Patents

Literature

54results about How to "Reduce cobalt content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

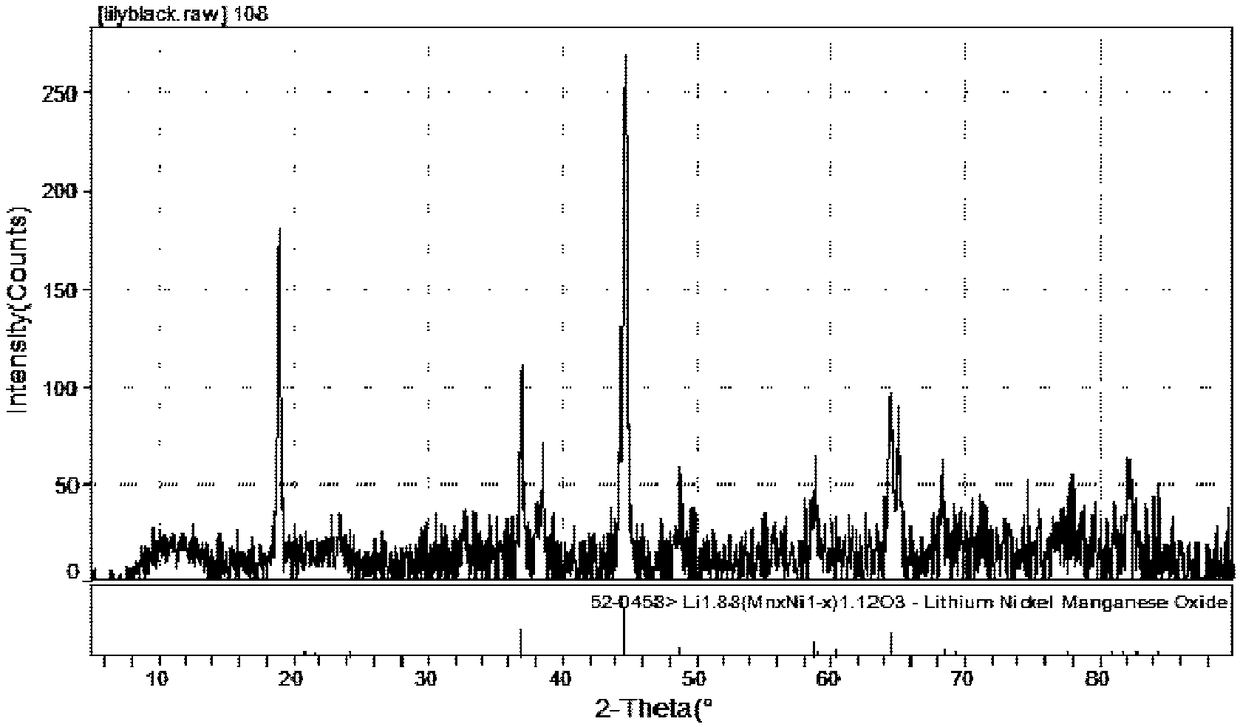

Lithium-rich manganese-based anode material and preparation method thereof

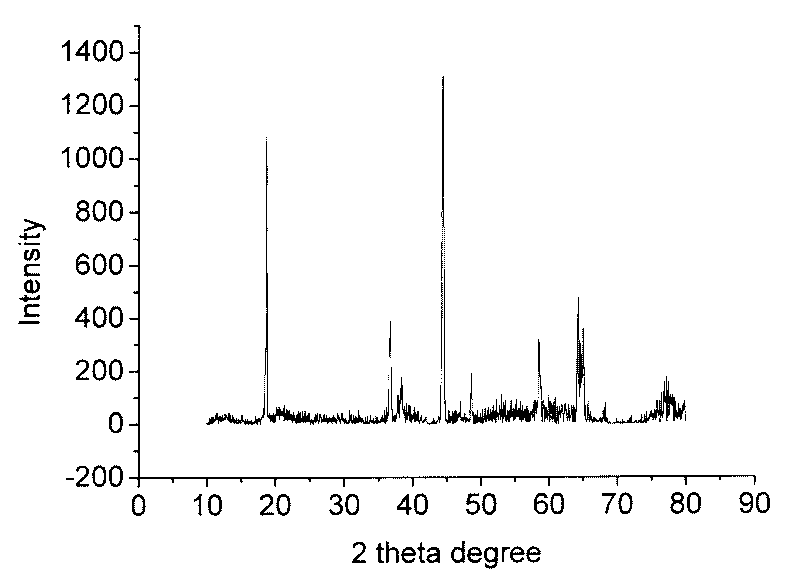

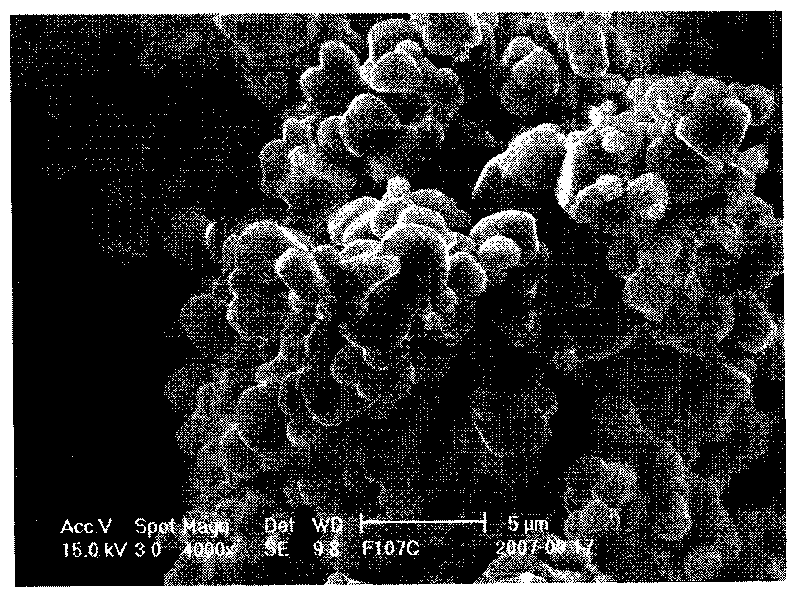

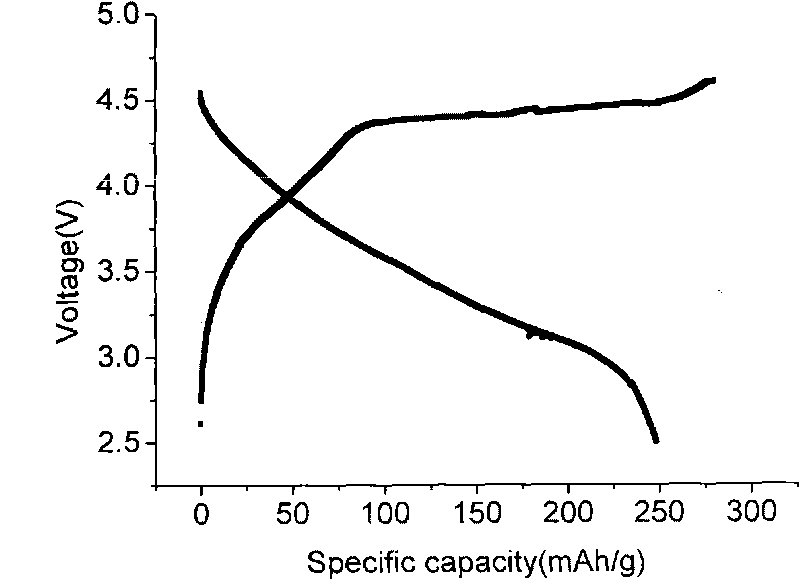

InactiveCN101694876AIncrease the charge cut-off voltageHigh specific capacityCell electrodesManganeseSpecific discharge

The invention relates to a lithium-ion secondary battery anode material technology, in particular to a lithium-rich manganese-based anode material Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu) and a preparation method thereof. A general formula of the lithium-rich manganese-based anode material is as follows: Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu), wherein x is more than 0 and less than or equal to 0.5, when M is Co and Al, y is more than 0 and less than 2x, a is equal to b, and b is equal to y / 2; when M is Ti, y is more than 0 and less than (2-x) / 3, a is equal to 0, and b is equal to y; and when M is Mg and Cu, y is more than 0 and less than x, a is equal to y, and b is equal to 0. The invention has high specific discharge capacity, excellent normal temperature and high temperature cycle performance, good safety, low raw material cost and production cost, and very high cost-performance ratio.

Owner:JIANGXI JIANGTE LITHIUM LON BATTERY MATERIAL +1

Gradient composite deposite for continuous casting crystallizer copper plate and production method thereof

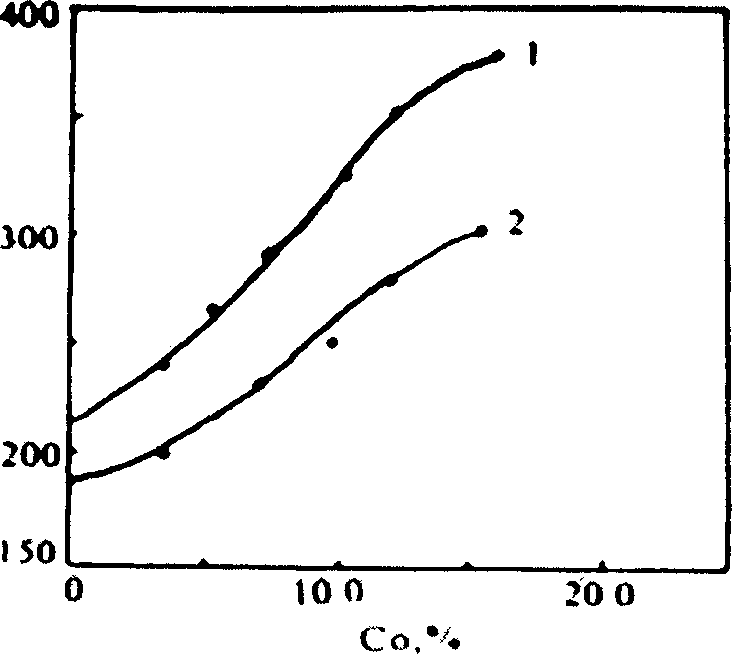

InactiveCN1500916AImprove the state of the structureImprove acceleration performanceElectrolytic coatingsSulfonatePre treatment

The gradient composite coating layer for continuous casting crystallizer copper plate contains Co in 50-79.9 vol%, Ni in 20-49.9 vol% and Al2O3 grains of size below 0.5 micron in 0.1-10 vol%. The coating is in gradient structure with outwards gradually increased Co and Al2O3 content and decreased Ni content. During production of the composite coating layer, inside amino sulfonate system with Al2O3 grains in 10-80 g / L and size below 0.5 micron added, gradient Co-Ni-Al2O3 coating is deposited onto copper or copper alloy via specific Al2O3 grain activating pre-treatment and electric deposition process. In the activating pre-treatment, FC-4 cation surfactant is used as ion dispersant. The composite Co-Ni-Al2O3 coating may be used in various high temperature wear resisting fields widely.

Owner:BAOSHAN IRON & STEEL CO LTD +1

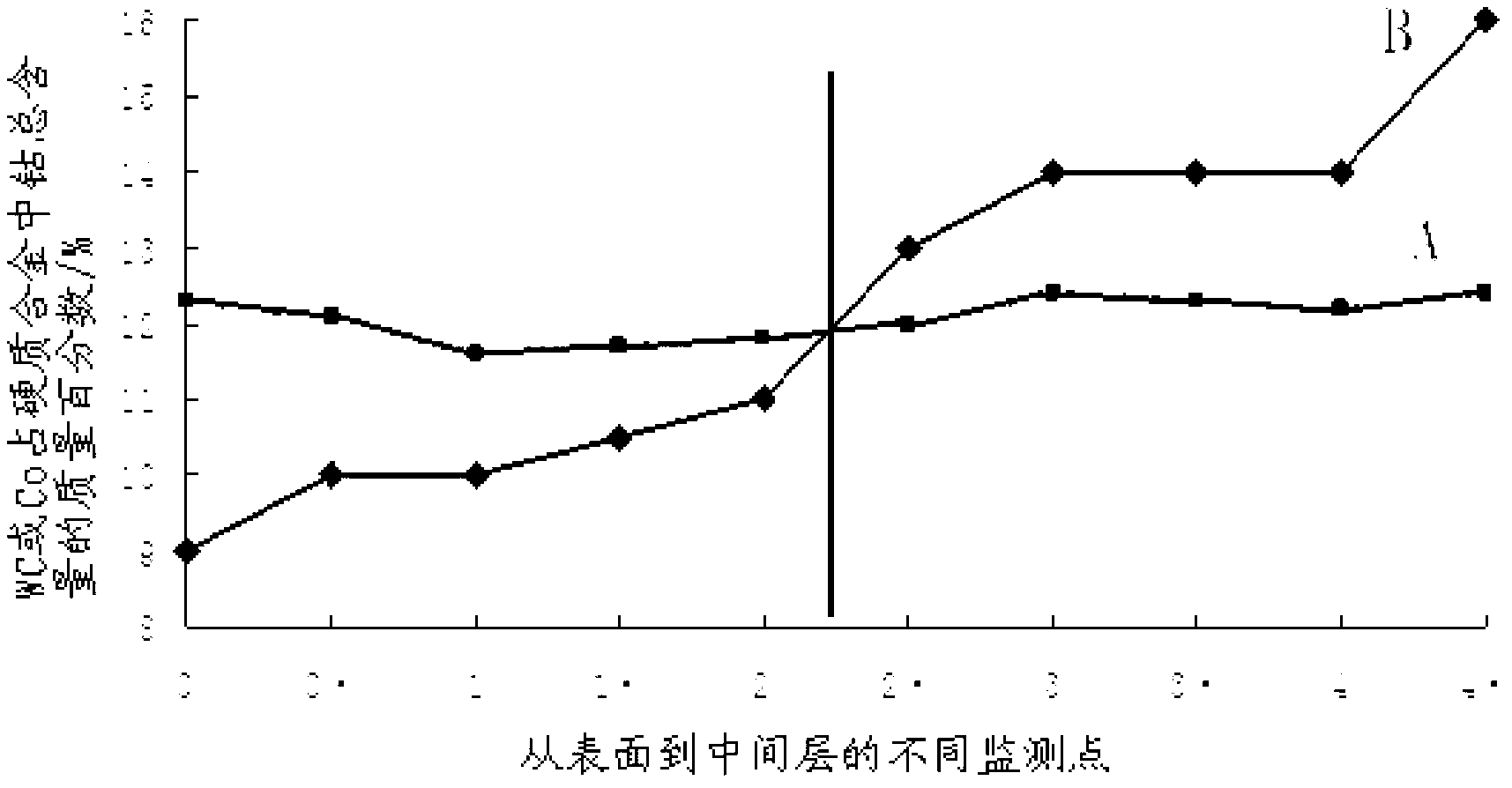

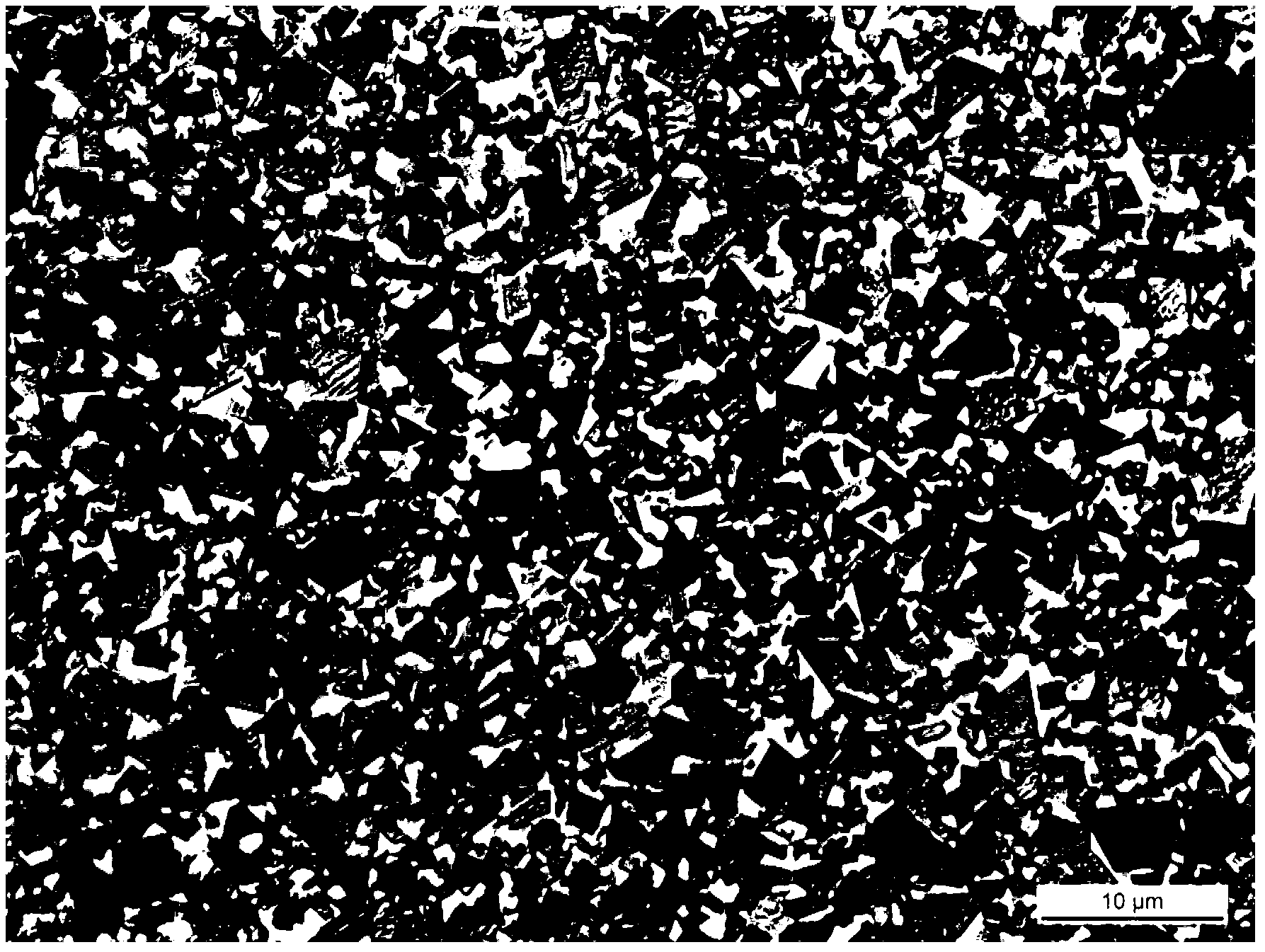

Cemented tungsten carbide alloy material with gradient cobalt content

ActiveCN102703790ANo porosityImprove mechanical propertiesSolid state diffusion coatingAlloyCemented carbide

The invention provides a tungsten carbide-cobalt hard alloy with gradient cobalt content, comprising the following components: 75-90wt% of WC and 6-15wt% of Co, wherein cobalt content is progressively increased from the surface of the hard alloy to the center of the hard alloy. The hard alloy disclosed by the invention has high wearability and high toughness. The invention also provides a preparation method of the tungsten carbide-cobalt hard alloy with the gradient cobalt content.

Owner:SEED TECH CORP LTD

Tungsten carbide base hard alloy powder metallurgical material and its preparation method

The invention provides a tungsten carbide based cemented carbide powder metallurgical material and method for preparation, wherein the the constituents (by weight percentage) include WC 86-95%, Co 4-8%, Al 1-3%, TiC 0-2%, and VC 0-2%. The preparing process consists of pre-grinding, mixing, ball-grinding, and finally consolidating through electric current flash sintering method.

Owner:SOUTH CHINA UNIV OF TECH

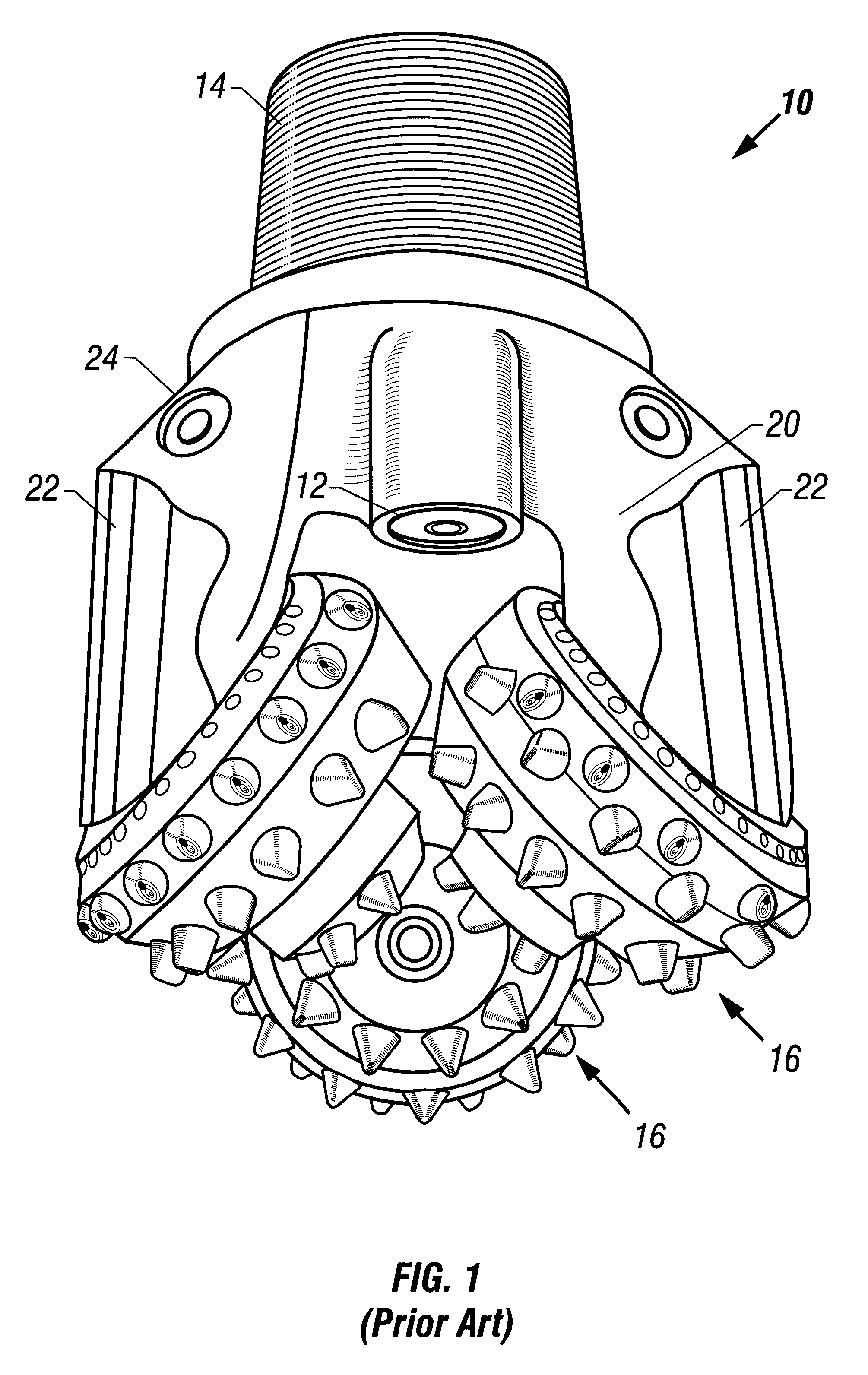

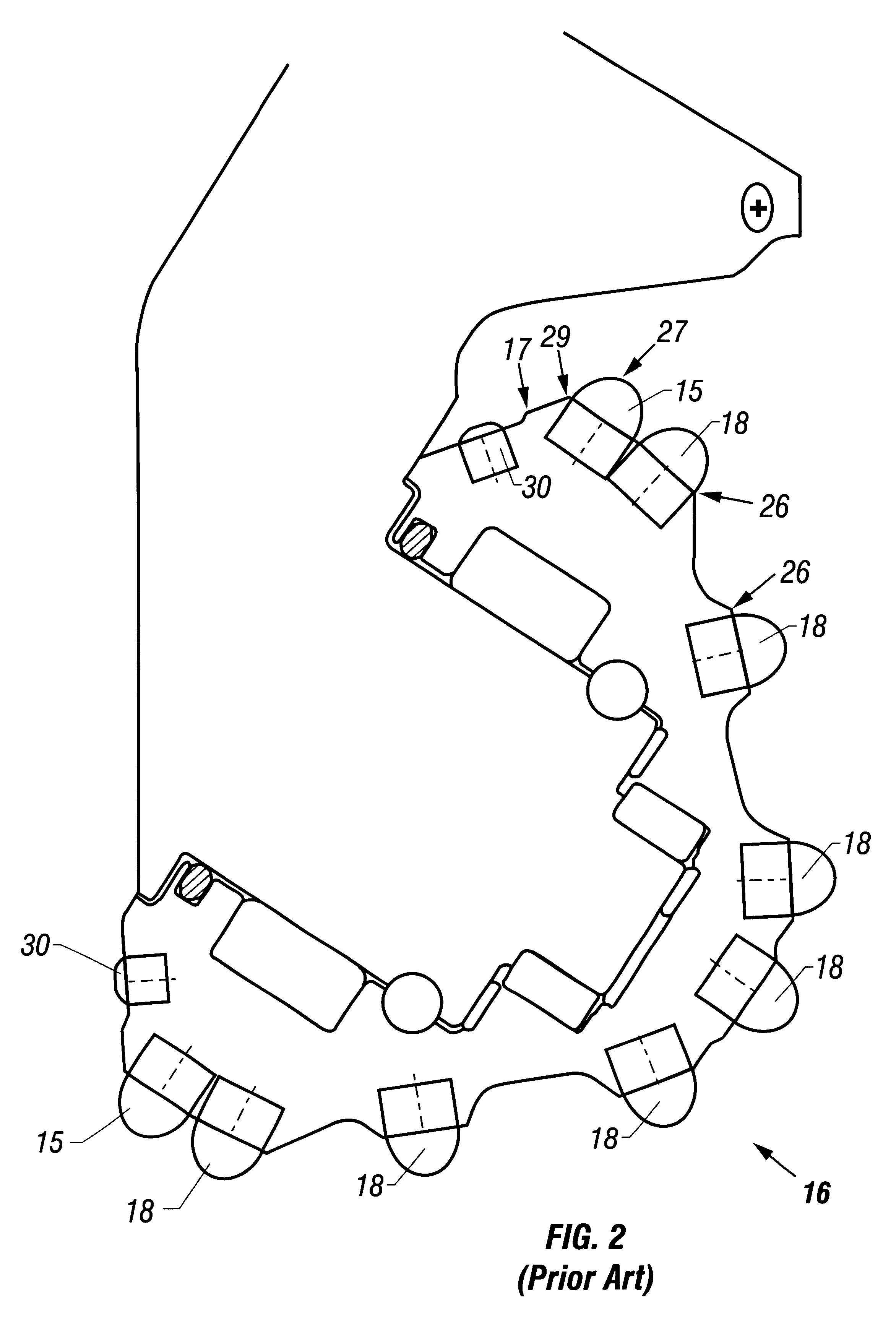

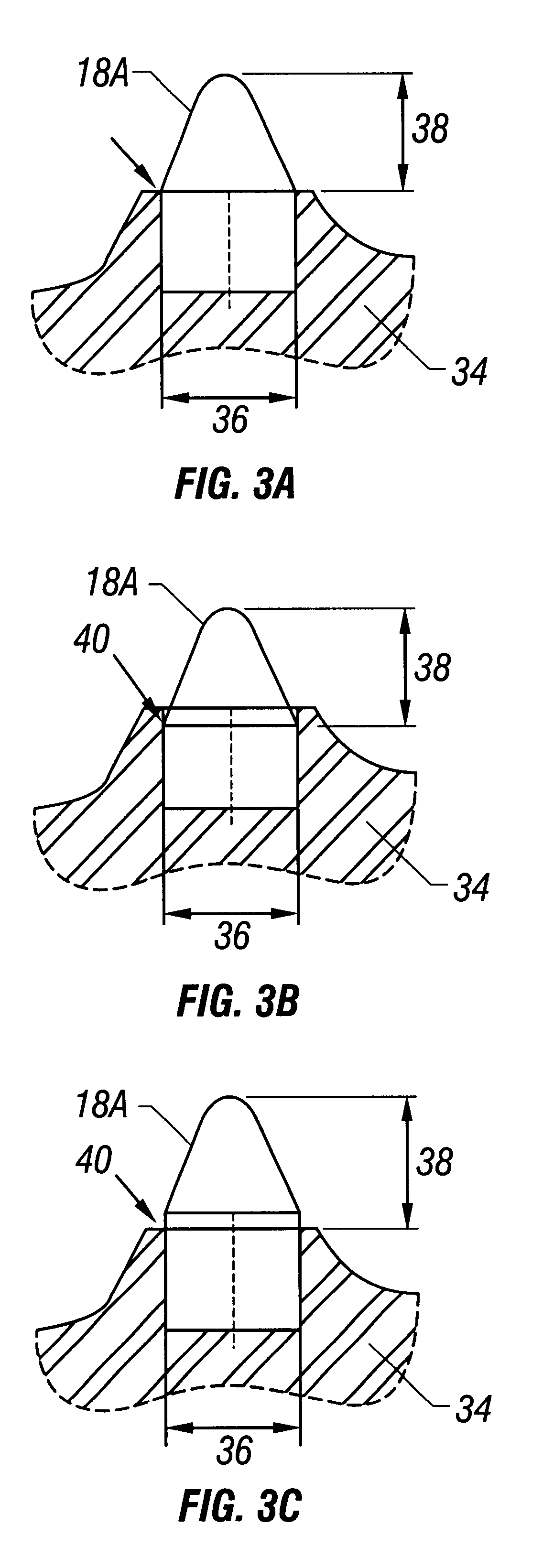

Earth-boring bit having cobalt/tungsten carbide inserts

InactiveUS6244364B1Improve thermal fatigue resistanceDecreasing resistanceDrill bitsConstructionsHardnessCobalt

An earth-boring device such as a drill bit is disclosed. The earth boring device includes a rotary main cutting structure, an insert on the main cutting structure. The insert is formed of a composition having tungsten carbide and cobalt. The cobalt makes up less than approximately 9% by weight of the composition. The composition has a Rockwell A hardness greater than approximately an Hmin as determined by the following formula: Hmin=91.1-0.63X, where X represents a cobalt content by weight of the composition.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method for preparing corrosion-resistant high-performance sintered neodymium iron boron magnets

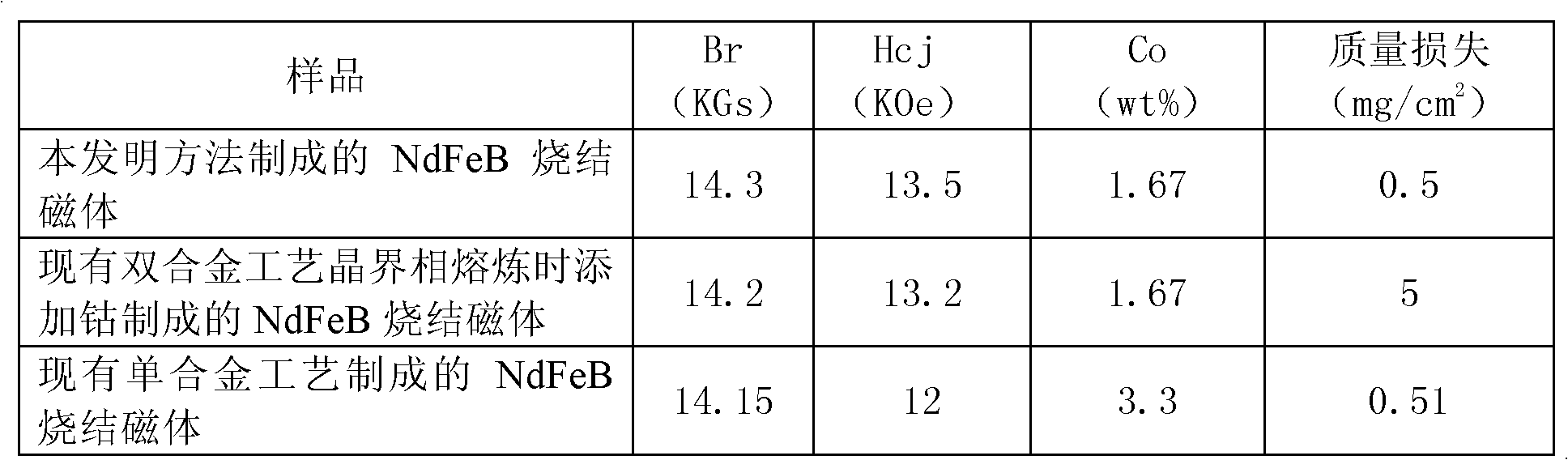

ActiveCN102568809AImprove corrosion resistanceReduce cobalt contentInductances/transformers/magnets manufactureQuenchingMaterials science

The invention relates to a method for preparing corrosion-resistant high-performance sintered neodymium iron boron magnets, which belongs to a preparation method. The method includes: melting main-phase alloy materials in a continuous casting furnace with blanks, casting the melted main-phase alloy materials to be main-phase alloy pieces, manufacturing crystal-boundary phase alloy materials to rapid-quenching crystal-boundary phase alloy bands; powdering the main-phase alloy pieces and the crystal-boundary phase alloy bands, adding the crystal-boundary phase alloy powder in the anaerobic environment into nanometer Co powder to be mixed uniformly, mixing the crystal-boundary phase alloy powder which is mixed with the nanometer Co with the crushed main-phase alloy powder uniformly, orienting and pressing the mixture into pressed blanks in the magnetic field of the anaerobic environment, feeding the pressed blanks into a vacuum sintering furnace in the anaerobic environment under the protection of the inert gas, and preparing high-corrosion-resistance neodymium iron boron magnets after sintering at high temperature three times and ageing twice. The sintered neodymium iron boron magnets prepared by the method are high in corrosion resistance and low in cost.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Nickel-free black tin cobalt alloy plating solution and electroplating technology by using same

The invention relates to a nickel-free black tin cobalt alloy plating solution and an electroplating technology by using same. The parameters and contents of all components of the plating solution are as follows: the content of tin ions in a tin salt is 0.05-6g / L; the content of cobalt ions in a cobalt salt is 0.05-0.8g / L; the content of third metallic ions is 0.02-50g / L; the content of a complexing agent is 0.1-180g / L; the content of a blacking agent is 0.1-50g / L; the content of a PH buffer is 5-300g / L; the baume degree of the plating solution is 6-250; the temperature is 20-55 DEG C; and PH is 9-13. According to the technology provided by the invention, tin is taken as a main alloy layer and few cobalt and third and fourth metal ions are added in tin to form a ternary or quaternary alloy system; the cobalt content in the common black tin cobalt alloy plating solution excesses 8g / L, but the cobalt content is reduced to 0.05g / L according to the new electroplating technology provided by the invention; the special biodegradable or non-biodegradable stabilizing complexing agent and PH buffer are used, so that the production cost is lowered; and the nickel-free black tin cobalt alloy plating solution meets the limitation requirement on CO in the European Union Rosh standard, Germany LMBG standard, Mattel children toy standard, European Oeko-Tex Standard 100 standard and the like.

Owner:杜强

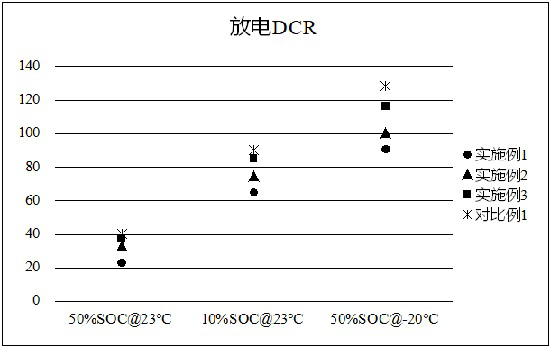

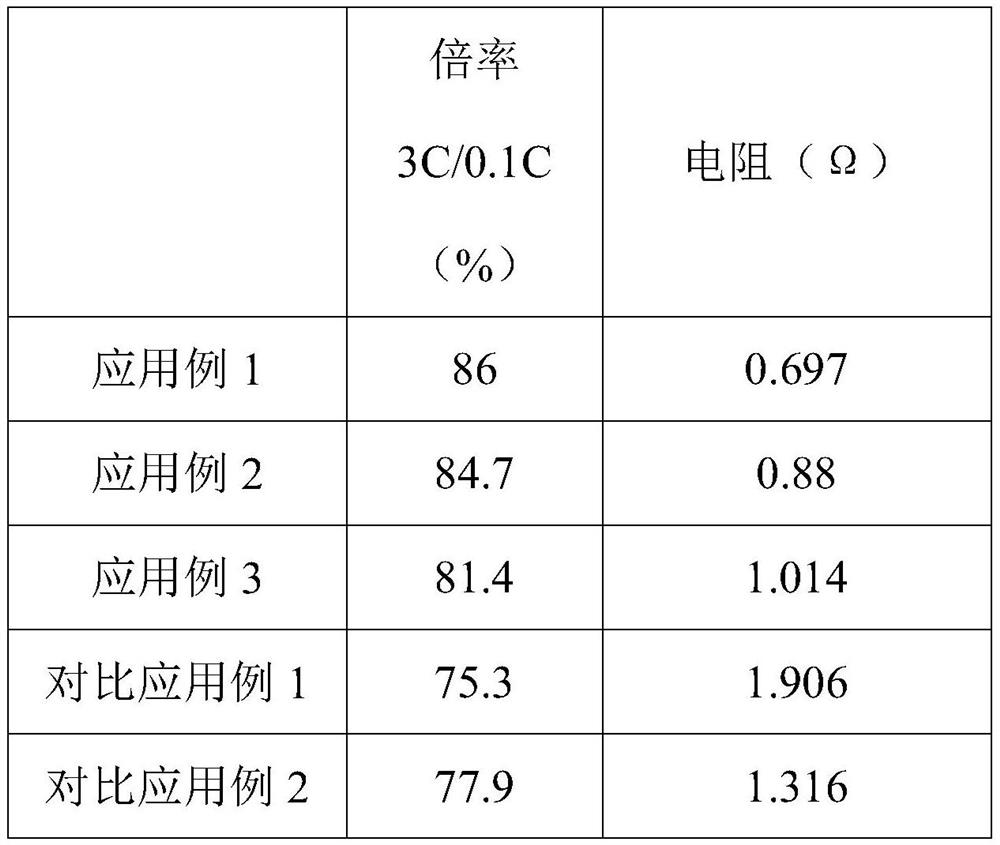

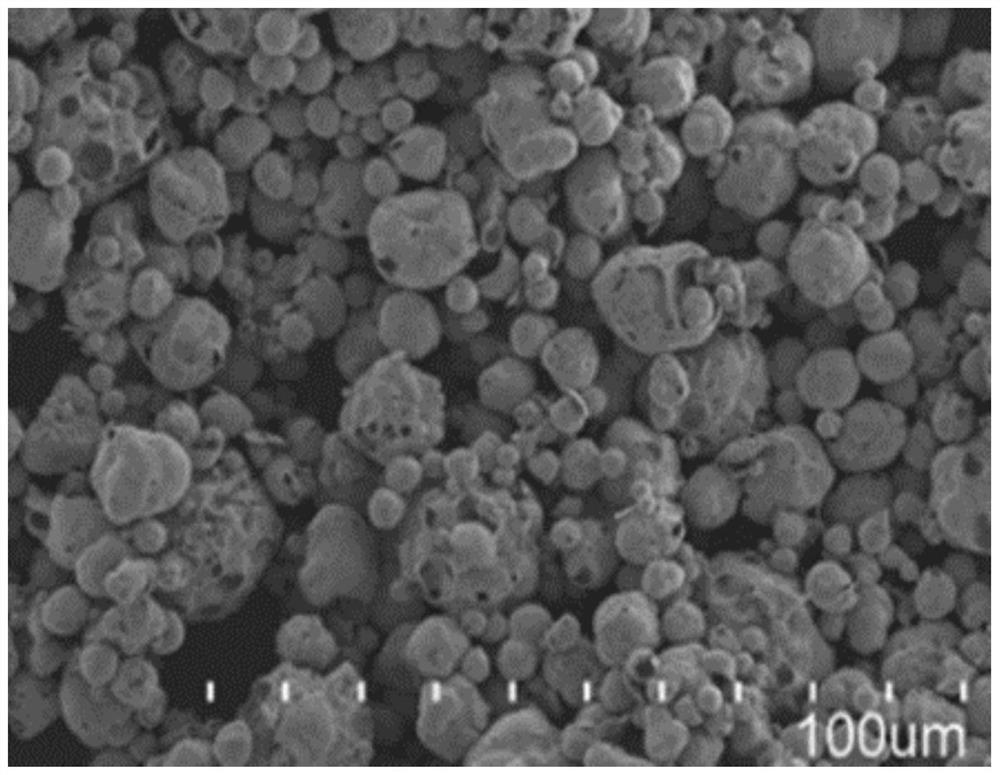

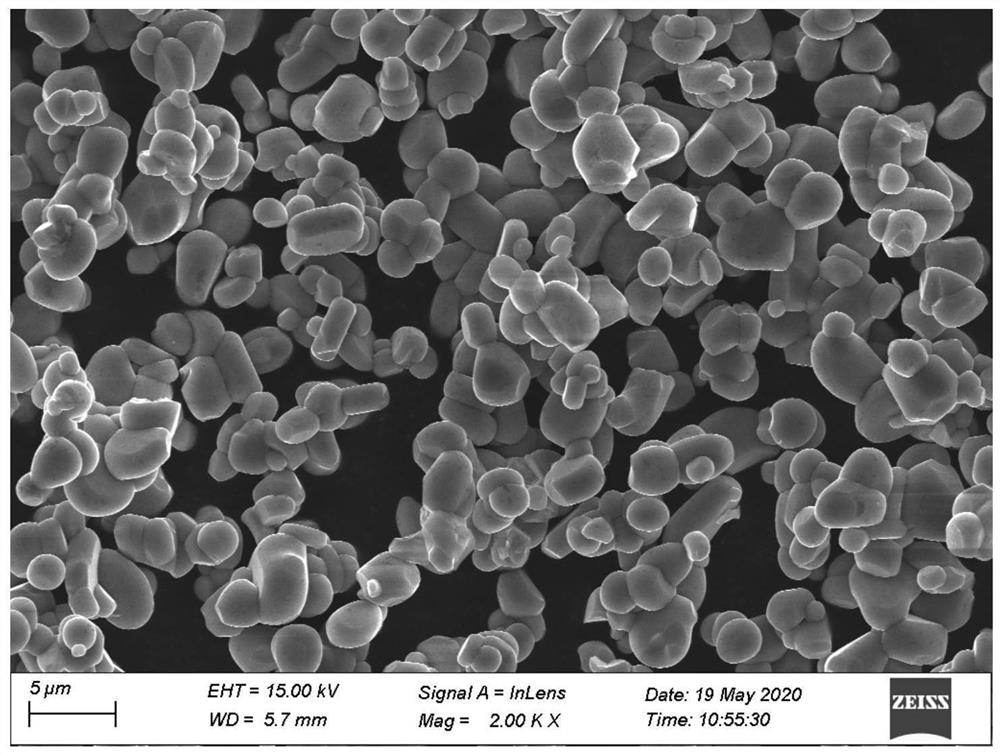

Anode material with uniform porous structure and preparation method thereof

InactiveCN113651373AImprove structural stabilityUniform porous structureSecondary cellsPositive electrodesOxalateManganate

The invention discloses a positive electrode material with a uniform porous structure. The morphology of the positive electrode material is the uniform porous structure, the secondary particle D50 of the material is 2-15 [mu] m, and the porosity of the positive electrode material is 1.5-5%. The preparation method comprises the following steps: synthesizing a nickel-cobalt-manganese oxalate precursor with a compact structure by adopting a coprecipitation method, subjecting the oxalate precursor with the compact structure and a metal oxide doped with elements to mixing and presintering to obtain a doped nickel-cobalt-manganese oxide precursor with a uniform porous structure; and uniformly mixing the doped nickel-cobalt-manganese oxide precursor having the uniform porous structure with a lithium salt, carrying out primary sintering, carrying out mixing with a coating compound, and carrying out secondary sintering to finally obtain the doped and coated nickel-cobalt-lithium manganate positive electrode material with the uniform porous structure. The process of the method is simple, cost is relatively low, the performance of the material is obviously improved, and the prepared nickel-cobalt-lithium manganate positive electrode material with the uniform porous structure still has excellent rate capability and output power under the condition of low cobalt content.

Owner:HENAN KELONG NEW ENERGY CO LTD

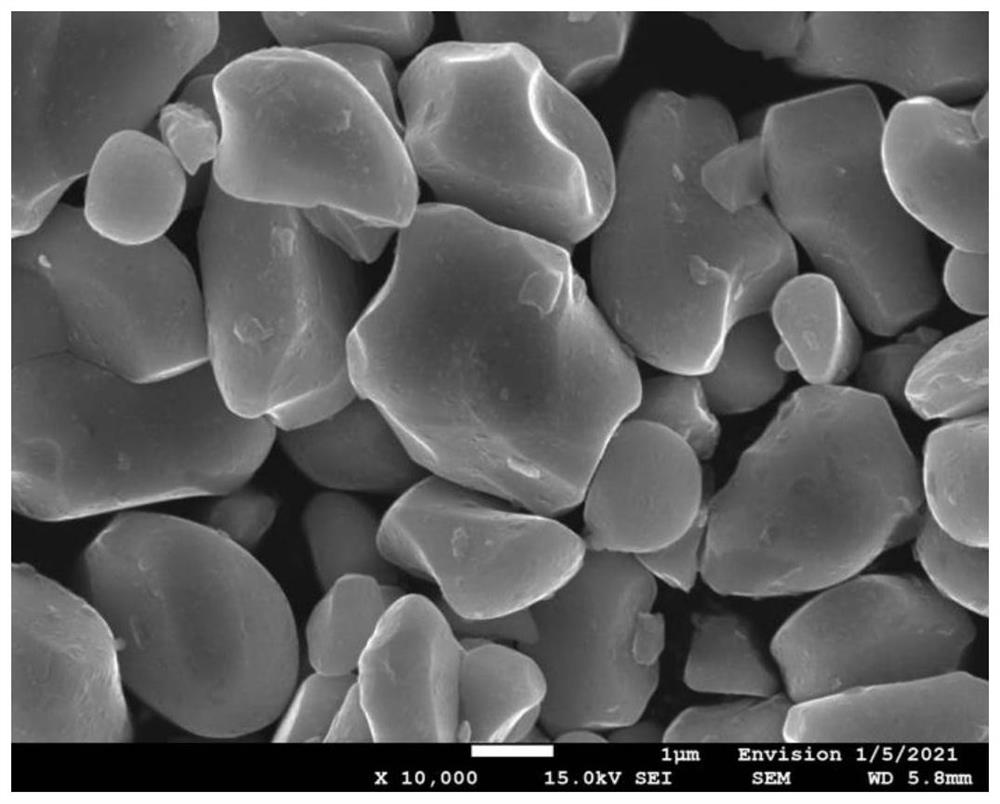

Nickel and Cobalt Plated Sponge Catalysts

InactiveUS20110011772A1Reduce cobalt contentReduce nickel contentRefining with metalsOrganic compound preparationChemistryOrganic compound

Novel nickel and / or cobalt plated sponge based catalysts are disclosed. The catalyst have an activity and / or selectivity comparable to conventional nickel and / or cobalt sponge catalysts, e.g., Raney® nickel or Raney® cobalt catalysts, but require a reduced content of nickel and / or cobalt. Catalysts in accordance with the invention comprise nickel and / or cobalt coated on at least a portion of the surface of a sponge support. Preferably, the sponge support comprises at least one metal other than or different from the metal(s) contained in the coating. The method of preparing the plated catalysts, and the method of using the catalysts in the preparation of organic compounds are also disclosed.

Owner:SCHMIDT STEPHEN RAYMOND

Hardened martensitic steel having a low or zero content of cobalt, process for manufacturing a part from this steel, and part thus obtained

ActiveCN101815797AHigh mechanical strengthReduce manufacturing costYielding couplingPower plant arrangements/mountingRare earthCobalt

Steel characterized in that its composition is, in percentages by weight: - C = 0.20 - 0.30%; - Co = traces - 1%; - Cr = 2 - 5%; - Al = 1 - 2%; - Mo + W / 2 = 1 - 4%; - V = traces - 0.3%; - Nb = traces - 0.1%; - B = traces - 30 ppm; - Ni = 11 - 16% with Ni = 7 + 3.5 Al; - Si = traces - 1.0%; - Mn = traces - 2.0%; - Ca = traces - 20 ppm; - rare earths = traces - 100 ppm; - when N < 10 ppm, Ti + Zr / 2 = traces - 100 ppm with Ti + Zr / 2 < 10 N; - when 10 ppm < N < 20 ppm, Ti + Zr / 2 = traces - 150 ppm; - O = traces - 50 ppm; - N = traces - 20 ppm; - S = traces - 20 ppm; - Cu = traces - 1%; - P = traces - 200 ppm, the remainder being iron and inevitable impurities resulting from the smelting. Process for manufacturing a part from this steel, and part thus obtained.

Owner:AUBERT & DUVAL FR

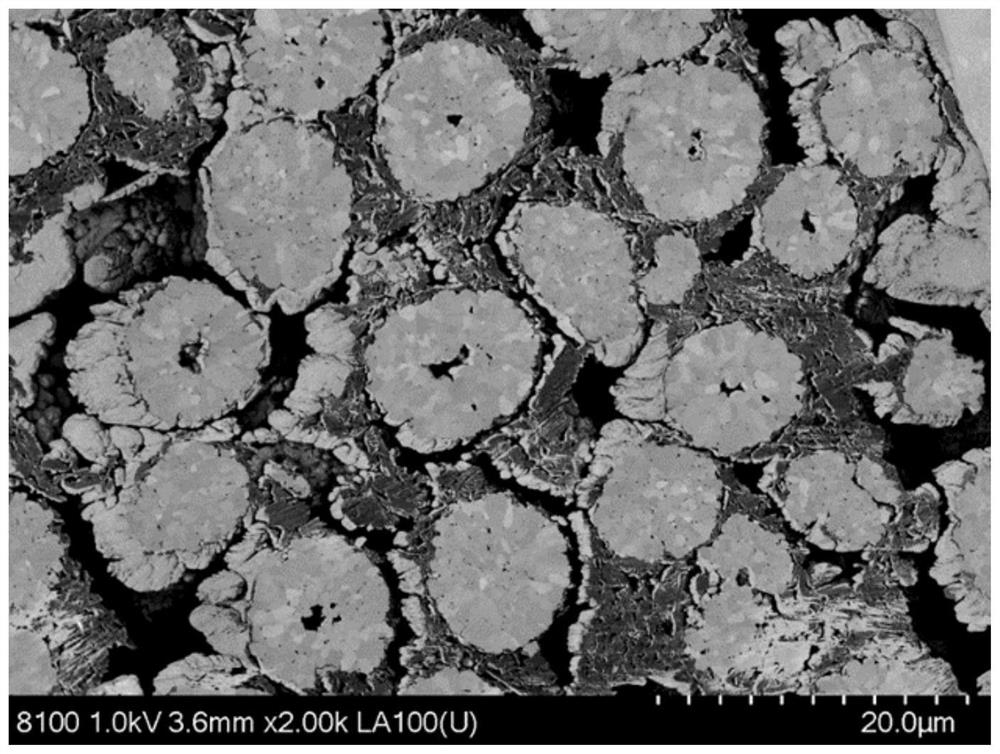

Low-cobalt positive electrode material and preparation method and application thereof

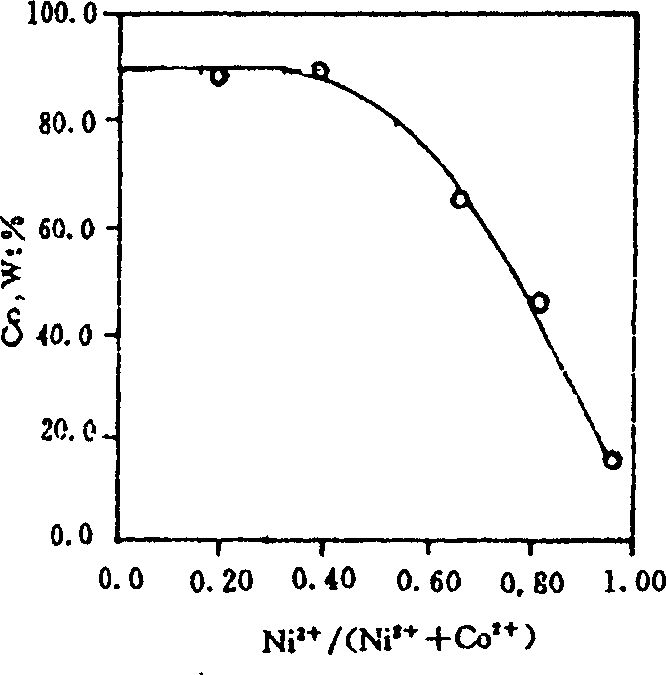

PendingCN113292115AConstant molarityIncreased molaritySecondary cellsPositive electrodesPhysical chemistryManganese

The invention provides a low-cobalt positive electrode material and a preparation method and application thereof. The preparation method comprises the steps that a nickel precursor, a cobalt precursor, a manganese precursor, a precipitator and a complexing agent are continuously added into a reaction kettle for a reaction, the molar concentration of the nickel precursor in the reaction kettle is kept unchanged, the molar concentration of the cobalt precursor is continuously increased, and the molar concentration of the manganese precursor is continuously reduced, so that ternary precursor particles are obtained; the ternary precursor particles and a lithium precursor are mixed and sintered to obtain the low-cobalt positive electrode material of which the cobalt content is gradually increased from inside to outside; and the low-cobalt positive electrode material has the advantages of low content and stable structure, and is beneficial to improving the electrical properties of a lithium ion battery.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

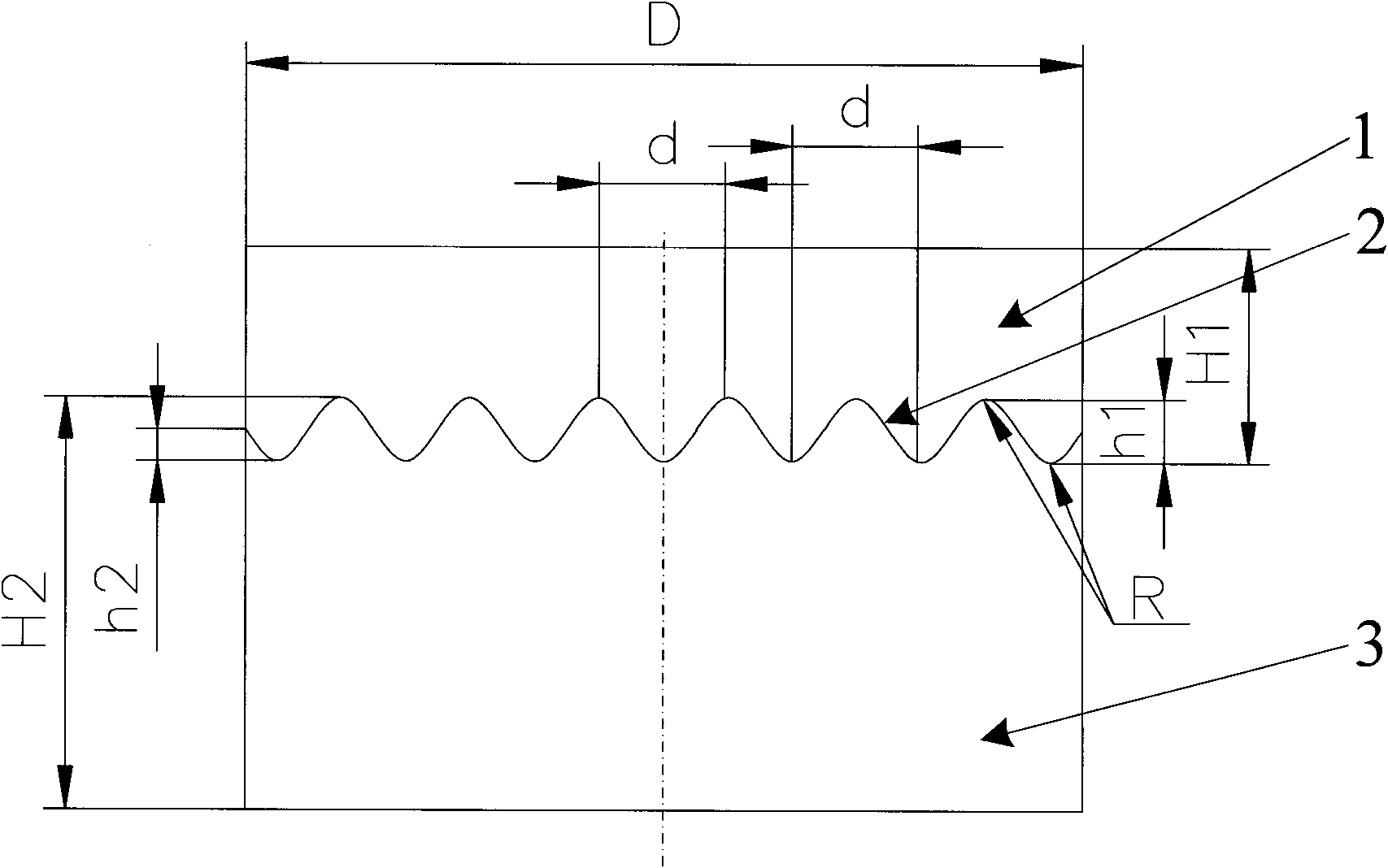

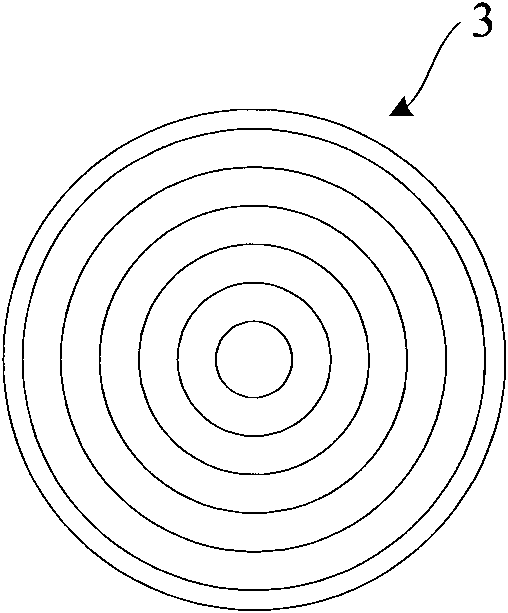

Diamond compact substrate

ActiveCN101852065AImprove thermal stabilityImprove wear resistanceDrill bitsLayered productsThermal stabilityCobalt

The invention provides a diamond compact substrate with two-layer structure. The substrate comprises an upper part and a lower part connected with the upper part, wherein the junction surfaces of the upper part and the lower part are embedded with each other and have round wave channel structure; the upper part comprises the following components by weight percent: 8-15% of cobalt and 85%-92% of tungsten carbide, wherein the grain size of tungsten carbide is 0.5-3mu m; the lower part comprises the following components by weight percent: 12-20% of cobalt and 80%-88% of tungsten carbide, wherein the grain size of tungsten carbide is 2-10mu m. As the upper part combined with diamond of the substrate has finer grains and lower cobalt content, the thermal stability and wear resistance of the compact can be further increased; as the upper part far from the diamond layer of the substrate has rougher grain and higher cobalt content, the toughness and service life of the compact can be increased; and as the round wave channel structure is adopted between the two substrates, the bonding strength of the two substrates is remarkably improved.

Owner:SHAREATE TOOLS

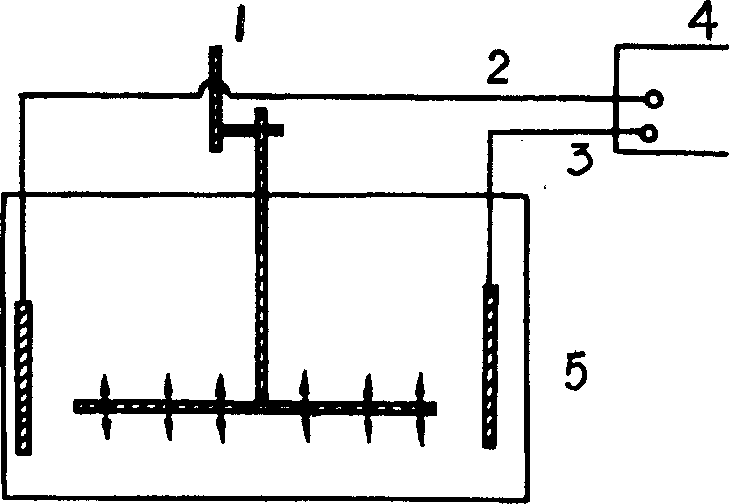

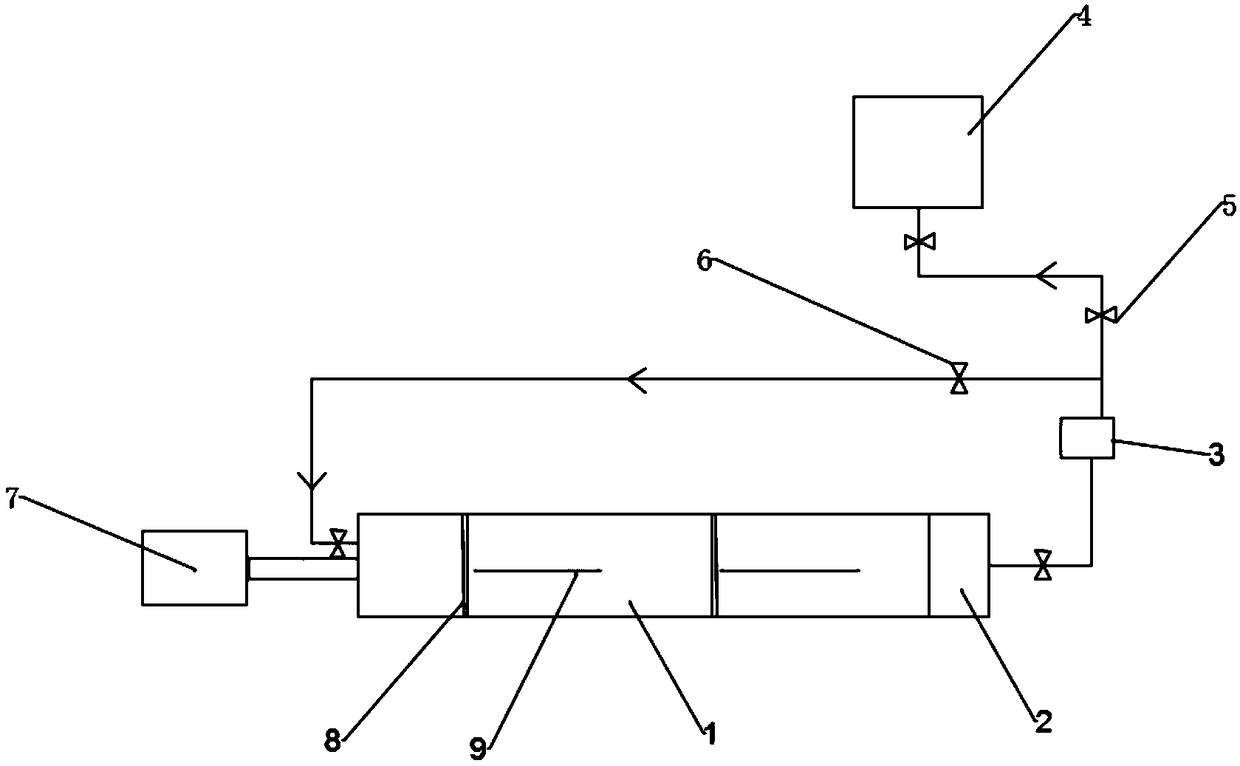

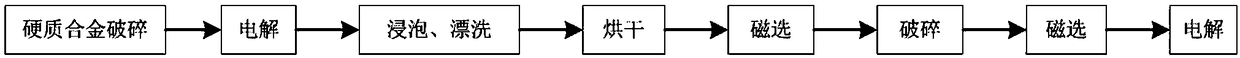

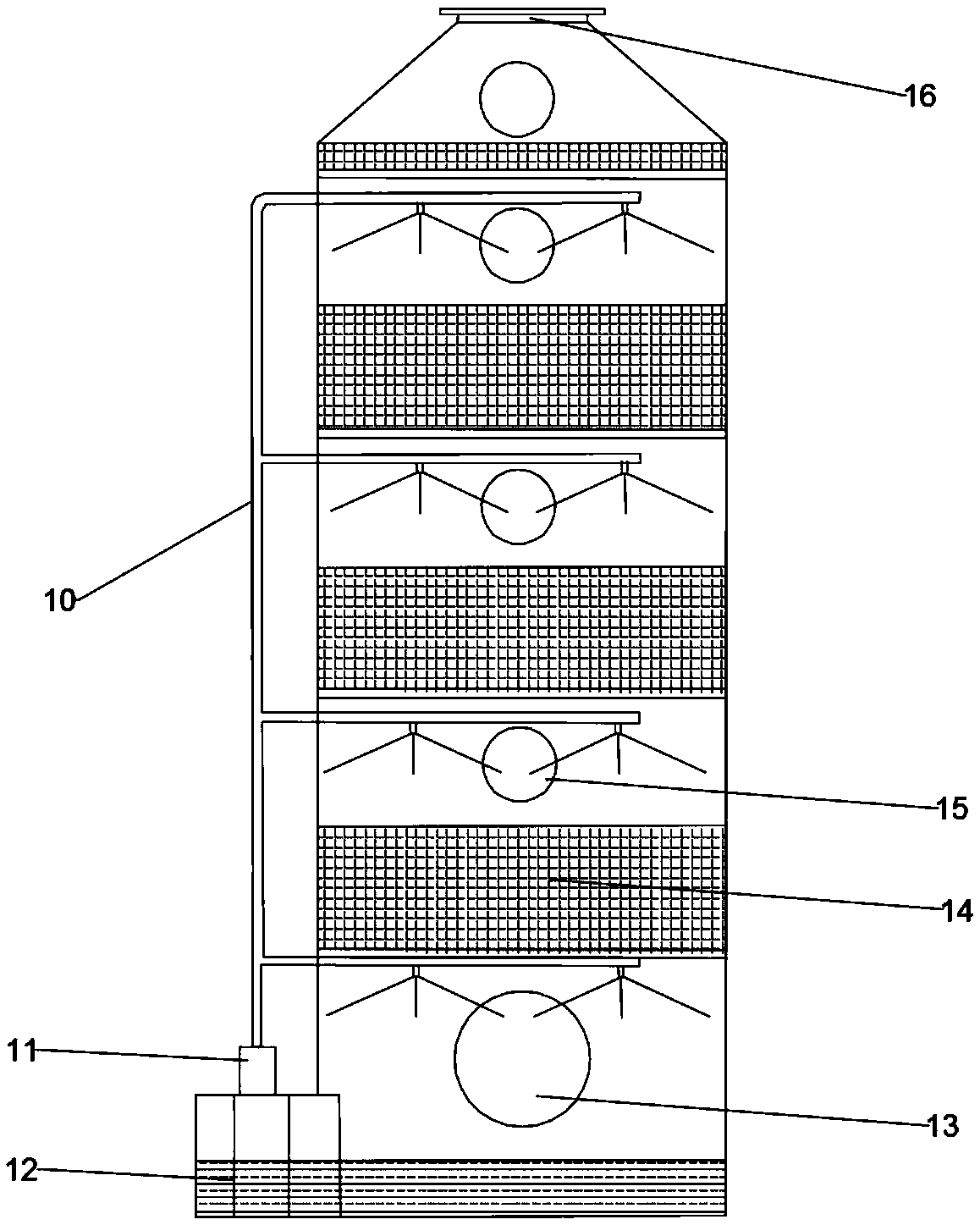

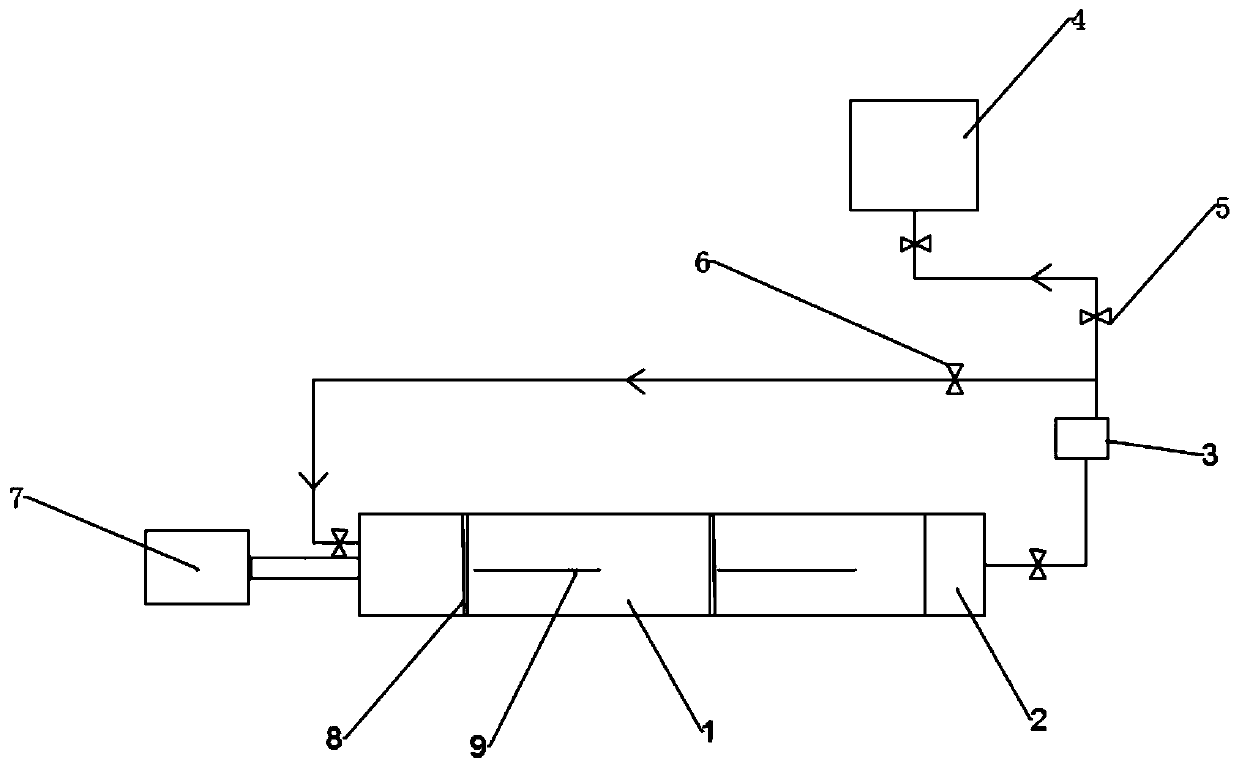

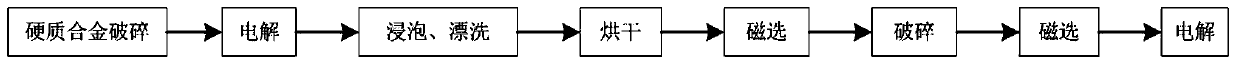

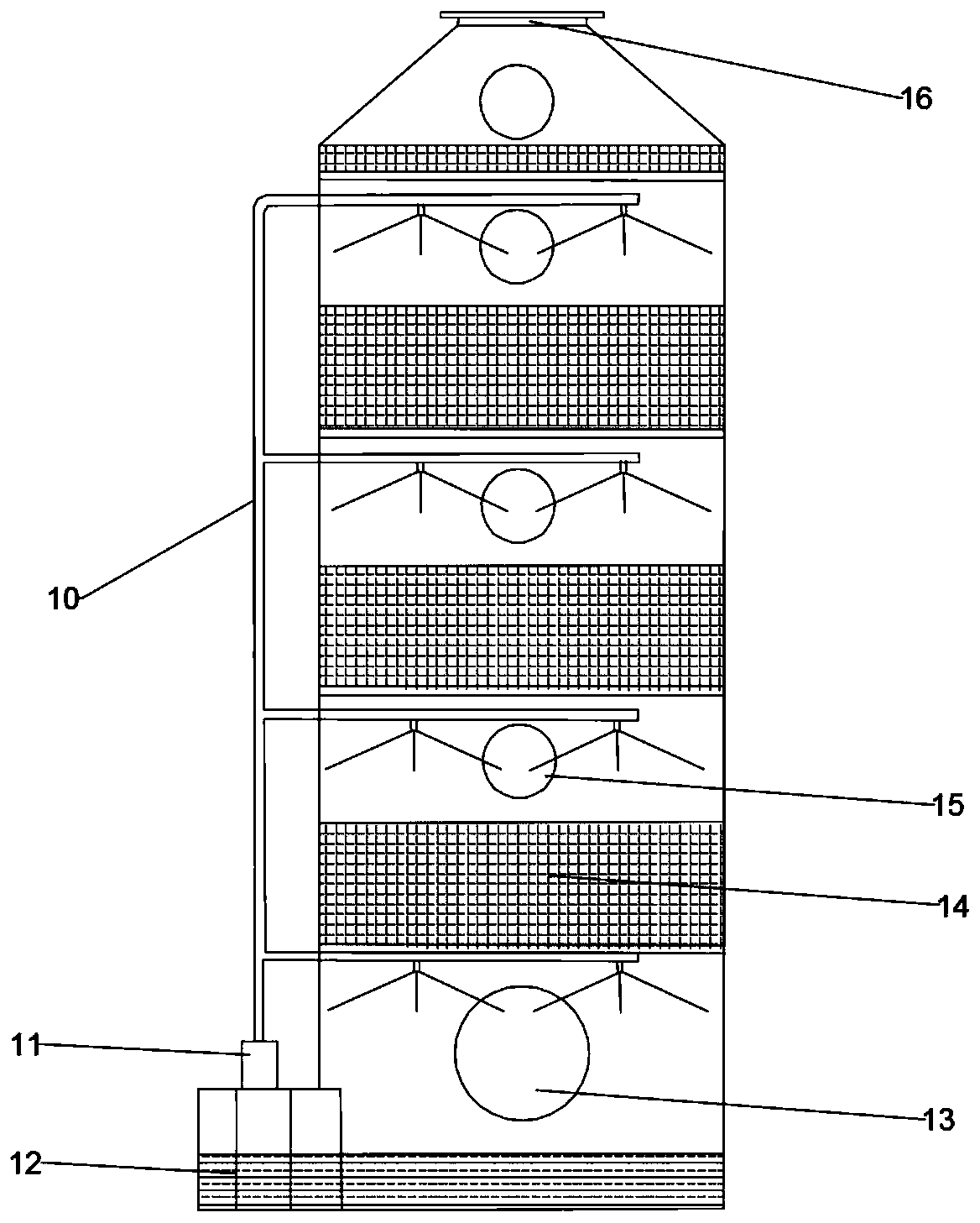

Method for extracting tungsten carbide and cobalt from waste hard alloy

ActiveCN108910966AHeating evenlySolve the pollution problemNickel halidesTungsten/molybdenum carbideSpecific gravityStart up

The invention provides a method for extracting tungsten carbide and cobalt from waste hard alloy, and belongs to the technical field. The method comprises the following steps: S1, crushing a hard waste alloy into particles, then loading into an electrolytic small box, placing in an electrolysis tank, electrolyzing, adding hydrochloric acid as an electrolyte solution, starting up a heater, and electrolyzing the electrolyte solution cyclically continuously under the action of an acid-resistant pump; S2, when the specific gravity of cobalt chloride in the electrolyte solution reaches 1.15-1.24 kg / dm<3>, pumping the electrolyte solution containing cobalt chloride into a storage tank, soaking the alloy particles with clear water, and then drying the alloy particles; and S3, carrying out magnetic separation of the dried alloy particles, smashing a cobalt-containing magnetic absorption material into particles with the diameter of 1-6 mm by an air heavy hammer, then loading into the electrolysis tank, electrolyzing again, and separating to obtain tungsten carbide and a cobalt chloride solution. By improvement of the electrolysis tank and the electrolytic process, the cobalt content in thefinished tungsten carbide product after electrolysis is completed is about 0.07%.

Owner:湖南金雕能源科技有限公司

Purification and cobalt removal method for zinc leaching solution

InactiveCN109536715AStrong antimagneticStrong paramagnetismElectrolysis componentsPhotography auxillary processesPregnant leach solutionField conditions

The invention relates to the technical field of hydrometallurgy, in particular to a purification and cobalt removal method for a zinc leaching solution. Zinc leachate is directly electrolyzed under amagnetic field condition, and the magnetic field intensity is accurately controlled and is kept at 7-9A / m, so that the content of cobalt in electrolyzed liquid is greatly reduced, the removal rate ofthe cobalt is improved, the circulation use capability of the electrolyzed liquid is realized, and the cobalt removal difficulty of the zinc leachate is reduced.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG +1

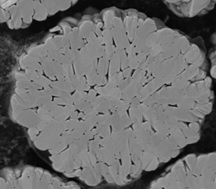

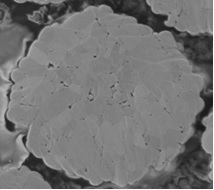

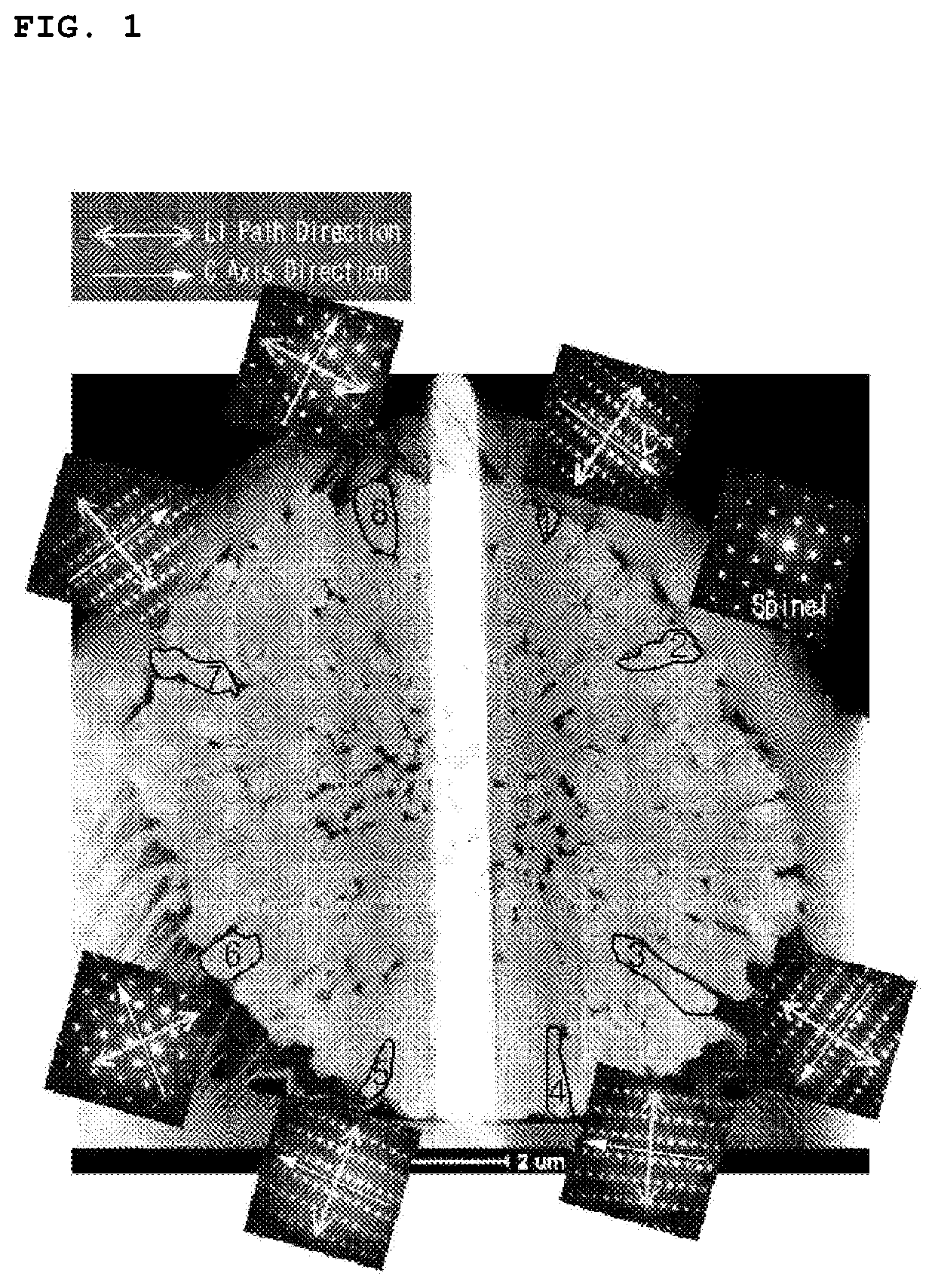

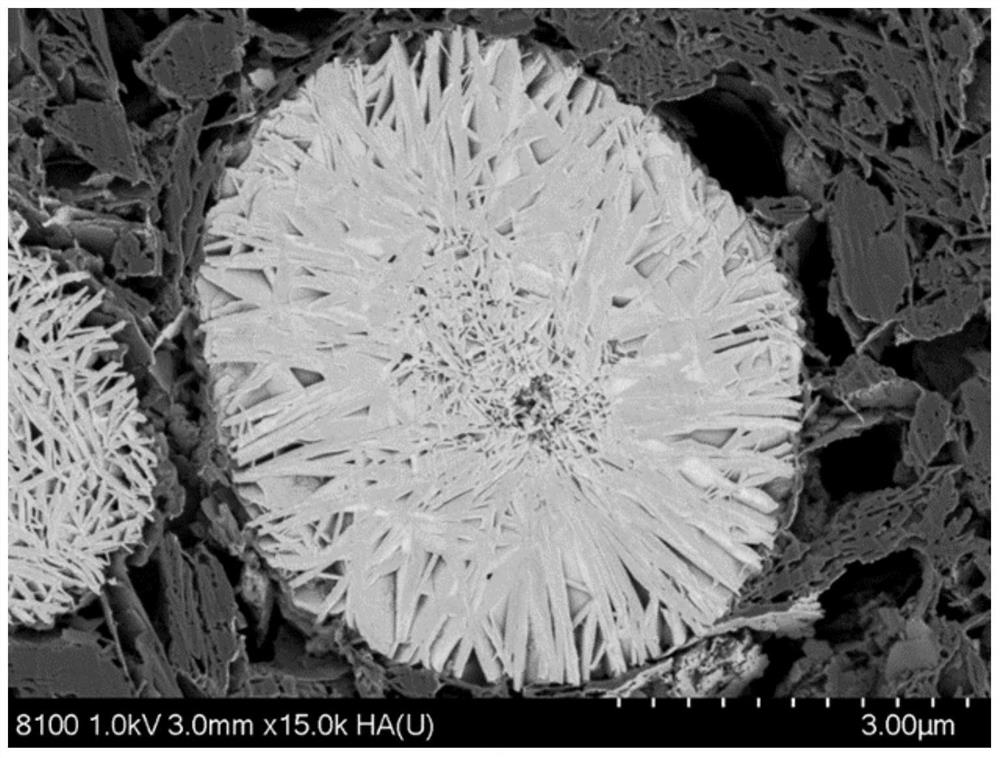

Positive Electrode Active Material For Lithium Secondary Battery, Method of Preparing the same, and Positive Electrode for Lithium Secondary Battery and Lithium Secondary Battery which include the positive Electrode Active Material

ActiveUS20210234155A1Reduce outputReduce cobalt contentElectrode thermal treatmentPositive electrodesManganeseBattery cell

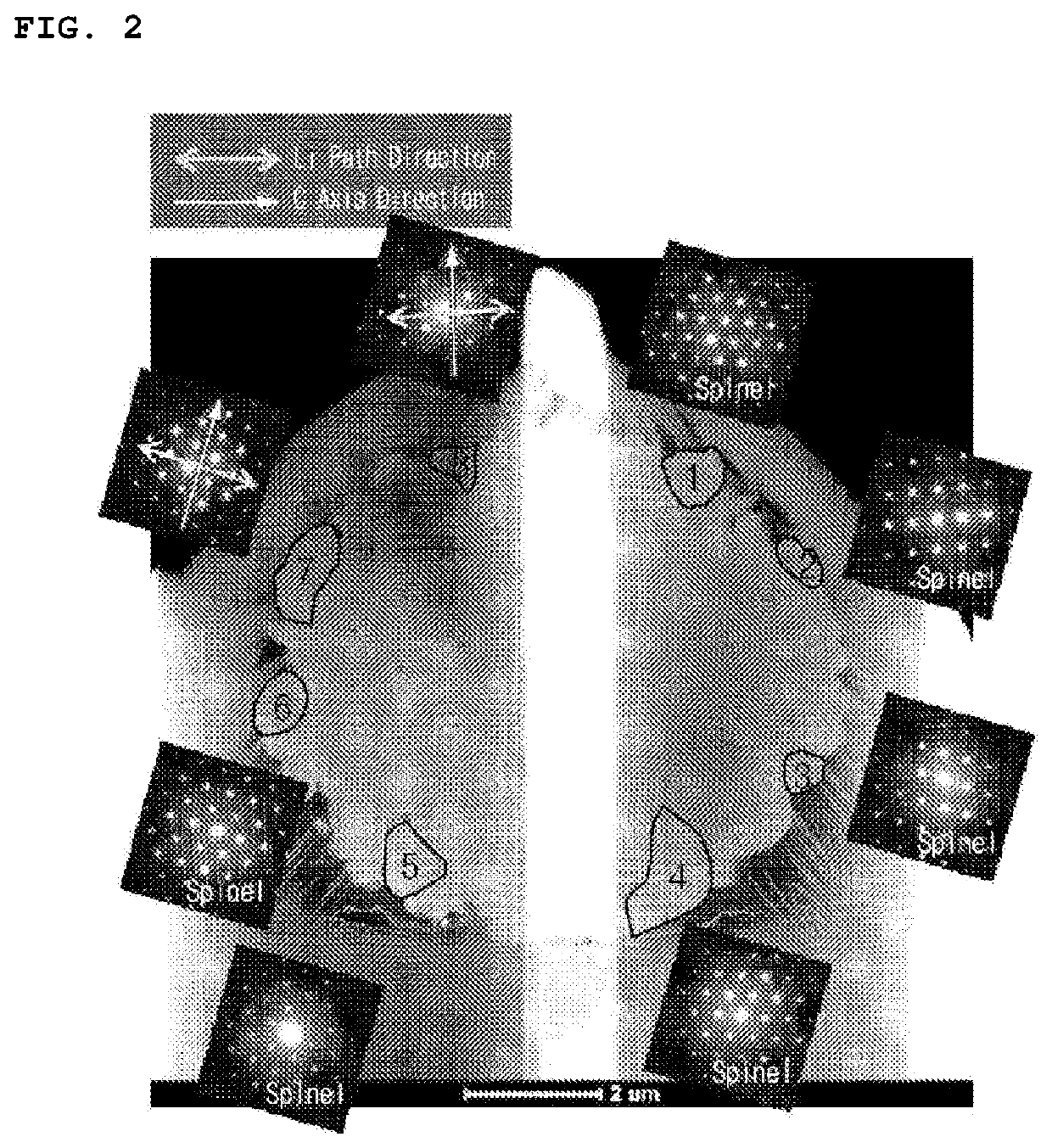

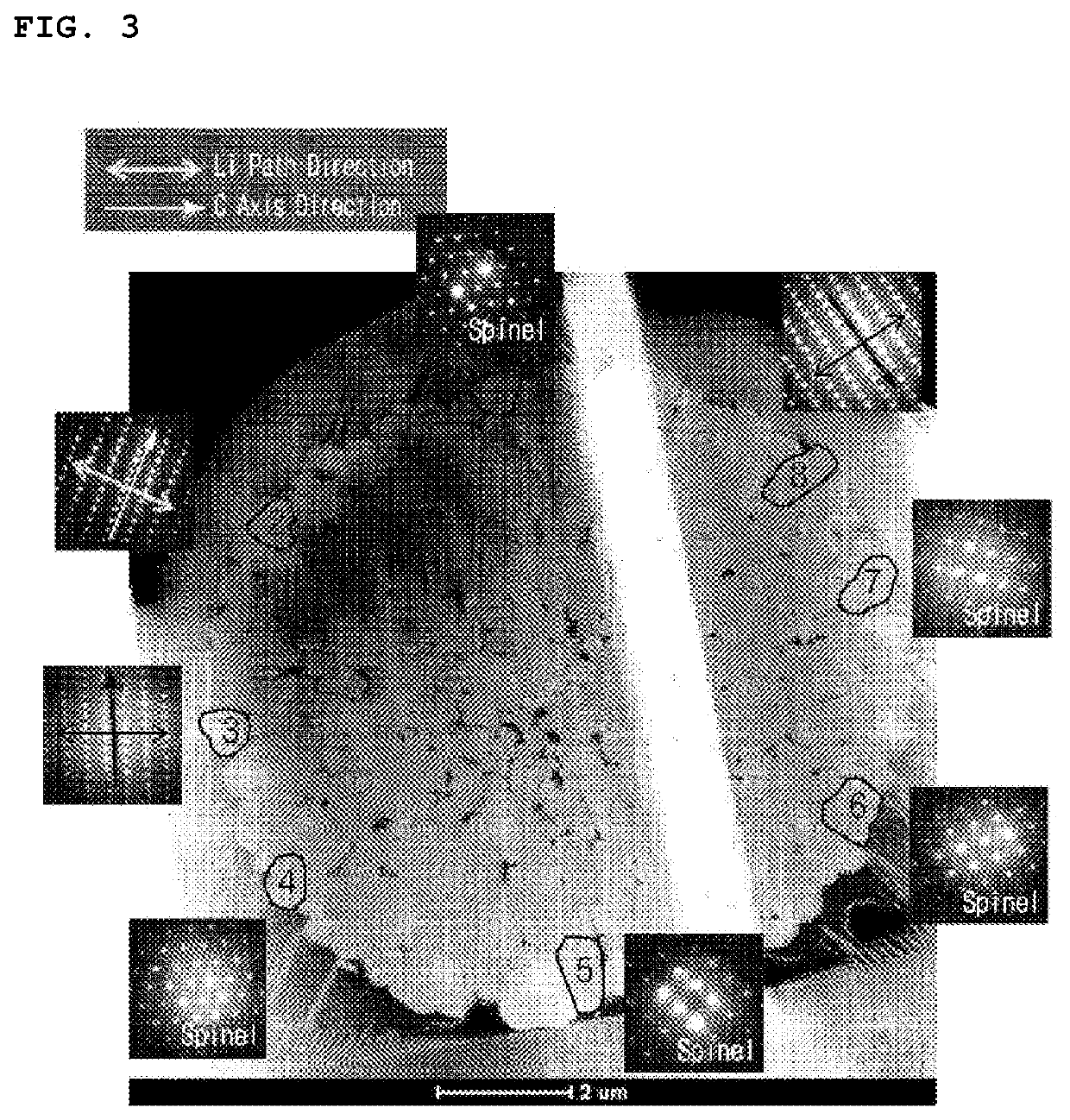

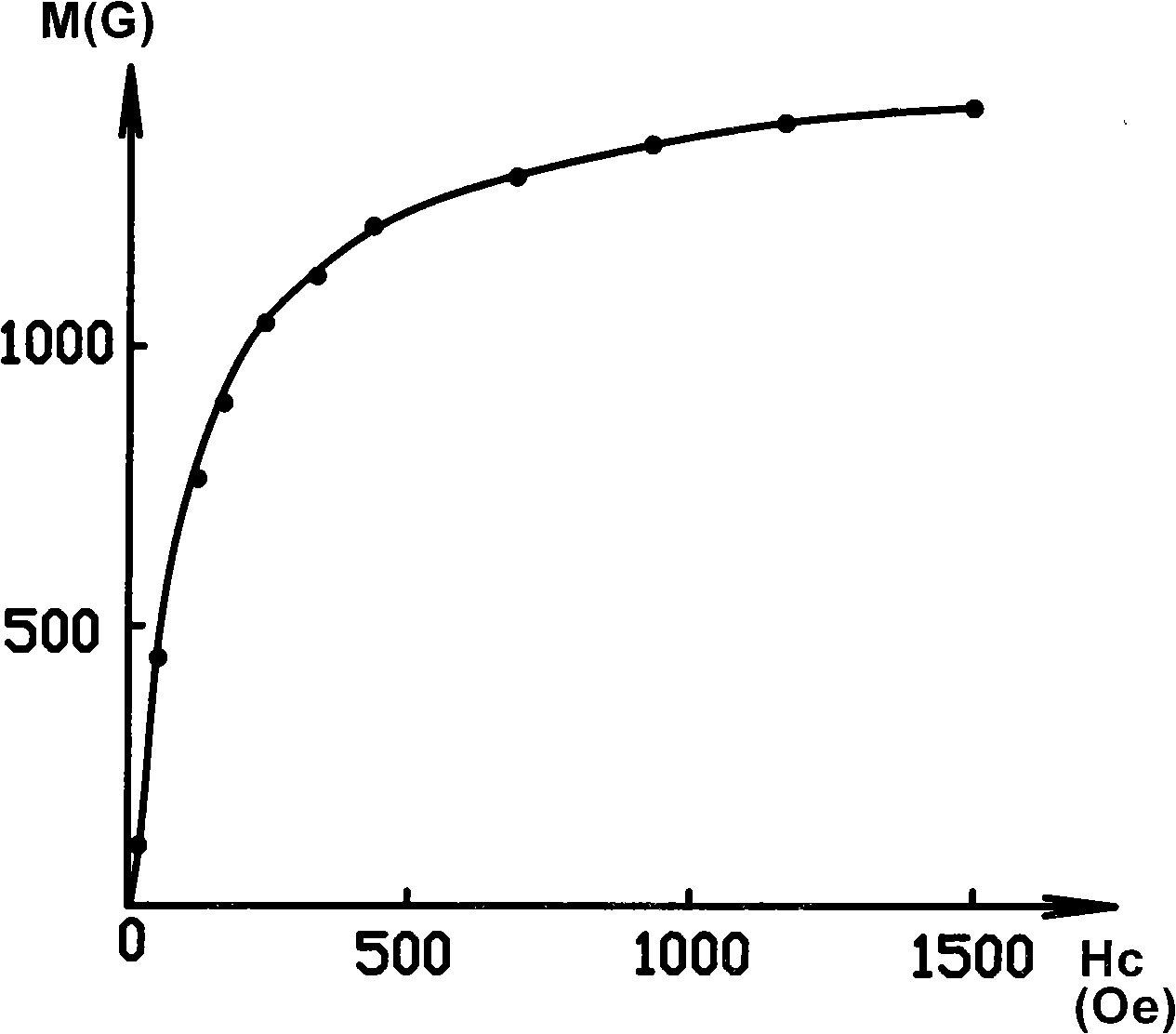

The present invention relates to a positive electrode active material, which includes a lithium transition metal oxide having an average composition represented by Formula 1 in which a cobalt content in the lithium transition metal oxide is less than a manganese content, wherein at least one of nickel, cobalt, and manganese in the lithium transition metal oxide has a concentration gradient that gradually changes from a center of a particle to a surface thereof, the positive electrode active material is in the form of a secondary particle formed by agglomeration of primary particles, and a ratio in which angles between c-axis directions, which are measured at at least 8 points on a surface of the positive electrode active material by TEM analysis, and a growth direction of the particle at the measuring point satisfy 85° to 95° is 60% or more, a method of preparing the positive electrode active material, and a positive electrode for a lithium secondary battery and a lithium secondary battery which include the positive electrode active material:Li1+aNixCoyMnzM1wO2 [Formula 1]in Formula 1, 0≤a≤0.3, 0.65≤x<1, 0<y≤0.35, 0<z≤0.35, 0≤w≤0.02, and y<z, and M1 includes at least one selected from the group consisting of aluminum (Al), zirconium (Zr), magnesium (Mg), zinc (Zn), yttrium (Y), iron (Fe), and titanium (Ti).

Owner:LG CHEM LTD

Method for manufacturing copper-iron-based diamond cutter teeth

The invention discloses a method for manufacturing copper-iron-based diamond cutter teeth. The method is characterized by including the following steps of preparing green body material through framework material and adhesive metal, mixing the material after preparation, packaging the material after mix so as to be subjected to thermal pressing formation, cooling the material after thermal pressing formation, and machining the material after cooling, wherein the material prepared in the green body material preparation process include, by weight, 35% of iron powder, 50% of copper powder, 5% of cobalt powder, 5% of nickel powder and 5% of manganese powder, diamond accounting for 5.04% of the total weight of the green body material is added in the mixing process, the material is mixed in a stainless steel ball mill, the material to ball ratio is 1:2, the rotation speed of the ball mill is 46 r / min, the material mixing time ranges from 12 hours to 35 hours, the sintering temperature in thermal pressing formation is 1020 DEG C, the sintering time ranges from 5 minutes to 10 minutes, the pressure ranges from 12 Mpa to 13 Mpa, and the tapping temperature is 550 DEG C.

Owner:铜陵长江金刚石工具股份有限公司

Sintering process of diamond compact for petroleum drill bit

InactiveCN108941577AReduce wearIncreased carbon-carbon bondingDrill bitsTransportation and packagingHeat resistanceStrong acids

The invention relates to a sintering process of a diamond compact for a petroleum drill bit. The sintering process includes the following steps of S1, raw material pre-assembling; S2, primary sintering of the diamond compact, wherein an assembly part in S1 is fed into a high-pressure sintering synthesis chamber to be sintered in the high-pressure sintering synthesis chamber for 4-6 min, a hard alloy matrix I is removed, and a diamond compact crude finished product is obtained for use; S3, machining of the crude finished product; and S4, secondary sintering of the diamond compact, wherein a binder of the diamond compact crude finished product is removed with a strong acid soaking method, after being washed 2-3 times with clean water, the diamond compact crude finished product is dried at high temperature in a high-temperature furnace, the diamond compact crude finished product and a hard alloy matrix II are put in a shielding cup to form an assembly part, the assembly part is fed into the high-pressure sintering synthesis chamber, the assembly part is sintered for 6-8 min in the high-pressure sintering synthesis chamber with the temperature of 1,400-1,450 DEG C and the pressure of 5.6 GPa, a finished product is obtained after secondary sintering of the diamond compact, and then the finished product is machined into the required size again. The sintering process has the beneficial effects of improving the performance of the product and improving the heat resistance and the abrasion resistance of the product.

Owner:立府精密机械有限公司

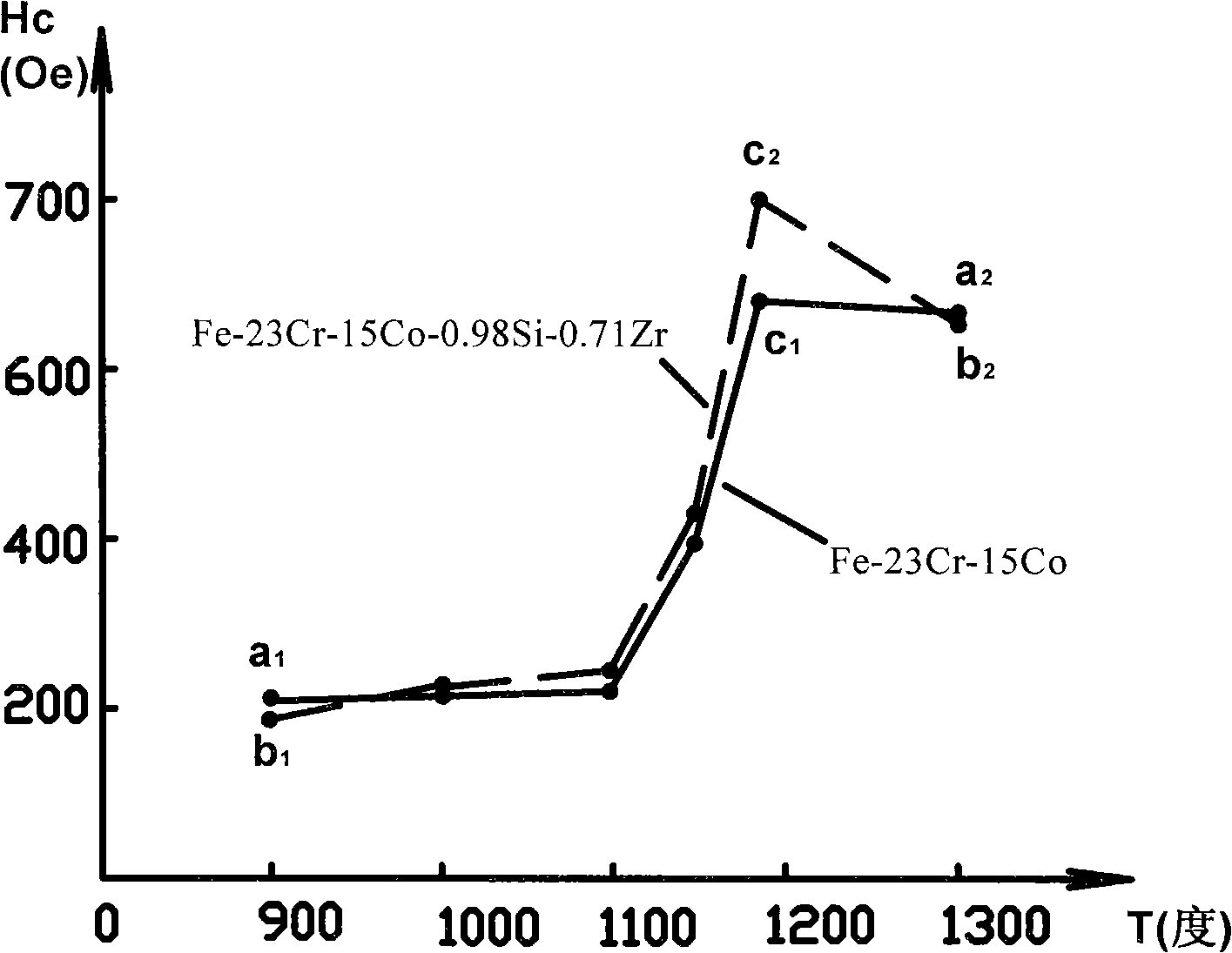

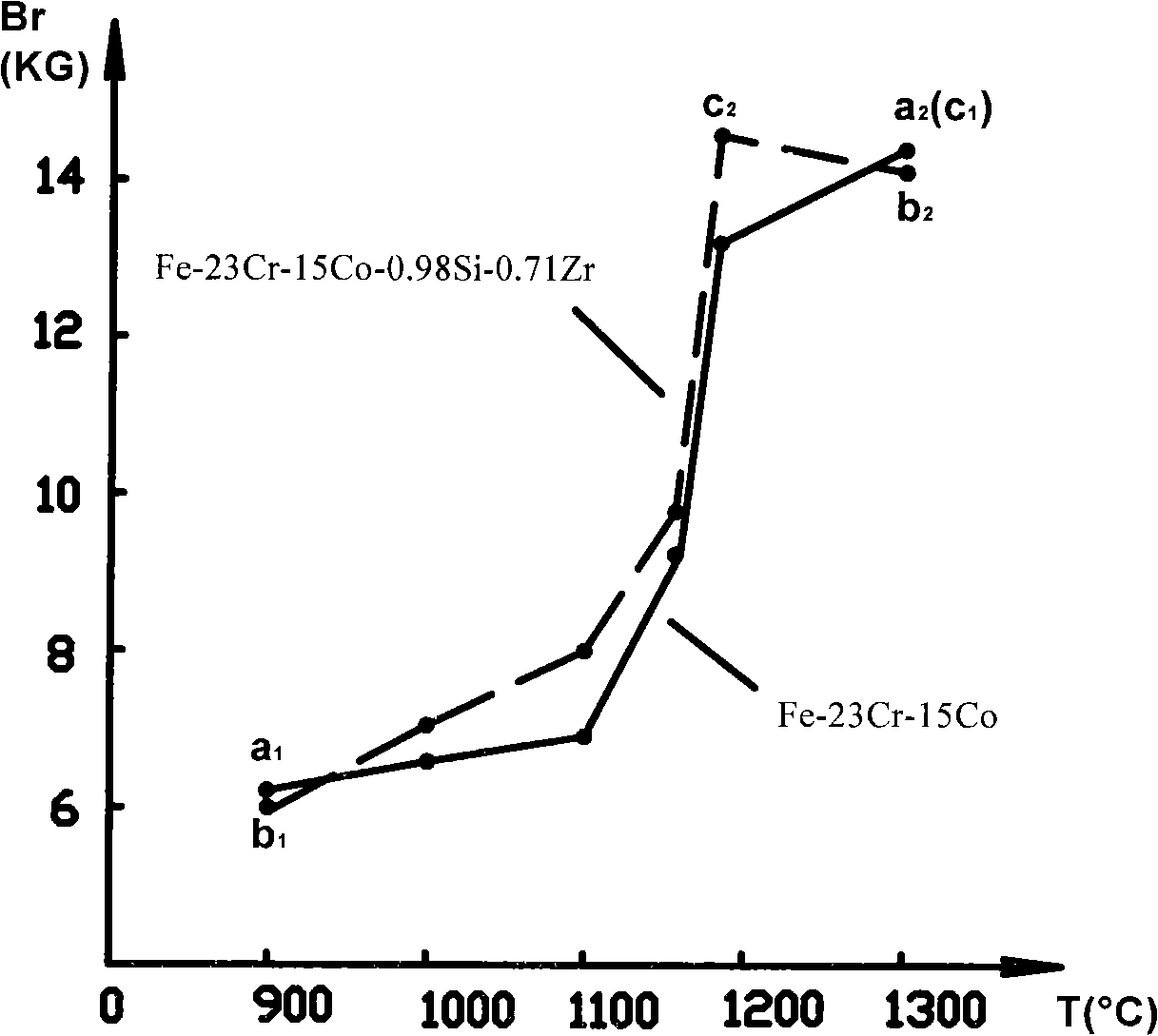

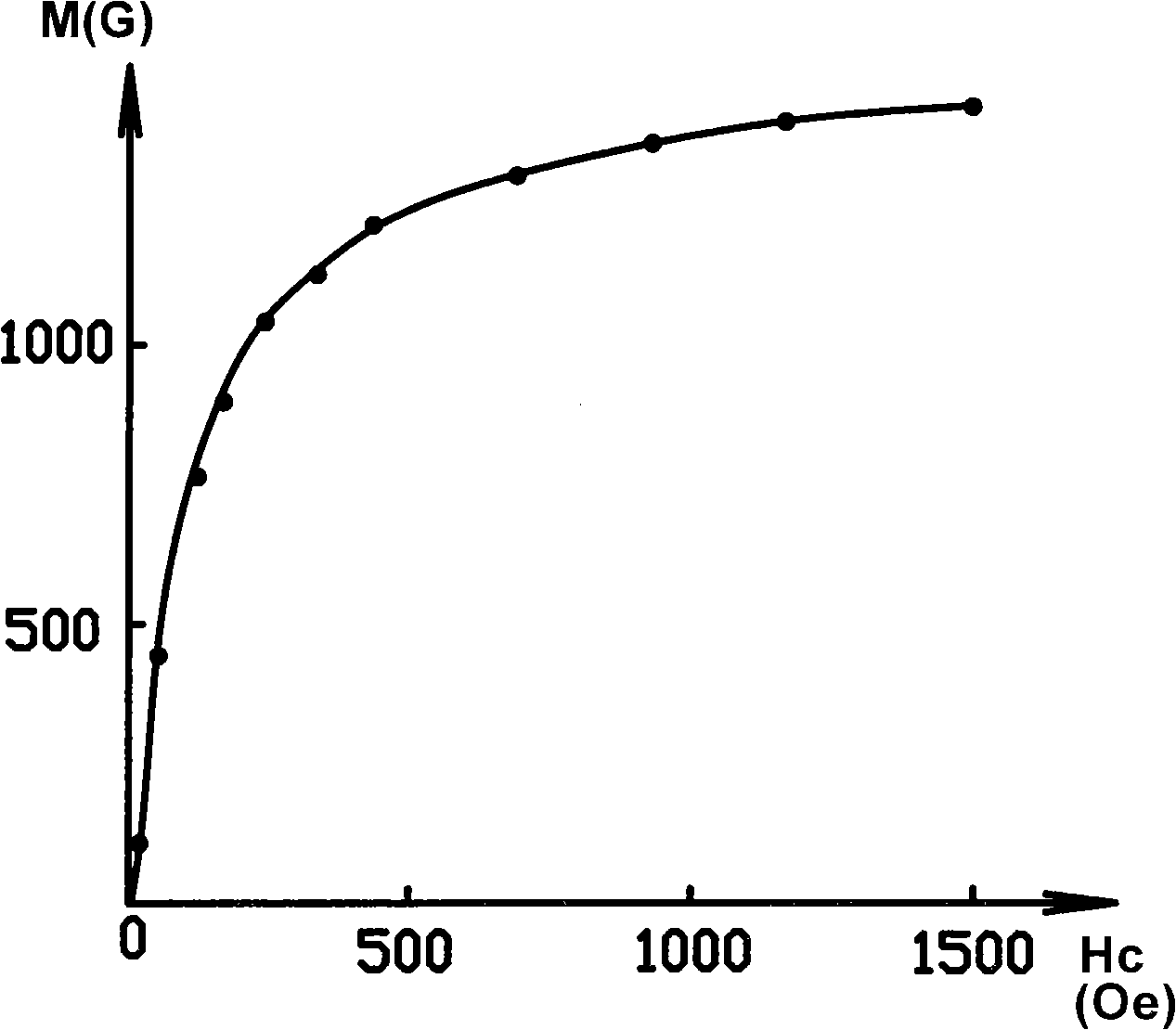

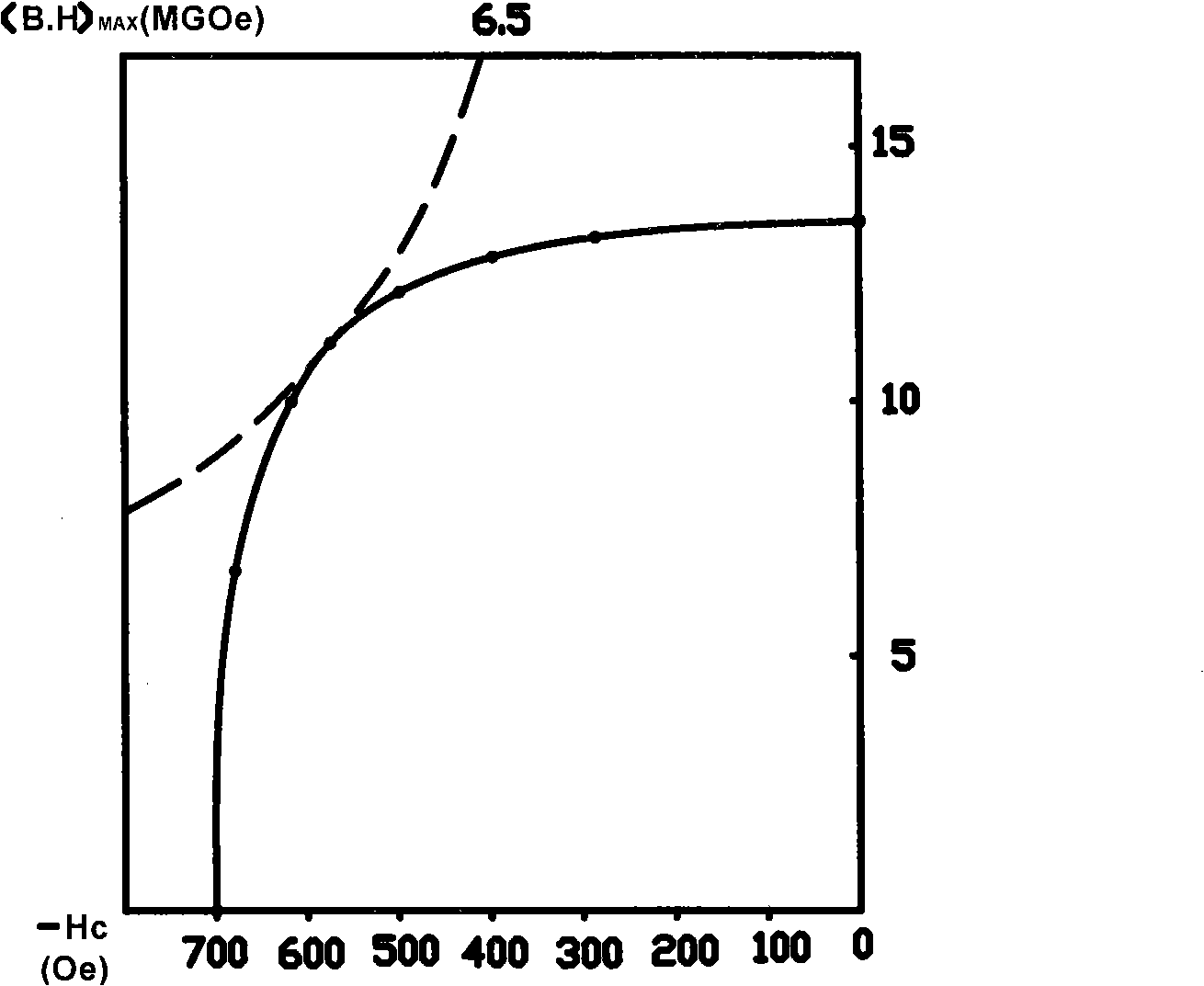

Iron-chromium-cobalt permanent magnetic alloy compounding vanadium and tungsten and deformation processing technology thereof

InactiveCN101285155AOptimize structural configurationImprove magnetismTemperature control deviceMagnetic materialsCobaltImpurity

The invention discloses a FeCrCo permanent magnet alloy compounding silicon and zirconium elements and a deformation processing technology thereof, which belongs to the FeCrCo permanent magnet alloy material field. The invention especially relates to a FeCrCo alloy which reduces cobalt content and improves processability and a deformation processing method thereof. The compositions in percentage by weight of the FeCrCo alloy are: 22 to 27 percent of Cr, 10 to 16 percent of Co, 0.8 to 1 percent of Si, 0.2 to 0.8 percent of Zr, the balance being Fe and inevitable impurities. The deformation processing technology of the alloy comprises smelting process, forging process, hot rolling process, pickling process, cold working process and magnetic property treating process. The FeCrCo alloy and the method have the advantages of effectively reducing the cobalt content and the material cost, and improving the magnetic property and machining property of the alloy material; the reasonable arrangement of the processing sequences provided by the invention further improves the magnetic property of the alloy and provides a better method for the deformation processing of the high magnetic property FeCrCo permanent magnet alloy material.

Owner:天津冶金集团天材科技发展有限公司

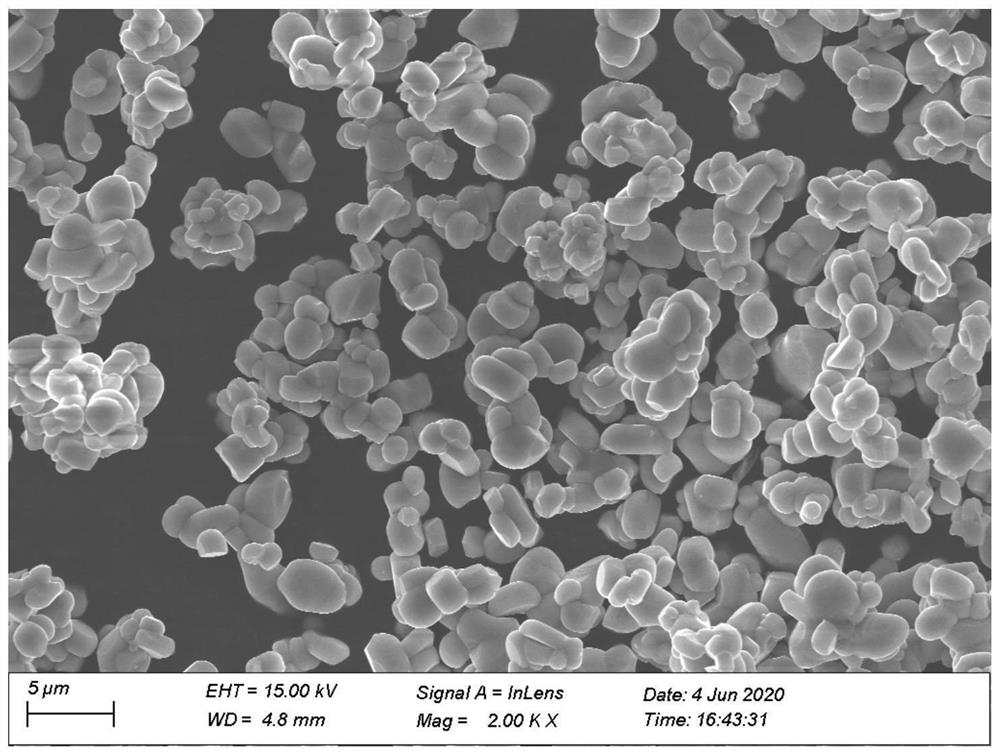

High-power multi-component material and preparation method thereof

PendingCN112054184AIncrease contactImprove power performanceSecondary cellsPositive electrodesMicrostructureParticle coating

The invention provides a high-power type multi-component material and a preparation method thereof, and the molecular formula of the high-power type multi-component material is as follows: LiNi1-a-bCoaMnbO2; 1-a-b is greater than or equal to 0.2 and is less than 1; 0.5> a; b> 0; the morphology features are as follows: the primary particle diameter is 0.2-1.5 mu m, the high-power type multi-component material is a hollow structure with the particle size D50 of internal multiple pores of 4-10 mu m, M elements are doped in the particles, and M is one or a combination of Ce, Nd, Eu, Er, Ta, W andSn. The high-power type multi-component material is a ternary material with a special microstructure, a primary particle polymerized secondary particle precursor with more pores inside is prepared through special process control, and an internal porous multi-element positive electrode material with a primary particle coating structure can be formed in a roasting process after the precursor is mixed with lithium salt; the secondary particle ternary material with high power and long service life can be obtained while the advantages of low cobalt content and low cost are guaranteed, the primary particle coating technology is used, the service life of the roasted material is effectively prolonged, meanwhile, the secondary sintering process is reduced, and the production cost of the material isgreatly reduced.

Owner:TIANJIN ENERGIES

Hot rolling or hot piercing of high performance Fe-Cr-Co permanent magnetic alloy material

The invention discloses an iron chromium cobalt permanent magnet alloy material with high performance and hot roll or hot perforation thereof; wherein the hot roll temperature is furnace entry temperature; the material is heated to a predetermined temperature for heat reservation, is hot rolled into a thickness belt and then is sharply quenched. Hot perforation for pipes is much difficult than hot roll for wire rods or belts; the material bears compression, extension and twist in the process of processing blanks so that the hot perforation for pipes demands higher requirement to the material and stricter procedure. The perforation procedures are as below: pipe blank is formed to a light rod which enters into the furnace, is heated up along with the furnace, preserves heat and is cooled after perforation.

Owner:天津冶金集团天材科技发展有限公司

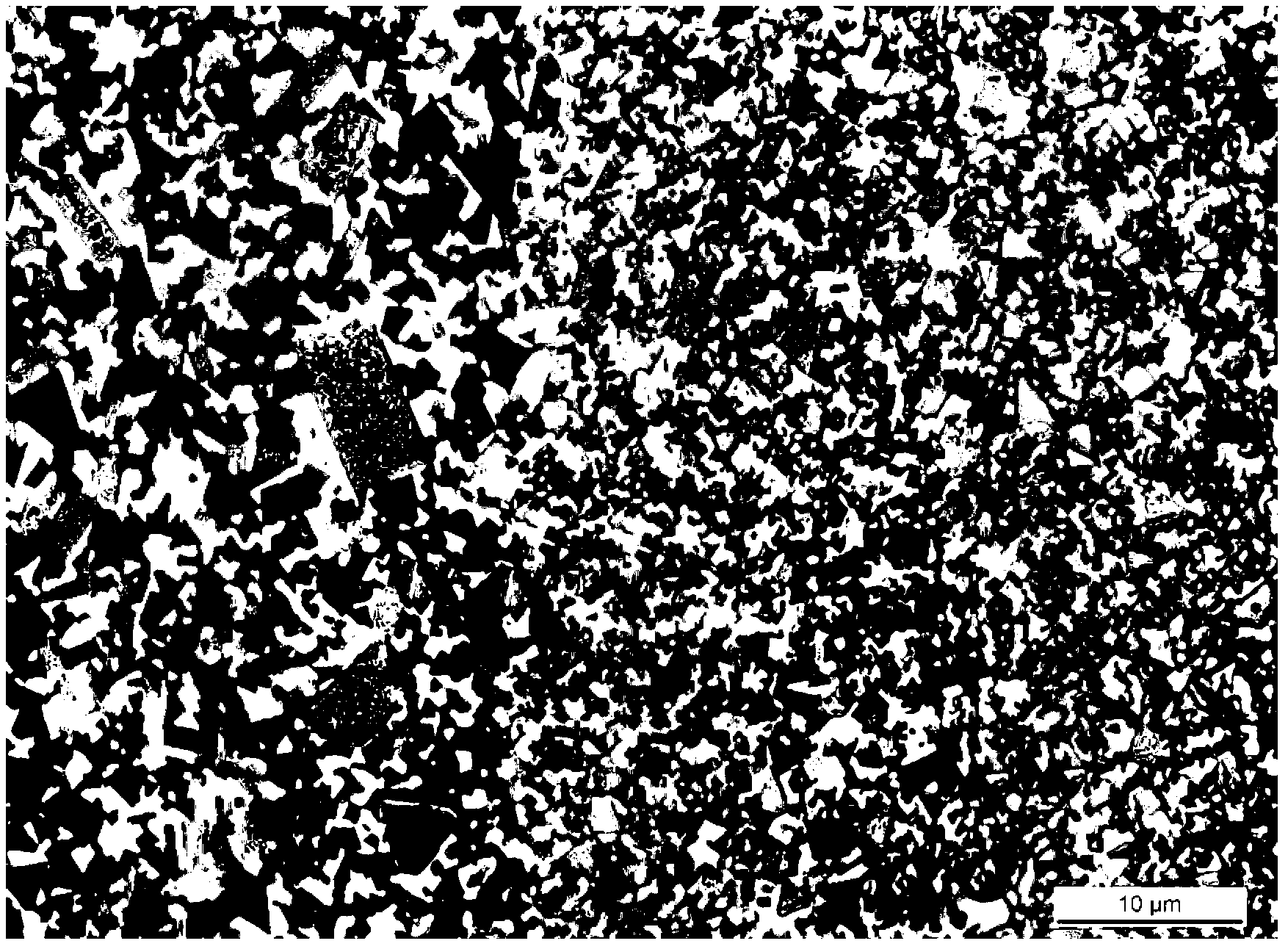

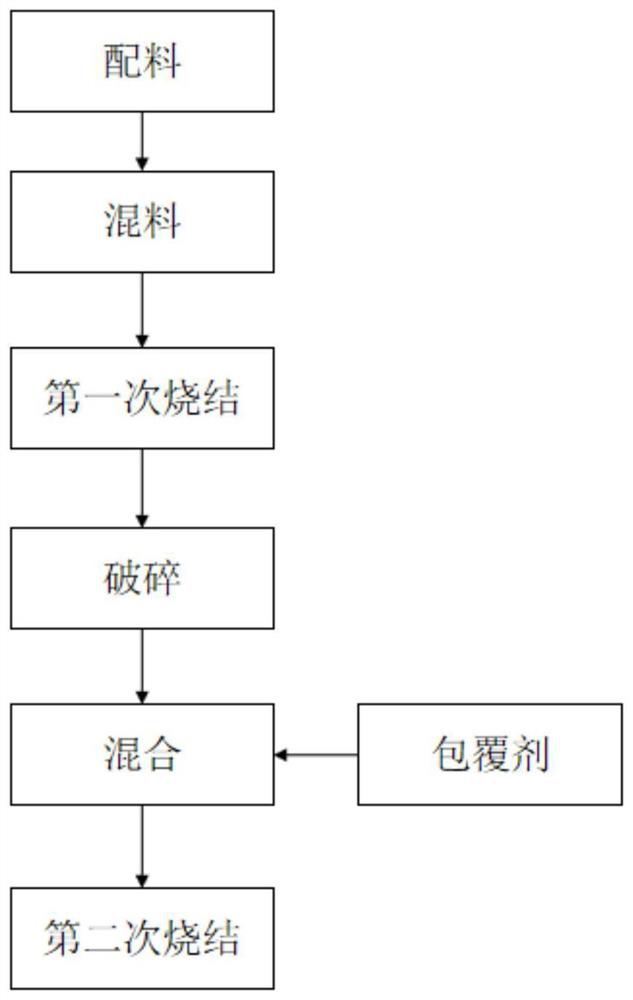

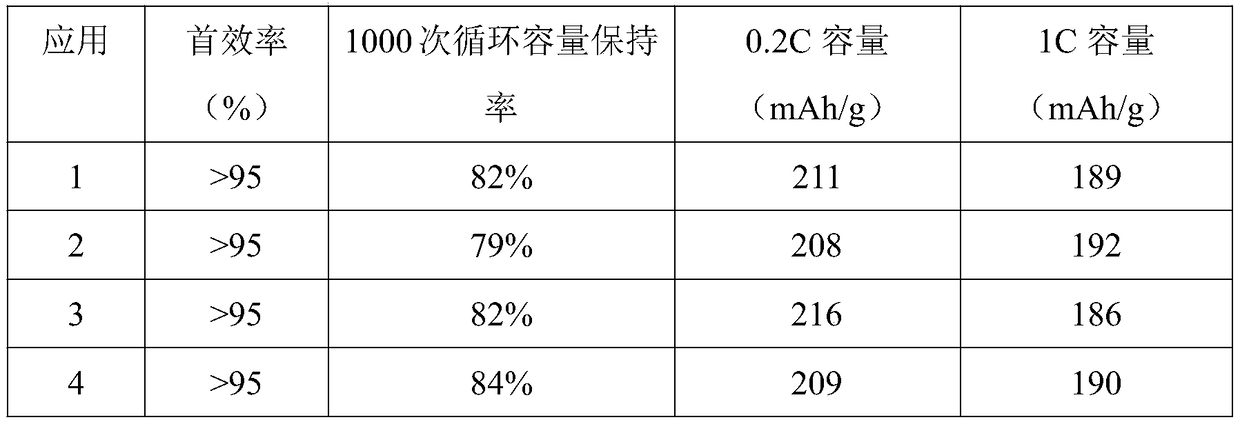

NCM613 single crystal type positive electrode material and preparation method thereof

InactiveCN111952581AHigh discharge specific capacityPromote circulationPolycrystalline material growthFrom solid stateLithium hydroxidePhysical chemistry

The invention relates to the technical field of positive electrode material preparation, and discloses an NCM613 single crystal type positive electrode material and a preparation method thereof. The method comprises the following steps: (1) sequentially adding part of lithium hydroxide, a precursor Ni0.6Co0.1Mn0.3(OH)2, an additive and residual lithium hydroxide in raw materials into a mixer, andperforming mixing to obtain a mixture; (2) putting the mixture into a sagger, dicing the sagger, and then transferring the sagger into a sintering furnace to be sintered for the first time; and (3) crushing the material obtained by the first sintering, then mixing the crushed material with a coating agent, and then transferring the mixture into a sintering furnace for second sintering, wherein themolar ratio of the precursor Ni0.6Co0.1Mn0.3(OH)2 to the lithium hydroxide is 1: (1.05-1.1). According to the method, the NCM613 single crystal positive electrode material with low cobalt type, highspecific discharge capacity and excellent cycle performance can be prepared.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

Tungsten carbide base hard alloy powder metallurgical material and its preparation method

The invention provides a tungsten carbide based cemented carbide powder metallurgical material and method for preparation, wherein the the constituents (by weight percentage) include WC 86-95%, Co 4-8%, Al 1-3%, TiC 0-2%, and VC 0-2%. The preparing process consists of pre-grinding, mixing, ball-grinding, and finally consolidating through electric current flash sintering method.

Owner:SOUTH CHINA UNIV OF TECH

Electrolyte for cobalt removal, method for surface modification of diamond composite teeth and diamond composite teeth

The invention relates to the field of composite diamond segments and discloses an electrolyte for cobalt removal, a surface modification method for a composite diamond segment and the composite diamond segment. The electrolyte comprises pyrophosphate, ammonium sulfide, sodium chloride and water. When the electrolyte is utilized to perform surface modification on a diamond layer of the composite diamond segment, the content of cobalt in the diamond layer of the composite diamond segment is less than 1.2% by weight, and the cobalt removal depth can reach 0.7-0.8 mm.

Owner:国宏中晶集团有限公司

A preparation method and application of low cobalt and high nickel ternary lithium

ActiveCN108963218AReduce cobalt contentImprove thermal stabilityCell electrodesSecondary cellsCOBALTOUS NITRATETitanate

The invention discloses a preparation method and application of ternary lithium with low cobalt and high nickel. The preparation method comprises the following steps: spray drying a mixed aqueous solution of nickel nitrate, titanium nitrate and manganese nitrate with a molar ratio of 8.75: 0.25: 1 to obtain a precursor; mixing precursor, traction agent and lithium hydroxide in water according to amolar ratio of 30: 1:30 to obtain a suspension liquid, stirring at 120-180 DEG C for 6-12h, spray drying, calcining at 650-850 DEG C in an oxygen atmosphere for 4-8h; The preparation method of the precursor comprises the following steps of: adding ethanol to lithium acetate; Adding tetrabutyl titanate and cobalt nitrate aqueous solution into the aqueous solution dropwise to form gel; keeping constant temperature at 100 to 120 DEG C for 8 to 12 hours, and then evaporating and crystallize to obtain that product. This method firstly improves the cell structure of ternary materials by using titanium element with better cell parameters, then initiates titanium-cobalt interchange by using traction agent so as to obtain higher nickel ternary materials with better cell parameter structure. Due tothe improvement of the cell structure, the ternary material not only further reduces the cobalt content, but also greatly improves its thermal stability, cycle life and safety.

Owner:王丹亮 +1

Molybdenum-titanium composite iron-chromium-cobalt permanent magnetic alloy and deformation processing technique

ActiveCN101298648AOptimize structural configurationImprove magnetismTemperature control deviceMagnetic materialsAdditive ingredientTitanium

The invention discloses a permanent magnet alloy of Fe, Cr and Co with composite molybdenum and titanium and a deforming and processing technique thereof, belongs to the field of permanent magnet alloy materials of Fe, Cr and Co, and particularly relates to the alloy of Fe, Cr and Co that has reduced Co content and improved processing performance and the deforming and processing method thereof. The permanent magnet alloy of Fe, Cr and Co with composite molybdenum and titanium consists of following ingredients by weight: 23 to 27 percent of chromium (Cr), 10 to 16 percent of cobalt (Co), 1 to 3 percent of molybdenum (Mo), 0.5 to 1.0 percent of titanium (Ti) and residual quantity of ferrum and unavoidable impurities. The invention can effectively reduce Co content, lower material cost, and improve the magnetic performance and the mechanical processing performance of the alloy material; the processing technique that is provided by the invention comprises a smelting procedure, a smithing procedure, a hot rolling procedure, an acid cleaning procedure, a cold processing procedure and a magnetic performance processing procedure, each of which is arranged reasonably, thus further obtaining higher magnetic performance of the alloy and providing a better method for the deforming and processing of the permanent magnet alloy material of Fe, Cr and Co with high magnetic performance.

Owner:天津冶金集团天材科技发展有限公司

A method for extracting tungsten carbide and cobalt from waste cemented carbide

ActiveCN108910966BHeating evenlyImprove cycle performanceNickel halidesTungsten/molybdenum carbideElectrolytic agentAlloy

The invention provides a method for extracting tungsten carbide and cobalt from waste hard alloy, and belongs to the technical field. The method comprises the following steps: S1, crushing a hard waste alloy into particles, then loading into an electrolytic small box, placing in an electrolysis tank, electrolyzing, adding hydrochloric acid as an electrolyte solution, starting up a heater, and electrolyzing the electrolyte solution cyclically continuously under the action of an acid-resistant pump; S2, when the specific gravity of cobalt chloride in the electrolyte solution reaches 1.15-1.24 kg / dm<3>, pumping the electrolyte solution containing cobalt chloride into a storage tank, soaking the alloy particles with clear water, and then drying the alloy particles; and S3, carrying out magnetic separation of the dried alloy particles, smashing a cobalt-containing magnetic absorption material into particles with the diameter of 1-6 mm by an air heavy hammer, then loading into the electrolysis tank, electrolyzing again, and separating to obtain tungsten carbide and a cobalt chloride solution. By improvement of the electrolysis tank and the electrolytic process, the cobalt content in thefinished tungsten carbide product after electrolysis is completed is about 0.07%.

Owner:HUNAN GOLDEN EAGLE ENERGY TECH CO LTD

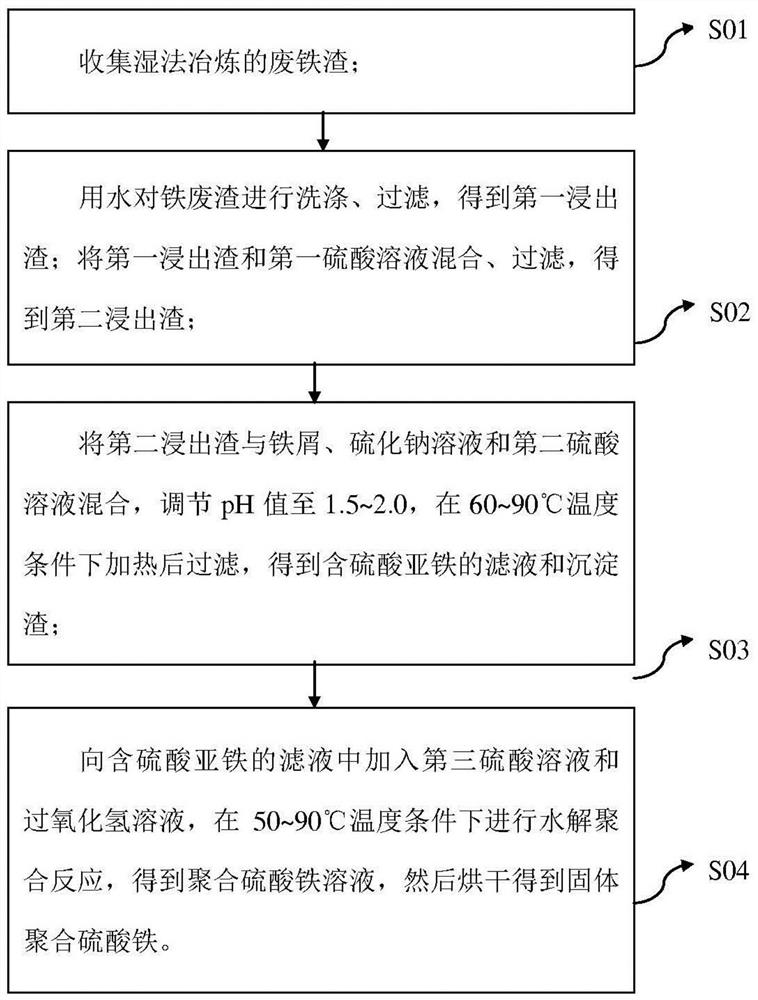

Recovery method of hydrometallurgy iron slag

InactiveCN114045397AReduce cobalt contentEfficient manufacturingIron sulfatesProcess efficiency improvementIron sulfateSlag

The invention relates to the technical field of metal smelting recovery processes, in particular to a recovery method of hydrometallurgy iron slag. The method comprises the following steps: washing and filtering waste iron slag with water to obtain first leaching slag; mixing the first leaching residues with a first sulfuric acid solution, and filtering to obtain second leaching residues; mixing the second leaching residues with scrap iron, a sodium sulfide solution and a second sulfuric acid solution, adjusting the pH value to 1.5-2.0, heating at the temperature of 60-90 DEG C, and filtering to obtain filtrate containing ferrous sulfate and precipitation residues; and adding a third sulfuric acid solution and a hydrogen peroxide solution into the filtrate containing ferrous sulfate, and carrying out hydrolytic polymerization reaction at the temperature of 50-90 DEG C to obtain a polymeric ferric sulfate solution. The method not only can recycle cobalt effectively , but also can prepare polymeric ferric sulfate efficiently, and has the advantages of being low in equipment requirement, short in process and low in energy consumption.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

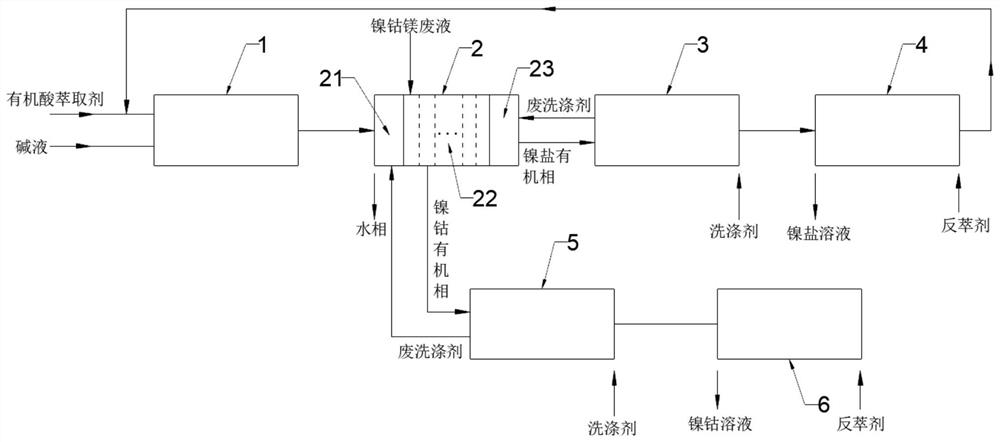

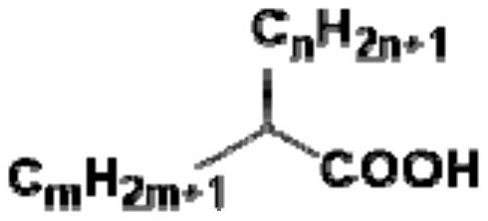

Three-outlet extraction method and system device for obtaining nickel salt solution and nickel-cobalt solution through separation

The invention provides a three-outlet extraction method and system device for obtaining a nickel salt solution and a nickel-cobalt solution through separation, and the method comprises the following steps: carrying out three-outlet multi-stage fractional extraction on a nickel-cobalt-magnesium waste liquid by adopting an organic acid extraction solution, and respectively obtaining a nickel salt organic phase and a nickel-cobalt organic phase after extraction, and a nickel salt solution and a nickel-cobalt solution are obtained through washing and reverse extraction in sequence. According to the three-outlet extraction method provided by the invention, the organic acid extraction solution is used as the extraction agent to realize direct extraction and separation of nickel and cobalt, and the adopted organic acid extraction solution has high extraction rate on nickel and cobalt, so that the problems of long technological process and high investment in the prior art are effectively solved.

Owner:BOTREE CYCLING SCI & TECH CO LTD

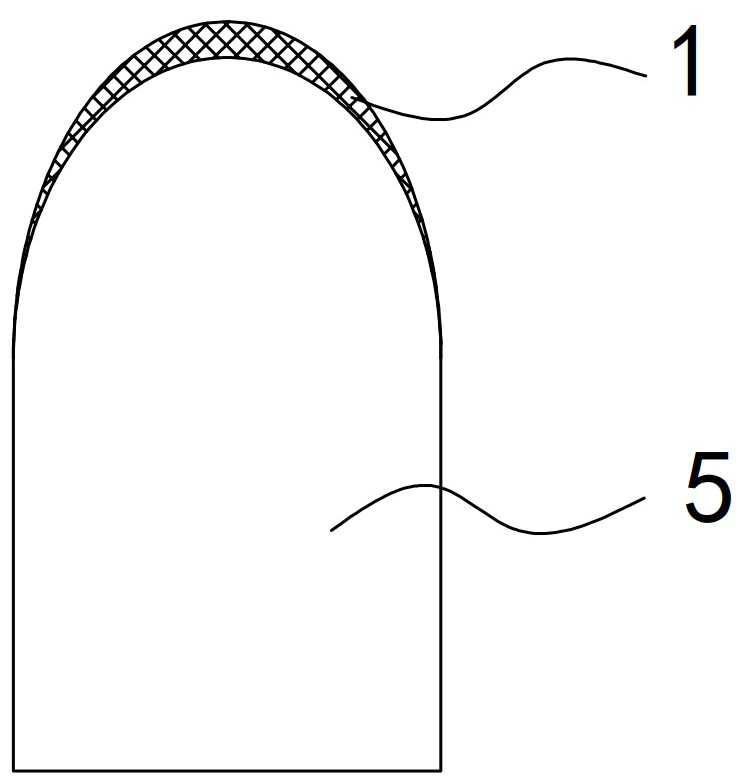

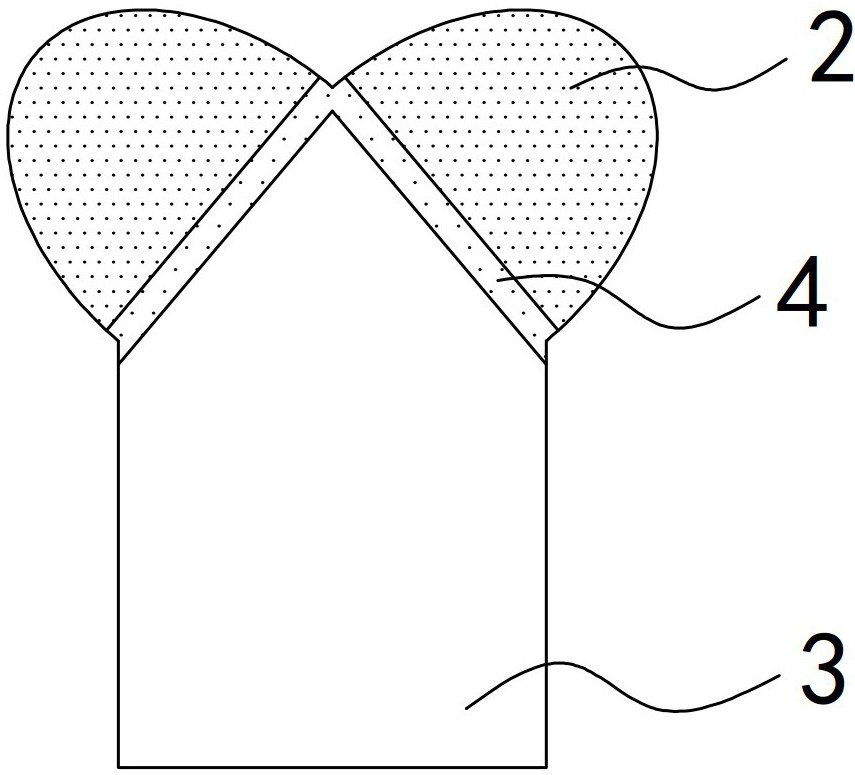

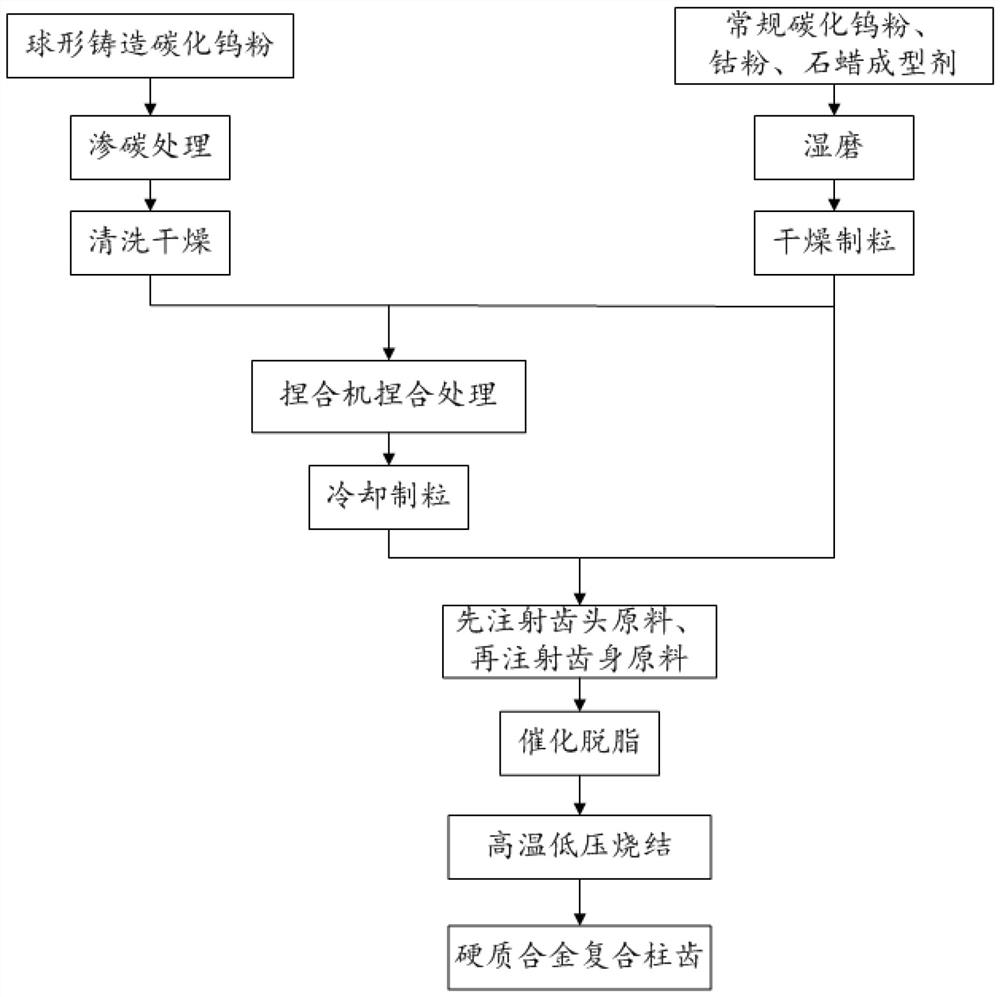

A kind of multi-tooth-head cemented carbide composite column tooth and its preparation method

ActiveCN111451510BImprove toughnessHigh hardnessDrill bitsTransportation and packagingAlloy compositeCemented carbide

A multi-head cemented carbide composite column tooth and a preparation method thereof, wherein the cemented carbide composite column tooth is designed into a tooth head and a tooth body in the height direction, the tooth head includes 2 to 3 tooth heads, and the tooth head It is axisymmetrically distributed, including the steps: Step 1: Prepare the tooth body raw material and the tooth head raw material; the tooth head includes 10~20wt% carbonized spherical cast tungsten carbide particles, 1~7wt% wax-based composite molding agent, and the balance is Tooth material. Step 2: Inject the tooth head raw material and the tooth body raw material into the mold respectively through a co-injection molding method to obtain a soft cylindrical tooth blank with a composite structure. Step 3: Carrying out high-temperature and low-pressure sintering on the soft billet of the column tooth with a composite structure, the metallurgical reaction at the bonding interface of the tooth head and the tooth body forms a transition layer, and integrally forms a cemented carbide composite column tooth with multiple tooth heads. It solves the technical problem that the existing cemented carbide column tooth cannot take into account both wear resistance and toughness at the same time, and significantly improves the wear resistance and rock breaking efficiency of the column tooth, thereby improving the service life and drilling speed of the drilling tool.

Owner:SHAREATE TOOLS

Nickel-free ferrous tin-cobalt alloy plating solution and process for utilizing plating solution for electroplating

The present invention relates to a nickel-free ferrous tin-cobalt alloy plating solution and a process for utilizing the plating solution for electroplating. The plating solution comprises the following compositions: 0.2 to 6 g / L of tin, 0.6 to 4 g / L of cobalt, 8 to 180 g / L of complexant, 2 to 20 g / L of melanizing agent and 50 to 320 g / L of pH buffer. The parameters of the plating solution are as follows: the Baume of the plating solution is between 10 and 25 baume degrees; the temperature is between 28 and 48 DEG C; and the pH is between 10 and 13. The coating of the nickel-free ferrous tin-cobalt alloy plating solution is an alloy layer taking the tin as a main material, and a small amount of cobalt is added into the coating to form a binary alloy system; the cobalt content in a general ferrous tin-cobalt alloy plating solution exceeds 8 g / L, but the novel electroplating process can reduce the cobalt content to 0.8 g / L; and due to adoption of the special biodegradable stable complexant and the special biodegradable pH buffer, the production cost can be reduced, novel EU standards can be reached simultaneously, and various problems of the prior ferrous tin-cobalt alloy plating solution and the prior process can be solved.

Owner:佛山市兴中达化工实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com