Apparatus and method for continuous plating

A plating and plating solution technology, applied in gymnastics equipment, sports accessories, muscle training equipment, etc., can solve problems such as defective products, scratches, and long plating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in more detail with reference to the drawings.

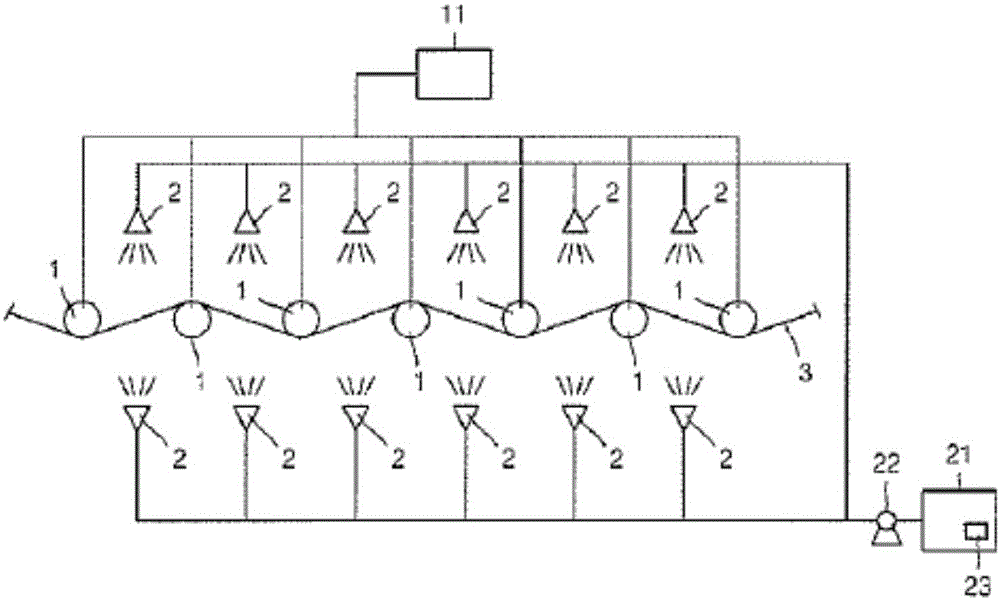

[0038] figure 1 It is a plan view schematically showing a continuous plating apparatus according to an embodiment of the present invention.

[0039] refer to figure 1 , the continuous plating device comprises a cathode roller (1) and a spray unit (2).

[0040] Such as figure 1 As shown, a plurality of the above-mentioned cathode roller (1) and spray unit (2) may be provided, but it is not necessarily limited thereto, and at least one or more may be provided.

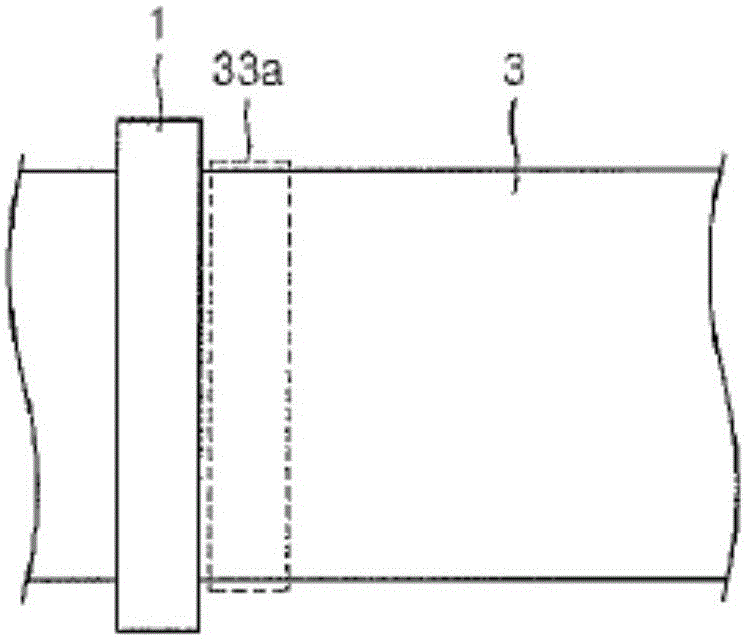

[0041] It is arranged so that the material to be plated (3) including the pattern to be plated (pattern) passes between the plurality of cathode rolls (1).

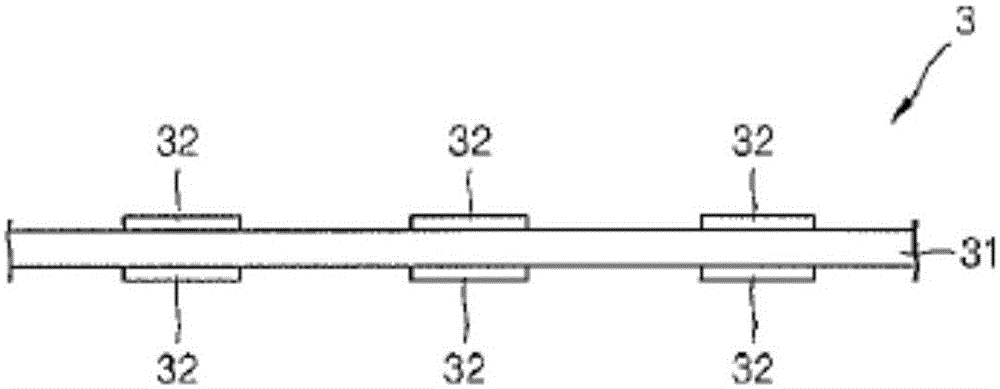

[0042] Such as figure 2 As shown, the material to be plated (3) may include a base member (31) in the form of a film, and a plurality of pads (32) formed on the surface of the base member. A plating layer may be formed at a contact point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com