High-power multi-component material and preparation method thereof

A high-power, multi-dimensional technology, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve problems such as structural peeling, price rise, collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare 20L of nickel-cobalt-manganese salt solution with a concentration of 2M, the molar ratio of nickel-cobalt-manganese is 8.2:1:0.8, add 25g of tin chloride to the nickel-cobalt-manganese salt solution, and continue stirring with 35g of KN-B additive to obtain a mixed solution.

[0036] Add 5L of deionized water and 5g of KN-B into the reactor under nitrogen protection, add the prepared mixed solution at a constant speed of 1L / h at a speed of 600rpm, and at the same time control the pH value at 10.6±0.02 by adding ammonia water to the sodium hydroxide solution until the mixed solution is completely poured in to obtain a solid-liquid mixture.

[0037] The solid-liquid mixture was separated by centrifugal filtration, washed to neutrality and then dried at 220°C for 4 hours. After sieving, the 8-series high-power ternary precursor material of the present invention can be obtained.

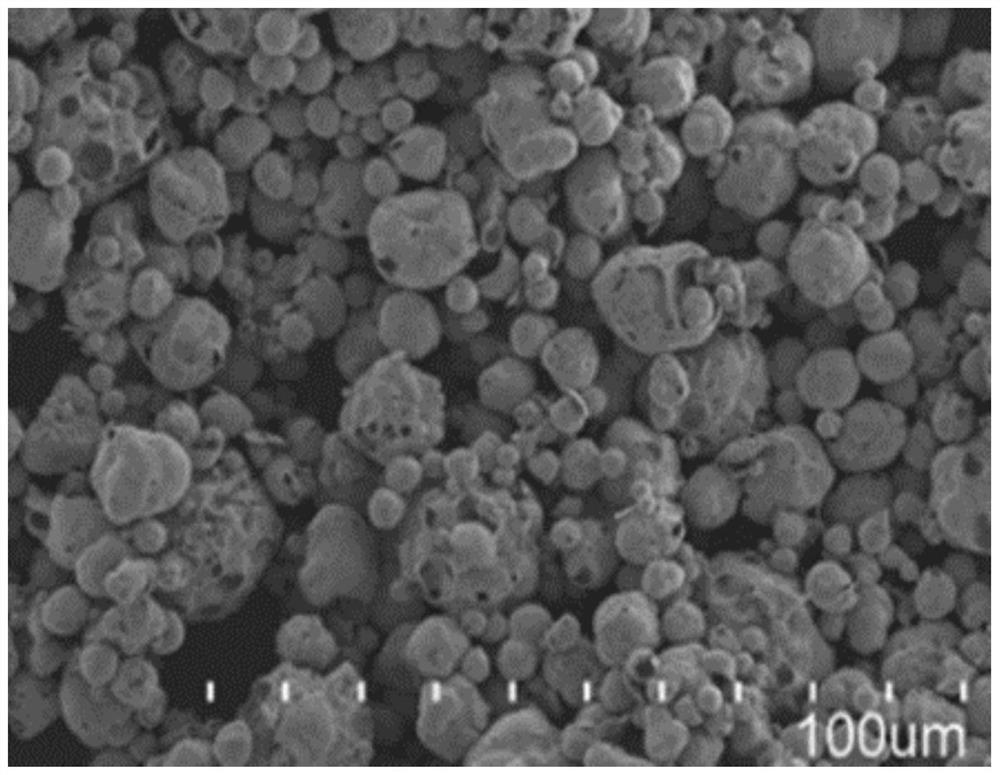

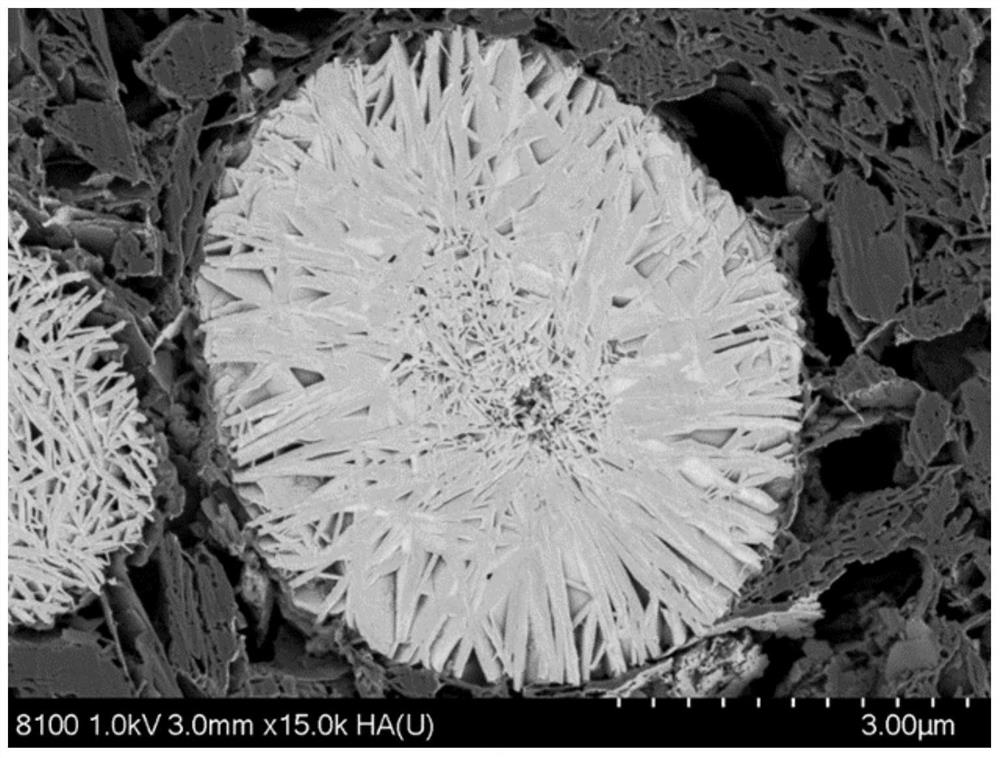

[0038] Such as figure 1 As shown, the primary particle size of the material is 0.1-0...

Embodiment 2

[0040] Prepare 20L of nickel-cobalt-manganese salt solution with a concentration of 2M, the molar ratio of nickel-cobalt-manganese is 55:15:30, add 30g KN-R and 25g niobium nitrate, and keep stirring to obtain a mixed solution.

[0041] Add 5L of deionized water and 5g of KN-R into the nitrogen-protected reactor, and add the prepared mixed solution at a constant speed of 1L / h at a speed of 800rpm, and at the same time control the pH value at 10.95±0.02 by adding ammonia water to the sodium hydroxide solution , until the salt solution is completely injected, and a solid-liquid mixture is obtained.

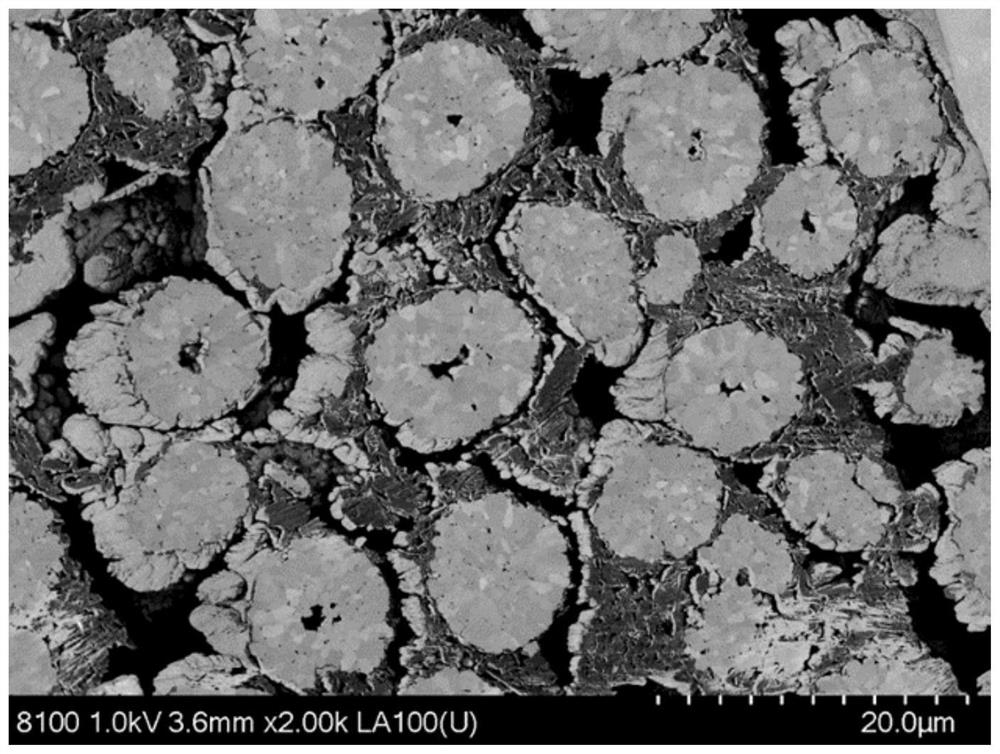

[0042]The solid-liquid mixture was separated by centrifugal filtration, washed to neutrality and then dried at 280°C for 4 hours. After sieving, the high-power ternary precursor material of the present invention can be obtained. Mix the precursor and lithium carbonate uniformly at a molar ratio of 1:1.03, bake in an air atmosphere furnace at 750 degrees for 6 hours, and bake at 920...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com