Low-cobalt positive electrode material and preparation method and application thereof

A positive electrode material and reaction technology, applied in the field of low-cobalt positive electrode materials and their preparation, can solve the problems of low-cobalt material stability needs to be improved, low-cobalt material preparation methods are complicated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

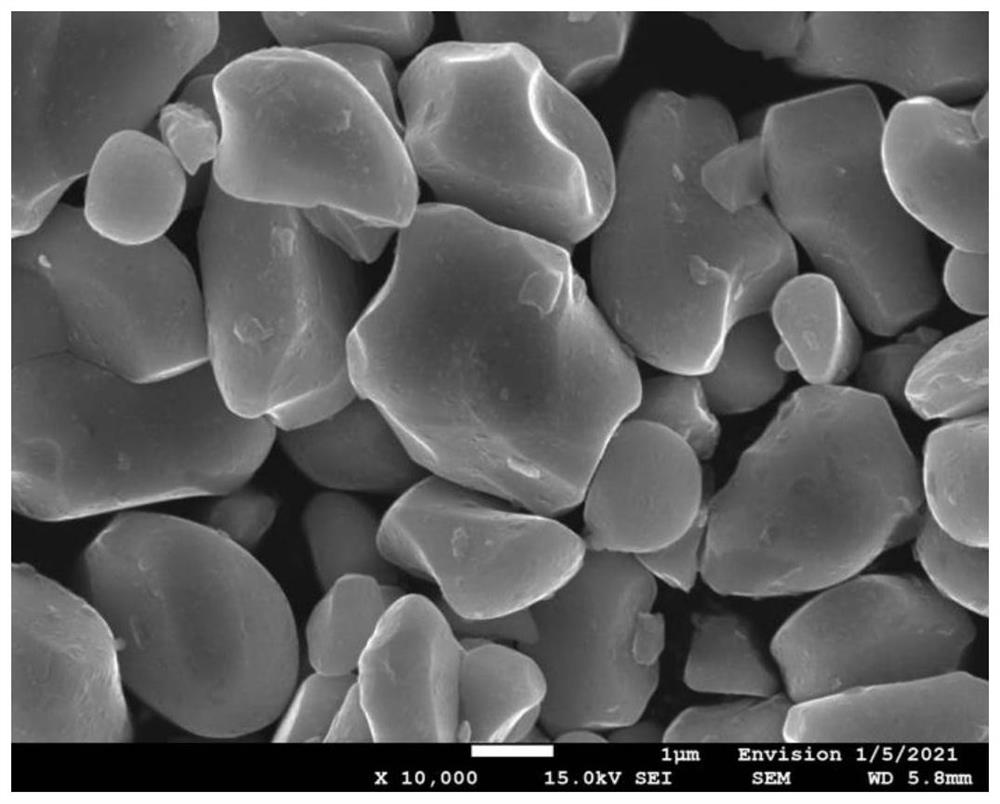

Image

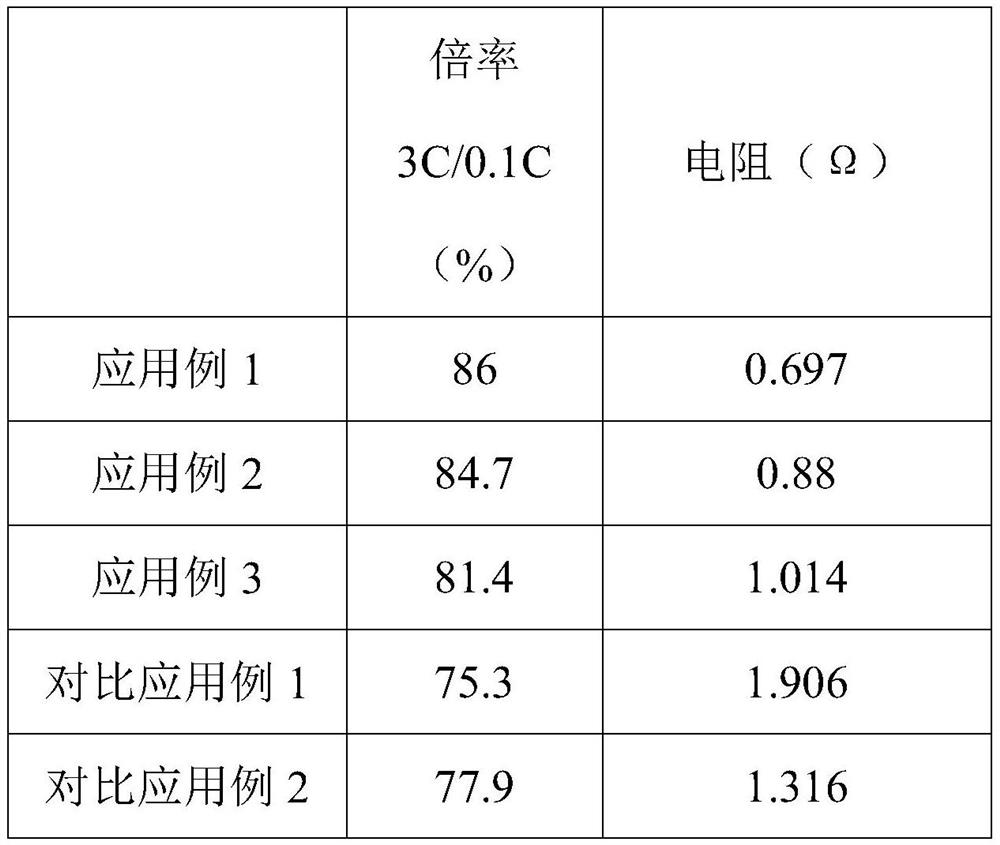

Examples

Embodiment 1

[0046] A preparation method of a low-cobalt cathode material, the preparation method comprising the steps of:

[0047] (1) Nickel sulfate, cobalt sulfate, manganese sulfate, ammonia water and sodium hydroxide are continuously added to the reactor for reaction to obtain ternary precursor particles;

[0048] The add-on of sodium hydroxide is 15L / h in the process of adding reactor; The add-on of ammoniacal liquor is 10L / h; According to the increase rate of 0.0002mol / L.min increased to 0.15mol / L, the molar concentration of manganese decreased from 0.4mol / L to 0.3mol / L according to the decrease rate of 0.0002mol / L.min, the ammonia water The molar concentration is 3mol / L, and the molar concentration of sodium hydroxide is 10mol / L;

[0049] (2) Mix the ternary precursor particles obtained in step (1) with the lithium precursor at a molar ratio of 1:1.06, and sinter at 950° C. for 8 hours to obtain the low-cobalt positive electrode material.

Embodiment 2

[0051] A preparation method of a low-cobalt cathode material, the preparation method comprising the steps of:

[0052] (1) Add nickel sulfate, cobalt sulfate, manganese sulfate / ammonia water and sodium hydroxide to the reaction kettle for reaction to obtain ternary precursor particles;

[0053] The add-on of sodium hydroxide is 10L / h in the process of adding reactor; The add-on of ammoniacal liquor is 5L / h; According to the increase rate of 0.0002mol / L.min increased to 0.14mol / L, the molar concentration of manganese decreased from 0.36mol / L to 0.26mol / L according to the decrease rate of 0.0002mol / L.min, the mole of ammonia Concentration is 2mol / L, and the molar concentration of sodium hydroxide is 10mol / L;

[0054] (2) Mix the ternary precursor particles obtained in step (1) with the lithium precursor at a molar ratio of 1:1.06, and sinter at 1000° C. for 7 hours to obtain the low-cobalt positive electrode material.

Embodiment 3

[0056] A preparation method of a low-cobalt cathode material, the preparation method comprising the steps of:

[0057] (1) Add nickel sulfate, cobalt sulfate, manganese sulfate / ammonia water and sodium hydroxide to the reaction kettle for reaction to obtain ternary precursor particles;

[0058] The add-on of sodium hydroxide is 20L / h in the process of adding reactor; The add-on of ammoniacal liquor is 15L / h; According to the increase rate of 0.0002mol / L.min increased to 0.14mol / L, the molar concentration of manganese decreased from 0.45mol / L to 0.36mol / L according to the decrease rate of 0.0002mol / L.min, the mole of ammonia Concentration is 3mol / L, and the molar concentration of sodium hydroxide is 10mol / L;

[0059] (2) Mix the ternary precursor particles obtained in step (1) with the lithium precursor at a molar ratio of 1:1.06, and sinter at 900° C. for 9 hours to obtain the low-cobalt positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com