High-concentration fast preparation method for silver nanowires

A silver nanowire, high-concentration technology, applied in the field of high-concentration and rapid preparation of silver nanowires, to achieve high yield, good stability, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

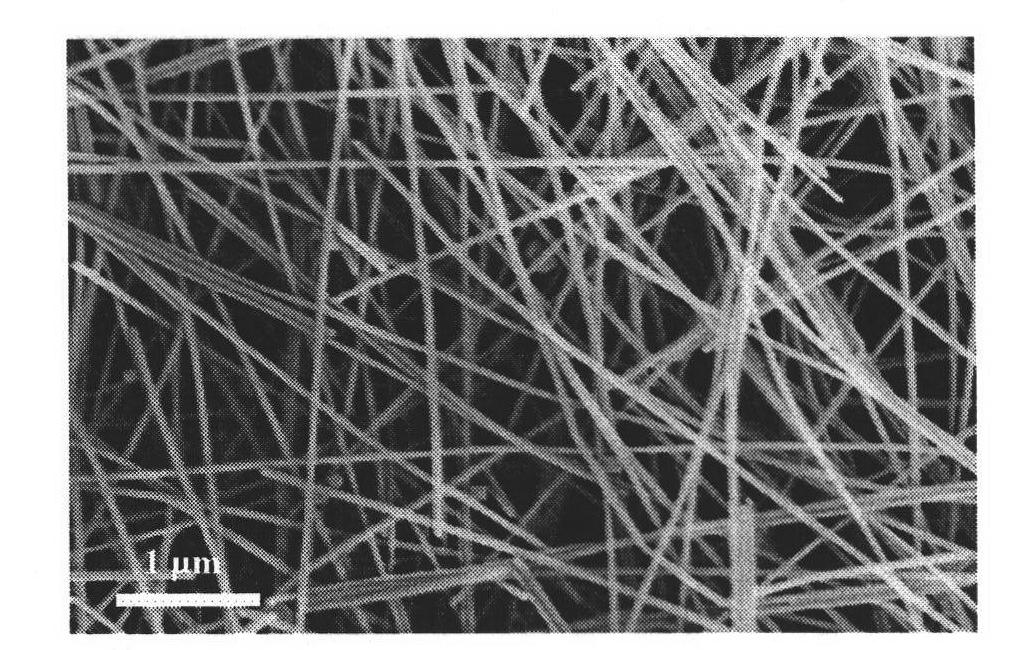

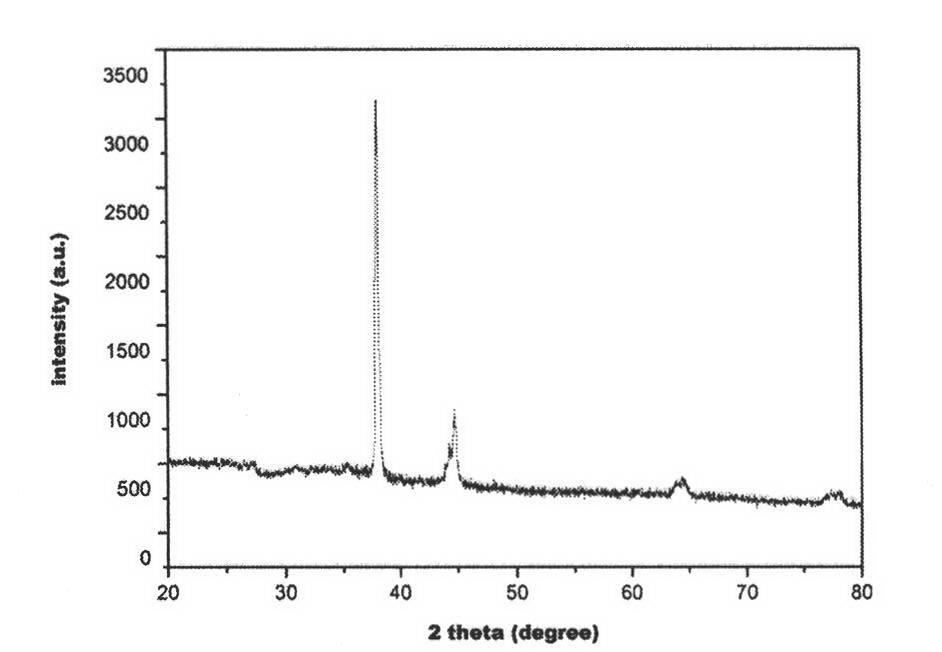

Embodiment 1

[0036] A closed 100ml three-necked flask equipped with a condensing reflux device was filled with argon and placed in an oil bath at 180°C; 10ml of ethylene glycol was added and preheated with a magnetic stirrer for 30min; then the molar concentration of 10ml was 0.3M The ethylene glycol solution of silver nitrate was added to the preheated ethylene glycol solution, and the addition rate was controlled to 50ml / min. At the same time, 10ml of polyvinylpyrrolidone glycol solution with a molar concentration of 0.3M was added. The alcohol solution contains copper chloride with a molar concentration of 0.05 mM, and the addition rate is controlled to be 1 ml / min; the reaction time is 15 minutes; the mother liquor of silver nanowires is obtained by cooling to room temperature; after the reactants are naturally cooled, the mother liquor of silver nanowires is transferred to Three 50ml centrifuge tubes, add a solution of 10:1 volume ratio of acetone to ethanol; ultrasonic for 1min to mix ...

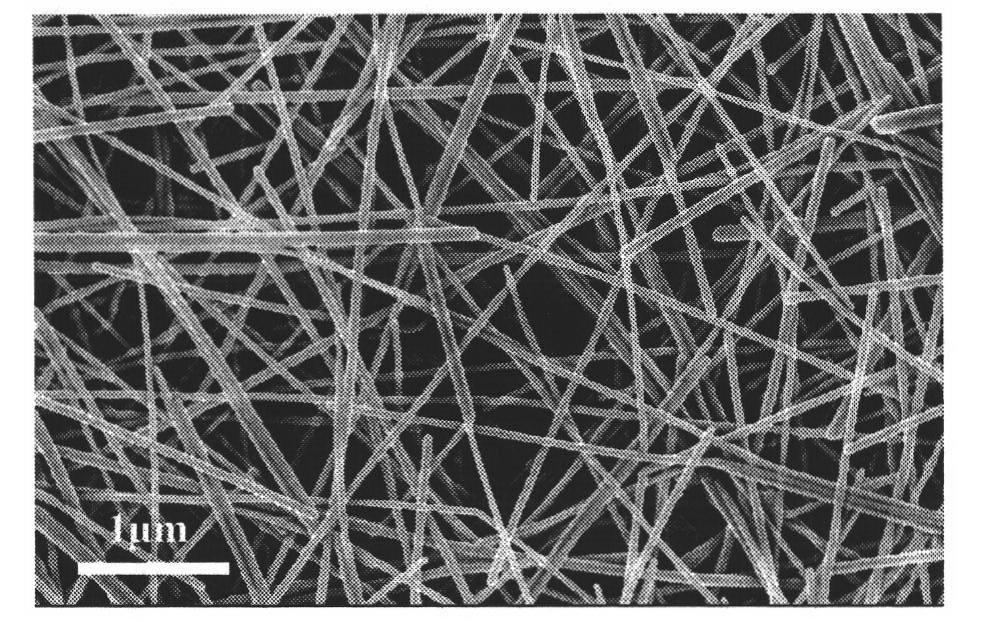

Embodiment 2

[0038] A closed 100ml three-necked flask equipped with a condensing reflux device was filled with argon and placed in an oil bath at 180°C; 10ml of ethylene glycol was added and preheated with a magnetic stirrer for 30min; then the molar concentration of 10ml was 0.3M The ethylene glycol solution of silver nitrate was added to the preheated ethylene glycol solution, and the addition rate was controlled to 50ml / min. At the same time, 10ml of 0.5M polyvinylpyrrolidone glycol solution with a molar concentration of 0.5M was added. The alcohol solution contains copper chloride with a molar concentration of 0.05 mM, and the addition rate is controlled to 10 ml / min; the reaction time is 30 minutes; the mother liquor of silver nanowires is obtained by cooling to room temperature; after the reactants are naturally cooled, the reaction mother liquor is transferred to 3 Add a 50ml centrifuge tube with a volume ratio of acetone to ethanol of 5:1; sonicate for 1 min to mix well and centrifug...

Embodiment 3

[0040] A closed 100ml three-necked flask equipped with a condensing reflux device was filled with argon and placed in an oil bath at 180°C; 10ml of ethylene glycol was added and preheated with a magnetic stirrer for 30min; then the molar concentration of 10ml was 0.3M The ethylene glycol solution of silver nitrate was added to the preheated ethylene glycol solution, and the addition rate was controlled to 50ml / min; at the same time, 10ml of polyvinylpyrrolidone ethylene glycol solution with a molar concentration of 1.5M was added. The alcohol solution contains copper chloride with a molar concentration of 0.05 mM, and the addition rate is controlled to 5 ml / min; the reaction time is 15 minutes; the mother liquor of silver nanowires is obtained by cooling to room temperature; after the reactants are naturally cooled, the reaction mother liquor is transferred to 3 Add a 50ml centrifuge tube with a solution of 10:1 volume ratio of acetone and ethanol; ultrasonicate for 1min to mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com