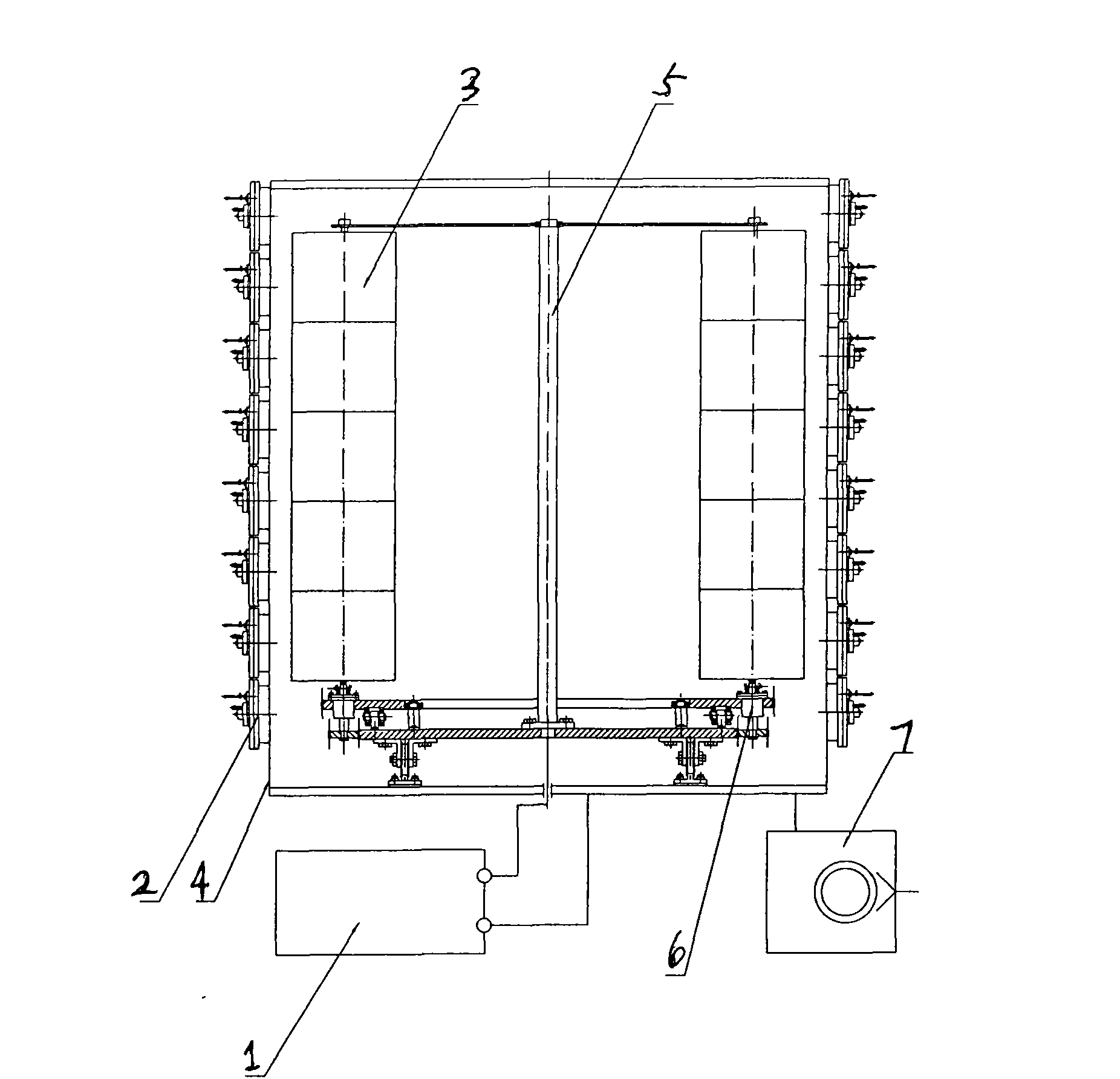

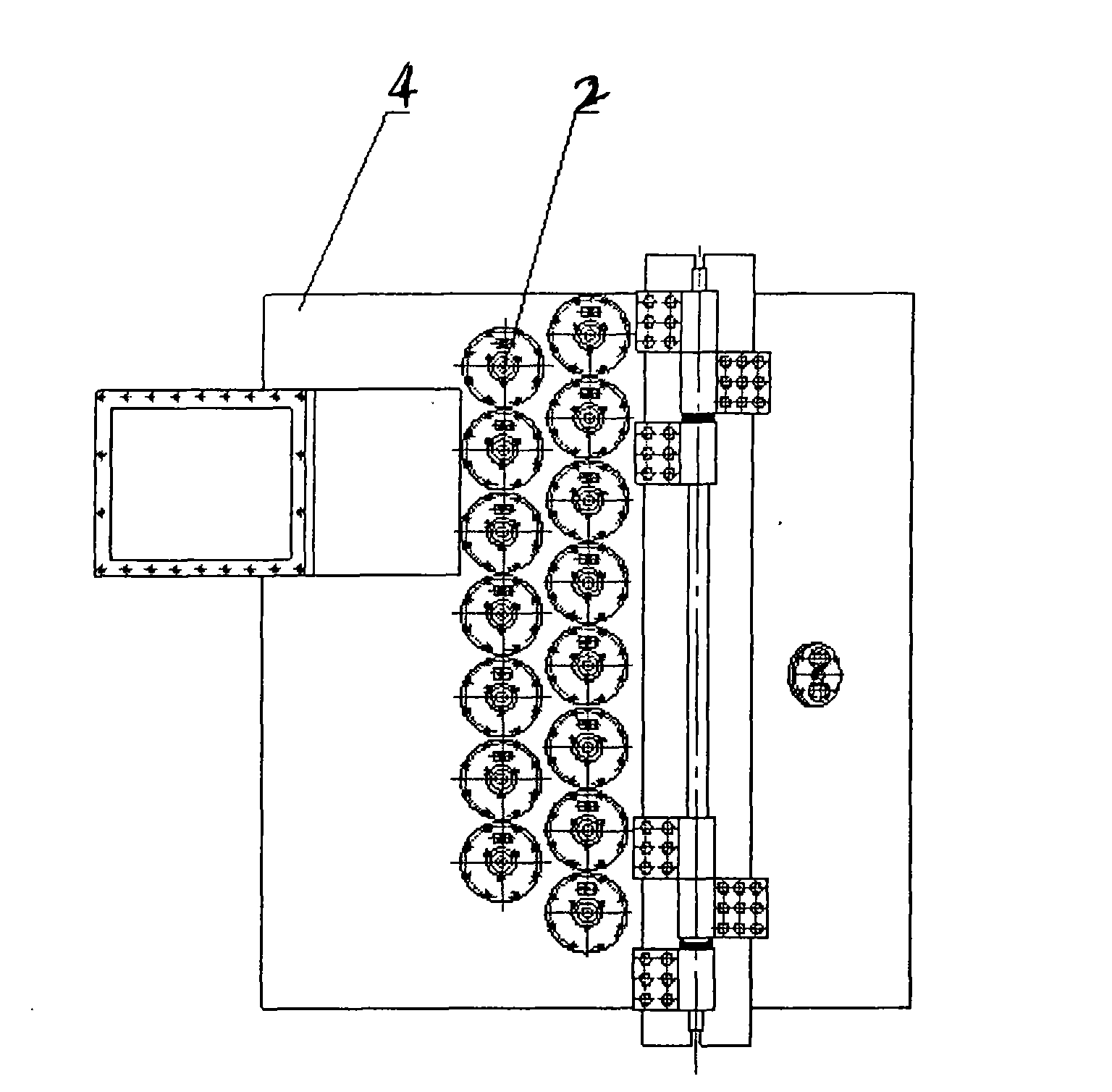

Intellectualization ceramic tile vacuum ion membrane plating equipment

InactiveCN101525736AQuality improvementGood effectVacuum evaporation coatingSputtering coatingVacuum pumpingVacuum chamber

The invention belongs to the technical field of vacuum membrane plating, and in particular relates to intellectualization ceramic tile vacuum ion membrane plating equipment. The intellectualization ceramic tile vacuum ion membrane plating equipment comprises a vacuum chamber which is connected with a vacuum pumping system, a rotary piece rack type multifunctional sample table, voltaic arc metal ion sources which are uniformly distributed on both sides of the vacuum chamber and a PLC programmable centralized controller. The intellectualization ceramic tile vacuum ion membrane plating equipment is characterized in that the rotary piece rack type multifunctional sample table is isolated from the vacuum chamber; a washing electrode of a gas ion washing source is positioned on the rotary piece rack type multifunctional sample table and is connected with a gas ion washing power supply outside the vacuum chamber; and the number of the voltaic arc metal ion sources is 30, and the space between the ion sources and a plating piece is 150 millimeters. The intellectualization ceramic tile vacuum ion membrane plating equipment has the advantages of good quality and effect of a membrane plating layer, low loss, small volume and strong membrane-base bonding force.

Owner:王桂岳

Formula of electroplate liquid for automobile front cover

The invention discloses a formula of electroplate liquid for an automobile front cover. The formula comprises the following steps: 20-36g of aluminum hydroxide, 20-46g of aluminum oxide, 12-16g of sodium hydroxide, 15-18g of silicic acid, 50-64g of magnesium carbonate, 12-16g of methyl methacrylate, 7-12g of potassium chloride, 3-11g of ferroferric oxide, 2-5g of silver nitrate and 300-500g of water. The formula is low in cost, the used electroplating current is relatively low, the electroplating time is relatively short, the formula of the electroplate liquid can be suitable for wide use in the electroplating process of the automobile front cover; people can use relatively beautiful automobiles within a relatively large range; and the people's life is beautified.

Owner:张志良

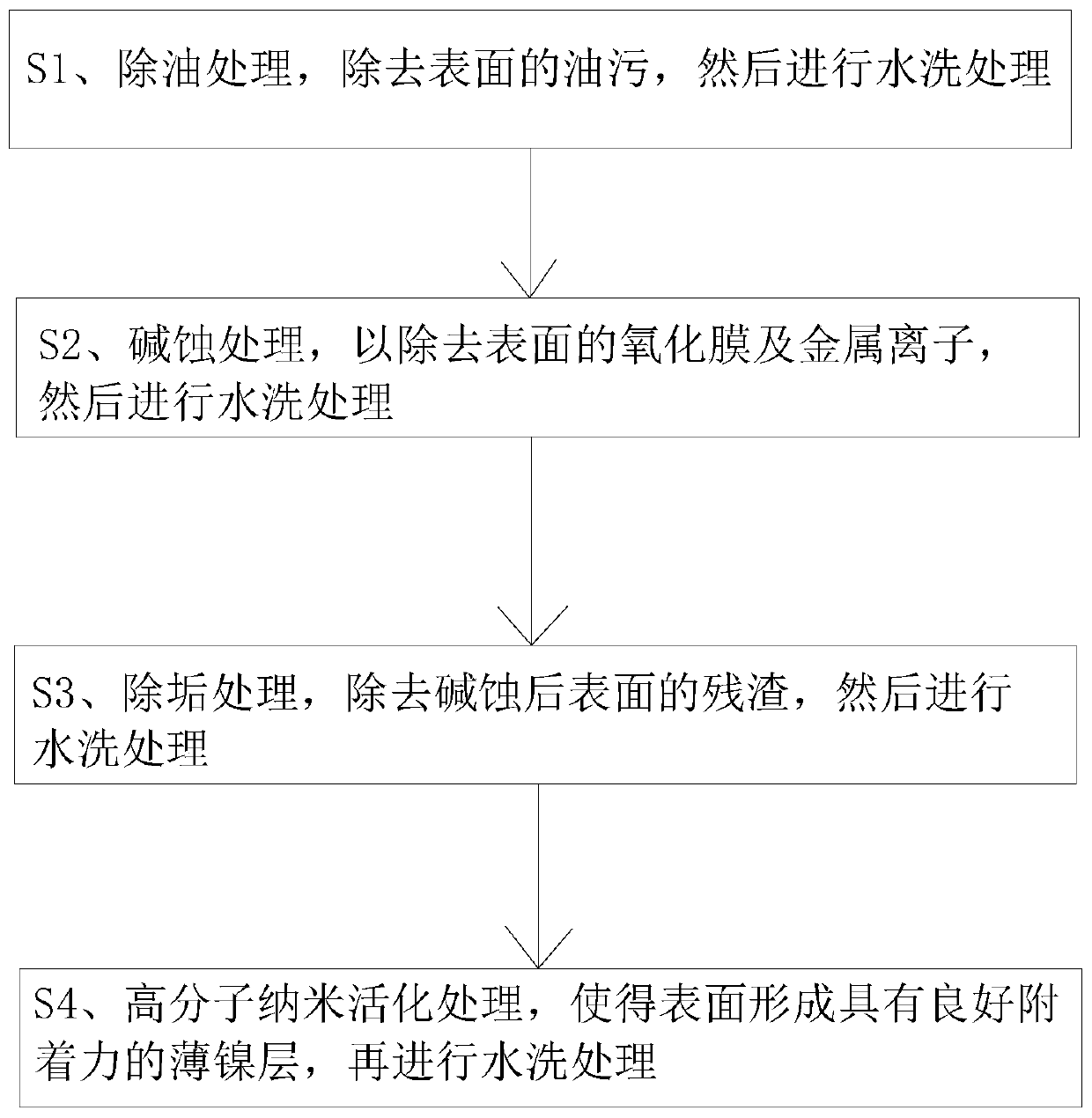

Die-casting aluminum alloy electroplating pretreatment process

InactiveCN110714214AEmission reductionLow costMetallic material coating processesElectroless nickelWastewater

The invention relates to the technical field of metal surface treatment, and particularly relates to a die-casting aluminum alloy electroplating pretreatment process. According to the die-casting aluminum alloy electroplating pretreatment process, activation treatment is adopted to replace traditional procedures such as primary zinc precipitation, zinc removal, secondary zinc precipitation and alkaline chemical nickel precipitation, the technological process is simplified, the production efficiency is improved, wastewater discharge is greatly reduced, the raw material cost is saved, the equipment investment is reduced, and the labor cost is reduced; and in addition, phosphorus discharge is reduced through the descaling process, and the process is more environmentally friendly. Due to the fact that the plating time of an activating solution is short, the raw material consumption is low, the change of a bath solution is slow, the cost is low, a die-casting aluminum alloy piece subjectedto activation treatment has good adhesive force, and a good foundation is laid for the electroplating procedure; and in addition, the surface activity of a product plated with the activating solutionis high, and plating is started in a chemical nickel bath for 1-2 seconds after activation.

Owner:东莞市百镀通五金电镀实业有限公司

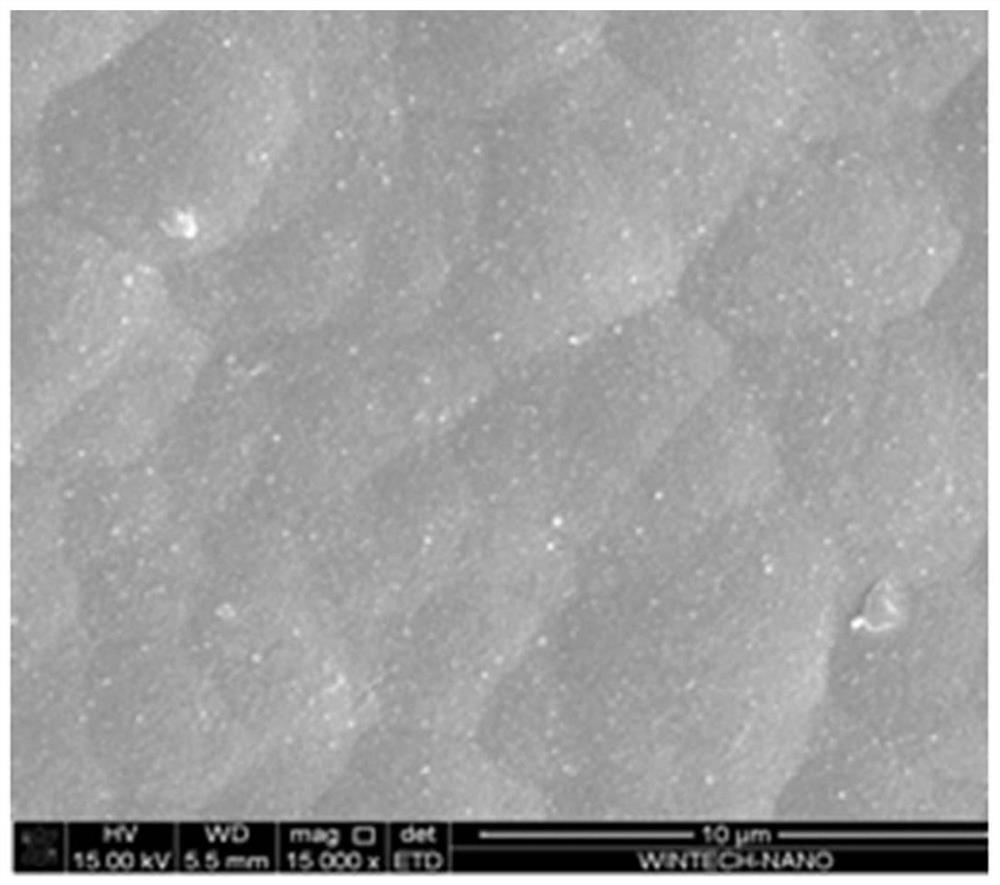

Chemical nickel plating method of aluminum base composite material

InactiveCN107287580AGood lookingDense internal organizationLiquid/solution decomposition chemical coatingChemical platingSolvent

The invention relates to a chemical nickel plating method of an aluminum base composite material, and solves the problems of high implementation cost and narrower application range in traditional surface chemical nickel plating technologies of silicon carbide particle reinforced aluminum base composite material and high silicon aluminum materials. The chemical nickel plating method comprises the following steps: the pH value of chemical plating liquid is adjusted within 9-11; the plating is continued at the temperature of the chemical plating liquid of 70-90 DEG C to finish the chemical nickel plating; a solvent of the chemical nickel plating is de-ionized water; and solutes are NiSO4.6H2O, NaH2PO2.H2O, C6H5Na3O7.2H2O and NH4Cl. The chemical nickel plating method has the advantages of: (1) excellent appearance of a nickel plating layer, compact internal structure, and high bonding force; (2) simple process, high repeatability, short plating time, and no need of external direct-current power supply; (3) low nickel plating cost; and (4) no corrosion to welding lines, glass components and the like. The chemical nickel plating method is mainly used for chemical nickel plating.

Owner:허난징타이에어로우스페이스하이테크머터리얼스테크놀로지컴퍼니리미티드

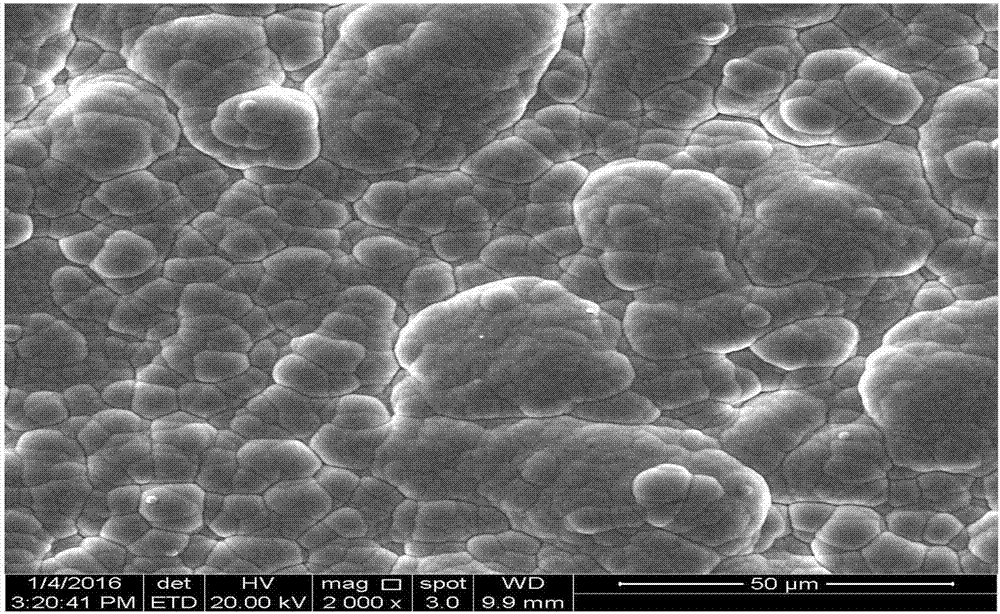

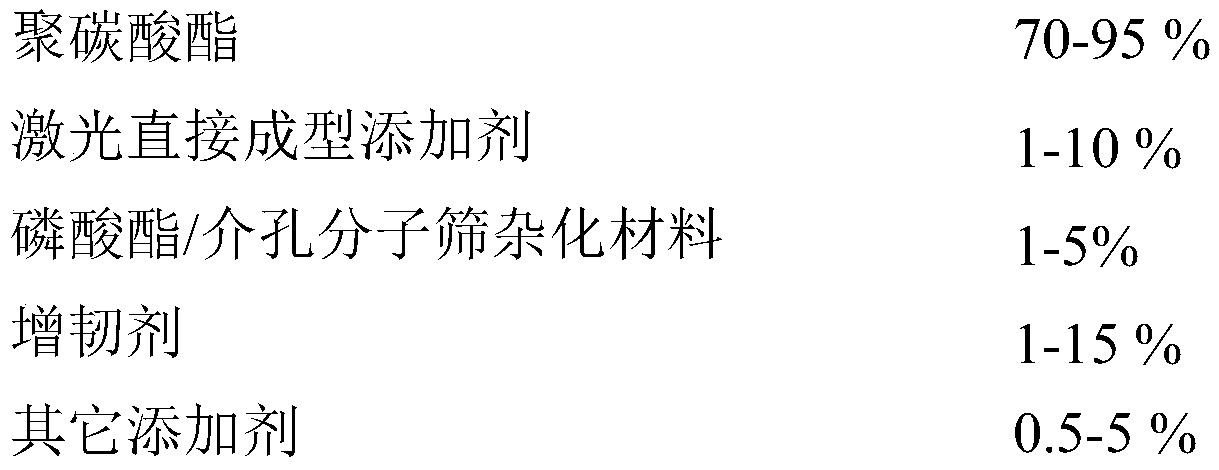

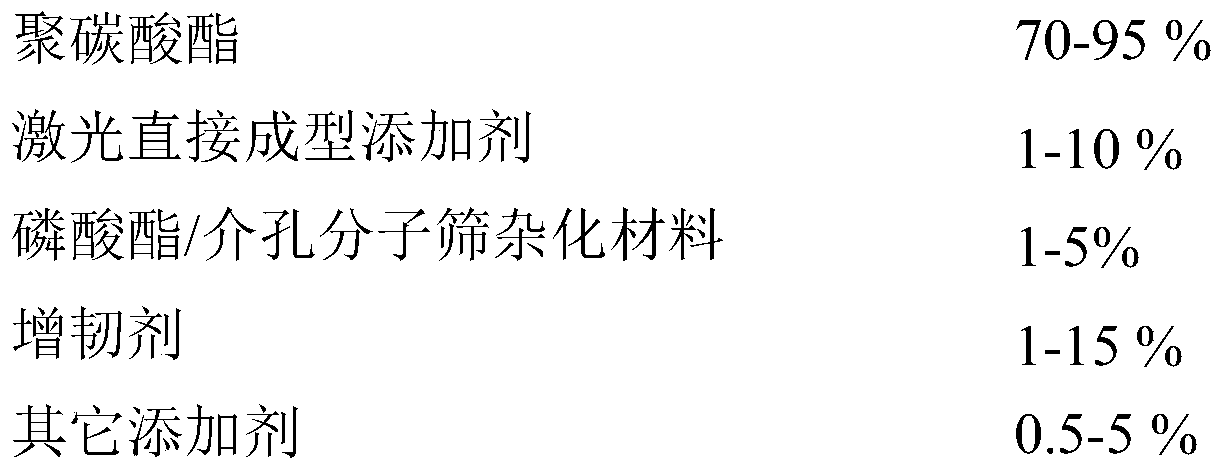

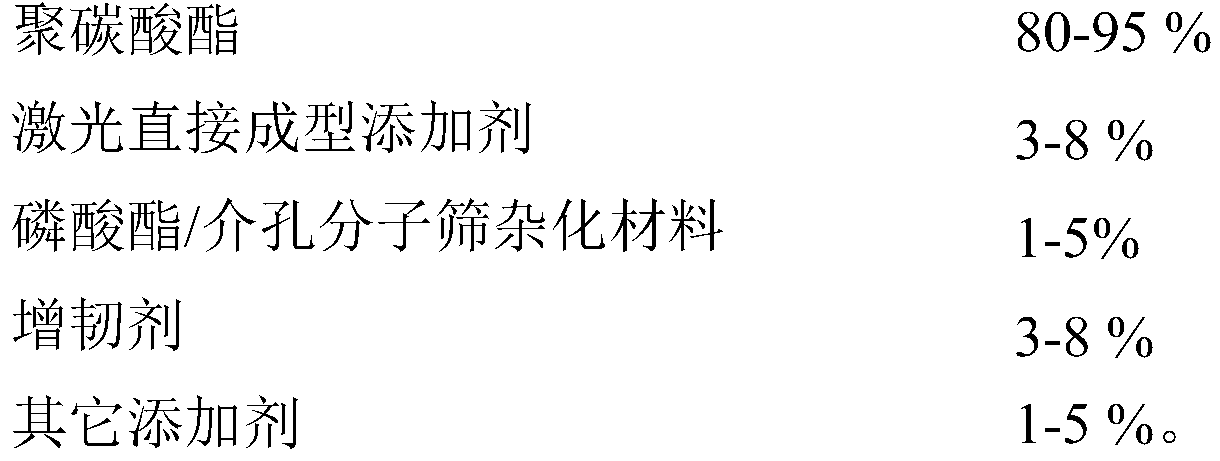

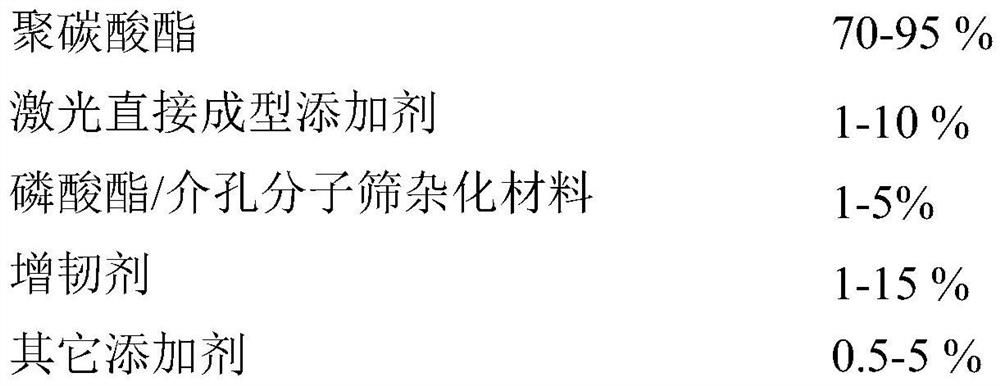

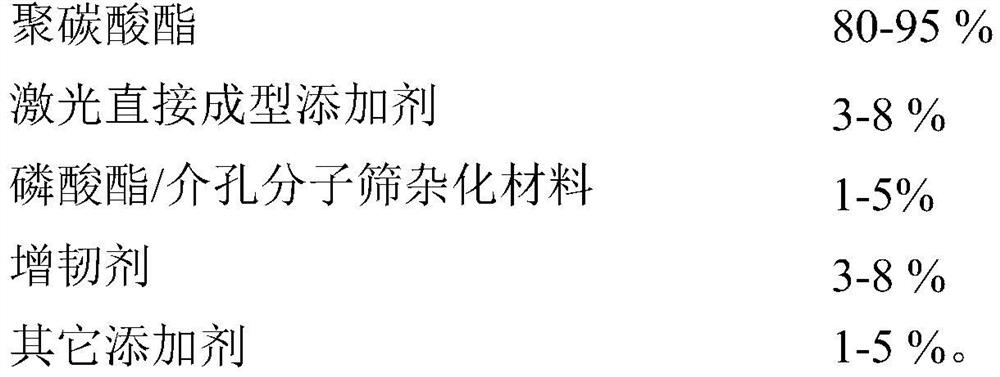

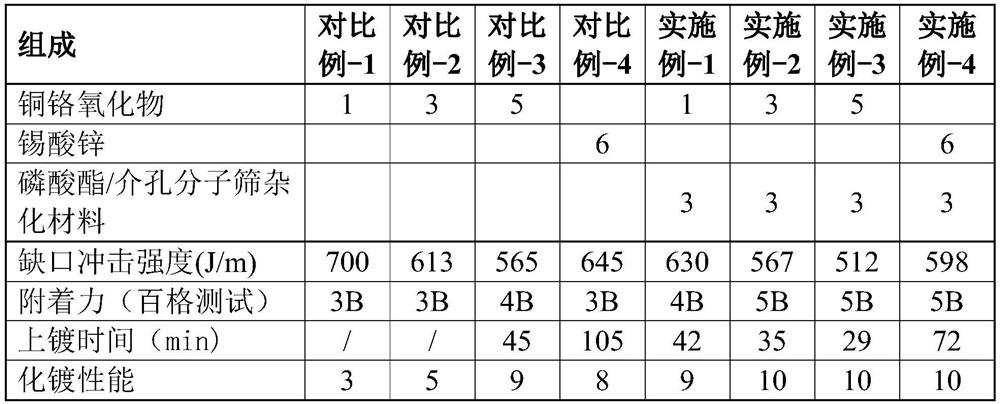

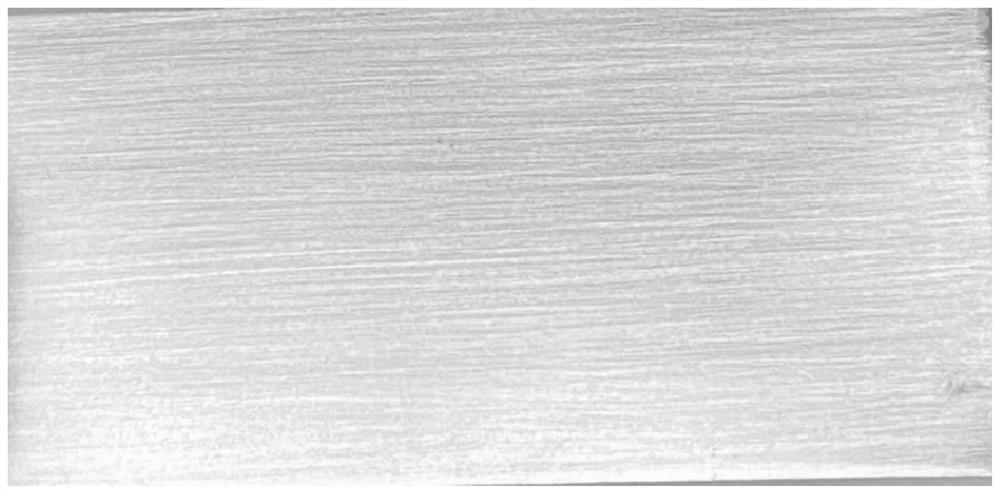

Mesoporous molecular sieve compound laser direct structuring material and application thereof

The invention discloses a mesoporous molecular sieve compound laser direct structuring material. The mesoporous molecular sieve compound laser direct structuring material is prepared from, by weight, 70-95% of polycarbonate, 1-10% of a laser direct structuring additive, 1-5% of a phosphate ester / mesoporous molecular sieve hybrid material, 1-15% of a flexibilizer and 0.5-5% of other additives. The phosphate ester / mesoporous molecular sieve hybrid material is prepared from phosphate ester and a mesoporous molecular sieve. The invention further discloses the phosphate ester / mesoporous molecular sieve hybrid material and a preparation method thereof. The mesoporous molecular sieve compound laser direct structuring material, the phosphate ester / mesoporous molecular sieve hybrid material and the preparation method thereof have the advantages that the phosphate ester / mesoporous molecular sieve hybrid material can promote the carbon formation action during laser activation, and is conductive to shortening the plating time; the special structure of the mesoporous molecular sieve is conductive to the adhesion of metal to the surface of a base material, and can significantly improve the bonding strength between a cladding layer and the base material.

Owner:无锡赢同新材料科技有限公司

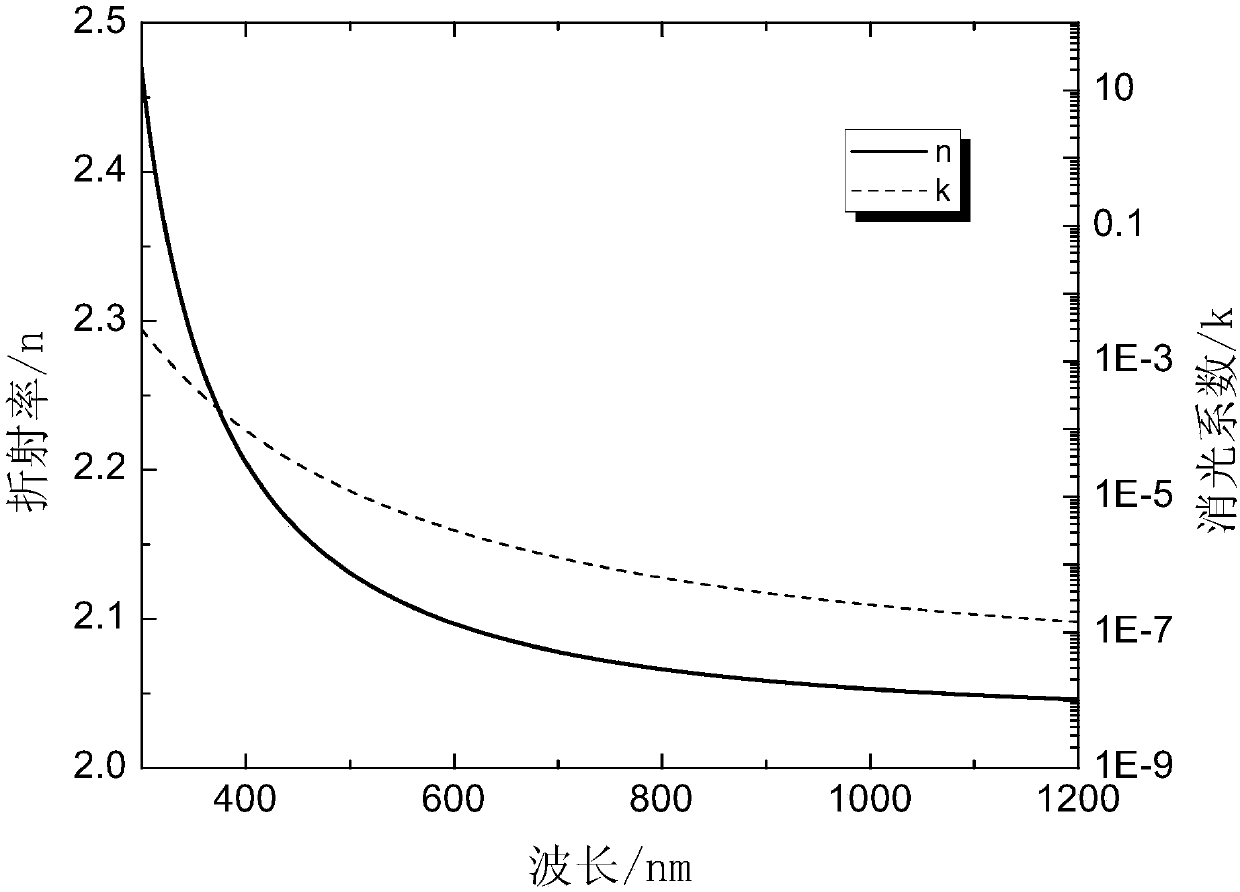

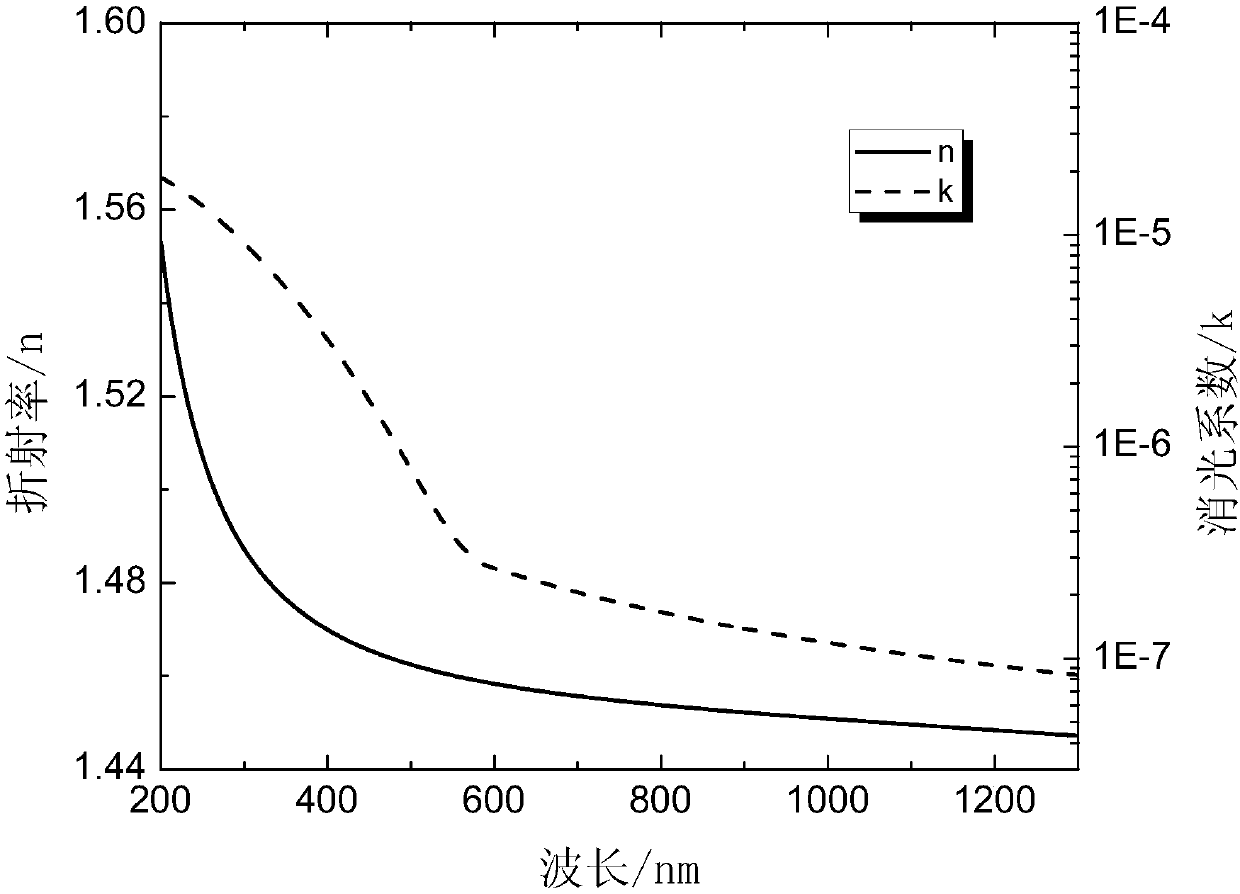

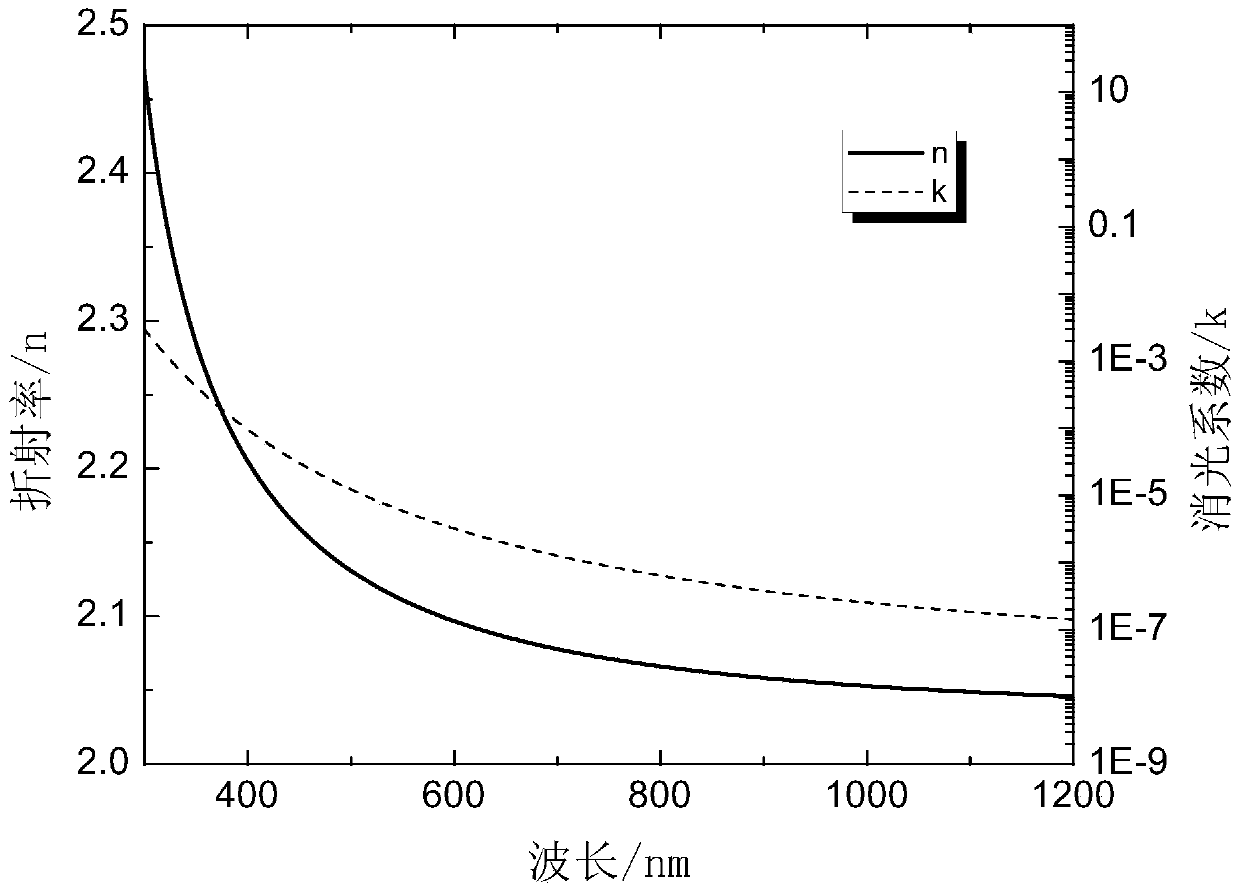

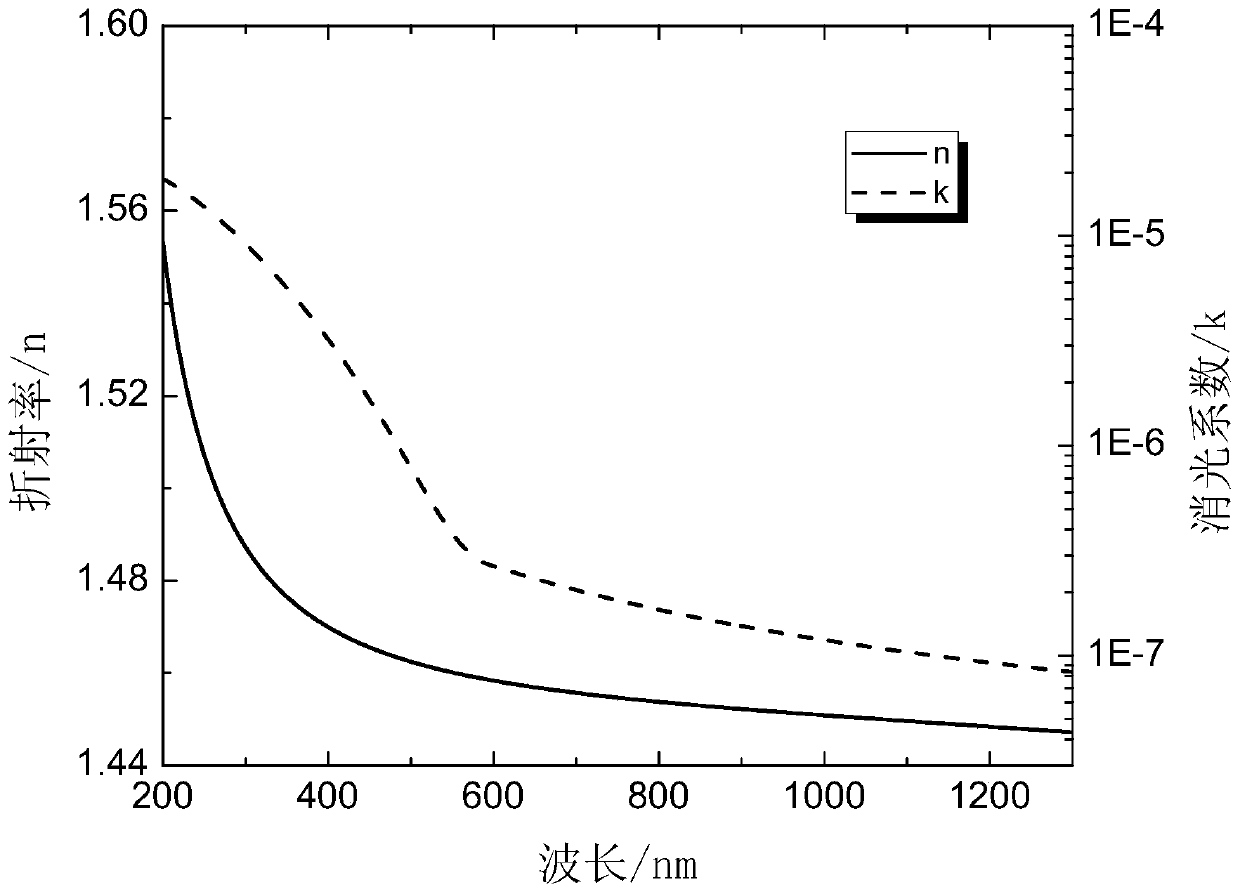

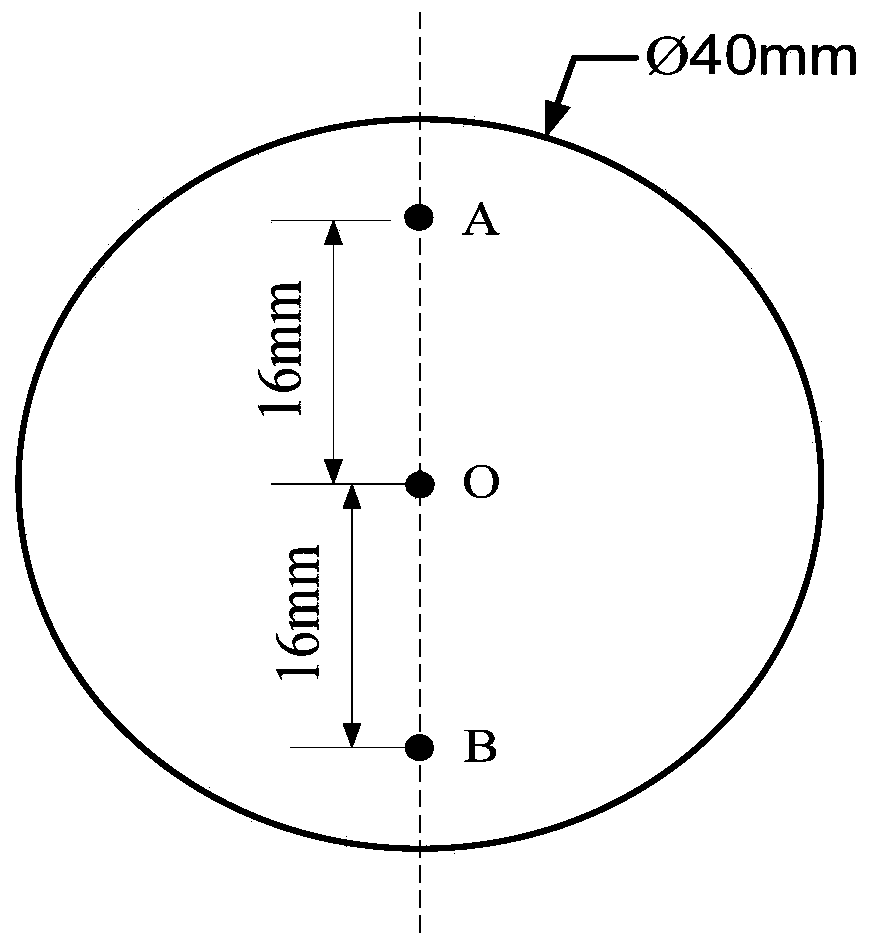

Large-aperture uniform optical filter and method for preparing same

The invention discloses a method for preparing a large-aperture uniform optical filter and belongs to the technical field of optical films. The method solves a possible transmittance decrease of the optical filter due to the slight drift of a central wavelength because of the high sensitivity of a large-aperture narrowband optical filter to the central wavelength. The method comprises plating a substrate with a half of a total film system and optically bonding the two plated films in opposite directions so as to help improve the uniformity of the large-aperture narrowband optical filter. Results show that the method contributes to the improvement of the uniformity of the large-aperture narrowband optical filter and achieves the preparation of the large-aperture uniform narrowband optical filter.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

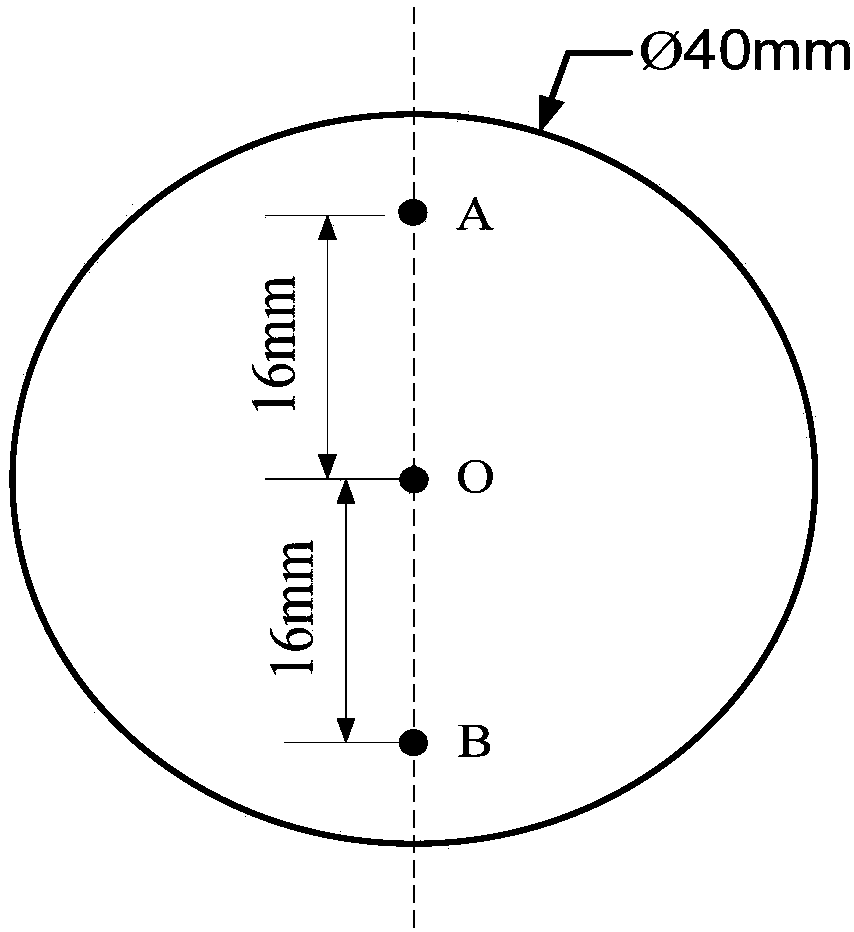

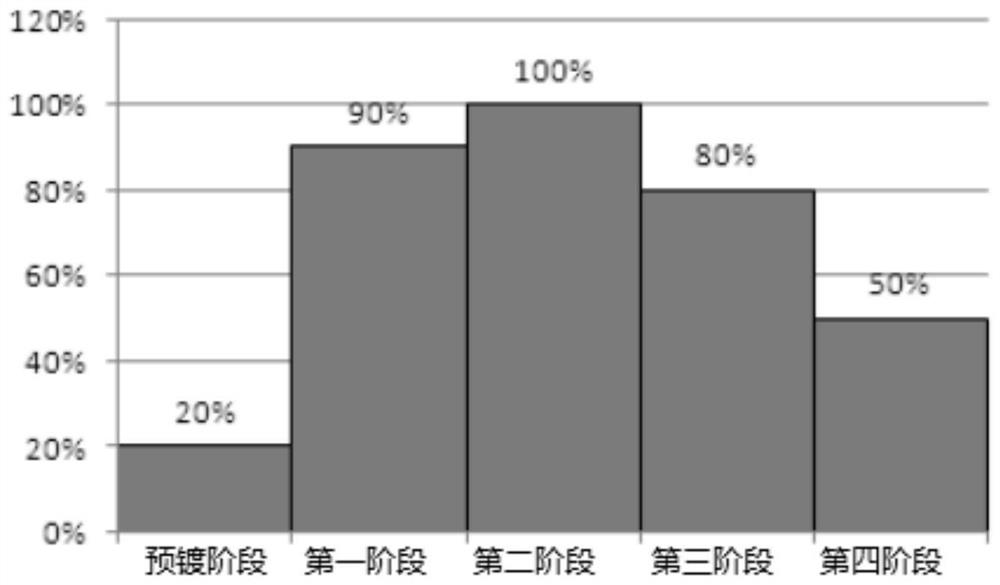

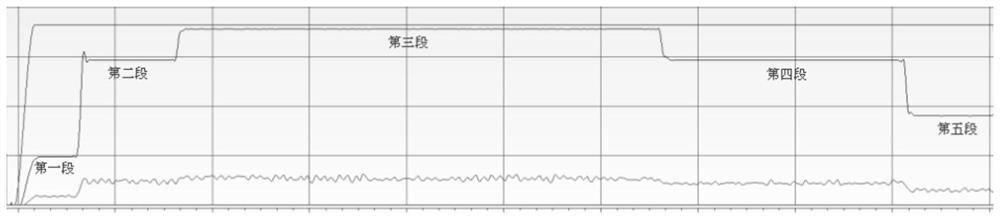

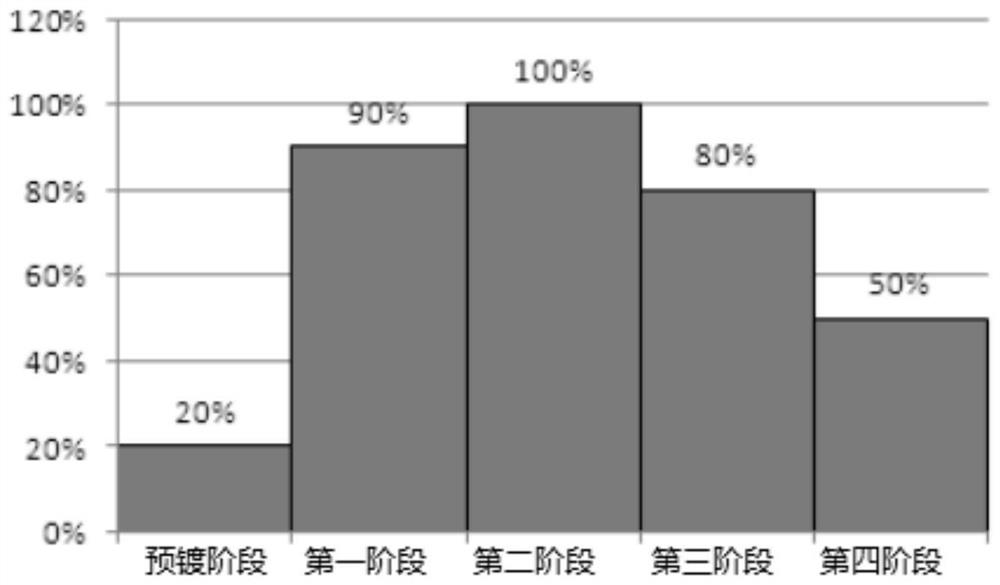

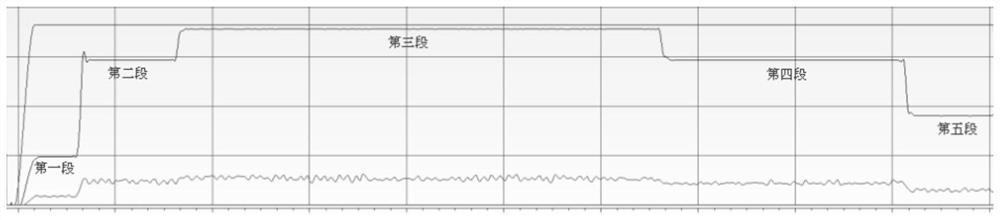

Multi-stage nickel plating process

The invention provides a multi-stage nickel plating process, and relates to the technical field of electroplating. An electroplating solution of the nickel plating process comprises nickel sulfamate,nickel bromide and boric acid. The electroplating process comprises the following stages of a pre-plating stage, a the first stage, a second stage, a third stage and a fourth stage; in the pre-platingstage, the current density is 0.1 ASD-0.2 ASD, the pre-plating time is 240 seconds-360 seconds; in the first stage, the current density is 0.4 ASD-0.7 ASD, the electroplating time is 840 seconds-960seconds; in the second stage, the current density is 0.5 ASD-0.8 ASD, the electroplating time is 4000 seconds-4600 seconds; in the third stage, the current density is 0.4 ASD-0.6 ASD, the electroplating time is 3200 seconds-3800 seconds; and in the fourth stage, the current density is 0.2ASD-0.4 ASD; and the electroplating time is 1200 seconds-2200 seconds. According to the multi-stage nickel plating process, a staged electroplating mode is set, so that a plating layer is prevented from being damaged by instantaneous current; and in the last two electroplating stages, correcting is carried outon crystals on the surface of the plating layer, so that burns on the surface of the plating layer are eradicated, and the welding performance is remarkably improved.

Owner:翔声科技(厦门)有限公司

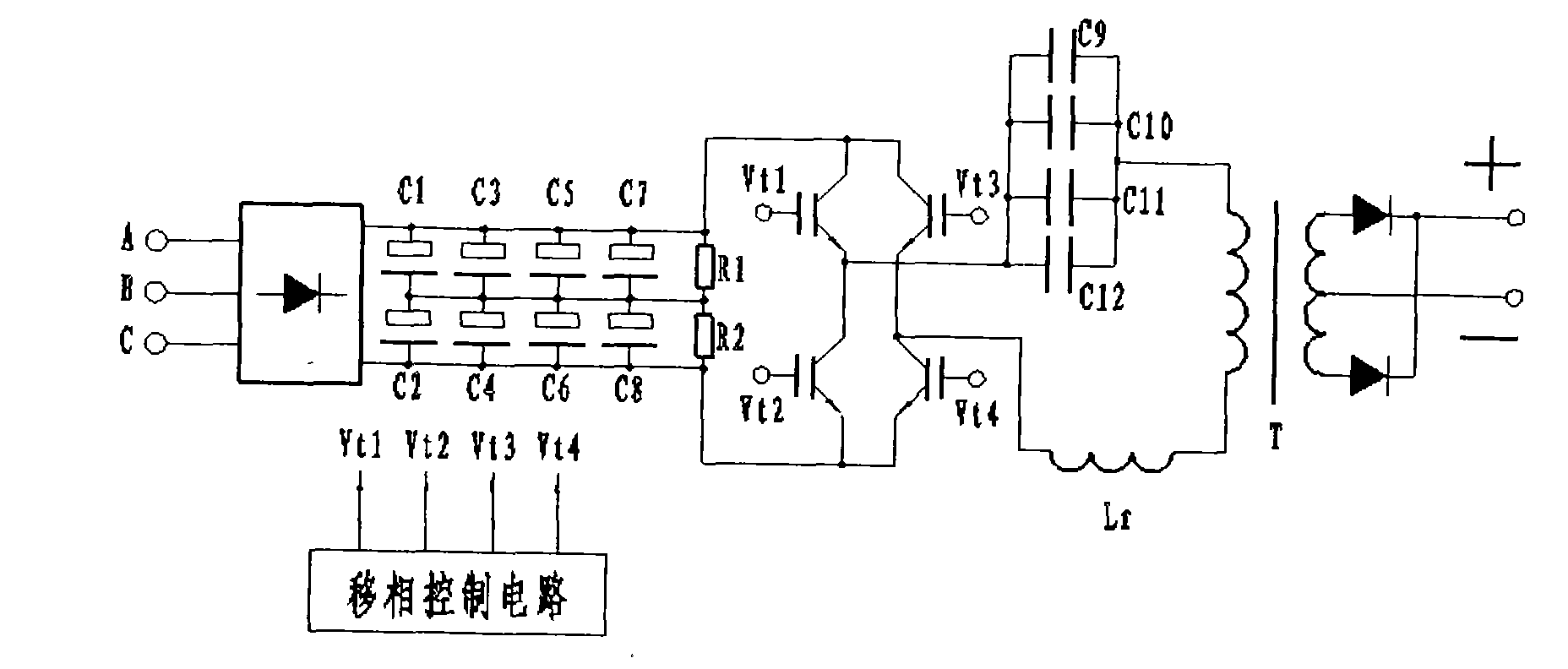

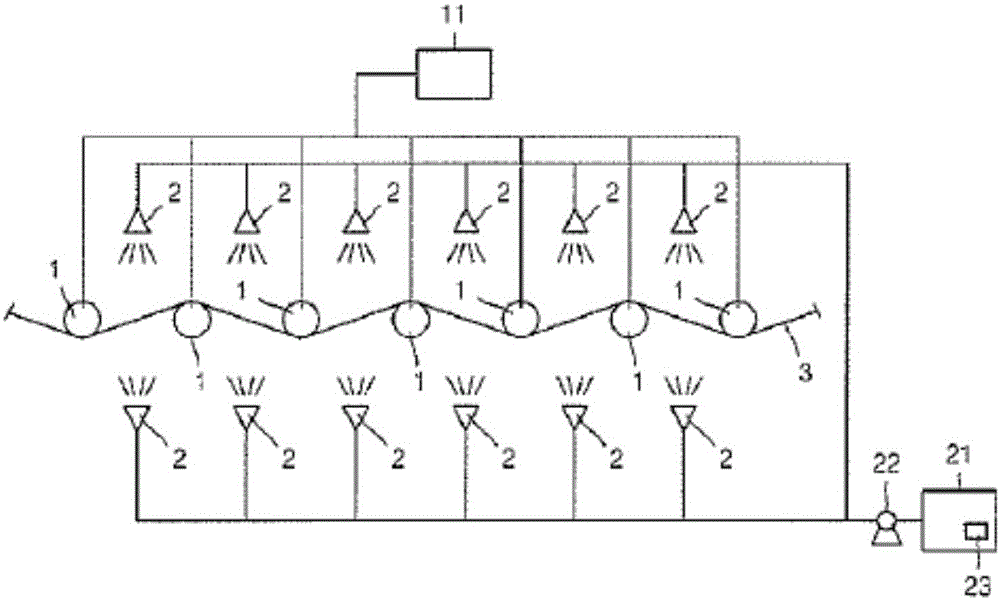

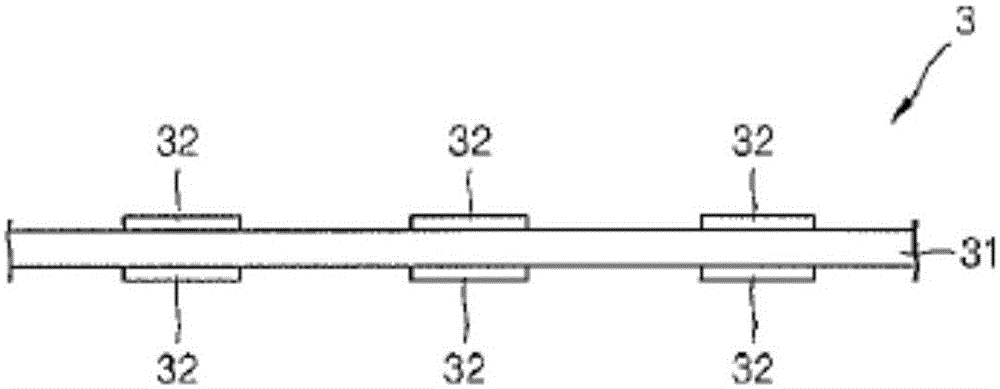

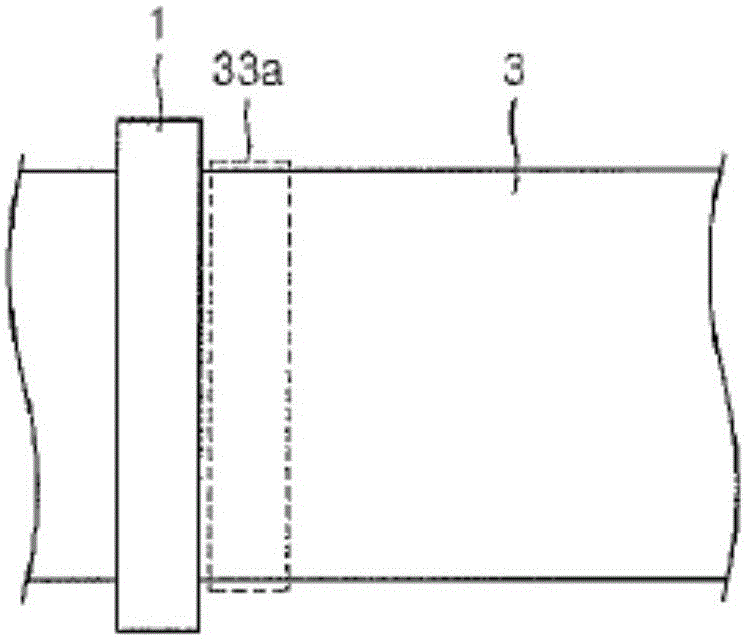

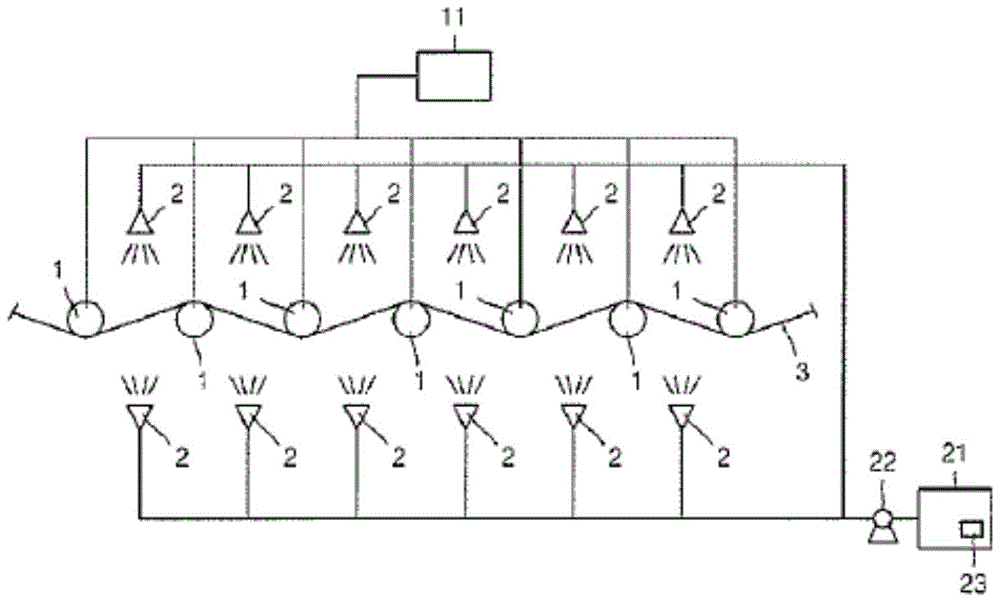

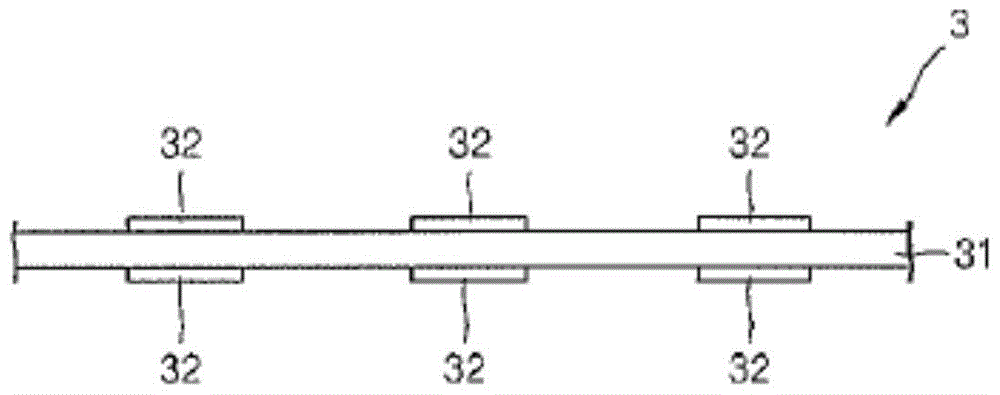

Apparatus and method for continuous plating

InactiveCN105143522AWide plating areaShort plating timePrinted circuit manufactureMuscle exercising devicesElectricityEngineering

The present invention relates to an apparatus and a method for continuous plating, the apparatus comprising: cathode rollers each having at least the outer surface thereof which is electrically conductive, and disposed so as to come into contact with an object to be plated; a first power source electrically connected to the outer surface of the cathode rollers so as to apply negative electricity thereto; spray units, positioned at a distance from the cathode rollers, for spraying a plating solution containing positive ions in the direction of the object to be plated; and a first storage tank, connected to the spray units, for supplying the plating solution to the spray units.

Owner:INKTEC CO LTD

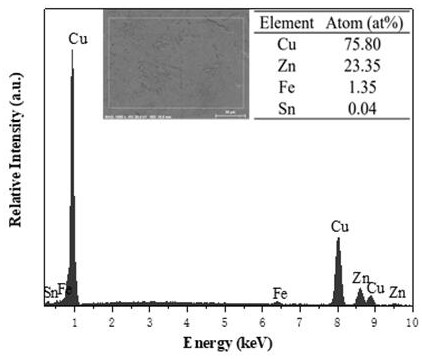

Cyanide-free gold-imitating copper-zinc-tin alloy electroplating process for surface of carbon steel

The invention discloses a cyanide-free gold-imitating copper-zinc-tin alloy electroplating process for the surface of carbon steel. The process comprises the following steps of: immersing pretreated carbon steel to be electroplated into an electroplating bath filled with a pre-plating solution, and electroplating at room temperature to obtain carbon steel with a pre-plated copper layer, wherein the pre-plating solution is prepared by dissolving copper sulfate, potassium hydroxide, carboxylate, a sulfur-containing grain refiner and an amine-containing brightener in deionized water; and immersing the carbon steel with a pre-plated copper layer into an electroplating bath filled with an electroplating solution, and electroplating at room temperature to obtain the carbon steel of which the surface contains a gold-imitating plating layer containing three elements of copper, tin and zinc, wherein the electroplating solution is prepared by dissolving potassium pyrophosphate, copper pyrophosphate, zinc sulfate, stannous pyrophosphate, hydroxyethylidene-1, 1-diphosphonic acid, an additive and a brightener in deionized water. The obtained plating layer is high in quality, golden and uniform in color and good in discoloration resistance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

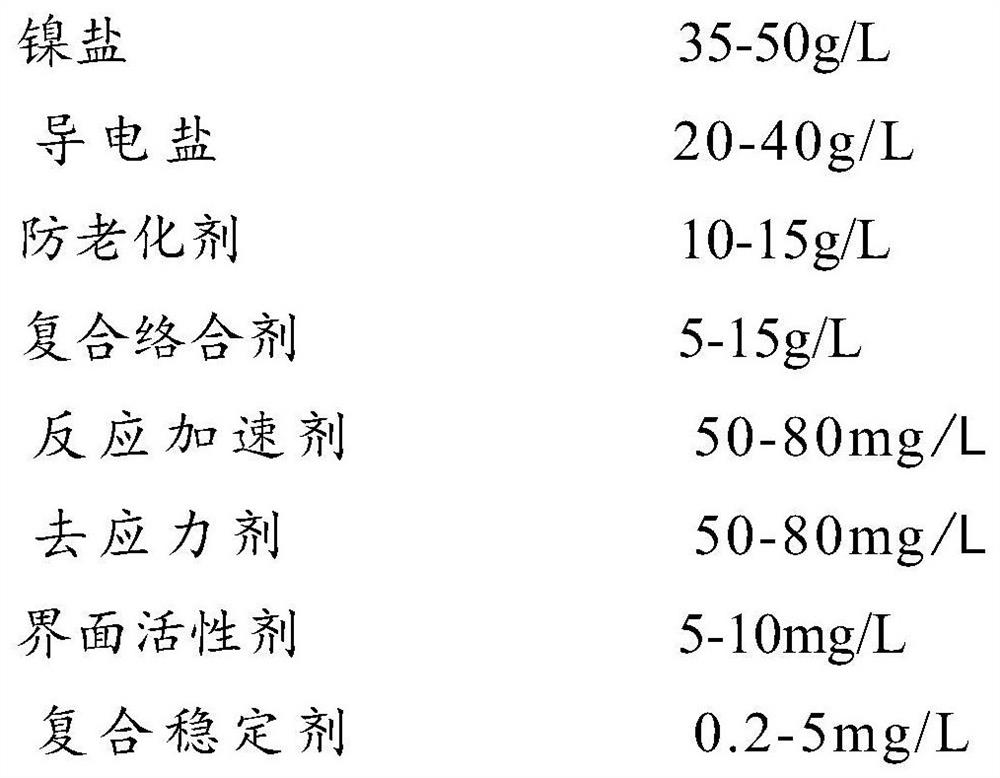

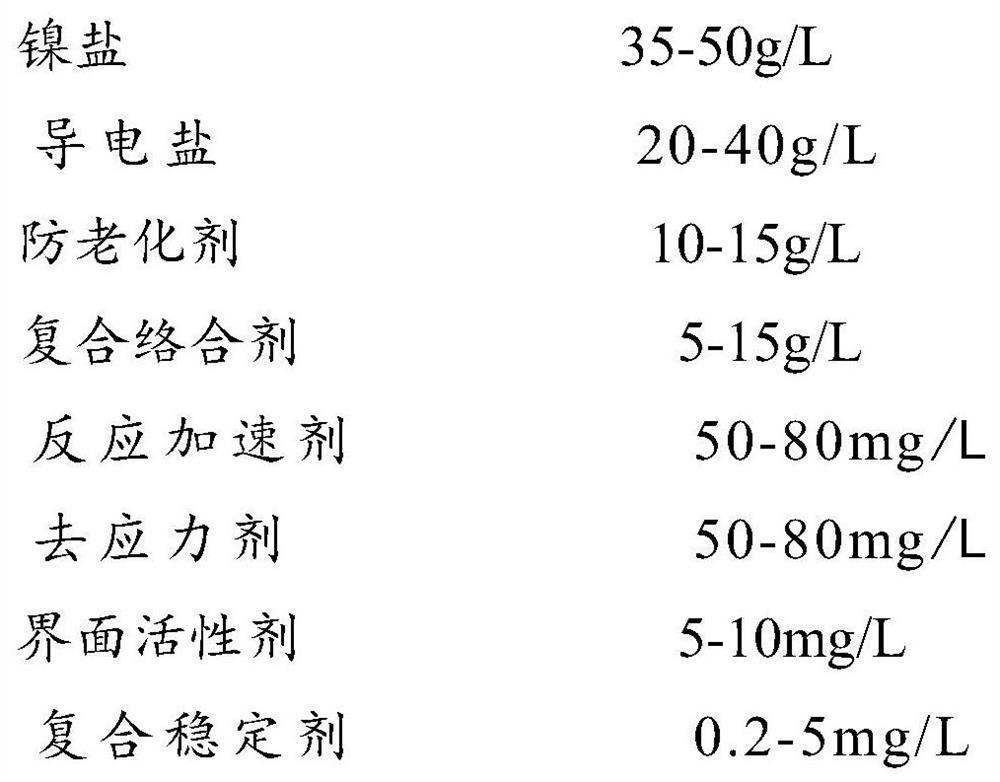

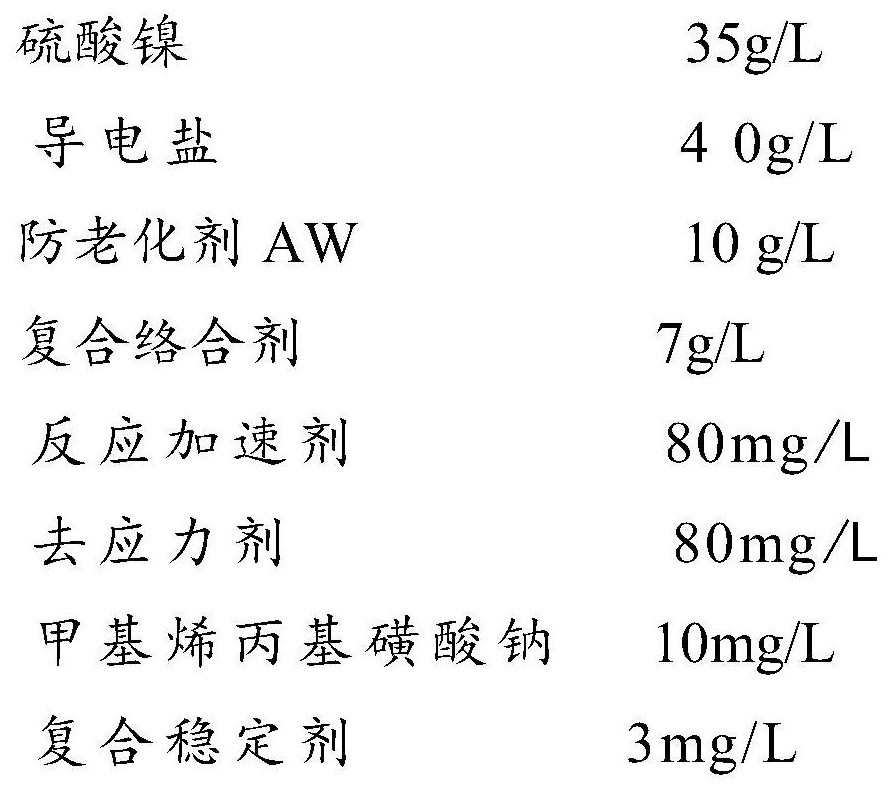

Nickel plating solution applied to printed circuit board and nickel electroplating method thereof

ActiveCN113789553ASpeed up the activation reactionStable bonding strengthPrinted circuit manufactureNickel saltMetallurgy

The invention discloses a nickel plating solution applied to a printed circuit board and a nickel electroplating method thereof. The nickel plating solution comprises the following components including, by mass concentration, 35-50 g / L of nickel salt, 20-40 g / L of conductive salt, 10-15 g / L of an anti-aging agent, 5-15 g / L of a composite complexing agent, 50-80 mg / L of a reaction accelerator, 50-80 mg / L of a stress relieving agent, 5-10 mg / L of a surfactant, and 0.2-5 mg / L of a compound stabilizer. The composite complexing agent comprises a component A and a component B, wherein the mass concentration ratio of the component A to the component B is 3: (1-2). The component A comprises, by mass concentration, 1-5 g / L of citric acid, 1-2 g / L of ammonium acetate, and 1-5 g / L of malic acid. According to the solution, the binding force strength between a plating layer and a base body is guaranteed, so that a nickel plating layer has good adhesiveness, and the plating layer is uniform. According to the process, the electroplating uniformity is guaranteed, and the electroplating time is shorter.

Owner:SHENZHEN CHENGGONG CHEM

Cyanogen-free imitation gold electroplating liquid and magnesium alloy electroplating technology thereof

The invention belongs to the technical field of metal surface electroplating, and relates to a cyanogen-free imitation gold electroplating liquid and a magnesium alloy electroplating technology thereof. The electroplating liquid comprises 200-300 g / L of potassium pyrophosphate, 18-24 g / L of cupric pyrophosphate, 1.5-2.6 g / L of stannous pyrophosphate, 40-50 g / L of zinc sulfate, 15-20 g / L of HEDP, 2-3 mL / L of AESS and 1-3 mol / L of imidazolium ionic liquid, and pH is 8-9. The electroplating technology comprises the steps that firstly, a magnesium alloy sample is sequentially subjected to oil removal, acid pickling and activation treatment; secondly, then, primary zinc immersion, zinc return and secondary zinc immersion treatment are conducted; and thirdly, the magnesium alloy sample obtainedafter zinc immersion treatment is electroplated for 10-180 s at the room temperature under the current density of 0.1-2A / dm<2>, and cleaning and dry blowing are conducted. The imitation gold electroplating liquid is friendly to the environment and good in stability; and an imitation gold electroplated layer obtained on the surface of a magnesium alloy through electroplating is high in quality, andthe color changing resisting performance is good.

Owner:广西南宁诚格五金制品有限公司

A Multilayer Nickel Electroplating Additive with Improved Stability

Owner:广州睿邦新材料科技有限公司

A multi-stage nickel plating process

The invention provides a multi-stage nickel plating process and relates to the technical field of electroplating. The electroplating solution of the nickel plating process includes nickel sulfamate, nickel bromide and boric acid. The electroplating process includes the following stages: pre-plating stage: current density is 0.1-0.2ASD, pre-plating time is 240-360s; first stage: current density is 0.4-0.7ASD; electroplating time is 840-960s; second stage: current The density is 0.5~0.8ASD, the plating time is 4000~4600s; the third stage: the current density is 0.4~0.6ASD; the plating time is 3200~3800s; the fourth stage: the current density is 0.2~0.4ASD; the plating time is 1200~ 2200s. By setting a staged electroplating method, the instantaneous current damage to the coating is avoided. In the last two electroplating stages, the crystallization of the coating surface is corrected to prevent burns on the coating surface and significantly improve the welding performance.

Owner:翔声科技(厦门)有限公司

A large aperture uniformity filter and its preparation method

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

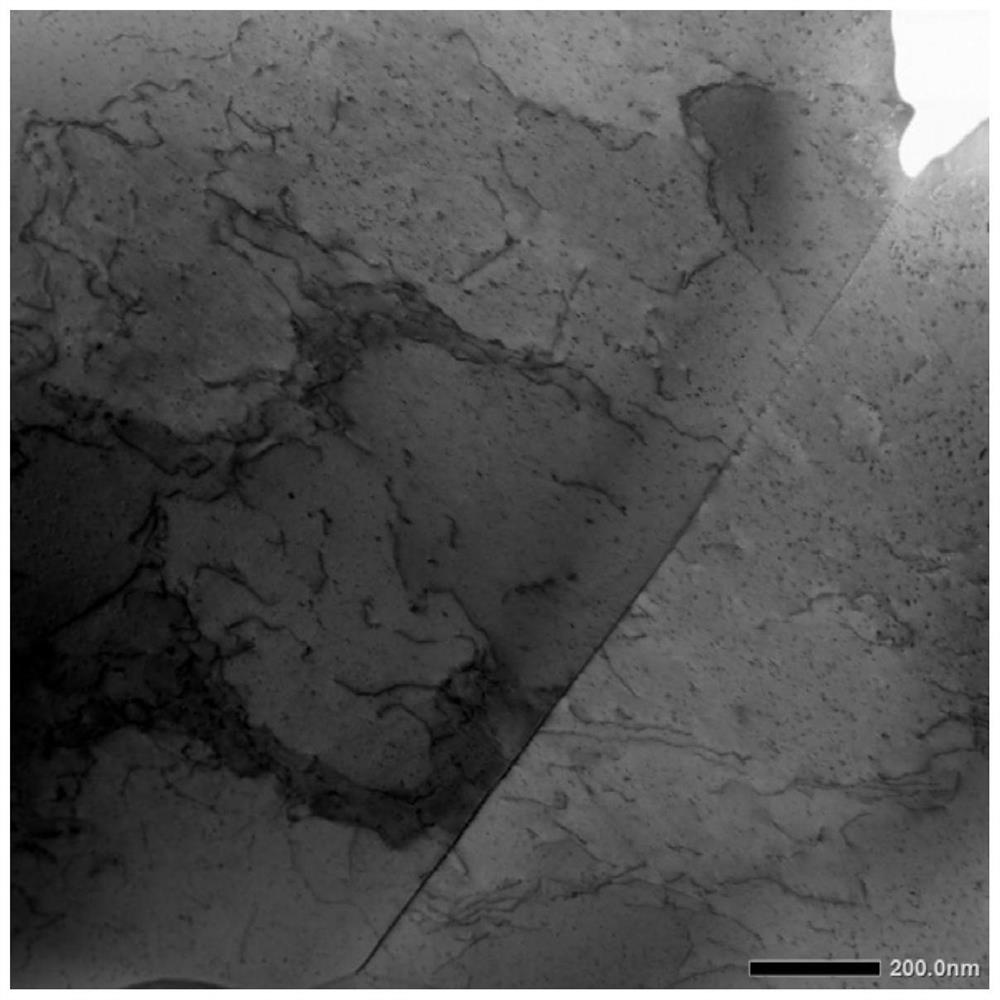

Copper element modified carbon fiber reinforced copper-based contact material and preparation method thereof

ActiveCN114045449AImprove bindingEnhanced interface bindingContact materialsLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a preparation method of a copper element modified carbon fiber reinforced copper-based contact material. The preparation method comprises the following steps: (1) pretreating carbon fibers; (2) placing the pretreated carbon fibers in a plating solution for chemical plating of a copper metal layer on the surfaces of the carbon fibers, cleaning and drying after copper plating is completed, and obtaining copper element modified carbon fibers; (3) mixing the copper element modified carbon fibers and electrolytic copper powder in an argon atmosphere according to a mass ratio of 2: (8-9); and (4) loading mixed copper element modified carbon fiber-copper powder into a high-strength graphite mold to be subjected to vacuum hot pressing sintering, and obtaining the copper element modified carbon fiber reinforced copper-based contact material after demolding. The invention further discloses the copper element modified carbon fiber reinforced copper-based contact material prepared by the method. According to the invention, the interface bonding between the carbon fibers and copper is improved, and the copper-based contact material with excellent performance is obtained.

Owner:JINAN UNIVERSITY

A cyanide-free chemical gold plating solution and its gold plating process applied in the field of wafer advanced packaging

ActiveCN113026068BAvoid narrow operating rangesQuickly achieve fillingCellsSemiconductor devicesCyanideActive agent

The invention discloses a cyanide-free chemical gold-plating solution and a gold-plating process applied to the field of advanced packaging of wafers. 10-60g / L; conductive salt 10-60g / L; buffer 30-60g / L; anti-aging agent 5-10g / L; surfactant 15-80mg / L; wetting agent 1-5mg / L; reaction Accelerator 50-80mg / L; Stabilizer 0.2-5mg / L; The reaction accelerator is a compound of 2,6-diaminopyridine and 3-pyridinemethanol, and 2,6-diaminopyridine and 3-pyridine The mass concentration ratio of methanol is 2:1. The solution obtained by the invention not only ensures the stability of the plating solution, but also makes it easy to spread the plated parts on the surface of the electrode to achieve the purpose of uniform plating, and further achieves the effect of filling the micropores of the wafer package without voids and gaps.

Owner:SHENZHEN CHENGGONG CHEM

A kind of nickel plating solution applied to printed circuit board and electroplating nickel method thereof

ActiveCN113789553BSpeed up the activation reactionStable bonding strengthPrinted circuit manufactureNickel saltMetallurgy

The invention discloses a nickel plating solution applied to printed circuit boards and a nickel electroplating method thereof, comprising components with the following mass concentrations: nickel salt 35-50g / L; conductive salt 20-40g / L; anti-aging agent 10 ‑15g / L; composite complexing agent 5‑15g / L; reaction accelerator 50‑80mg / L; stress reliever 50‑80mg / L; surfactant 5‑10mg / L; composite stabilizer 0.2‑5mg / L ; The composite complexing agent includes A component and B component, and the A component and the B component are 3:1-2 according to the mass concentration ratio; the A component includes a mass concentration of 1-5g / L citric acid, 1‑2g / L ammonium acetate, 1‑5g / L malic acid. The solution of the invention ensures the bond strength between the plating layer and the substrate, so that the nickel plating layer has good adhesion and uniformity of the plating layer; the process not only ensures the uniformity of electroplating, but also shortens the electroplating time.

Owner:SHENZHEN CHENGGONG CHEM

Mesoporous Molecular Sieve Composite Laser Direct Structuring Materials and Its Application

The invention discloses a mesoporous molecular sieve composite laser direct forming material, which comprises the following components in terms of weight percentage: 70-95% polycarbonate; 1-10% laser direct forming additive; 1-5wt% Phosphate ester / mesoporous molecular sieve hybrid material; 1-15wt% toughening agent; 0.5-5% other additives. The phosphate ester / mesoporous molecular sieve hybrid material is prepared from phosphate ester and mesoporous molecular sieve. The invention also discloses a phosphate / mesoporous molecular sieve hybrid material and a preparation method thereof. The beneficial effects of the present invention are: the phosphate / mesoporous molecular sieve hybrid material can promote the char formation in the laser activation process and help to shorten the plating time; at the same time, the special structure of the mesoporous molecular sieve is helpful for the metal to be deposited on the surface of the substrate. Adhesion, and can significantly improve the bonding strength between the coating and the substrate.

Owner:无锡赢同新材料科技有限公司

Acid zinc-nickel alloy electroplating additive and electroplating solution

PendingCN114525555ATo achieve the purpose of crystallization refinementImprove the leveling effectProcess efficiency improvementMetallurgyPolyethylene glycol

The invention relates to an acidic zinc-nickel alloy electroplating additive and electroplating liquid, and belongs to the technical field of electroplating. The acidic zinc-nickel alloy electroplating additive comprises 30-65 g / L of a brightening agent, 20-45 g / L of a coordination agent and 140-165 mL / L of a surface wetting agent according to the concentration in an electroplating solution, the brightening agent is prepared from 4 phenyl-3-butene-2-ketone, butynediol and o-phenylmethyl sulfimide, and the brightening agent is prepared from 4 phenyl-3-butene-2-ketone, butynediol and o-phenylmethyl sulfimide; the coordination agent is prepared from sodium salicylate, triethanolamine and sodium benzoate; the surface wetting agent is prepared from polyethylene polyamine, sodium ethanesulfonate and polyethylene glycol. The electroplating additive is suitable for an acidic zinc-nickel alloy plating seed, the purpose of crystal refinement of a plating layer is achieved through the coordination effect of the brightening agent, the coordination agent and the surface wetting agent, the leveling capacity and glossiness of the plating layer are effectively improved, the appearance of the plating layer is remarkably improved, and the plating layer has better flatness and glossiness; and plating can be performed at room temperature, the plating time is short, energy can be effectively saved, and the production efficiency is improved.

Owner:太仓鑫天健环保科技有限公司

A kind of cyanide-free imitation gold electroplating solution and its magnesium alloy electroplating process

The invention belongs to the technical field of metal surface electroplating, and relates to a cyanide-free imitation gold electroplating solution and a magnesium alloy electroplating process thereof. Electroplating solution includes: Potassium pyrophosphate 200~300g / L, copper pyrophosphate 18~24g / L, stannous pyrophosphate 1.5~2.6g / L, zinc sulfate 40~50g / L, hydroxyethylidene diphosphonic acid 15~20g / L, AESS 2~3mL / L and imidazole ionic liquid 1~3mol / L; pH is 8‑9. Electroplating process: (1) Degrease, pickle and activate the magnesium alloy sample in sequence; (2) Then perform zinc dipping, zinc stripping, and secondary zinc dipping treatments; (3) Magnesium after zinc dipping treatment Alloy sample at room temperature, current density 0.1‑2A / dm 2 Electroplating for 10‑180s, cleaning and drying. The imitation gold electroplating solution of the invention is environmentally friendly and has good stability; the imitation gold coating obtained by electroplating on the surface of the magnesium alloy has high quality and good discoloration resistance.

Owner:广西南宁诚格五金制品有限公司

Nickel-free ferrous tin-cobalt alloy plating solution and process for utilizing plating solution for electroplating

The present invention relates to a nickel-free ferrous tin-cobalt alloy plating solution and a process for utilizing the plating solution for electroplating. The plating solution comprises the following compositions: 0.2 to 6 g / L of tin, 0.6 to 4 g / L of cobalt, 8 to 180 g / L of complexant, 2 to 20 g / L of melanizing agent and 50 to 320 g / L of pH buffer. The parameters of the plating solution are as follows: the Baume of the plating solution is between 10 and 25 baume degrees; the temperature is between 28 and 48 DEG C; and the pH is between 10 and 13. The coating of the nickel-free ferrous tin-cobalt alloy plating solution is an alloy layer taking the tin as a main material, and a small amount of cobalt is added into the coating to form a binary alloy system; the cobalt content in a general ferrous tin-cobalt alloy plating solution exceeds 8 g / L, but the novel electroplating process can reduce the cobalt content to 0.8 g / L; and due to adoption of the special biodegradable stable complexant and the special biodegradable pH buffer, the production cost can be reduced, novel EU standards can be reached simultaneously, and various problems of the prior ferrous tin-cobalt alloy plating solution and the prior process can be solved.

Owner:佛山市兴中达化工实业有限公司

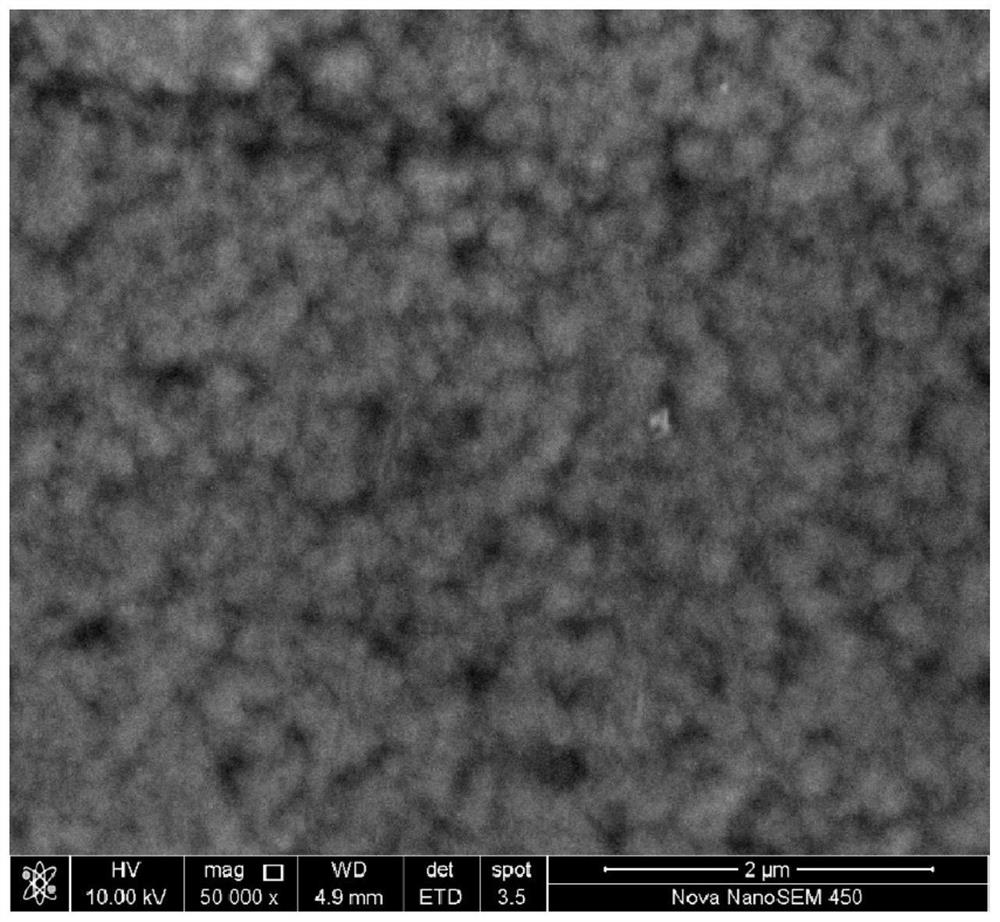

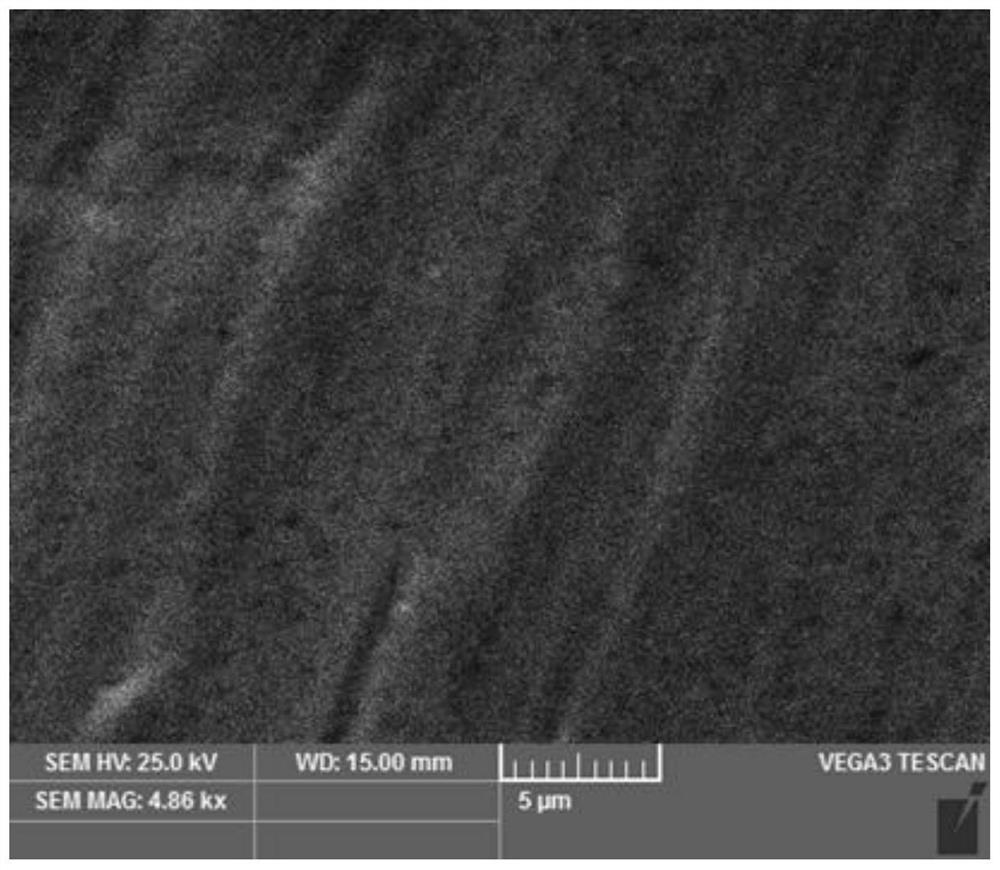

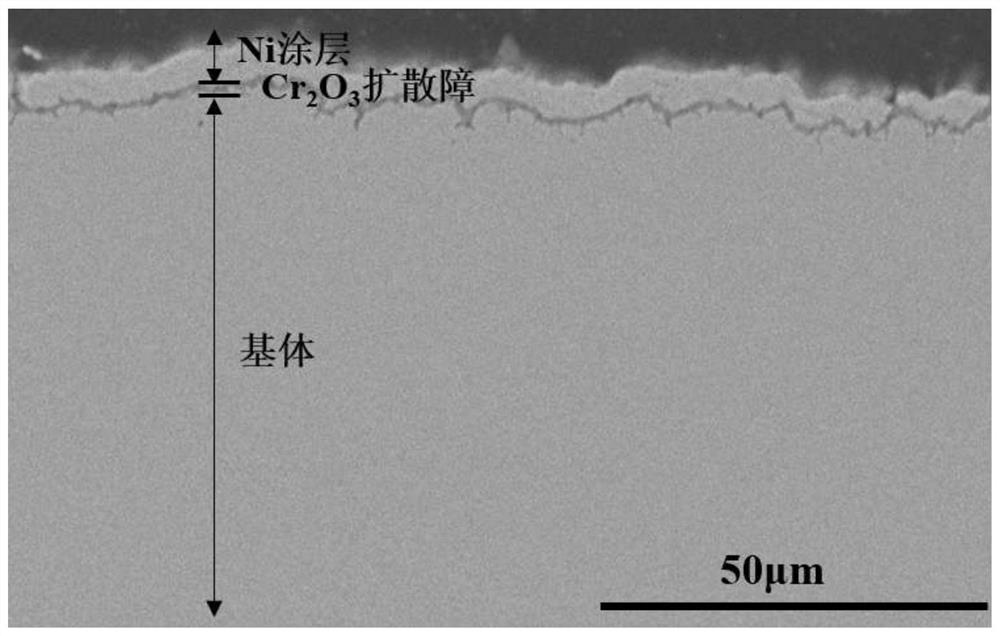

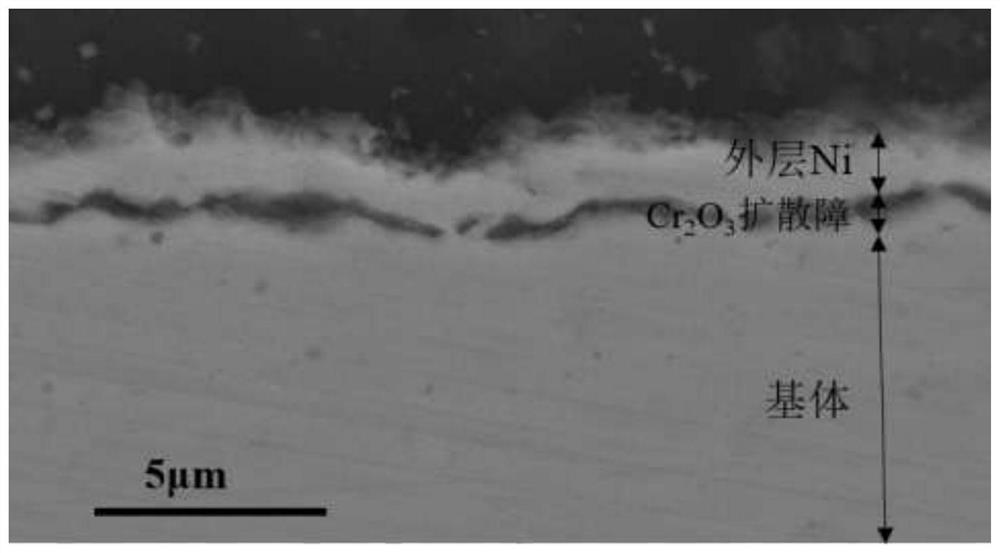

A preparation method for a composite coating for protection of Cr-containing stainless steel in molten fluoride salt

ActiveCN109943872BImprove controllabilityReduce porosityElectrolytic coatingsSS - Stainless steelDiffusion barrier

The invention discloses a preparation method of a composite coating for Cr-containing stainless steel protection in fused fluoride salt. The method comprises the following steps that (1) stainless steel is selected as a cathode base material, and a nickel sheet is selected as an anode base material; (2) the cathode base material and the anode base material are placed in a nano composite plating tank, nano composite pulse plating is carried out during stirring, and a Ni(NiO) transition layer is prepared; (3) the base materials are subjected to stirring and nickel plating in a bright nickel plating tank; and (4) the base materials are put in a container full of inert gas shielding to be subjected to heat treatment, the temperature of heat treatment ranges from 850 DEG C to 900 DEG C, the time of heat treatment is 8 h, Cr in the bas materials reacts with NiO in the transition layer, and then a Cr2O3 diffusion barrier is grown out on the surface in situ. According to the method, operationis simple and convenient; controllability of the plating layer is high; the anticorrosion effect is good; the electroplating time is reduced; few additives of plating liquid are needed; cost is reduced, and meanwhile pollution to the environment is reduced; and the compactness and binding force of the prepared coating are good.

Owner:GUANGXI UNIV

A kind of electroforming preparation method of silver solder with high indium content

InactiveCN106757205BKeep the glossImprove bindingWelding/cutting media/materialsSoldering mediaIndiumTube furnace

The invention discloses an electroforming preparation method of high-indium-content silver solder. The specific steps are as follows: (1) Electroplating is performed with the silver solder as the cathode and the indium plate as the anode. The composition of the electroplating solution is: In2+metal salt 20‑ 130g / L, 40‑120ml / L strong acid or 35‑65 g / L medium strong acid, 2‑80 g / L additive; 450°C high-temperature pipe for 30-50min; then placed in a tube furnace at 160-180°C for 6-10h; finally annealed at 450-500°C, and then rolled or drawn. The electroforming preparation method of the present invention has fast deposition rate, short plating time, high preparation efficiency, simple and convenient operation, and low cost, and solves the problems of low indium content and poor plasticity in the current AgCuZnIn solder, and the prepared solder The content of indium is high, which can reach 2.5-15%, and the solder has a low melting point, good plasticity, easy processing and preparation, and good wettability.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Continuous plating device

InactiveCN105143522BWide plating areaShort plating timePrinted circuit manufactureMuscle exercising devicesElectricityEngineering

The present invention relates to a continuous plating device and a continuous plating method. The continuous plating device includes: a cathode roll having at least an outer surface that is electrically conductive and the outer surface is in contact with a material to be plated; A first power supply, which is electrically connected to the outer surface of the cathode roller to apply cathode electricity to the outer surface; a spray unit, which is positioned in a manner spaced apart from the cathode roller, to the surface of the material to be plated directionally spraying a plating liquid containing anode ions; and a first storage tank connected to the spraying unit to supply the plating liquid to the spraying unit. According to the present invention, not only the plating area can be widened, but also the plating time can be reduced to maximize the efficiency.

Owner:INKTEC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com