Patents

Literature

51results about How to "Improved rate cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

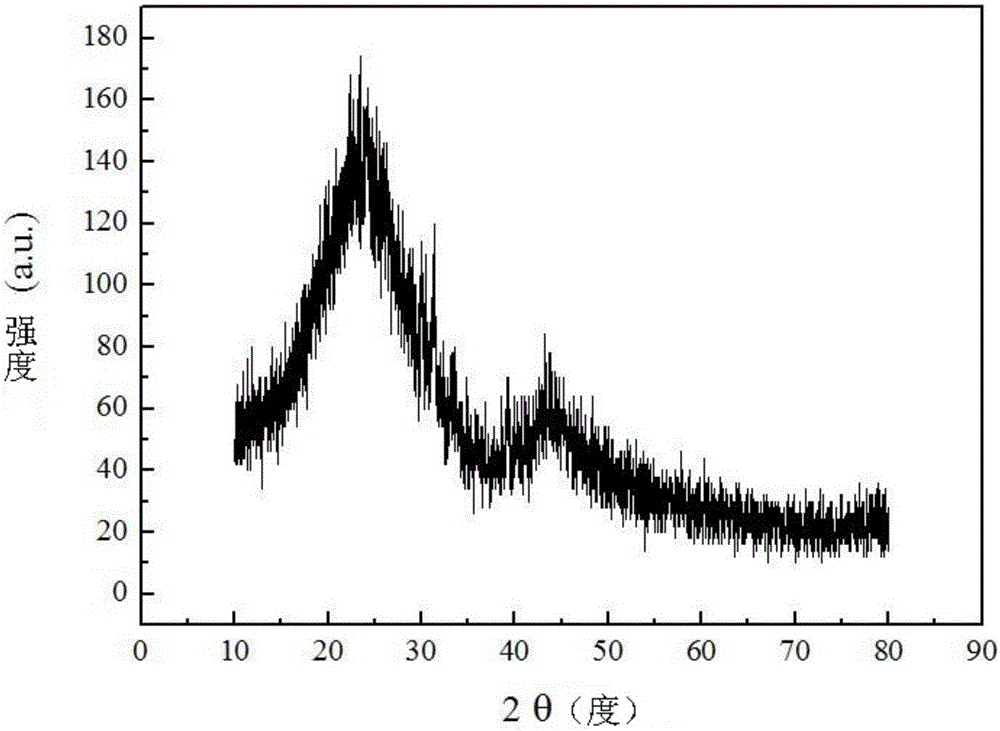

Preparation method and application of nitrogen-doped porous carbon negative electrode material

InactiveCN107919461AImprove conductivityImproved rate cycle performanceCell electrodesSecondary cellsPorous carbonHigh energy

The invention belongs to the technical field of carbon material preparation, belongs to the category of alkali metal ion secondary energy storage and relates to a method for preparing nitrogen-doped porous carbon from perinone nitrogen-containing polycyclic aromatic hydrocarbon as a carbon source and an application of the nitrogen-doped porous carbon as a negative electrode or positive electrode material for an alkali metal ion secondary battery. According to the method, perinone nitrogen-containing conjugated polycyclic aromatic hydrocarbon is firstly mixed with a template or an activator andthermal decomposition carbonization is carried out at the temperature within a certain range to obtain a nitrogen-doped porous carbon negative electrode or positive electrode material. By adopting the perinone nitrogen-containing conjugated polycyclic aromatic hydrocarbon with large molecular weight as the carbon source, the loss of a nitrogen element in a thermal treatment process can be reduced, high-proportion nitrogen doping in the porous carbon is effectively achieved and electrochemical oxidation reduction sites are effectively increased. According to the method, the specific surface area of the porous carbon can be adjusted and controlled through the carbon source screening, thermal treatment carbonization temperature and the mass ratio of the template or the activator, the chargeexchange interface is increased and high energy storage is effectively achieved. The material has the advantages that (1) the structure is abundant and the perinone material is cheap and available; and (2) the material has relatively high energy density, magnification power density and cycling stability.

Owner:NANJING UNIV OF TECH

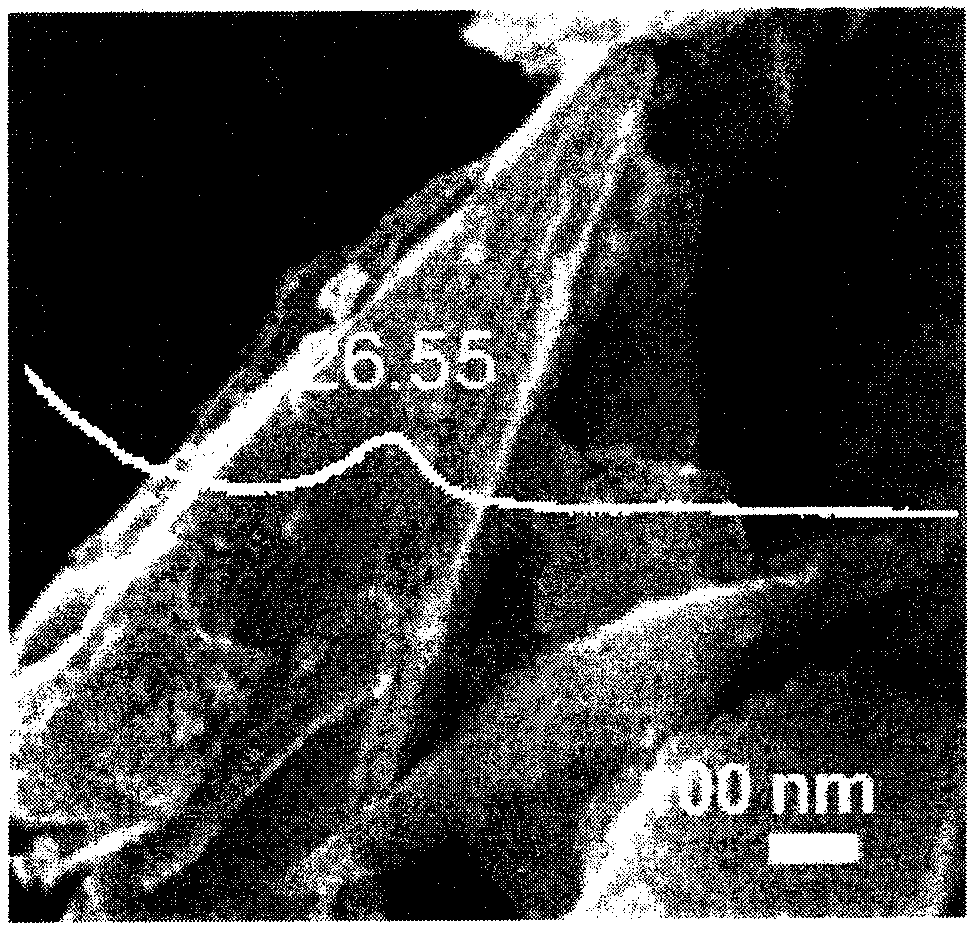

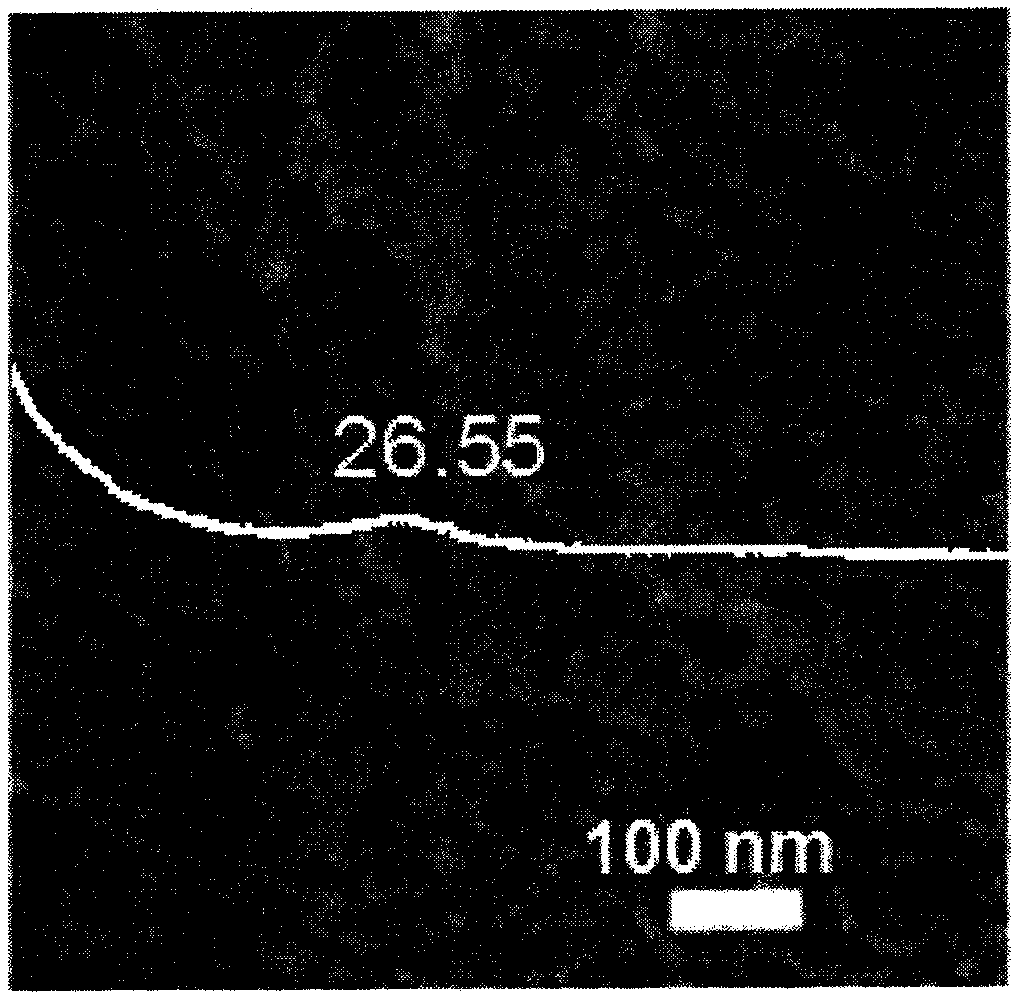

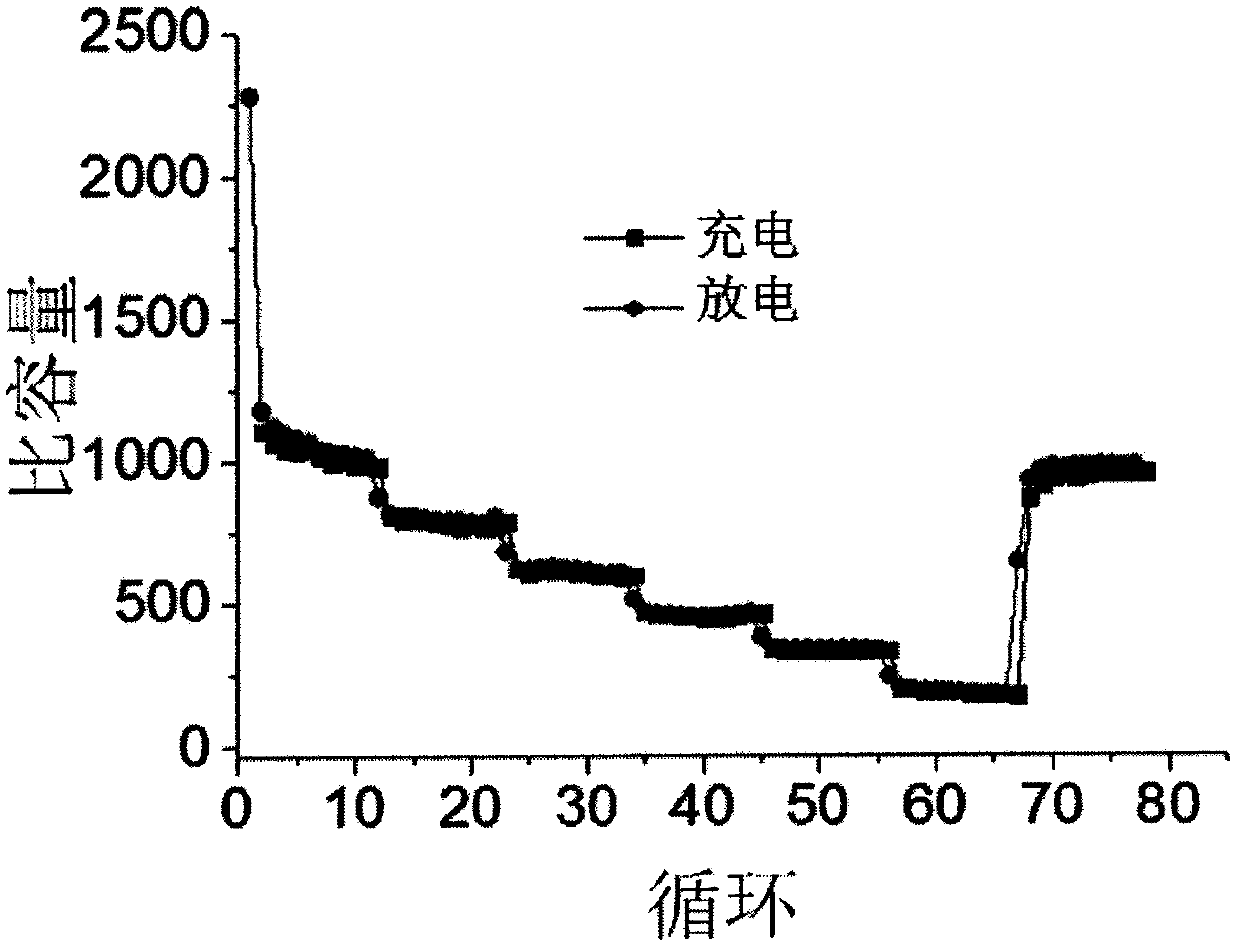

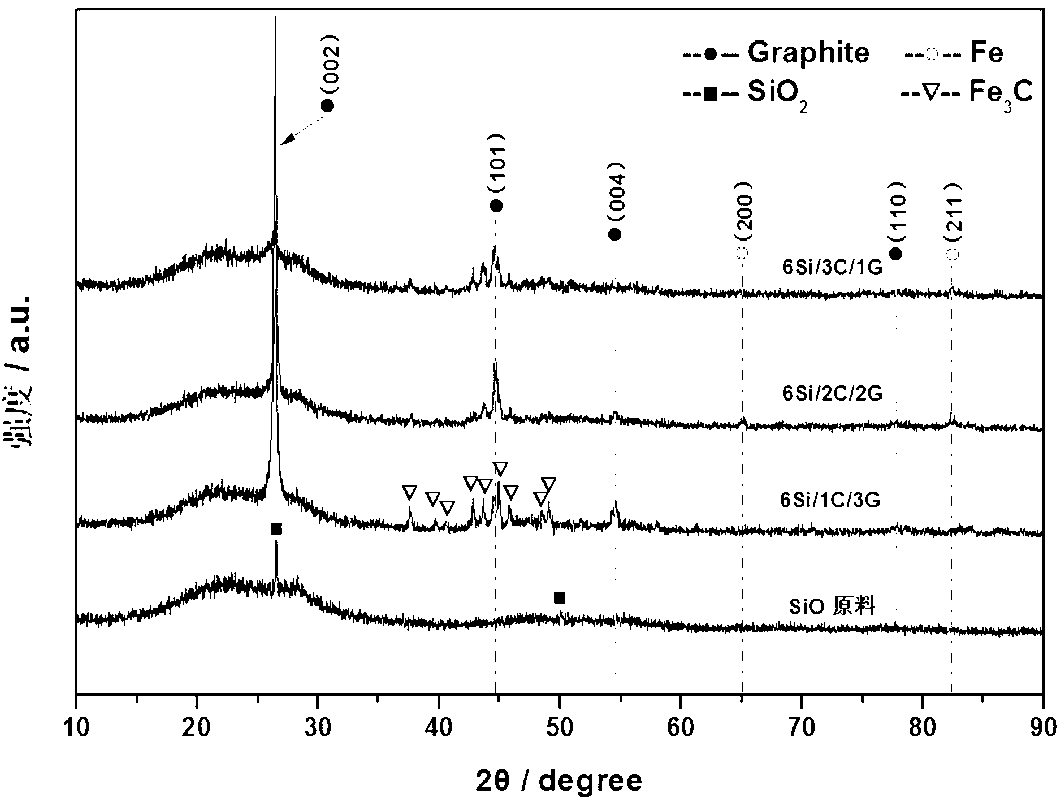

High-performance silicon monoxide/amorphous carbon/graphite composite negative electrode material and preparation method thereof

ActiveCN103258988AIncrease capacityImprove cycle stabilityCell electrodesSilicon monoxideHigh energy

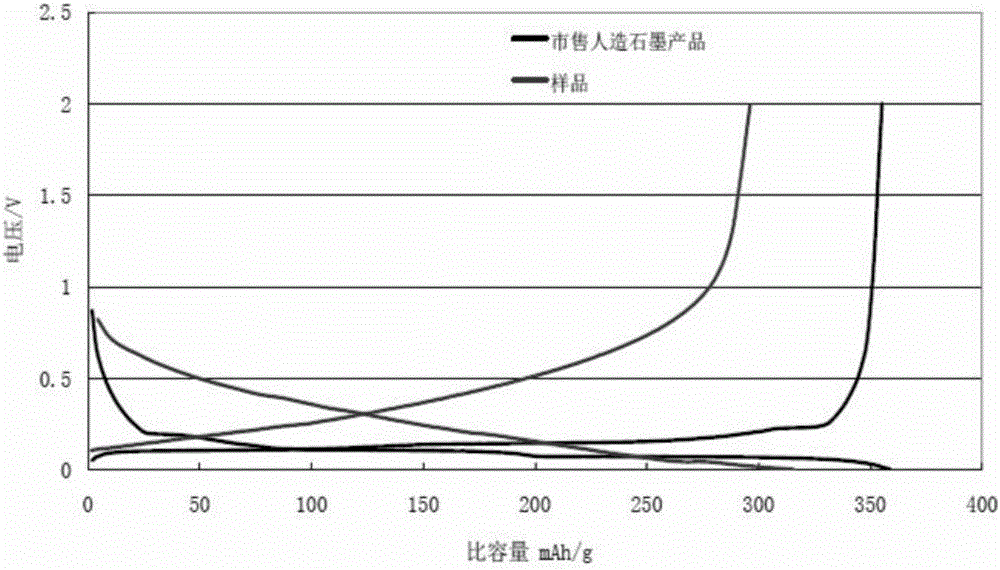

The invention discloses a high-performance silicon monoxide / amorphous carbon / graphite composite negative electrode material. The high-performance silicon monoxide / amorphous carbon / graphite composite negative electrode material comprises the following components in parts by weight: 5-7 parts of silicon monoxide, 1-2 parts of carbohydrate and 1-4 parts of natural flake graphite. The preparation method of the composite negative electrode material comprises the following steps of: mixing the materials; carrying out high-energy ball milling and high-temperature pyrolysis; and grinding and sieving to obtain the composite material. The composite negative electrode material is excellent in cycle performance and capacity performance, so that a certain feasibility choice is provided for practicability of the SiO negative electrode material. Moreover, the preparation method is simple to operate, environment-friendly, pollution-free and easy to popularize.

Owner:CHINA THREE GORGES UNIV +1

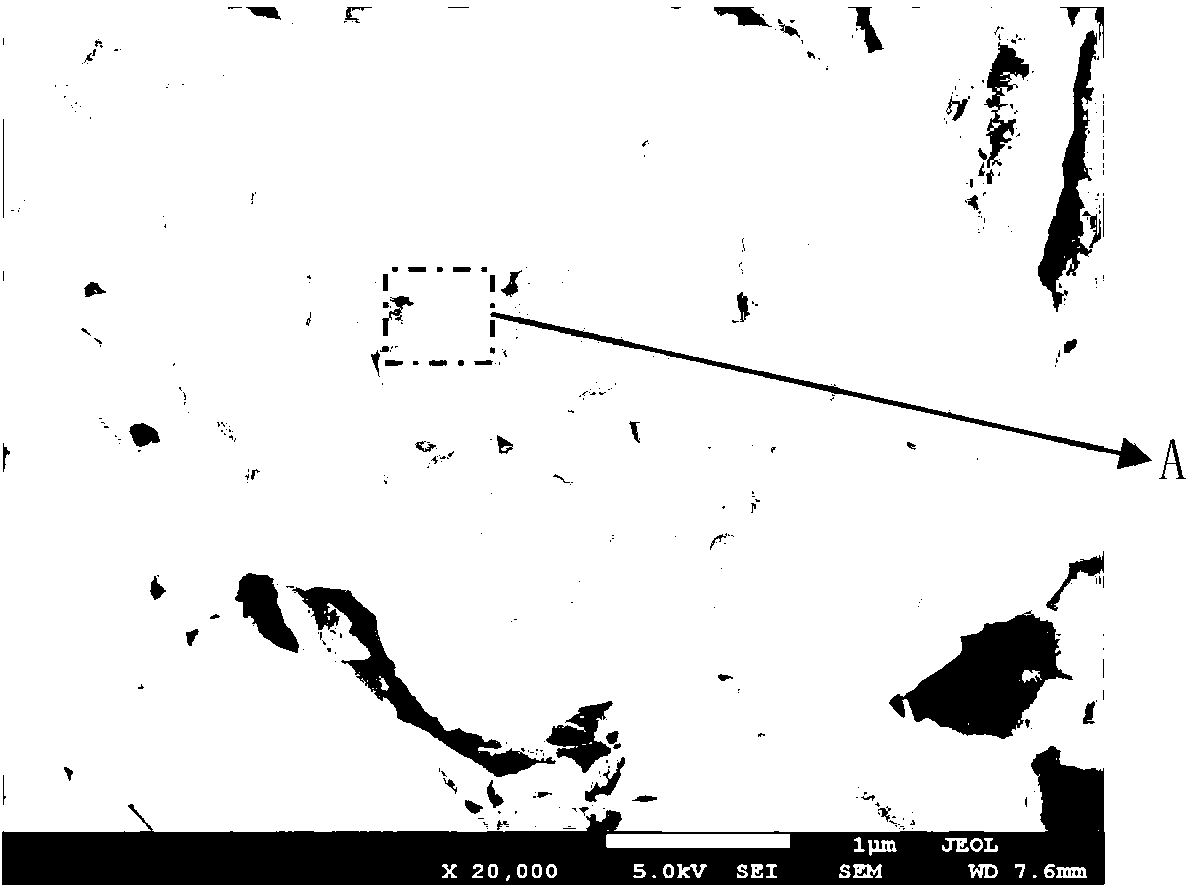

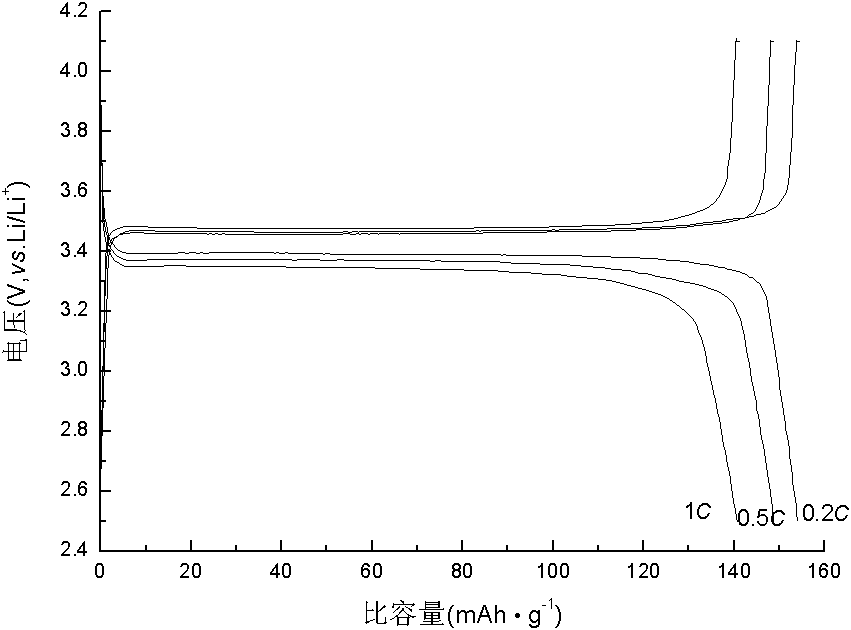

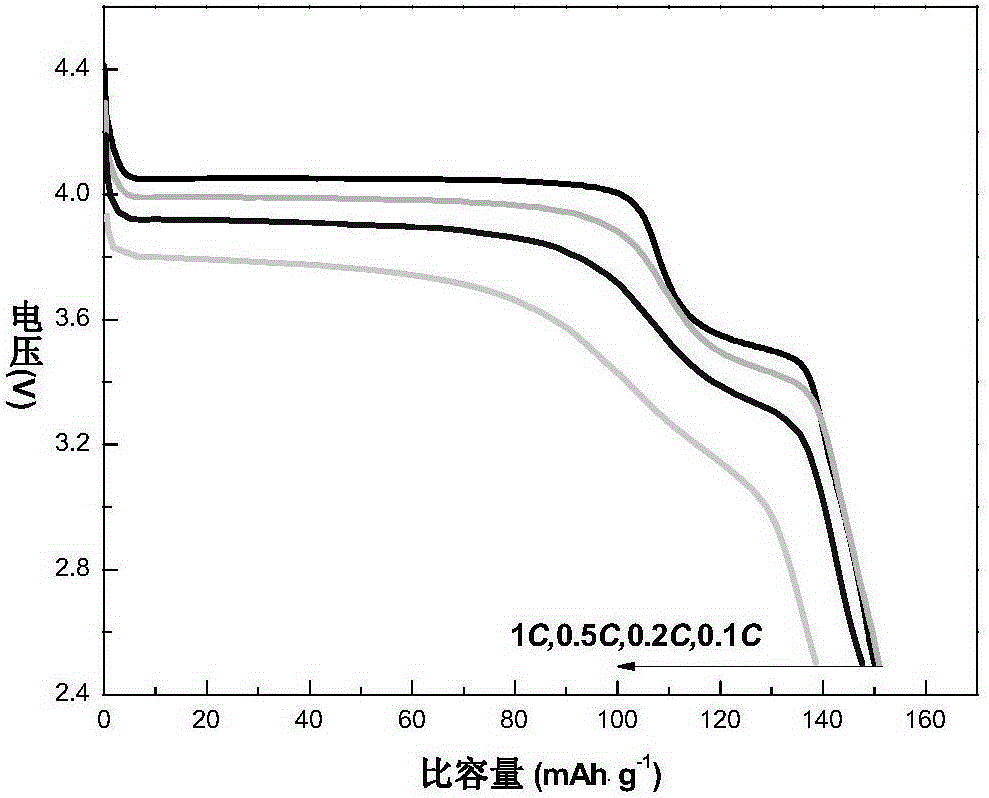

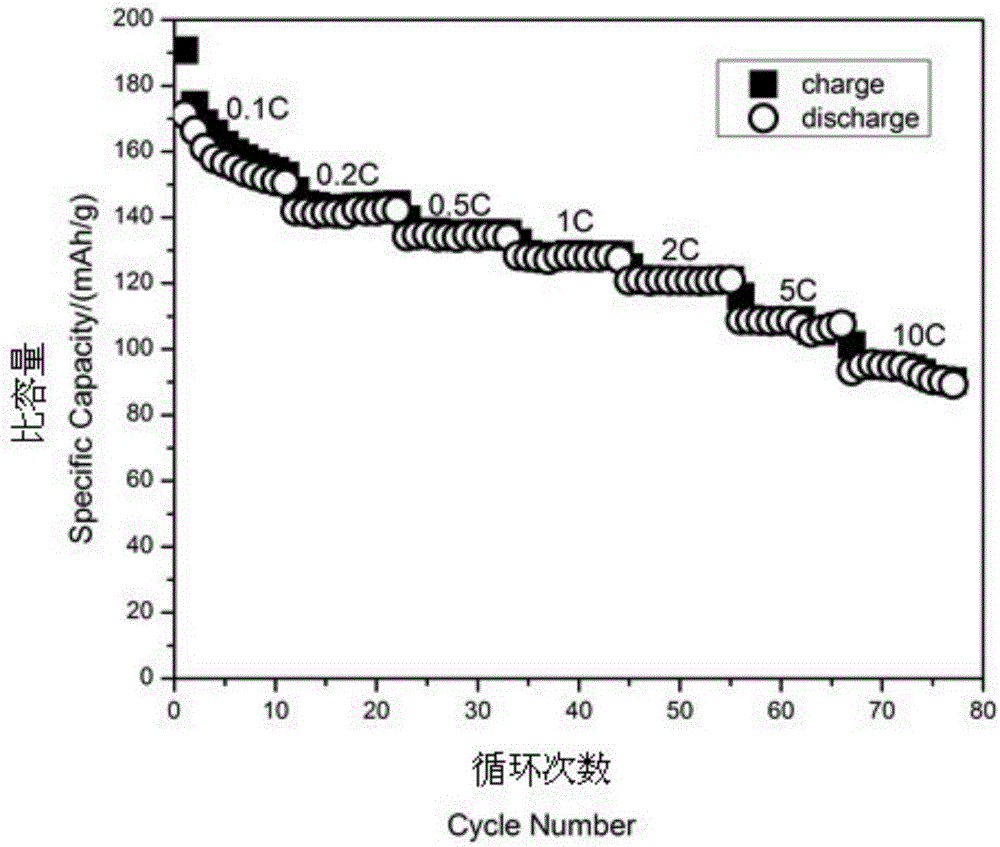

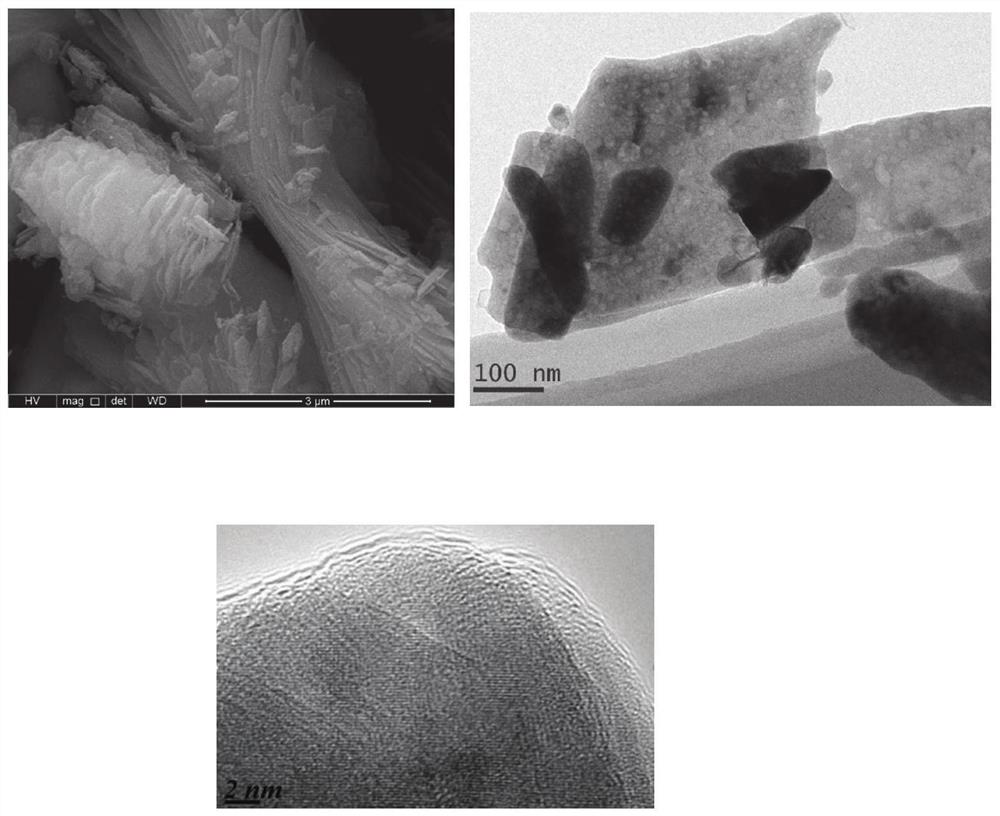

Preparation method of nano LiFel-xMxPO4/C lithium phosphate composite positive pole material

ActiveCN101789504AImprove dynamic conditionsComposition is stableCell electrodesChemical reactionHigh energy

The invention relates to a preparation method of nano LiFel-xMxPO4 / C lithium phosphate composite positive pole material. Lithium dihydrogen phosphate, iron powder, an M element source and an organic carbon source are uniformly mixed in a solvent medium, are treated for 2 to 7h through a high-energy ball mill, have chemical reaction under mechanical activation, and a uniformly dispersed precursor is prepared. The precursor is thermally treated for 2 to 10h at 600 to 800 DEG C under atmosphere protection and cooled to be room temperature, and the nano LiFel-xMxPO4 / C lithium phosphate composite positive pole material is prepared. The preparation method has simple and high-efficiency process and the whole process does not produce ammonia, wastewater and other polluting substances, and is applicable to industrial production. The primary particles of the prepared material are nano particles which are uniformly distributed, and the material is characterized by high specific capacity and good rate cycle performance.

Owner:四川浩普瑞新能源材料股份有限公司

Nitrogen-enriched carbon shell cladded nano core-shell-structure carbonaceous carrier as well as preparation method and application thereof

ActiveCN106711457ARich dopingImprove electrochemical performanceCell electrodesChemical adsorptionLithium sulfur

The invention discloses a nitrogen-enriched carbon shell cladded nano core-shell-structure carbonaceous carrier as well as a preparation method and application thereof. The carbonaceous carrier comprises a carbonaceous inner core and a nitrogen-enriched carbon shell covering the carbonaceous inner core. The carbonaceous carrier provided by the invention not only has abundant doping amount of a nitrogen element, but also has high polysulfide ion physical and chemical adsorption capabilities and excellent electrochemical stability; when the carbonaceous carrier is applied to a lithium-sulfur battery and is used as a positive electrode of a lithium-sulfur secondary battery, high capacity and rate circulating performance, and ultrahigh electrochemical stability can be kept even if the lithium-sulfur secondary battery is circularly charged and discharged for a long period, so that the whole electrochemical performance of the battery is improved; and meanwhile, a preparation process of the carbonaceous carrier has moderate conditions, low energy consumption and low cost and large-scale production is easy to realize.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

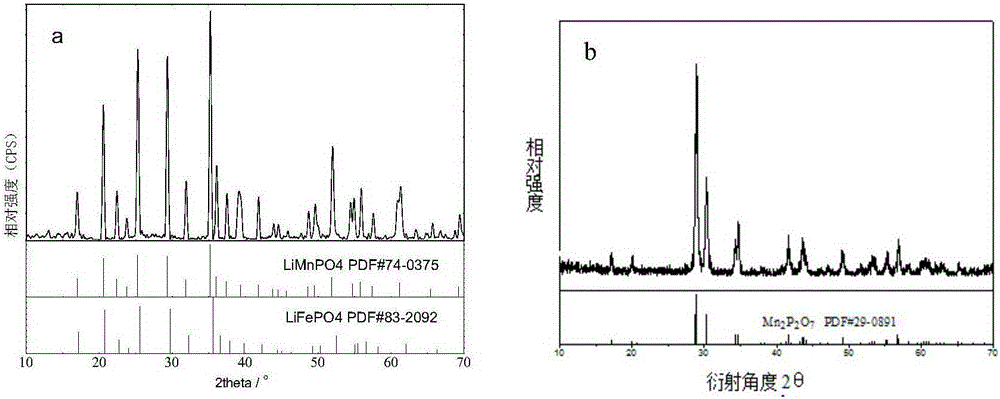

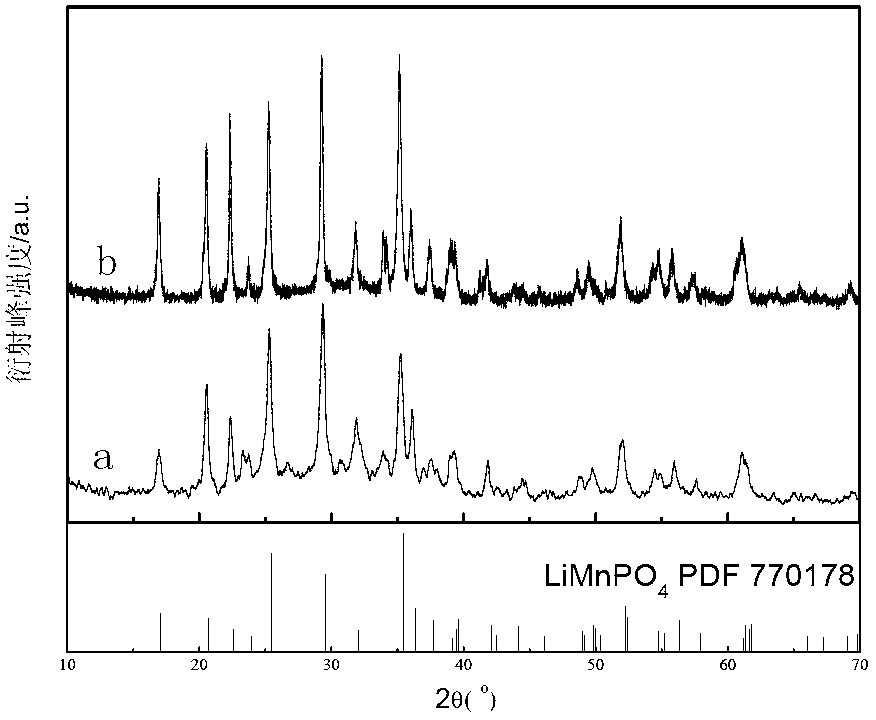

Synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4/C

InactiveCN105355885AUniform controlAdd lessSecondary cellsPositive electrodesHigh rateSynthesis methods

The invention relates to a synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4 / C. A manganese source, an iron source, a phosphorus source and an organic carbon source are evenly mixed and processed by a high-energy ball mill. Mixtures are subjected to heat treatment at 500-700 DEG C under the protection of inert atmosphere so that (Mn1-xFex)2P2O7 / C can be prepared; then, pyrophosphate / carbon, a lithium source and a carbon source are mixed, heat treatment is performed at 600-750 DEG C under protection of inert atmosphere, and ferromanganese lithium phosphate / carbon anode materials with a composite conductive network are obtained. The synthesis method is suitable for large-scale industrialized production, the prepared materials are composed of secondary particles of primary nano-crystals covered with amorphous carbon, distribution is uniform, and the uniform conductive network is formed on the surfaces of phosphate particles in an in-situ mode. The obtained composite cathode material has high rate capacity and high compaction intensity and has good application prospects in the aspect of high-energy-density lithium ion batteries.

Owner:CENT SOUTH UNIV

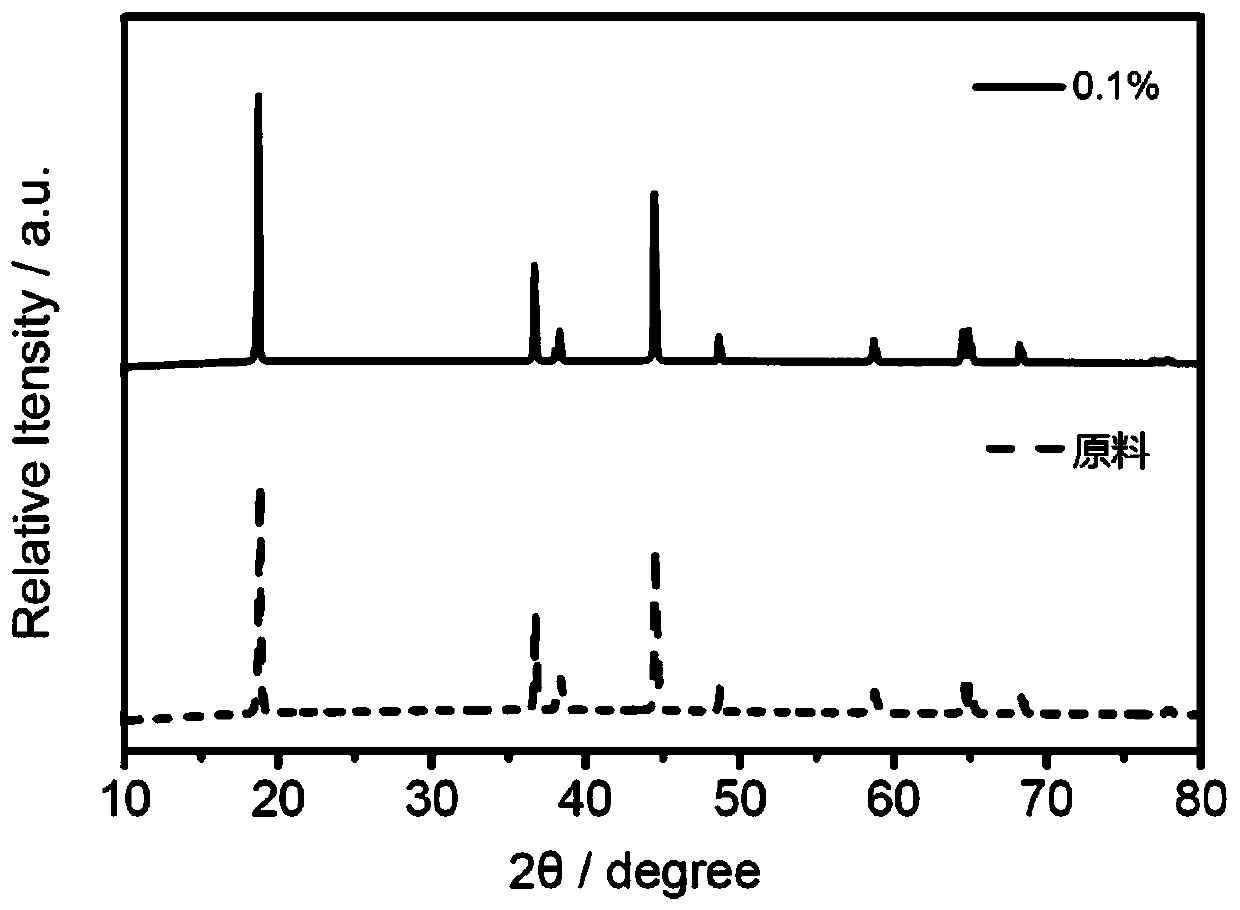

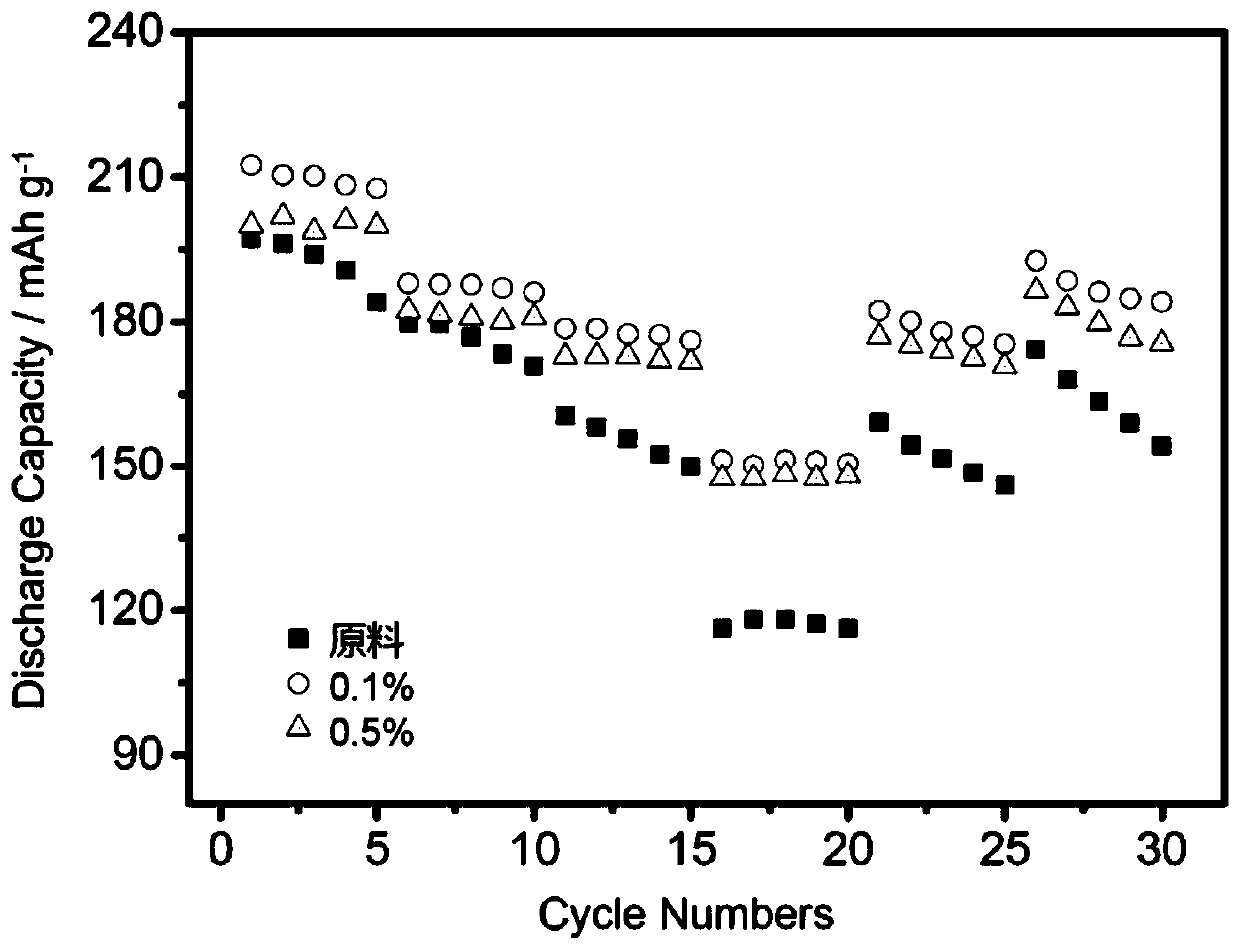

Method for preparing cobalt oxide coated ternary positive electrode material

InactiveCN109713262ALess surface impuritiesImproved rate cycle performanceCell electrodesSecondary cellsHigh rateHigh pressure

The invention relates to a method for preparing a cobalt oxide coated ternary positive electrode material, and belongs to the technical field of battery positive electrode materials. The problem to besolved is how to achieve a high rate performance by lowering the sintering temperature and a coating amount. The method for preparing the cobalt oxide coated ternary positive electrode material comprises placing a cobalt source and a high-nickel ternary positive electrode material in a vessel, stirring and mixing the two objects at a speed less than or equal to 700 rpm to obtain a corresponding mixture; in the air or oxygen atmosphere, subjecting the mixture to low-temperature solid-phase sintering at 250 to 550 degrees centigrade to obtain the corresponding cobalt oxide coated ternary positive electrode material, wherein the coating amount of the cobalt oxide is 0.1 wt% to 1.0 wt% of the mass of the ternary positive electrode material. The method can achieve a low cobalt oxide coating effect and achieves the rate and cycle performance of the material under high-voltage conditions.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

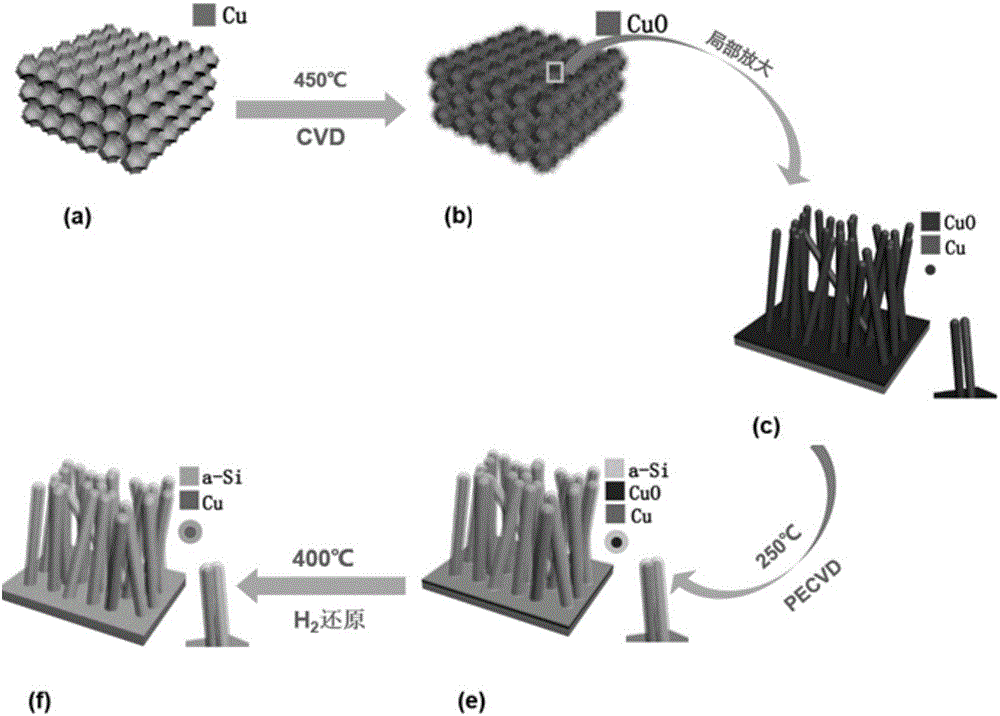

Preparation for interconnected nanowire core-shell structure material

InactiveCN105047936AEnhanced structural mechanical propertiesIncrease profitCell electrodesSecondary cellsCurrent collectorMicrometer

The invention discloses a preparation method for an interconnected nanowire core-shell structure material. The preparation method comprises the following steps of: 1) taking a foamy copper sheet with thickness of 0.2-0.5 millimeter as a substrate; 2) cleaning the surface of foamy copper by using an ordinary cleaning method, immersing the foamy copper in hydrochloric acid to remove an oxide, and then drying by using a nitrogen pistol; 3) calcining for 5 hours at 450 DEG C in air, leading the foamy copper to self-catalytically grow a CuO nanowire or other metal oxide nanowire with diameter of about 30 nanometers and length of 7-10 micrometers; 4) depositing amorphous Si(Ge) at 250 DEG C through plasma enhanced chemical vapor deposition (PECVD) to obtain an interconnected nanowire core-shell structure with diameter of about 100-200 nanometers, namely a Si(Ge) shell and a CuO core; 5) reducing the CuO core by using H2 at 400 DEG C to obtain a high-conductivity metallic Cu nanowire, and completing the building of a three-dimensional current collector; and 6) preparing and completing the three-dimensional interconnected metallic nanowire conductive core structure material.

Owner:NANJING UNIV

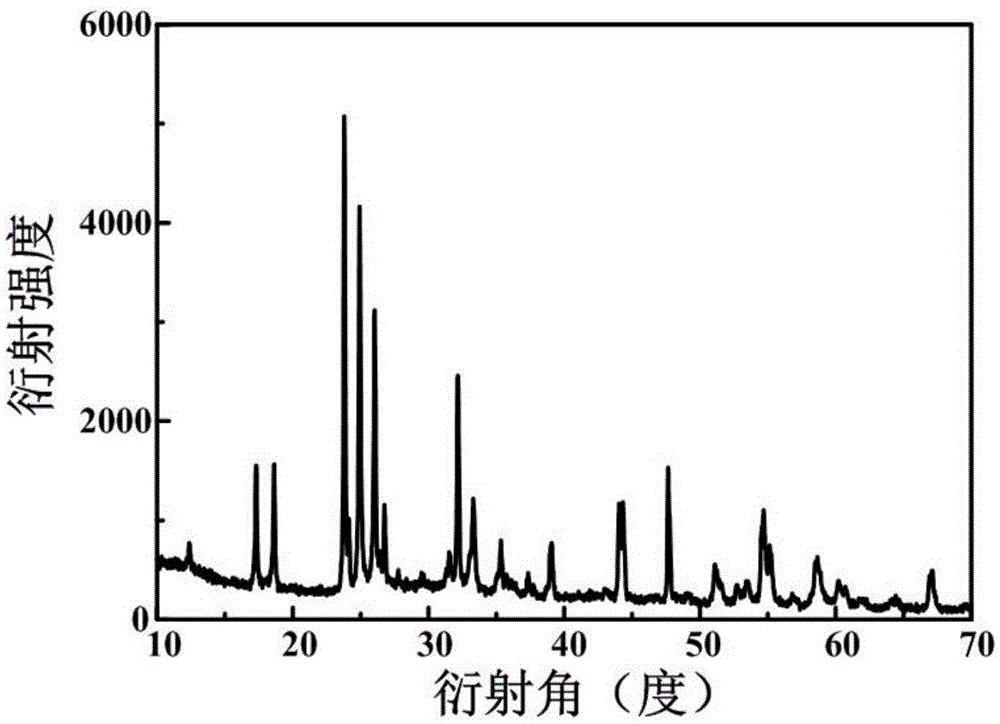

Preparation method of lithium ion battery negative material titanium niobate

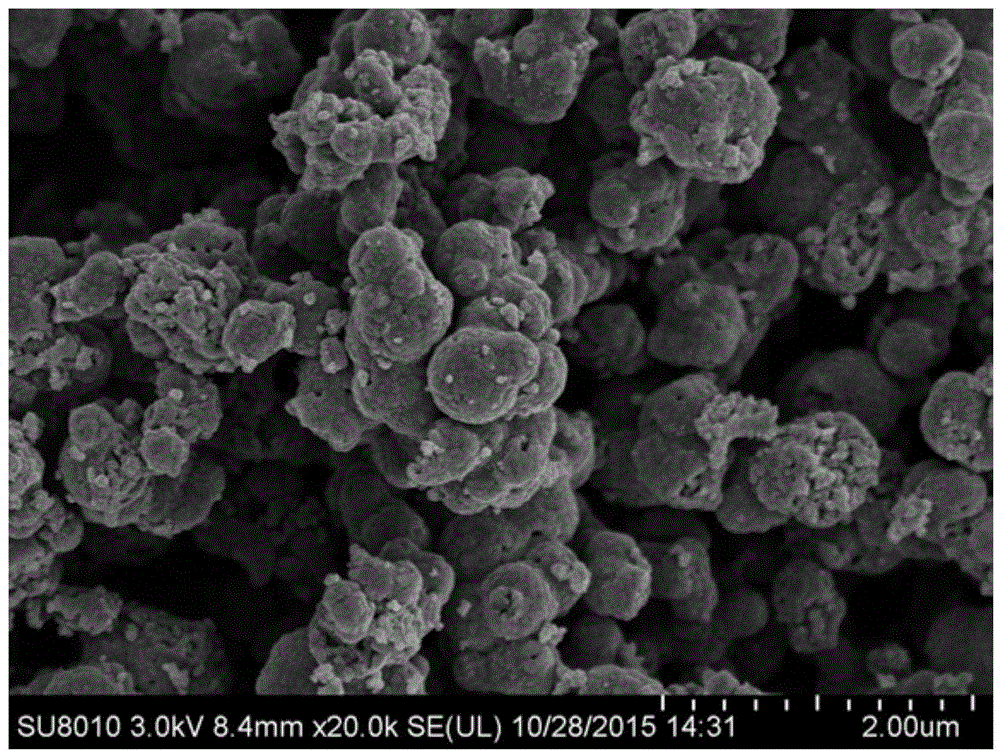

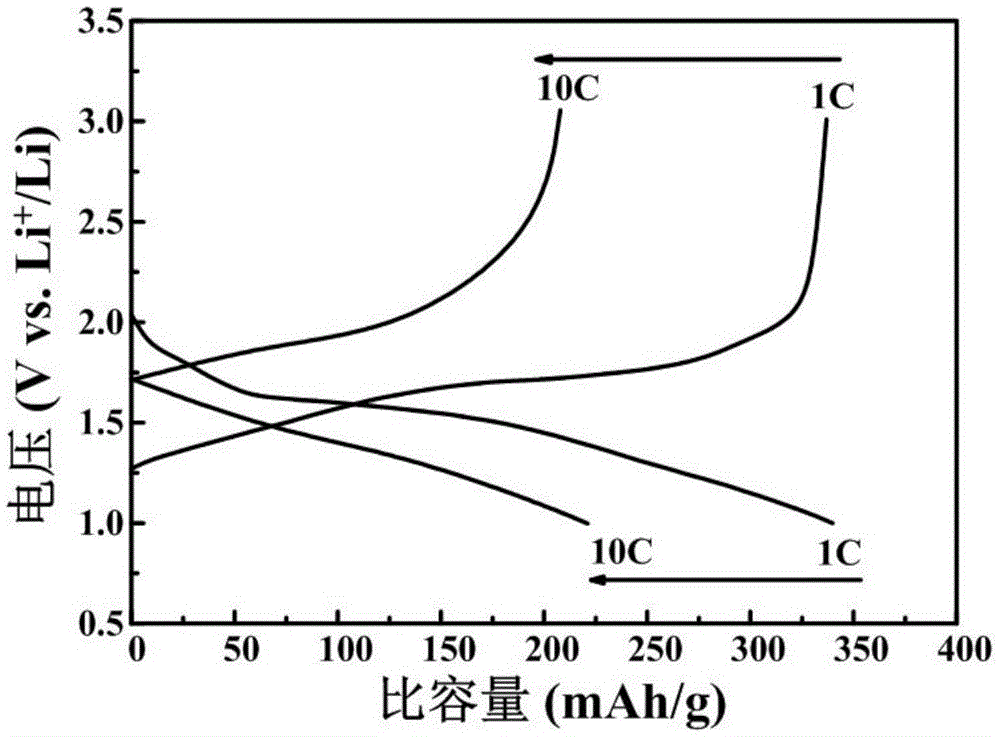

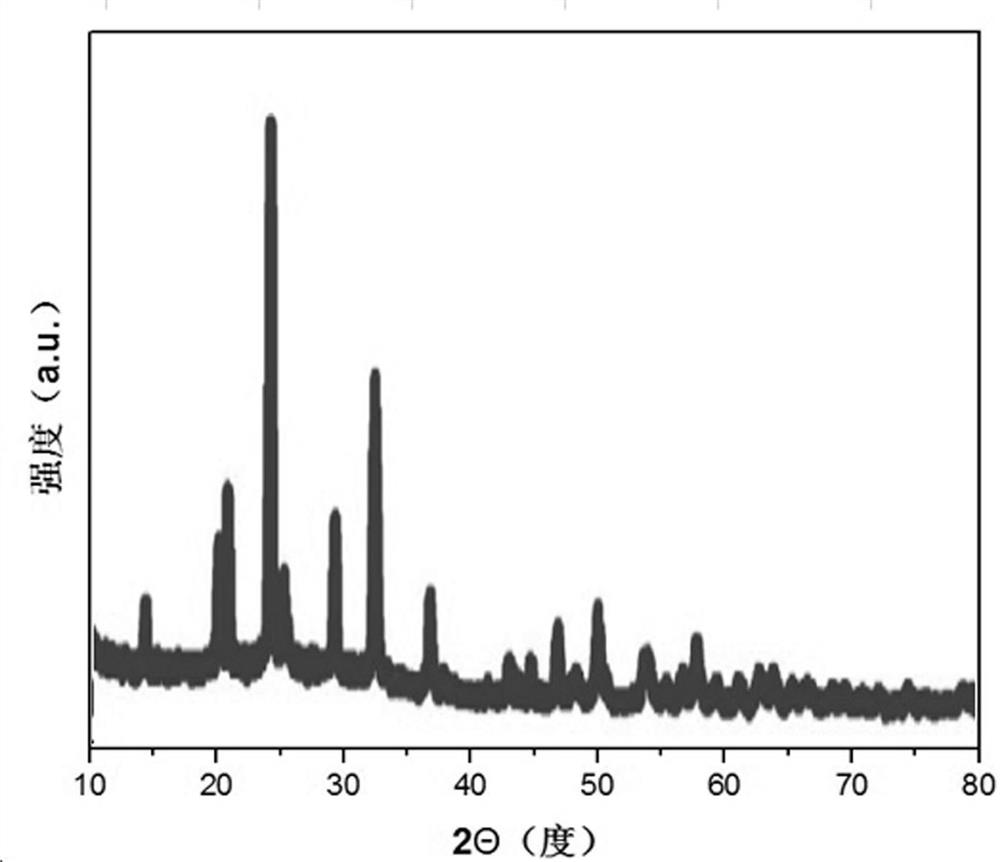

InactiveCN105633456ASmall sizeIncreased diffusion rateCell electrodesSecondary cellsNiobiumSpherical shaped

The invention discloses a preparation method of lithium ion battery negative material titanium niobate. The preparation method comprises the following steps: separately dissolving a niobium source and a titanium source into acetic acid, and slowly mixing the niobium source and the titanium source; loading a mixed solution obtained in the previous step into a reaction kettle, and heating to facilitate the reaction; after the reaction kettle is naturally cooled to the room temperature, washing obtained precipitates for multiple times by separately utilizing deionized water and ethanol, and drying in a vacuum drying oven to obtain powder; and roasting the obtained powder to obtain titanium niobate. The preparation method is moderate in conditions, simple in procedures, easy to operate and convenient in industrialized production. The prepared titanium niobate material is in a spherical shape and is relatively small in size, so that the diffusion speed of lithium ions in the material is increased; and when the prepared titanium niobate material is used as a lithium ion battery negative electrode, the charging-discharging specific capacity is relatively high, and the multiplying power cycling performance is excellent.

Owner:NANYANG NORMAL UNIV

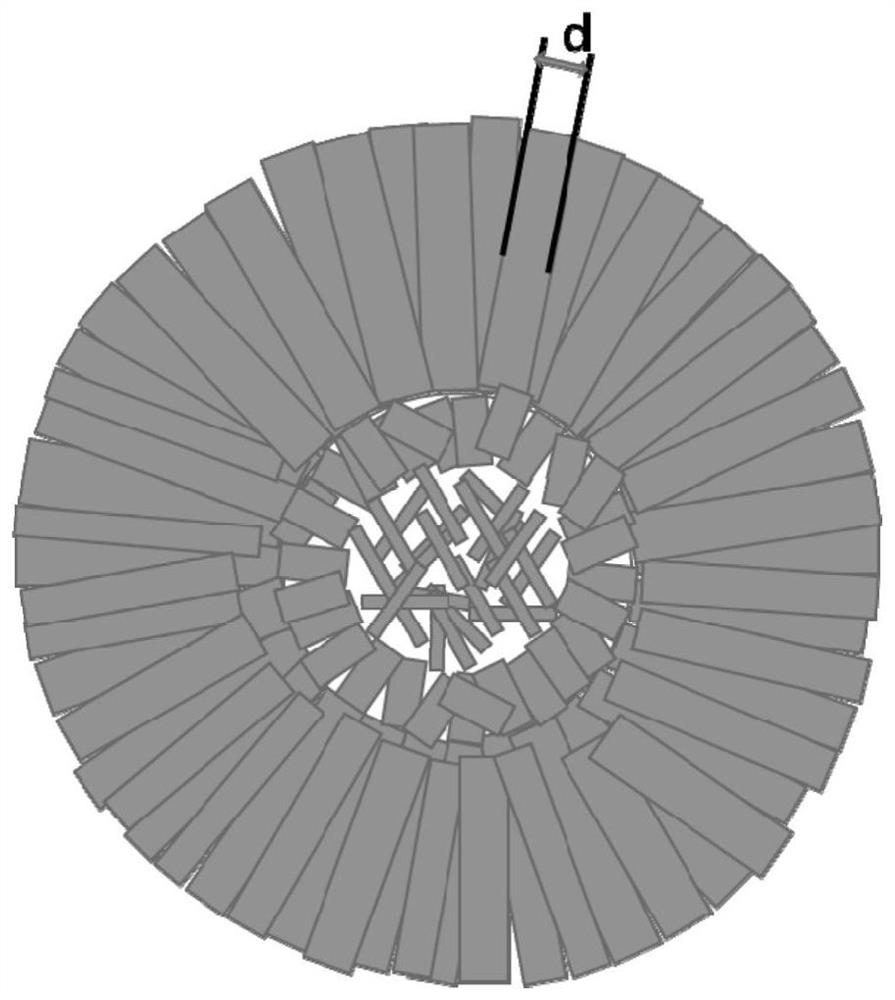

Nickel-containing precursor, nickel-containing composite material, and preparation methods and applications of nickel-containing precursor and nickel-containing composite material

PendingCN112624208AMaintain internal pore structureIncrease capacitySecondary cellsPositive electrodesLithium-ion batterySeed crystal

The invention belongs to the field of lithium ion batteries, and relates to a nickel-containing precursor, a nickel-containing composite material, and preparation methods and applications of the nickel-containing precursor and the nickel-containing composite material. The nickel-containing precursor comprises a nickel-containing seed crystal and primary particles distributed on the outer edge of the nickel-containing seed crystal in a radial direction. The composition of the nickel-containing precursor is represented by the chemical formula Ni<x>Co<y>M (OH)<2>, wherein M is Mn and / or Al, x is larger than or equal to 0.8, y is larger than or equal to 0 and smaller than or equal to 0.2, z is larger than or equal to 0 and smaller than or equal to 0.2, and x, y and z sum to 1. The nickel-containing seed crystal is composed of a primary particle loose inner core and a surface compact layer which are disorderly distributed inside, and has a hollow pore structure inside after solid-phase sintering. The nickel-containing composite material provided by the invention can significantly improve the capacity and rate cycle performance of a positive electrode material of a lithium ion secondary battery, and has wide application prospects.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

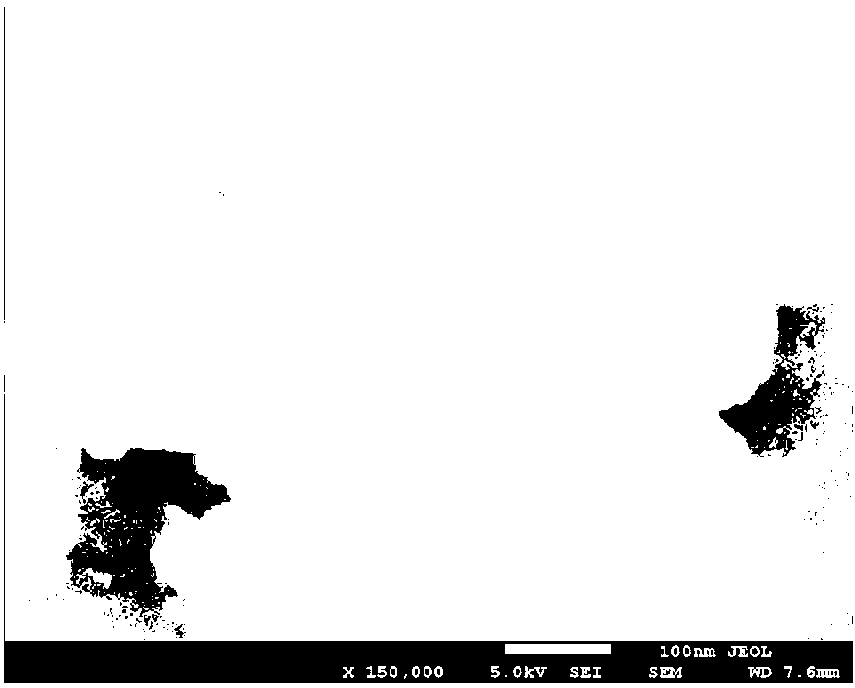

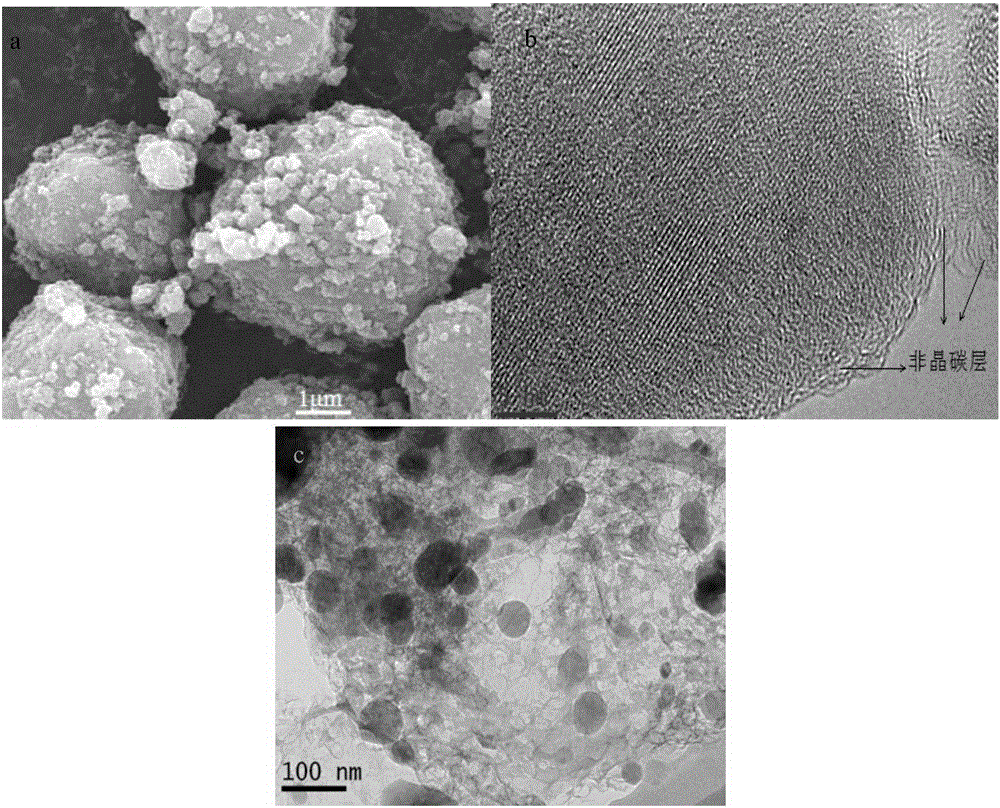

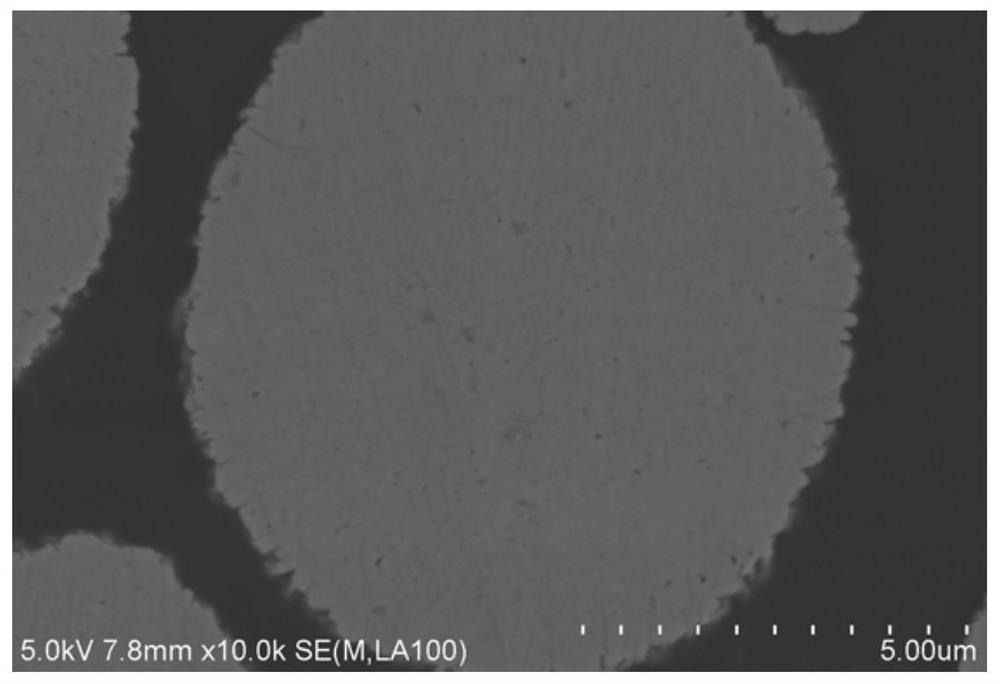

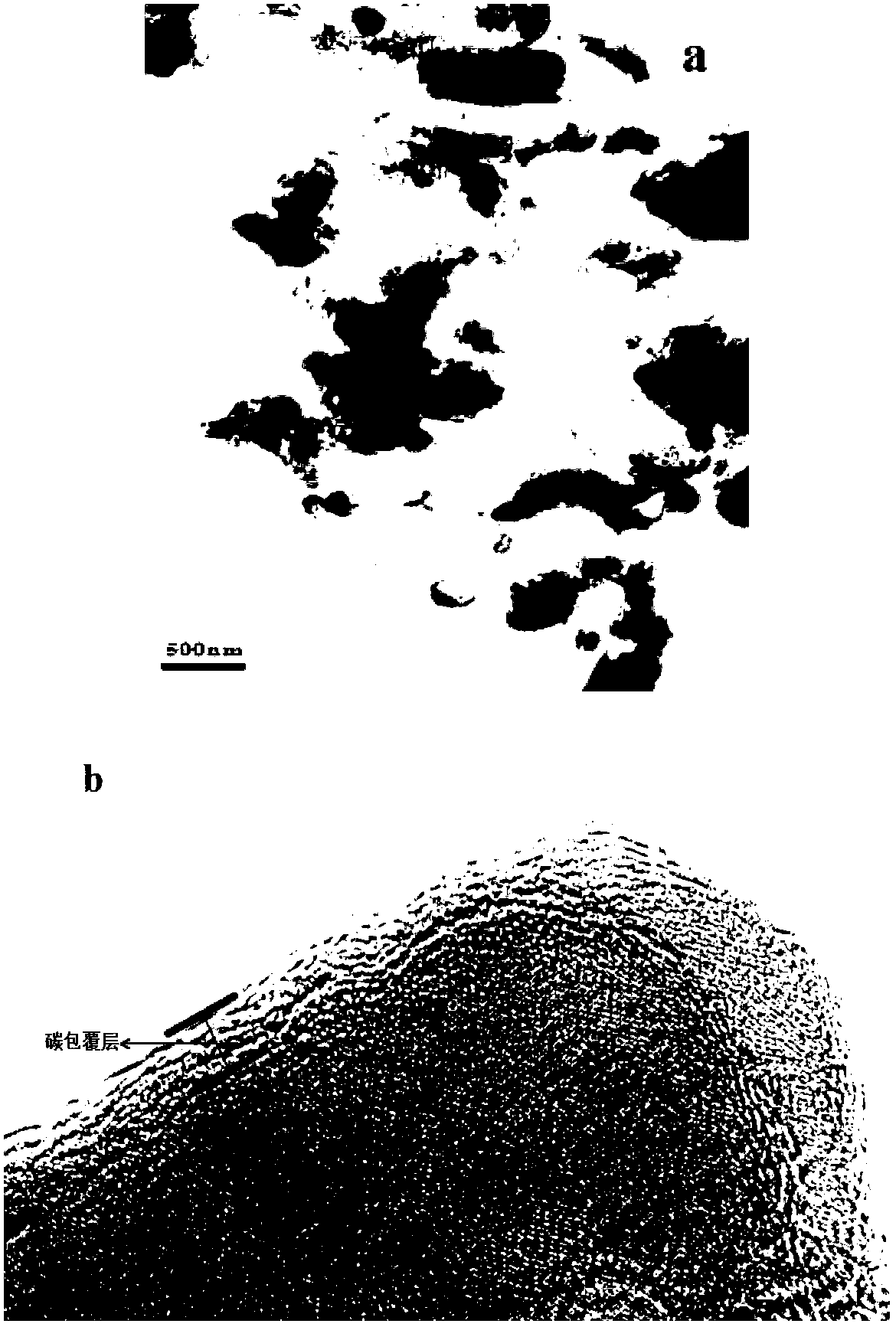

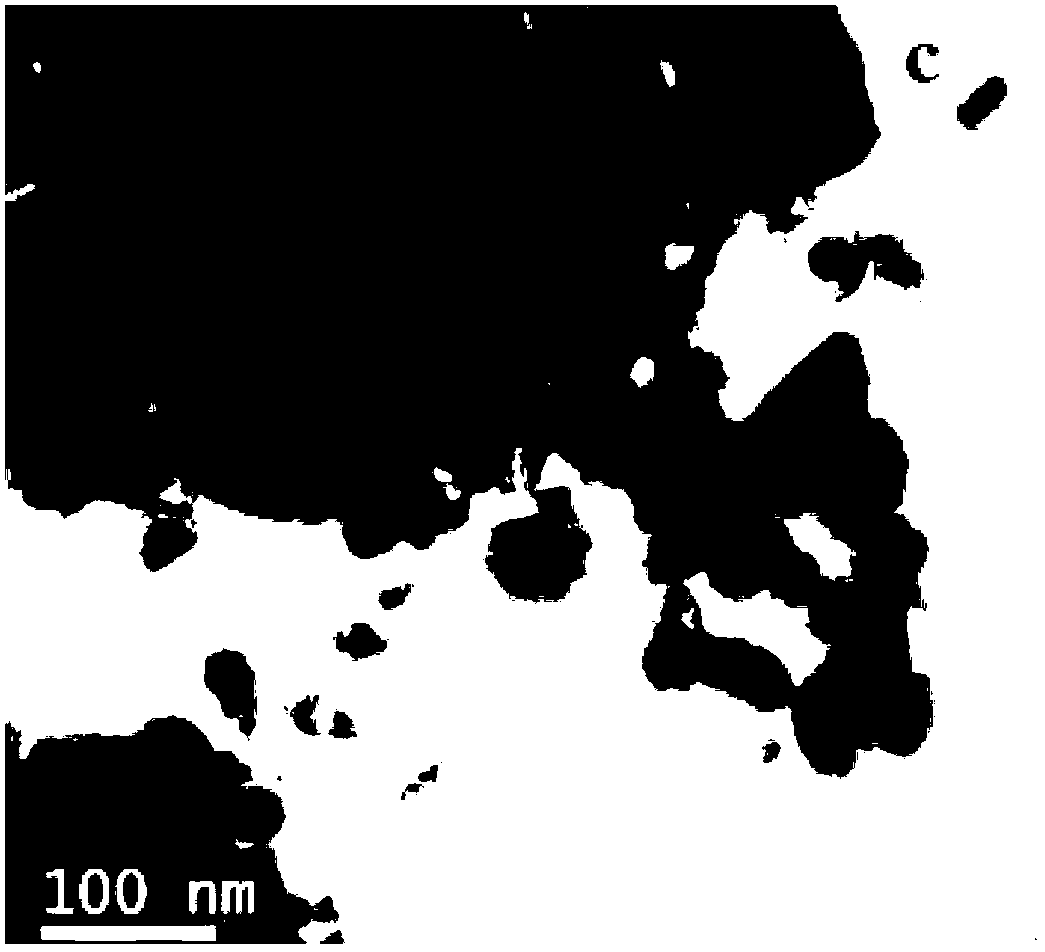

Synthesizing method of nano-grade lithium ion battery composite positive electrode material LiMnPO4/C

InactiveCN102931400AIncrease contact interfacePromote interdiffusionCell electrodesCarbon layerHigh energy

The invention relates to a synthesizing method of a nano-grade lithium ion battery composite positive electrode material LiMnPO4 / C. According to the invention, a lithium source, a phosphorous source, a manganese source and an organic carbon source are well mixed in a solvent medium; the mixture is processed for 2-7h in a high-energy ball mill, and a uniformly dispersed precursor slurry is obtained with the activation effect of mechanical forces; the precursor slurry is subjected to ultrasonic dispersion in a high-boiling-point polyol solvent, and is subjected to a reflux reaction; an obtained product is filtered and washed; and the product is subjected to a heat treatment for 1-10h under inert atmosphere protection and under a temperature of 600-800 DEG C, such that the nano-grade lithium manganese phosphate / carbon (LiMnPO4 / C) positive electrode material is obtained. According to the material provided by the invention, primary particles are well distributed nano-particles, and a conductive carbon layer is formed in-situ on the surfaces of the LiMnPO4 / C particles. The method provided by the invention is simple and highly efficient. With the method, no pollutant such as ammonia gas or wastewater is produced during the entire process. Therefore, a development requirement of green chemistry is satisfied.

Owner:CENT SOUTH UNIV

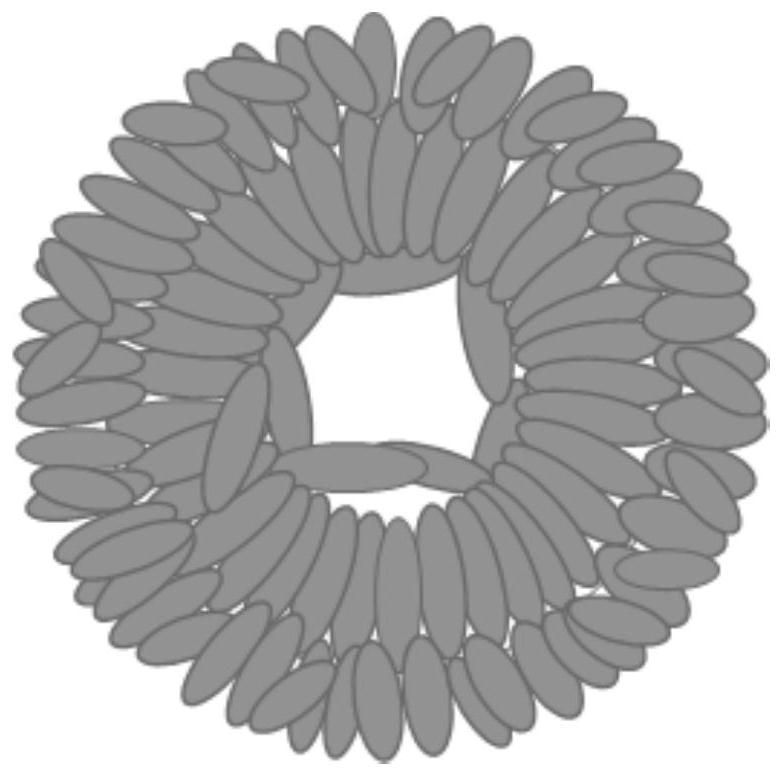

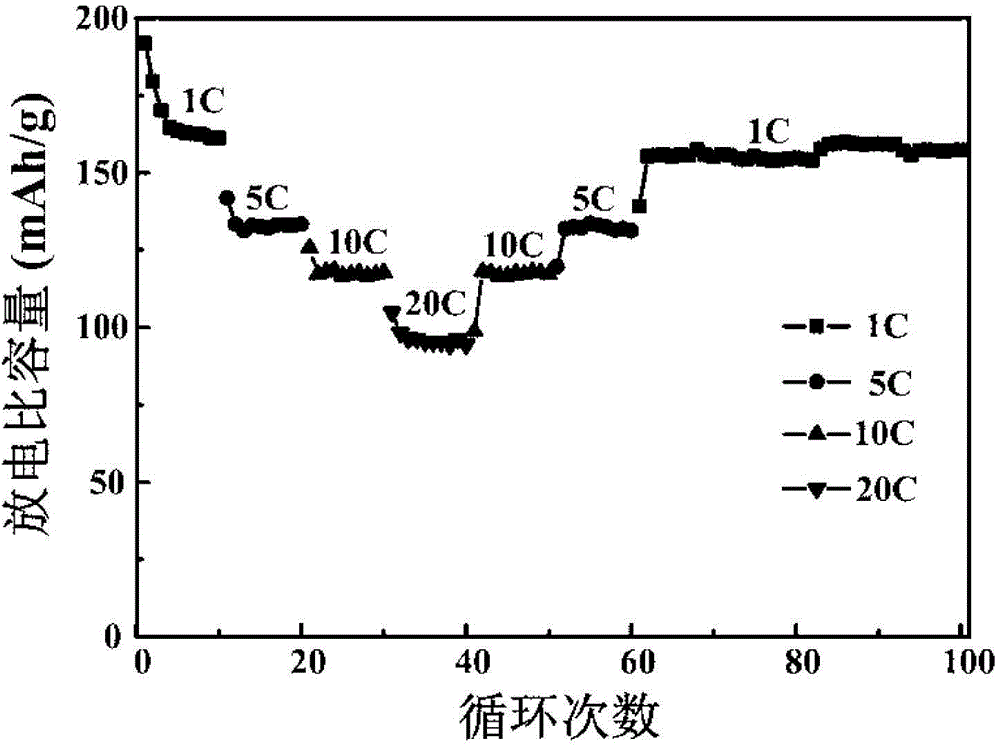

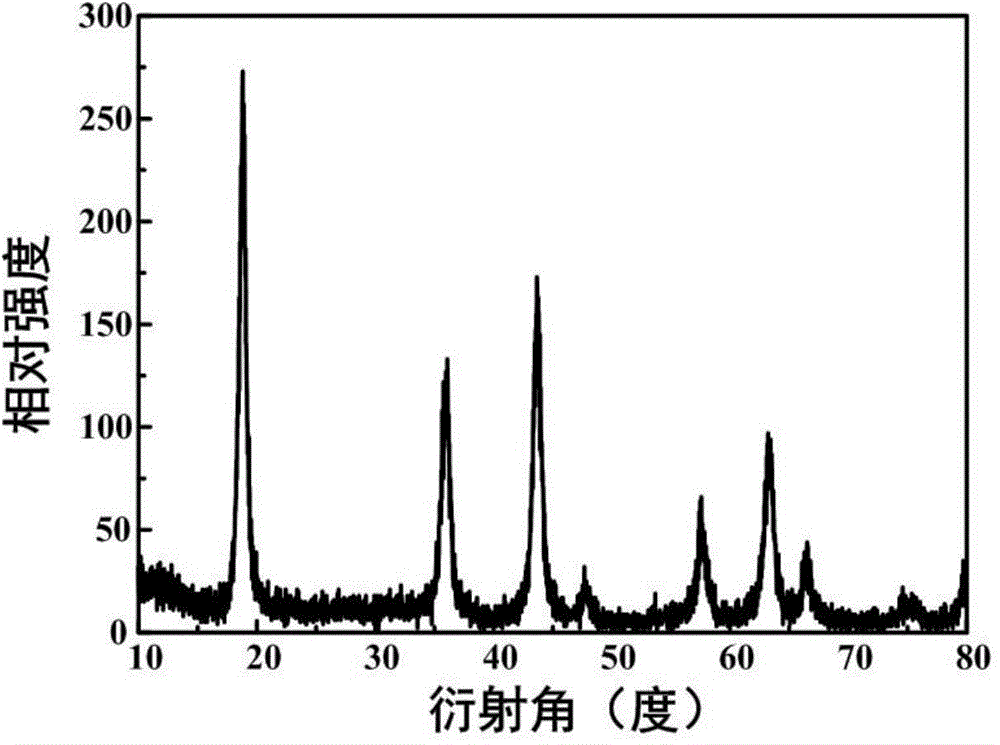

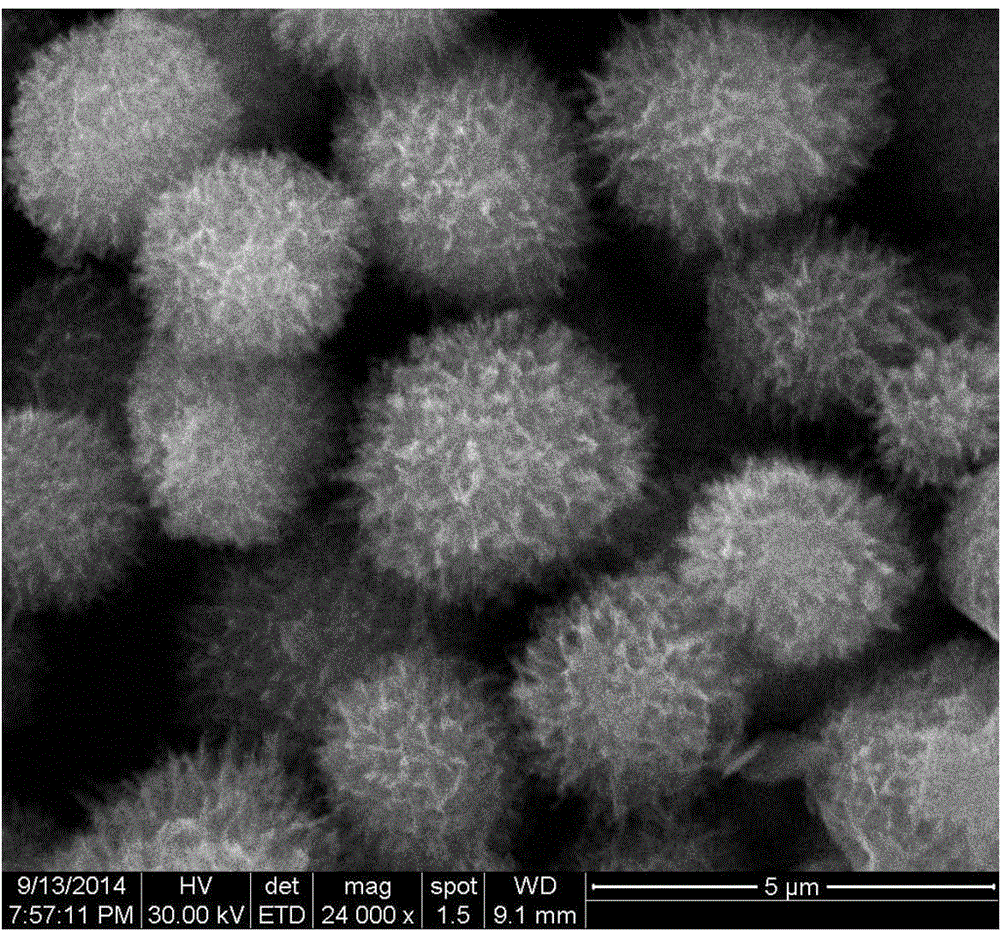

Sea urchin-like lithium titanate microsphere preparation method

InactiveCN104821397AHigh discharge specific capacityGood rate cycle performanceMaterial nanotechnologyCell electrodesEmulsionLithium

The present invention discloses a sea urchin-like lithium titanate microsphere preparation method, which comprises: adding metal titanium powder to a sodium hydroxide solution, stirring, carrying out a hydrothermal reaction at a temperature of 80-260 DEG C, carrying out centrifugation separation on the obtained precipitate, drying the precipitate to obtain a titanium dioxide precursor, adding a lithium salt and the titanium dioxide precursor to an ethanol and deionized water mixed solution, stirring to obtain an emulsion, carrying out a hydrothermal reaction, carrying out centrifugation separation on the obtained precipitate, drying to obtain white powder, carrying out a calcining heat treatment at a temperature of 300-1000 DEG C, and cooling to a room temperature to obtain the sea urchin-like lithium titanate microsphere. The method of the present invention has the following beneficial effects that: the sea urchin-like lithium titanate microsphere having the micro-nano grading structure is provided, and has characteristics of high discharge specific capacity and excellent rate cycle performance.

Owner:NANYANG NORMAL UNIV

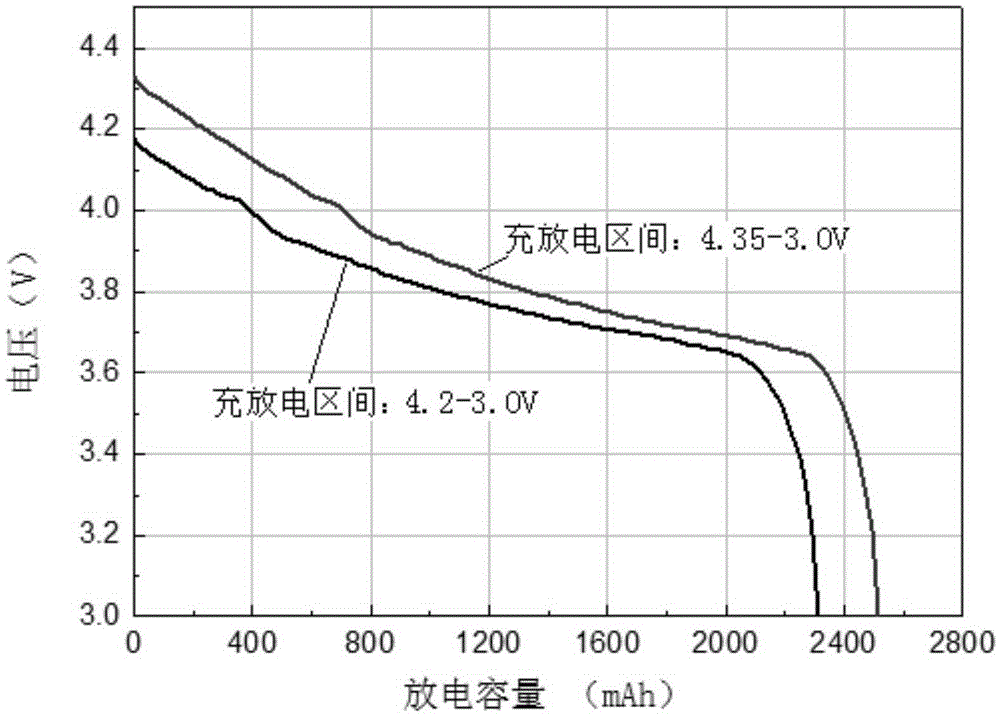

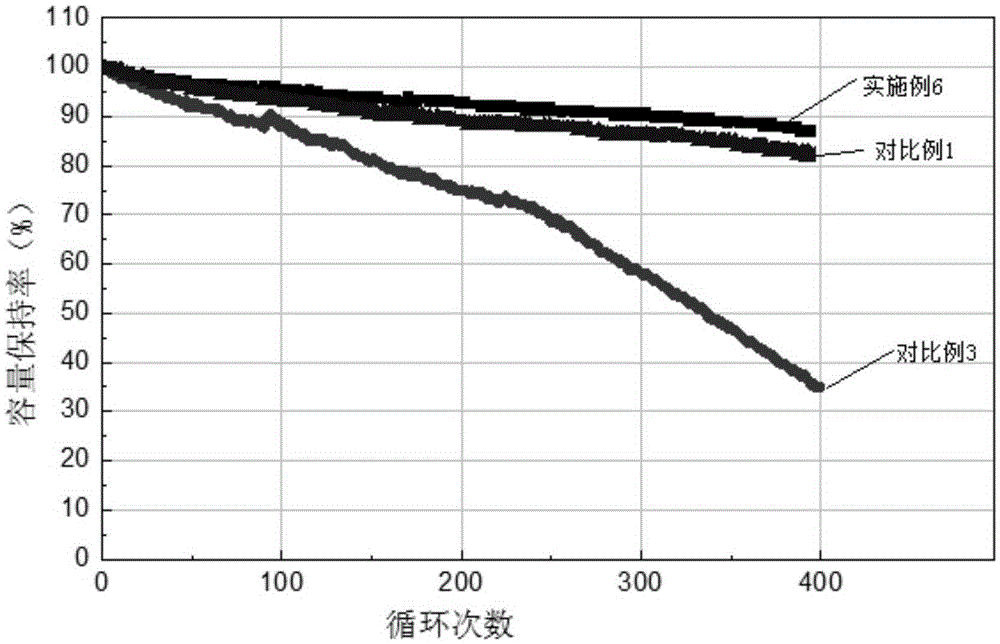

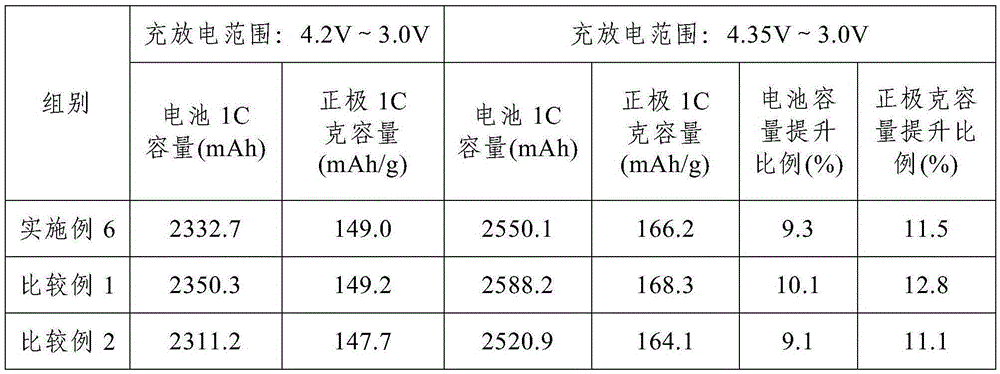

High-voltage high-magnification lithium ion battery

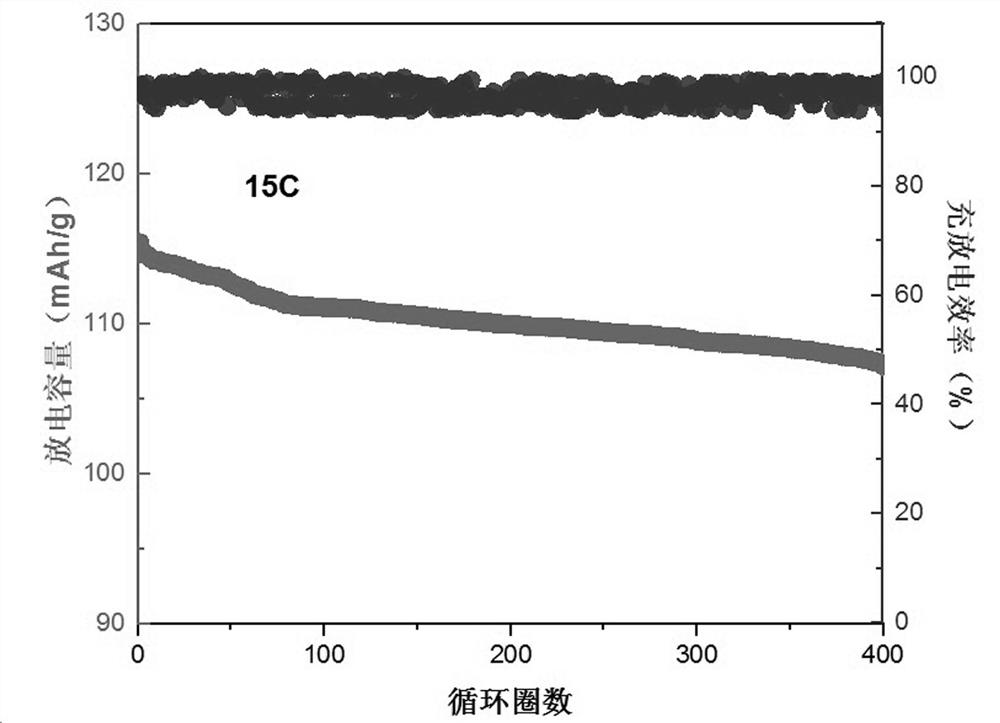

ActiveCN105355889AImprove cycle performanceImprove structural stabilityCell electrodesSecondary cellsMicrometerPhysical chemistry

The invention discloses a high-voltage high-magnification lithium ion battery. The high-voltage high-magnification lithium ion battery comprises a positive plate, a negative plate, a diaphragm, an electrolyte, a positive pole lug, a negative pole lug and a packaging shell. The positive plate is manufactured by smearing positive slurry containing a positive active material to the two faces of aluminum foil, and the positive active material is modified lithium cobalt oxides with the D50 grain size of 4.0 micrometers to 12.0 micrometers and the specific surface area of 0.5 m<2> / g to 1.2 m<2> / g. The battery has high-magnification discharge capacity and excellent magnification circulating capacity. Compared with a common lithium ion battery with the charge cut-off voltage of 4.35 V, the battery can support high-current discharge of 3 C to 45 C, the discharge ratio is 90% or above, high-current circulation of 3 C to 45 C is adopted at high voltage, and the service life can reach 400 weeks or above.

Owner:XIAN SAFTY ENERGY TECH

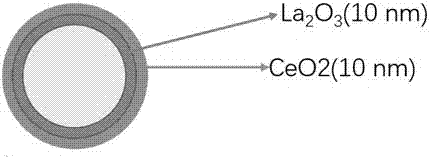

Lithium battery composite positive electrode material and preparation method thereof, and lithium battery positive electrode

InactiveCN107887589APerformance impactImproved rate cycle performanceMaterial nanotechnologyCell electrodesOxide compositeLanthanum

The invention provides a lithium battery composite positive electrode material comprising positive electrode material particles using as central cores, wherein the central cores are covered with lanthanum trioxide coating layers, the lanthanum trioxide coating layers are coated with cerium oxide coating layers, and diameters of the central cores are 10nm-10microns. An atomic layer deposition method is used for depositing metallic oxide on carbon powder with high specific surface area, and the mass ratio of the thin metallic oxide to the carbon with high specific surface area is 70%-90%. The invention simultaneously provides a method of preparing the high specific surface area carbon / metallic oxide composite electrode material by using the atomic layer deposition method. The high specific surface area carbon / metallic oxide composite electrode material provided by the invention has the characteristic of high mass ratio, and the lithium ion battery prepared by the electrode material has high cycle life and high capacity stability.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

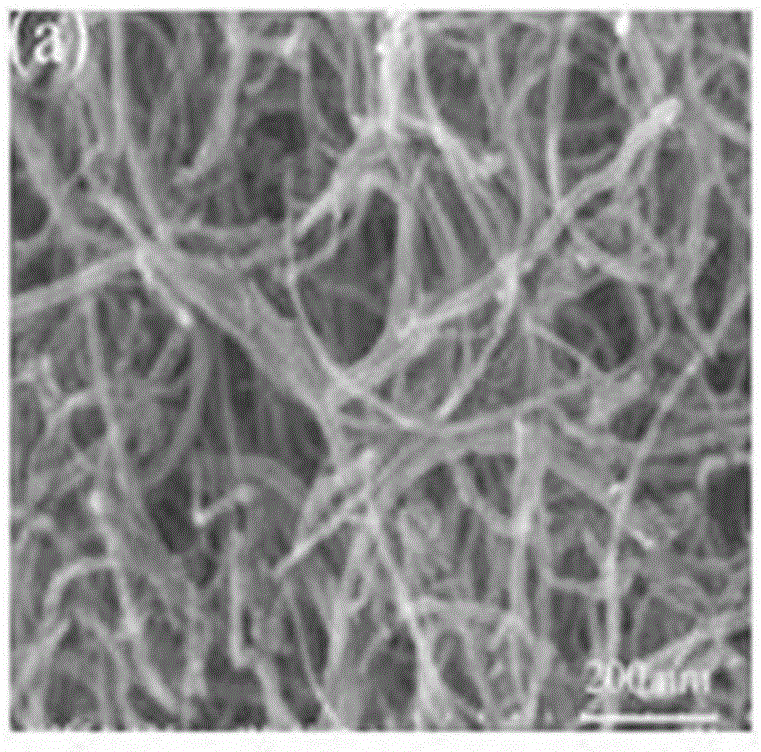

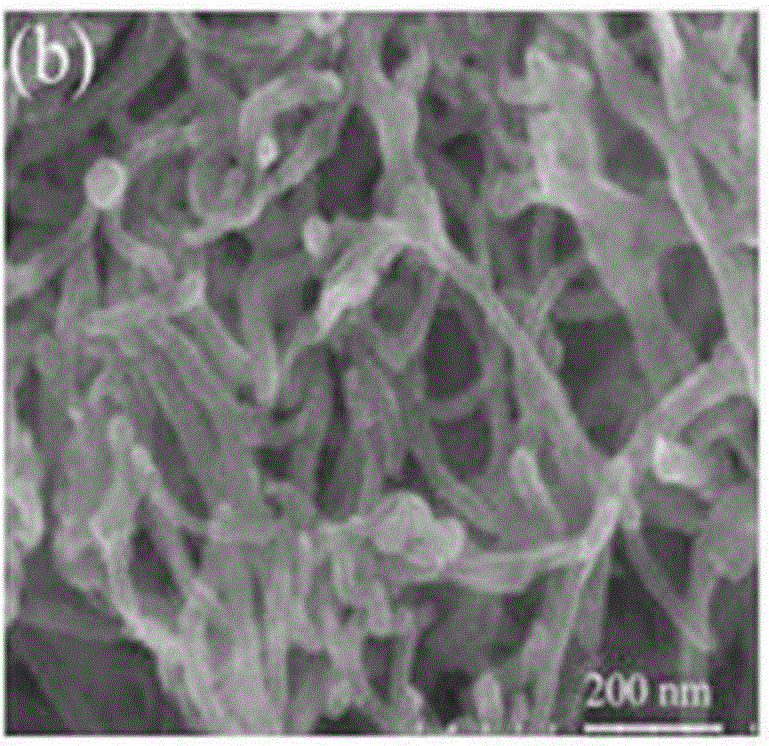

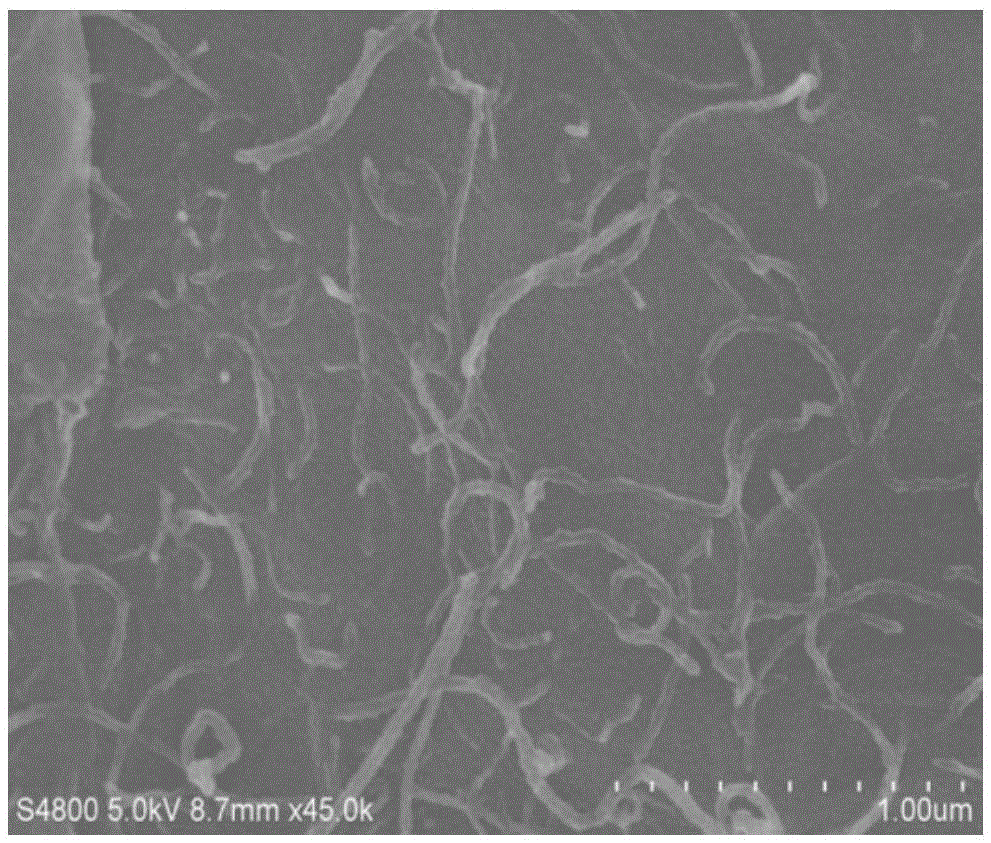

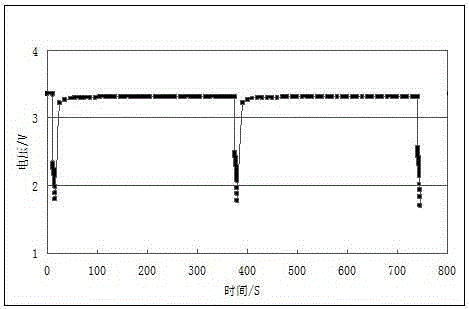

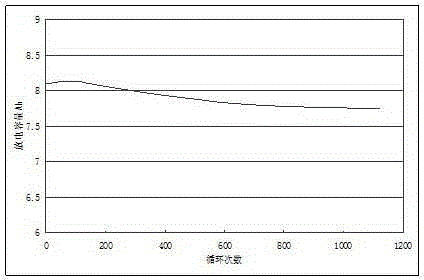

Prismatic lithium ion battery for hybrid electric vehicle startup power supply and manufacturing method thereof

ActiveCN105185996AExtend discharge timeExtended service lifePhosphatesElectrode thermal treatmentInternal resistanceElectrical battery

The invention relates to the technical field of manufacturing of lithium ion secondary batteries and provides a prismatic lithium ion battery for a hybrid electric vehicle startup power supply and a manufacturing method thereof. The battery comprises a positive plate, a negative plate, a diaphragm, an electrolyte, an insulating bushing and a battery case, wherein the positive plate contains a positive active material, a binding agent, a conductive agent, an aluminum foil and the like; the negative plate comprises a negative active material, a binding agent, a conductive agent, an aluminum foil and the like. A material system is optimized, the positive active material is lithium iron phosphate coated with a composite containing Al2O3-loaded N grapheme; the negative active material is natural graphite coated with a composite containing CuO / Cu-loaded multi-walled carbon nanotubes. The lithium ion battery manufactured under optimum conditions is low in internal resistance, is excellent in multiplying power cycling performance and heavy load discharge performance, and can meet hybrid electric vehicle startup power supply requirements.

Owner:江苏海四达电源有限公司 +1

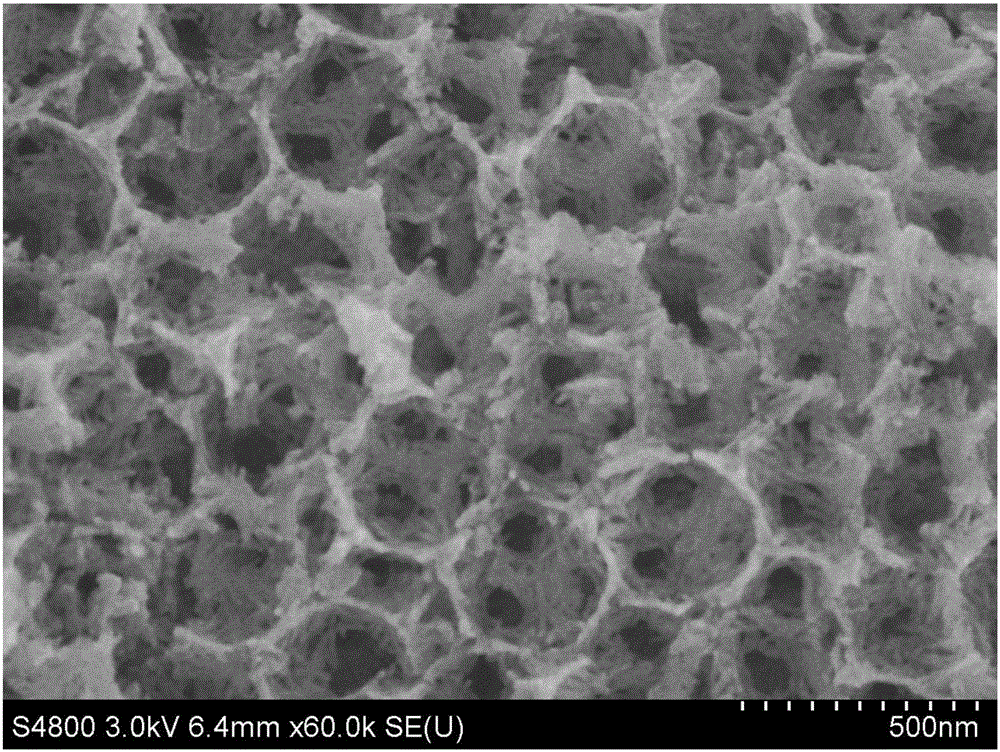

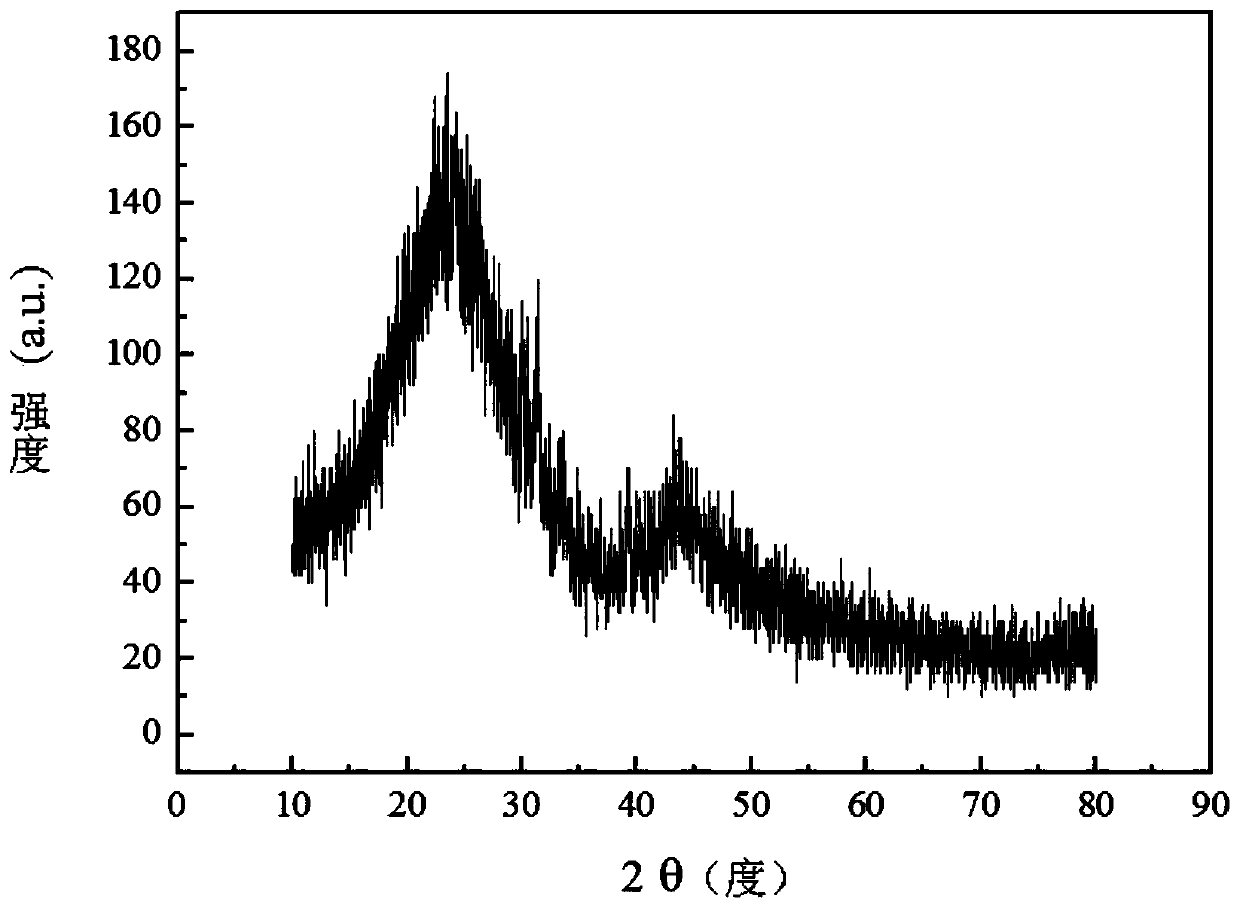

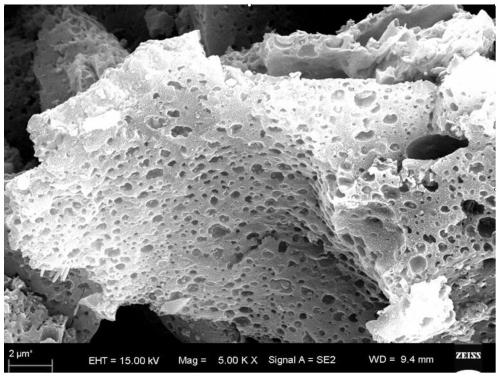

Honeycomb porous hard-carbon anode material for lithium ion battery, preparation method of honeycomb porous hard-carbon anode material as well as lithium ion battery

ActiveCN106744787AHigh reversible capacityImproved rate cycle performanceCell electrodesSecondary cellsAluminium-ion batteryElectrical battery

The invention discloses a honeycomb porous hard-carbon anode material for a lithium ion battery, a preparation method of the honeycomb porous hard-carbon anode material as well as the lithium ion battery. According to the method, coffee powder is prepared firstly and subjected to low-temperature carbonization in an inert gas, a precursor is prepared and subjected to organic carbon source coating treatment with a solvent and an organic carbon source, material particles are obtained and subjected to high-temperature carbonization, and the honeycomb porous hard-carbon anode material for the lithium ion battery is prepared. The method adopts a simple process and a simple and controllable synthetic route, micro-control of morphology and size of the material is easy, and the prepared honeycomb porous hard-carbon anode material for the lithium ion battery is high in reversible capacity, high in rate property and cycle performance and good in low-temperature performance.

Owner:博尔特新材料(银川)有限公司

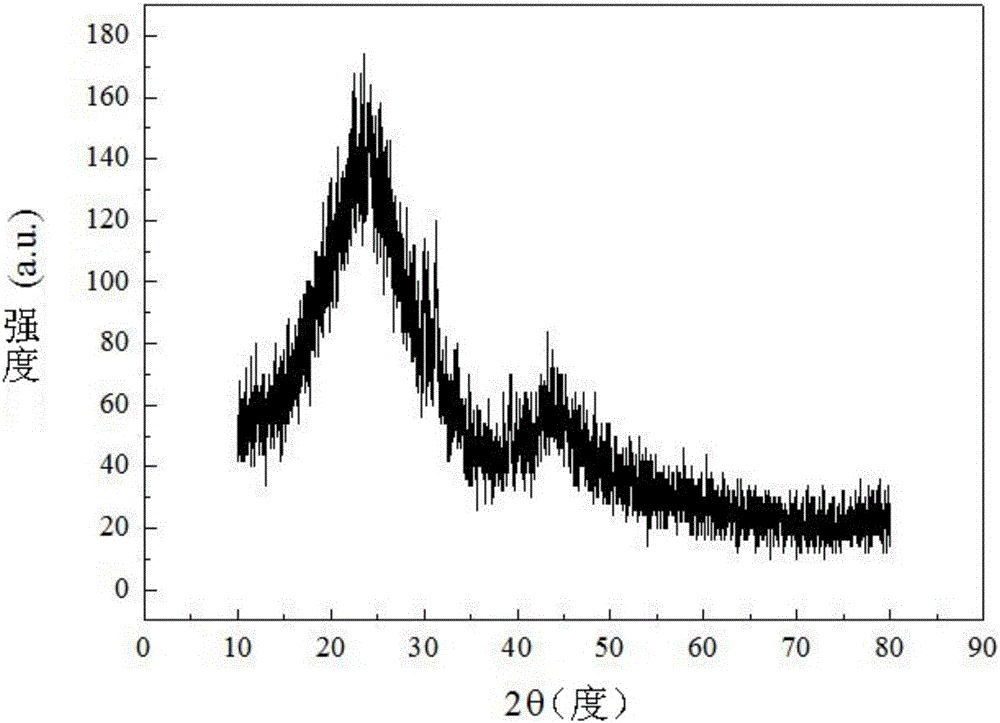

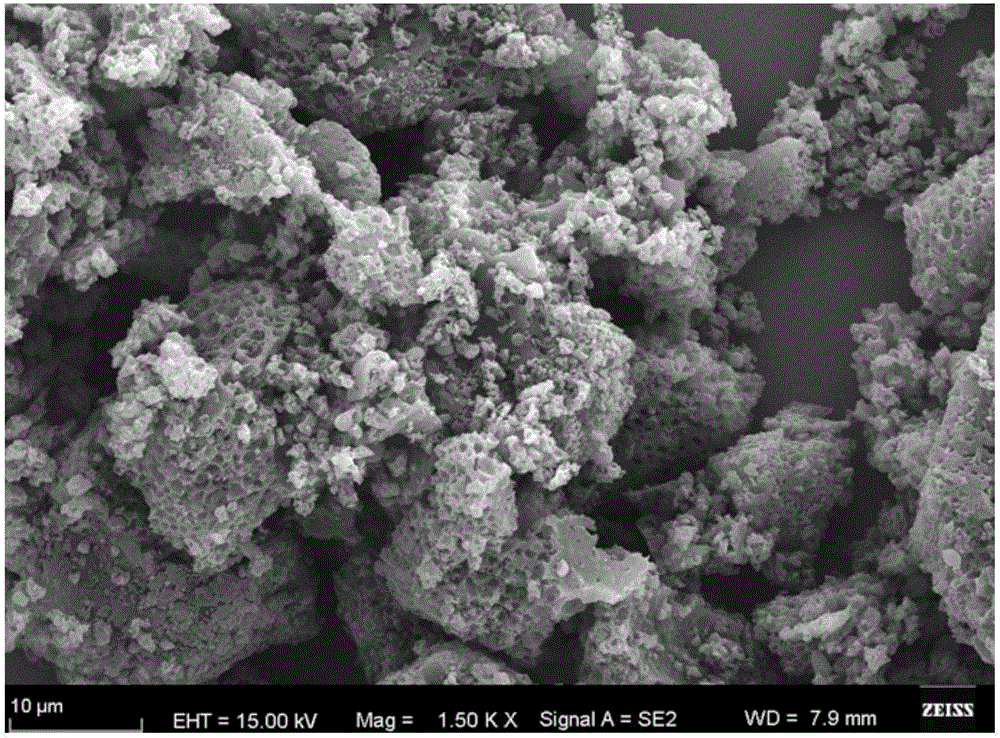

Synthesis method and application of hard carbon coated sodium ion battery nano composite material

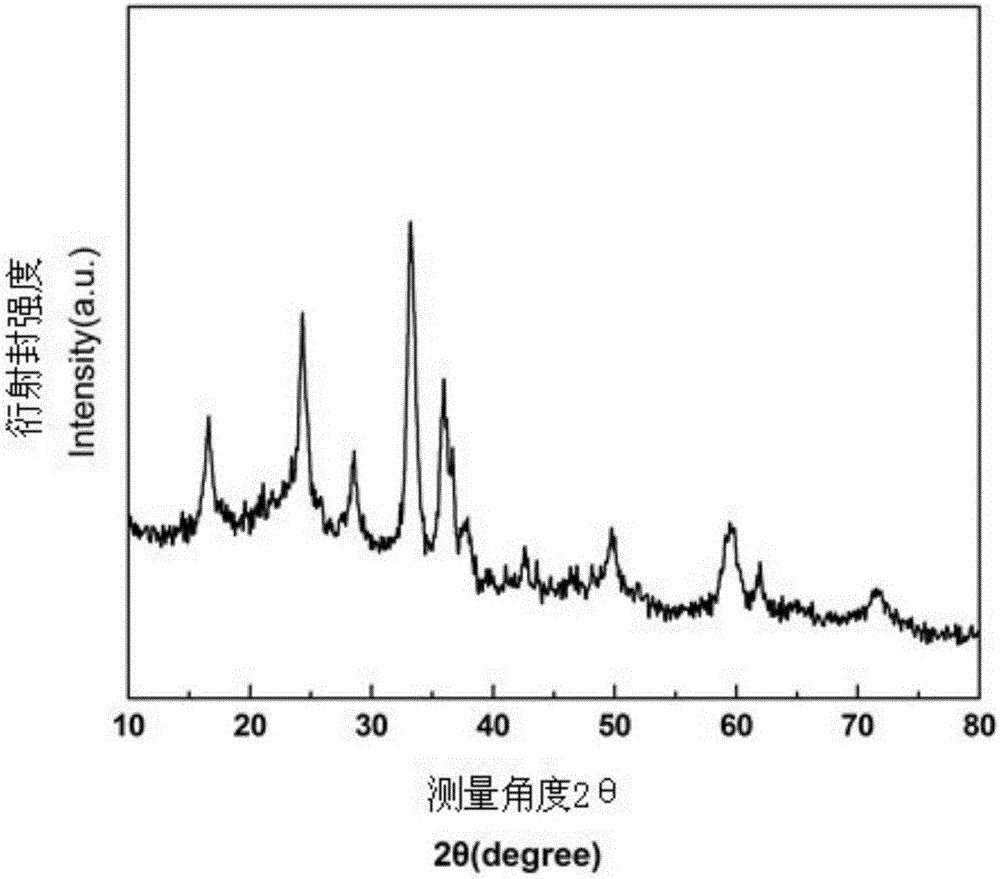

PendingCN114300659AMild reaction conditionsSimple processMaterial nanotechnologyCell electrodesCarbon sourceTemperature treatment

The invention relates to a synthesis method and application of a hard carbon coated sodium ion battery nano composite material, and belongs to the field of sodium battery materials. According to the technical scheme, the preparation method comprises the following steps: weighing LiNO3, NaNO3 and NH4H2PO4 according to a stoichiometric ratio, respectively dissolving the LiNO3, the NaNO3 and the NH4H2PO4 in deionized water, and mixing; ti (OC4H9) 4 is taken according to the stoichiometric ratio and added into a proper amount of ethyl alcohol to be stirred; adding an ethanol solution into the mixed solution of the Li salt and the Na salt, and mixing; adding a proper amount of carbon source and stirring; transferring the mixture into a hydrothermal reaction kettle for heat preservation; drying the mixture in an oven at 70 DEG C, and grinding the mixture into powder to obtain a precursor; and carrying out heat preservation on the precursor for a certain time under gas protection, then heating to high temperature treatment, carrying out heat preservation for a certain time, and naturally cooling to room temperature to obtain the nano composite material. The sodium-ion battery negative electrode material prepared by the method is high in reversible capacity and good in rate cycle performance.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

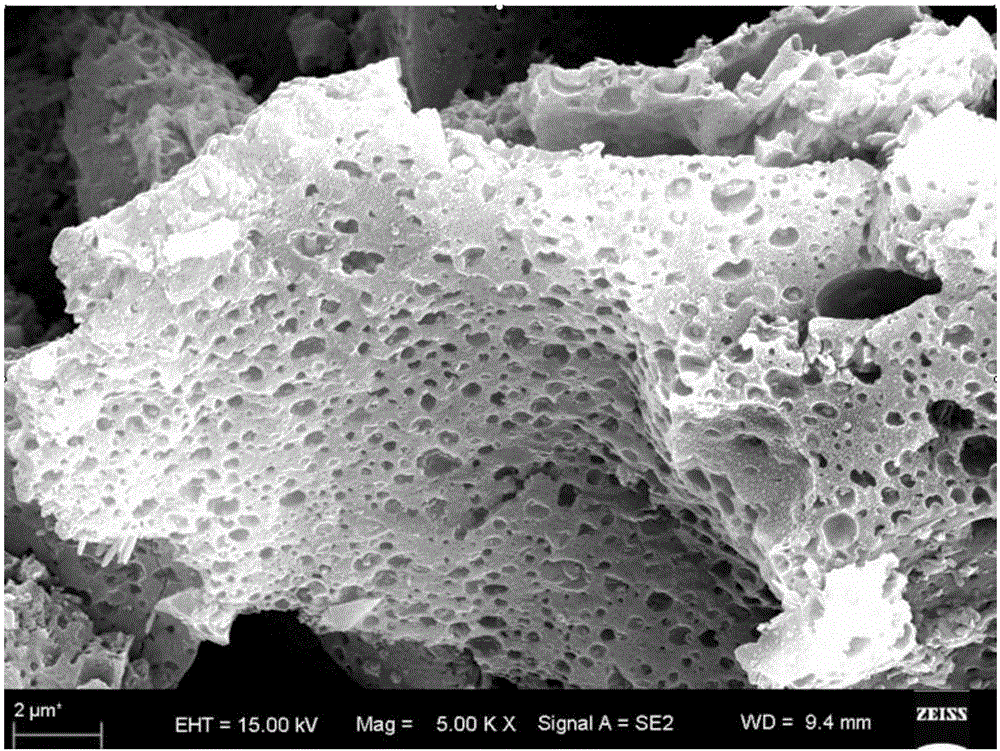

Meso-macroporous nano-fiber Li2FeSiO4 cathode active material

InactiveCN105047915AImproved rate cycle performanceAct as a three-dimensional channelMaterial nanotechnologyCell electrodesFiberSolvent

The invention discloses a nano-fiber macroporous Li2FeSiO4 lithium ion battery cathode active material, which is a three-dimensional ordered nano-fiber porous Li2FeSiO4 / C composite lithium ion battery cathode active material prepared from Li2FeSiO4 and amorphous carbon. A preparation method of the cathode active material comprises the following steps: (1) reacting to generate a polystyrene microsphere emulsion, and assembling a polystyrene colloidal crystal template by a gravitational self-sedimentation method; (2) dissolving a carbon material into a liquid solvent to form a first solution, sequentially weighing a silicon material, a lithium salt and a ferric salt again, additionally dissolving the silicon material, the lithium salt and the ferric salt into the liquid solvent to form a second solution, adding the second solution to the first solution, stirring the solution evenly at a constant temperature and evaporating the mixture at the constant temperature to form Li2FeSiO4 nano fiber gel; and (3) filling the polystyrene colloidal crystal template with the Li2FeSiO4 nano fiber gel under negative pressure, drying and solidifying the Li2FeSiO4 nano fiber gel at the room temperature, and finally carrying out thermal treatment to remove the polystyrene colloidal crystal template, thereby obtaining the nano-fiber macroporous Li2FeSiO4 lithium ion battery cathode active material.

Owner:CHANGAN UNIV

Porous hard-carbon lithium ion battery anode material, preparation method thereof and lithium ion battery

ActiveCN106450313AEasy to watch and controlHigh reversible capacityCell electrodesSecondary cellsAluminium-ion batteryVegetable oil

The invention discloses a porous hard-carbon lithium ion battery anode material, a preparation method thereof and a lithium ion battery. The method comprises steps as follows: hydrogenated vegetable oil powder is prepared firstly and then is subjected to low-temperature carbonizing treatment in inert gas, a precursor is prepared, the precursor is subjected to organic carbon source coating treatment with a solvent and an organic carbon source, material particles are prepared, finally, the material particles are subjected to high-temperature carbonizing treatment, and the porous hard-carbon lithium ion battery anode material is prepared. The method adopts a simple process, a synthesis path is simple and controllable, micro-control for morphology and size of the material is easy, and the prepared porous hard-carbon lithium ion battery anode material is high in reversible capacity and good in rate capability cycle performance and low-temperature performance.

Owner:博尔特新材料(银川)有限公司

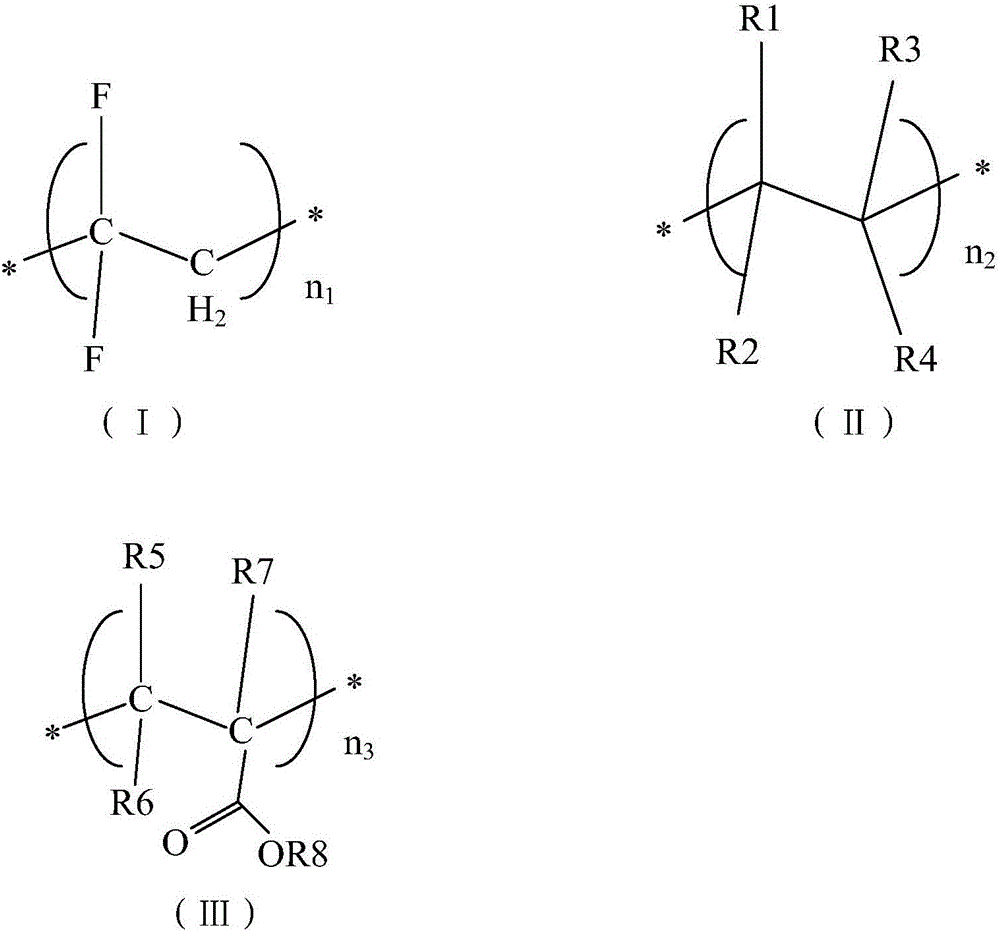

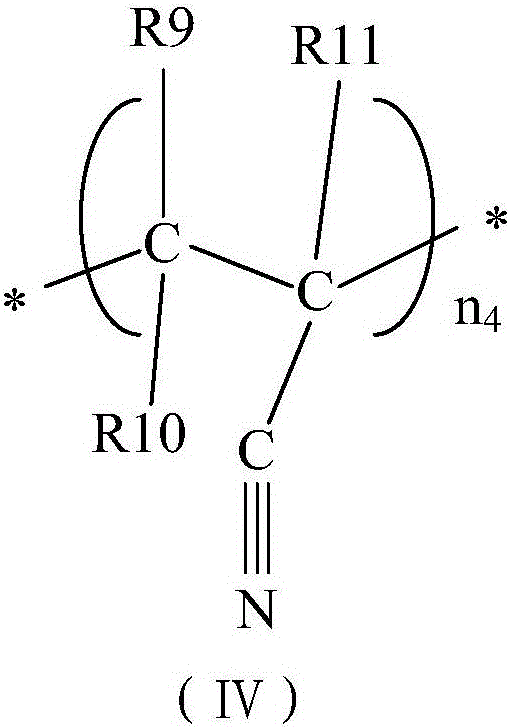

Binding agent and lithium ion battery

InactiveCN106299378AGood flexibilityImprove adhesionCell electrodesSecondary cellsAluminum foilLithium-ion battery

The invention discloses a binding agent and a lithium ion battery. The binding agent is copolymerization-modified PVDF, a structure unit shown in a formula III is included in a main chain of the binding agent, acid / ester functional groups are included on molecular chains and can easily interact with oxidation functional groups on the surface of aluminum foil to form the hydrogen-bond interaction, the flexibility and binding force of the binding agent are improved, and the influences on manufacturing and performance of batteries are relieved.

Owner:OPTIMUM BATTERY CO LTD

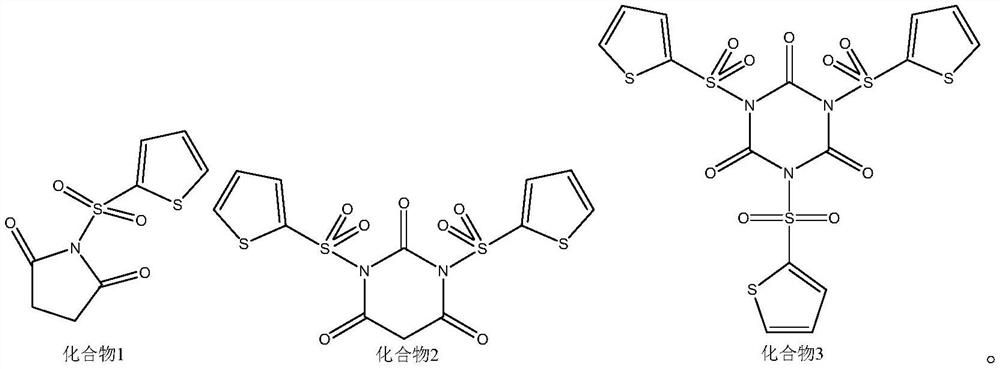

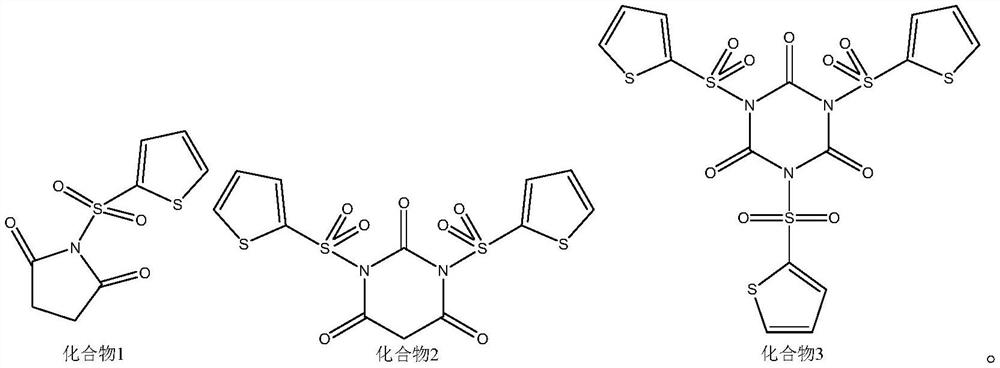

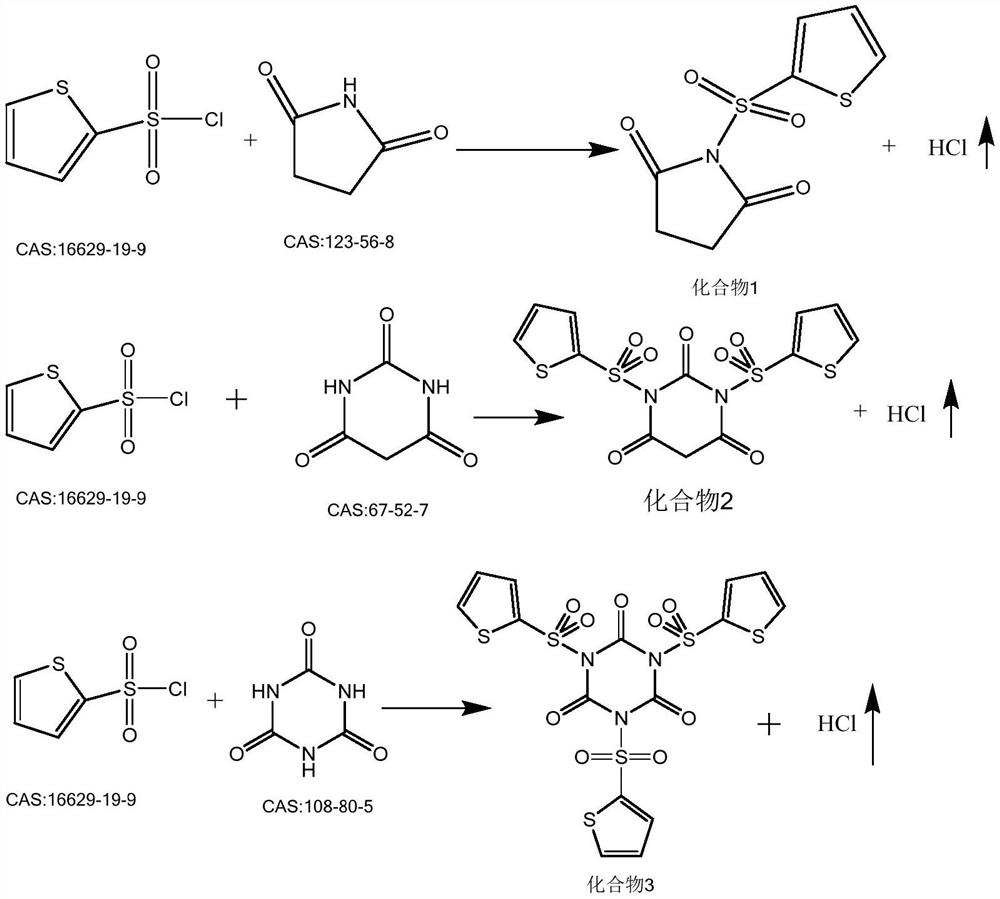

Additive and electrolyte and lithium ion battery using same

ActiveCN114188607AImproved rate cycle performanceImprove rate discharge performanceSecondary cellsBatteriesElectrolytic agentPhysical chemistry

The invention discloses an additive and an electrolyte and a lithium ion battery using the additive, the additive comprises a compound 1, a compound 2 or a compound 3, the additive can orderly form a film when the battery is charged and discharged for the first time, and a formed solid electrolyte interface film has the characteristics of strong conductivity, strong ionic conductivity and low electron conductivity; therefore, the rate cycle performance, the rate discharge performance and the storage performance of the lithium ion battery can be effectively improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Multiplying power type ternary battery and preparation method thereof

InactiveCN105591151AImprove conductivityImprove adhesionCell electrodesCell component detailsCeramic compositeProcess engineering

The invention designs a multiplying power type ternary battery. The battery shows better discharge capability and cycle performance at the discharge rate of 5-20 C. According to the main design scheme of the battery, a 111 or 532 type ternary material is adopted for a positive pole and a mesophase carbon microsphere and artificial graphite mixed material is adopted for a negative pole to improve the conductive capability and absorbing capability of the material. A diaphragm is a large-porosity PE or PP ceramic composite diaphragm for improving the lithium ion dis-embedding rate. Electrolyte is improved multiplying power type electrolyte. In addition, the battery pole piece manufacturing process, coating and rolling parameters of the positive pole and the negative pole are controlled, the internal polarization effect during battery discharge can be effectively alleviated, the large current discharge capacity of the battery can be improved, and discharge temperature of the battery can be reduced.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Preparation method of lithium titanate negative electrode material with nitrogen-doped and carbon-coated layer

InactiveCN107452945AImprove conductivityImproved rate cycle performanceMaterial nanotechnologyCell electrodesCrystallinityChemical vapor deposition

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a preparation method of a lithium titanate negative electrode material with a nitrogen-doped and carbon-coated layer. The preparation method comprises the steps of firstly, preparing a nanometer lithium titanate material with high crystallinity and electrochemical performance by taking lithium acetate as a lithium source, butyl titanate as a titanium source and cetyl trimethyl ammonium bromide as a surfactant; and finally, depositing the uniform and controllable nitrogen-doped and carbon-coated layer on a surface of the sheet-shaped lithium titanate material by employing acetonitrile steam as a carbon source and a nitrogen source and by a chemical vapor deposition method. Therefore, the electrical conductivity of the lithium titanate material is improved, meanwhile, the storage of sheet-shaped morphology of lithium titanate is facilitated, the rate cycle property of a lithium titanate battery is further improved, and the problem that the lithium titanate battery is easy to get bubbles is prevented; and moreover, the preparation method is low in cost and simple in process and is suitable for industrial production on a large scale.

Owner:MCNAIR TECH +3

Lithium ion supercapacitor with positive electrode pre-embedded with lithium

ActiveCN113241262AImproved rate cycle performanceImprove cryogenic storage performanceHybrid capacitor electrodesHybrid/EDL manufactureDoped grapheneMelamine formaldehyde resin

The invention relates to the field of lithium ion batteries, in particular to a lithium ion supercapacitor with a positive electrode pre-embedded with lithium. Lithium iron phosphate with an orthorhombic system olivine-type structure is one of positive electrode materials of lithium ion batteries and capacitors which are most widely applied in the current market, and the application of the lithium iron phosphate is greatly limited due to the problems of low electronic conductivity and poor ion diffusion rate. Based on the problem, the invention provides a lithium ion supercapacitor with a positive electrode pre-embedded with lithium, wherein the positive electrode material is a composite material obtained by compounding a spherical lithium iron phosphate material and heteroatom-doped graphene, and the outer side of the composite material is wrapped by a network carbon structure formed by carbonizing melamino-formaldehyde resin, so that the cycling stability and the rate capability of the lithium ion battery are effectively improved, and a relatively good application prospect is achieved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

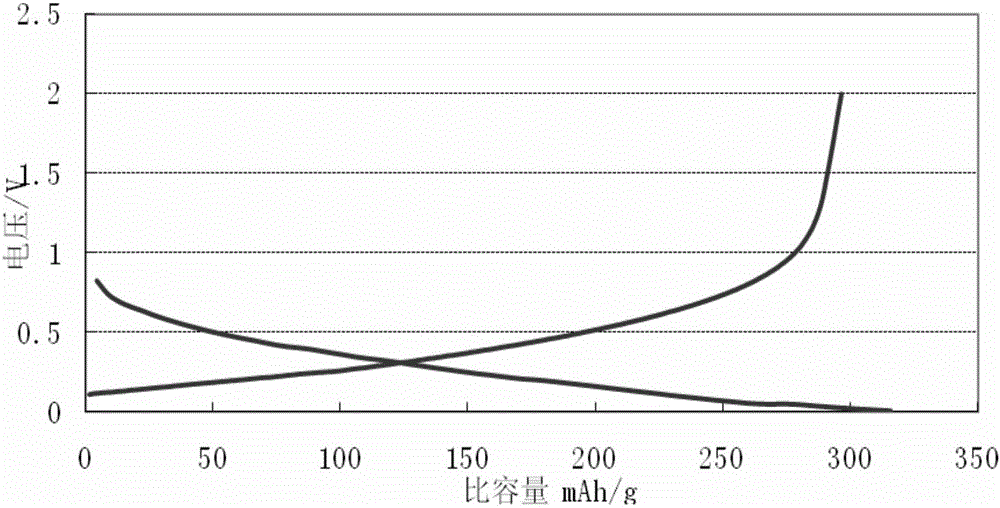

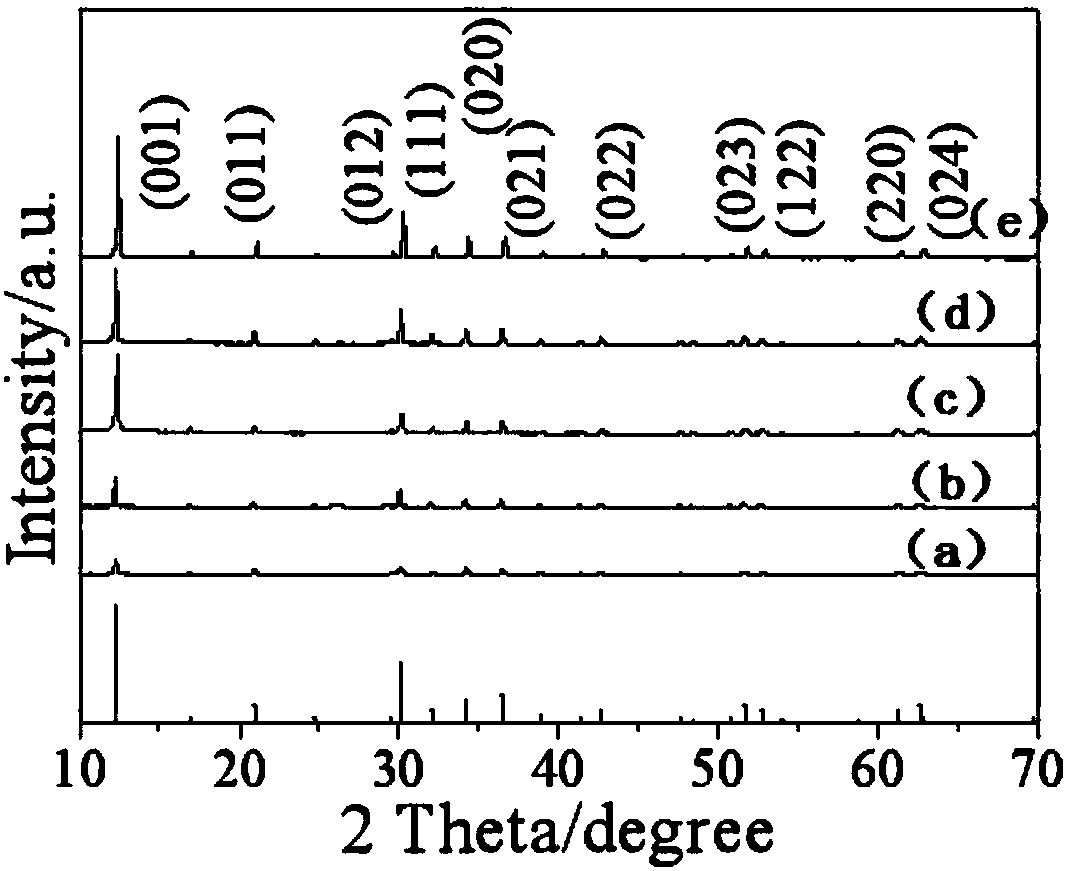

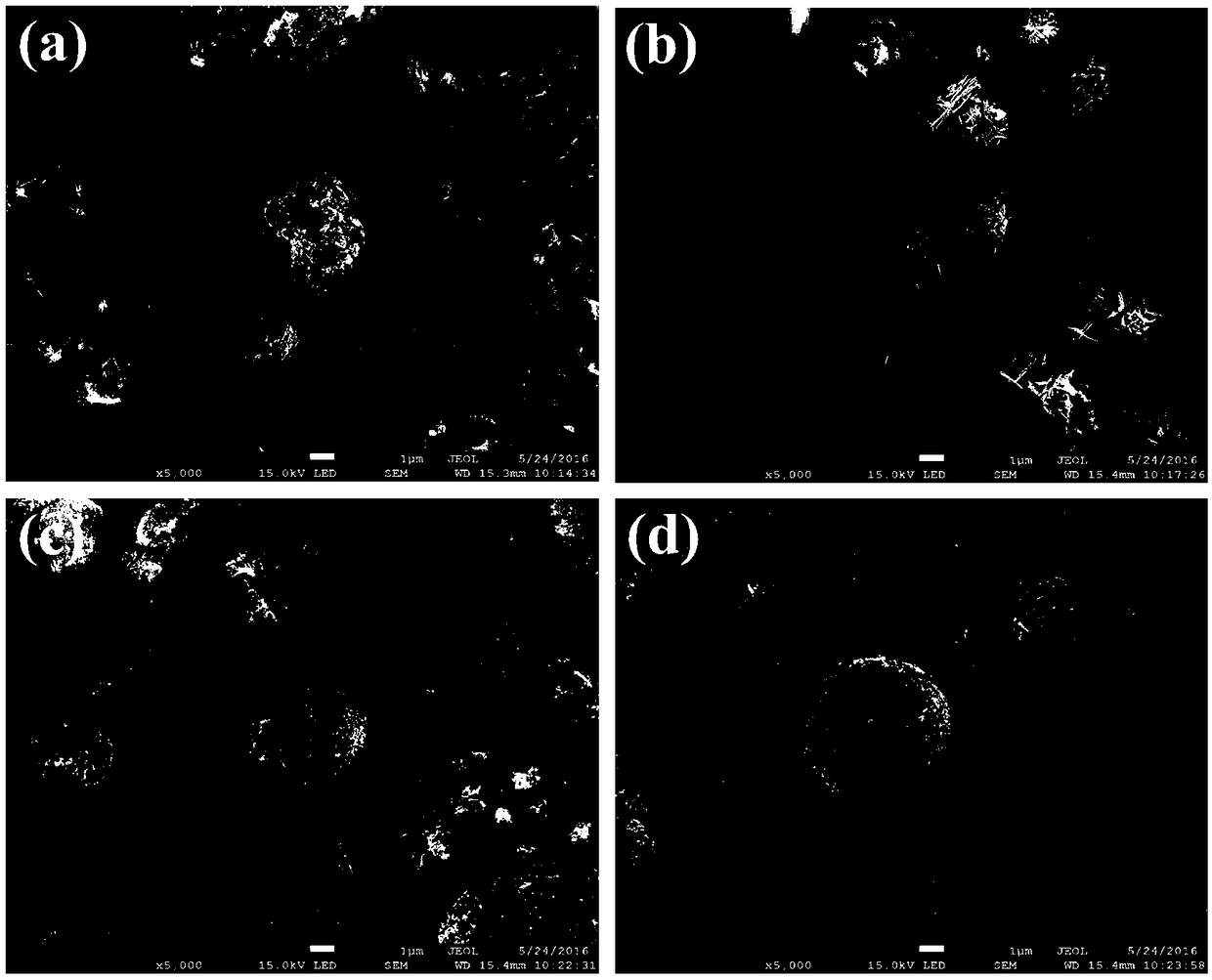

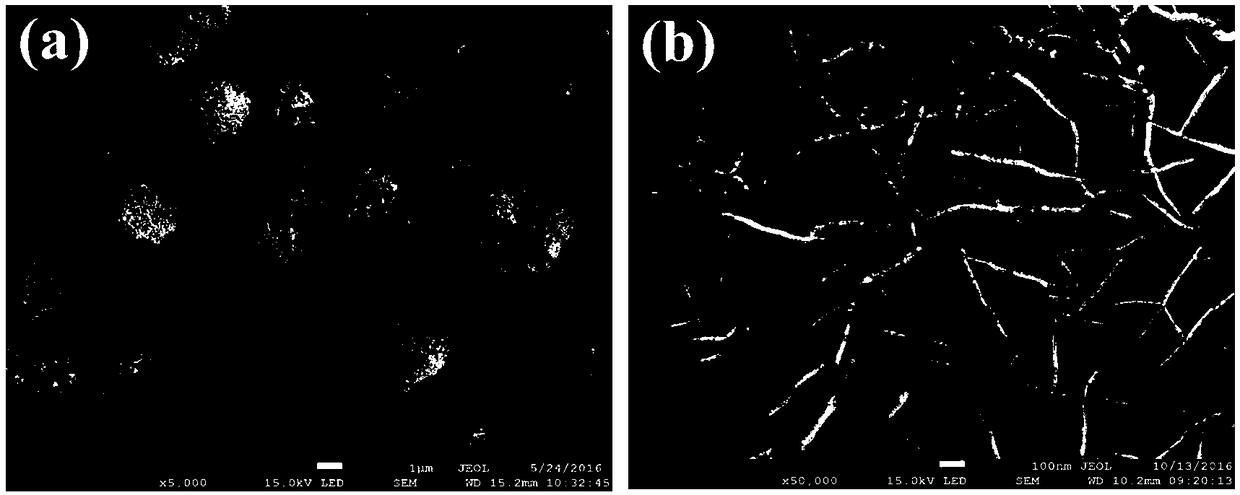

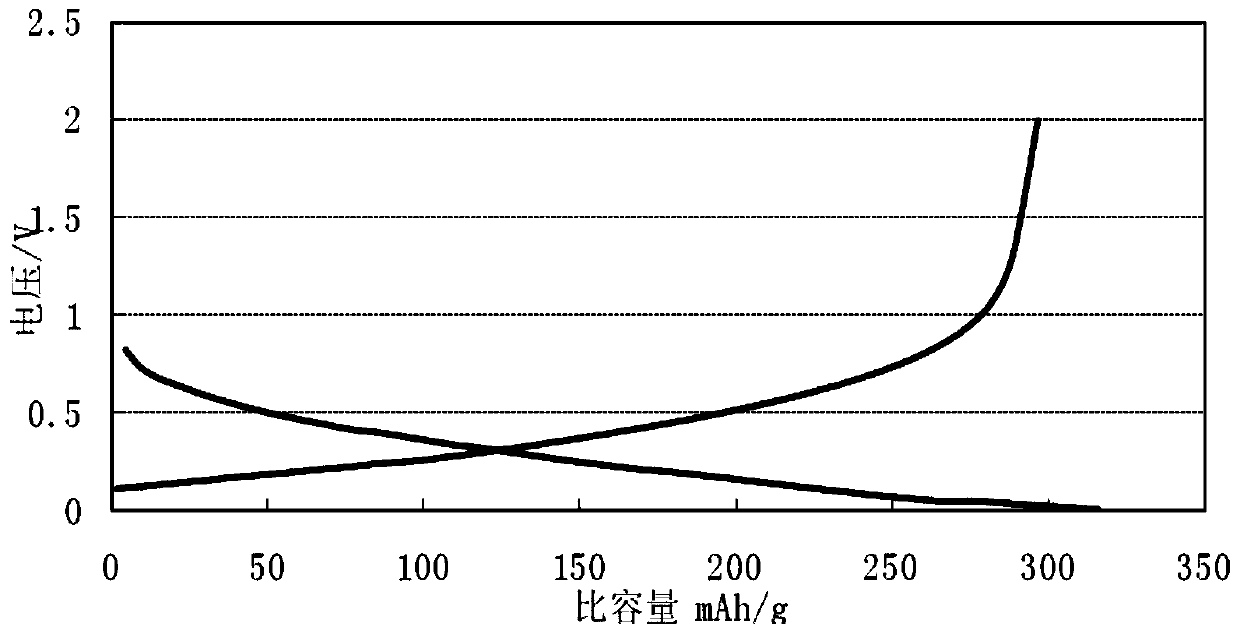

Preparation method and application of hydrated basic zinc pyrovanadate (Zn3V2O7(OH)2.2H2O) material

ActiveCN108217725AHigh purityHigh crystallinityNegative electrodesSecondary cellsElectrochemistryLithium-ion battery

The invention relates to a preparation method and an application of a hydrated basic zinc pyrovanadate (Zn3V2O7(OH)2.2H2O) material. VO(Ac)2 and ZnCl2 are dissolved in a dimethylformamide solvent sequentially in a mole ratio being 1:1.5-1:4, the materials are stirred uniformly, and a dark green solution is obtained; the dark green solution is transferred to a stainless steel reactor, and the reactor is placed into an oven, heated to 120-180 DEG C and subjected to a thermostatic reaction for 3-36 h; cooling is performed to room temperature finally, a product is washed with distilled water and absolute ethyl alcohol, centrifugal filtering and vacuum drying are performed, and the product hydrated basic zinc pyrovanadate (Zn3V2O7(OH)2.2H2O) is obtained. Hydrated basic zinc pyrovanadate prepared with the method has higher reversible specific capacity, excellent electrochemical cycle performance and good rate capability and can serve as a novel anode material to be applied to a lithium ion battery system.

Owner:HUBEI UNIV

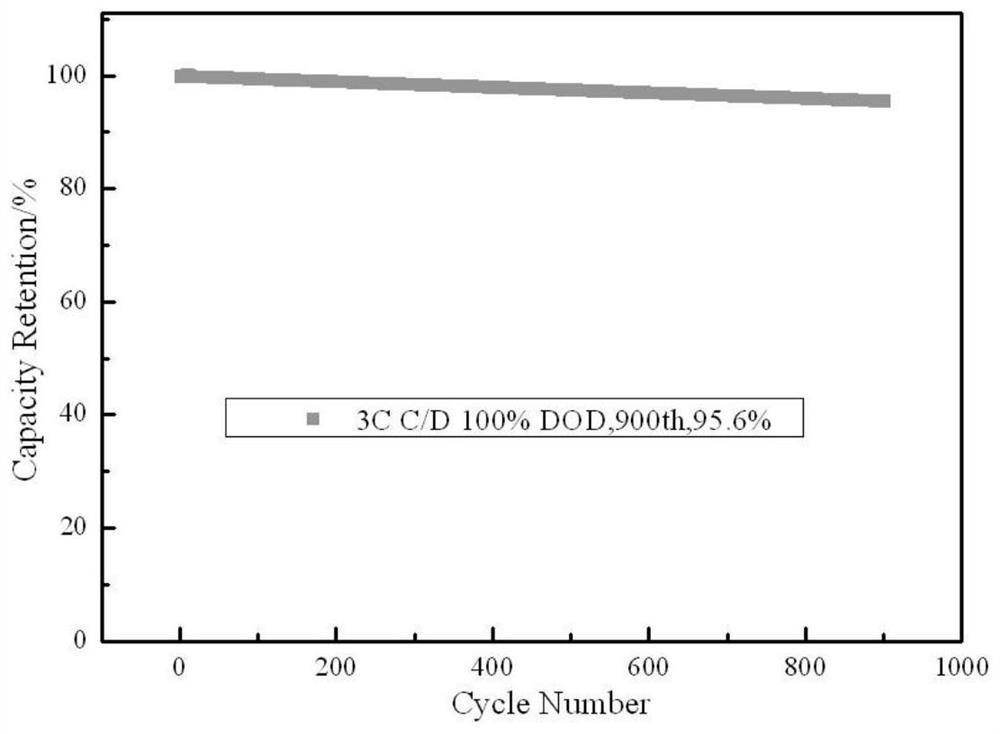

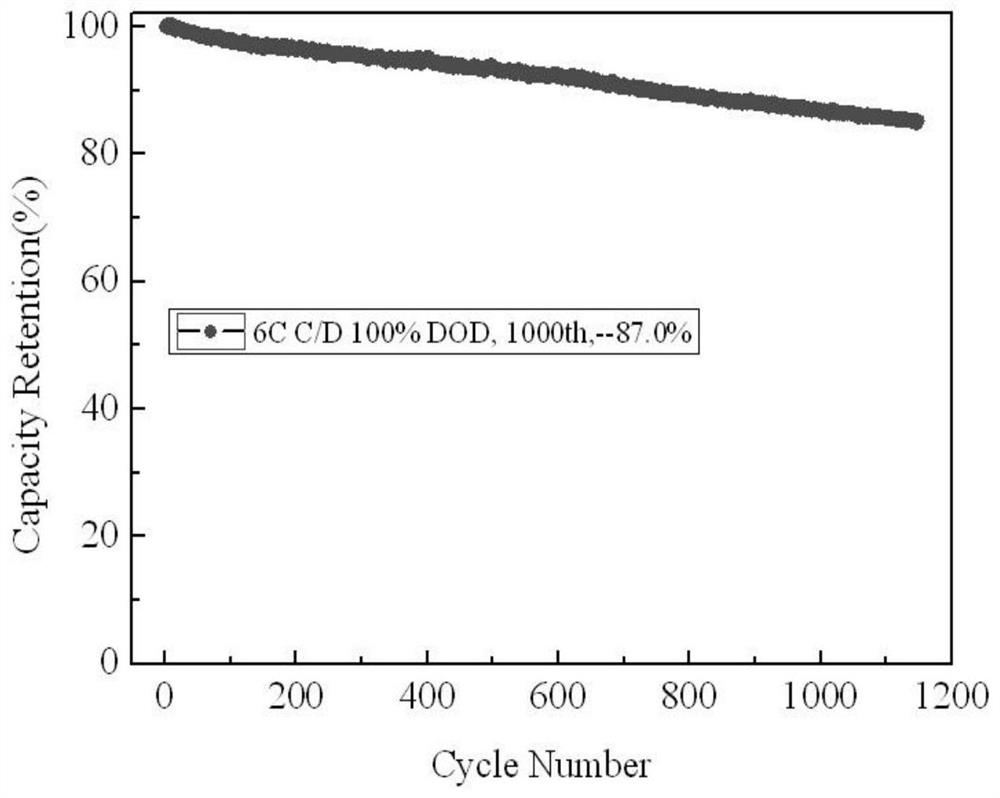

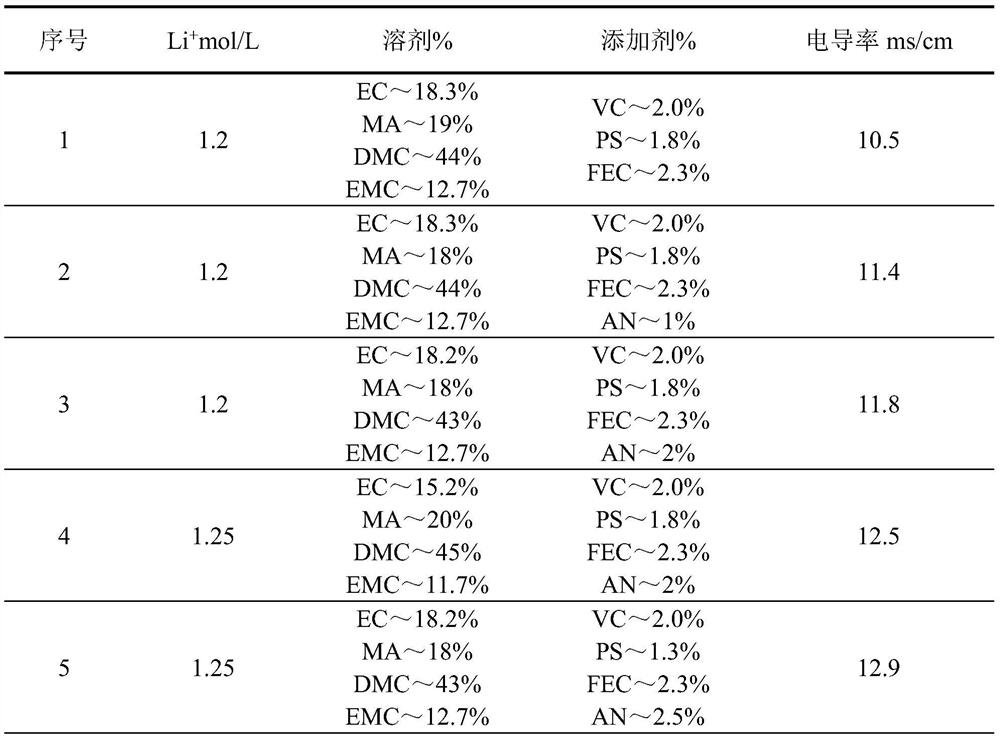

High-rate electrolyte of lithium iron phosphate power battery and preparation method thereof and battery

PendingCN112201842ASimple interfaceReduce decompositionCell electrodesSecondary cells servicing/maintenanceElectrolytic agentMethyl carbonate

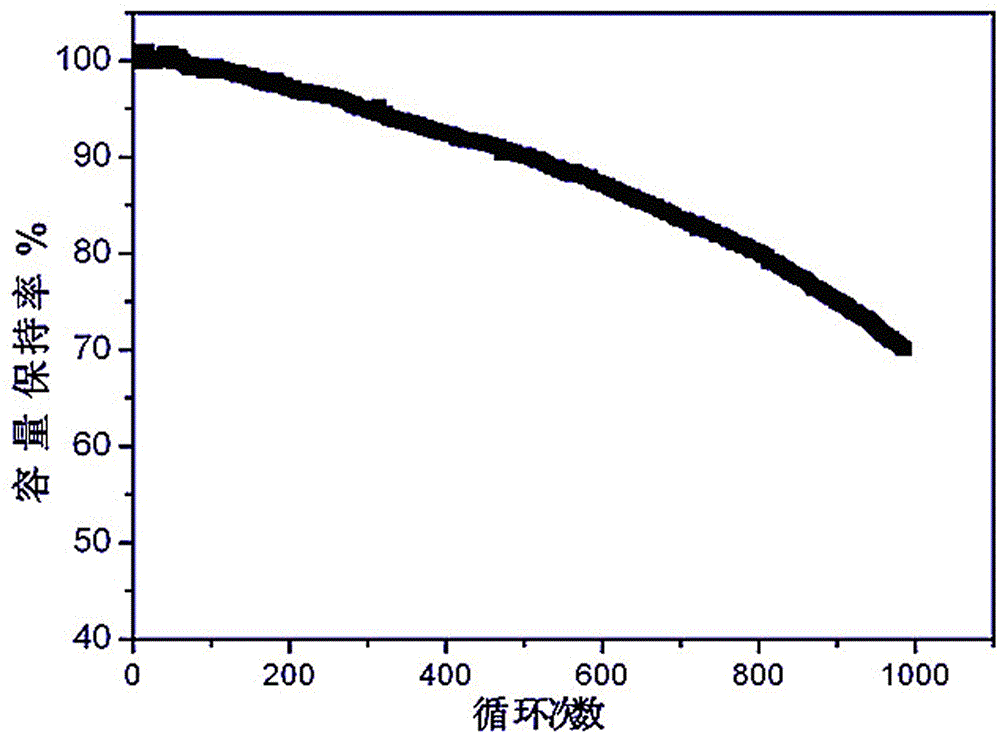

The invention discloses a high-rate electrolyte of a lithium iron phosphate power battery and a preparation method thereof and the battery. The battery comprises lithium salt and an organic solvent, wherein the organic solvent comprises 90 wt%-95 wt% of a non-aqueous organic solvent and 5 wt%-10 wt% of a functional additive, the non-aqueous organic solvent comprises ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate, the functional additive comprises vinylene carbonate, 1, 3-propane sultone, fluoroethylene carbonate and acetonitrile, and the electrolyte is suitable for the powerbattery with the multiplying power not lower than 6C lithium iron phosphate. According to the battery provided by the invention, the capacity of the battery is kept at 95.6% after 900 times of 3C charge-discharge cycles, the capacity of the battery is kept at 87% after 1000 times of 6C cycles, and the rate cycle performance of the battery is greatly improved.

Owner:DONG GUAN LONGTTECH COMPANY LTD

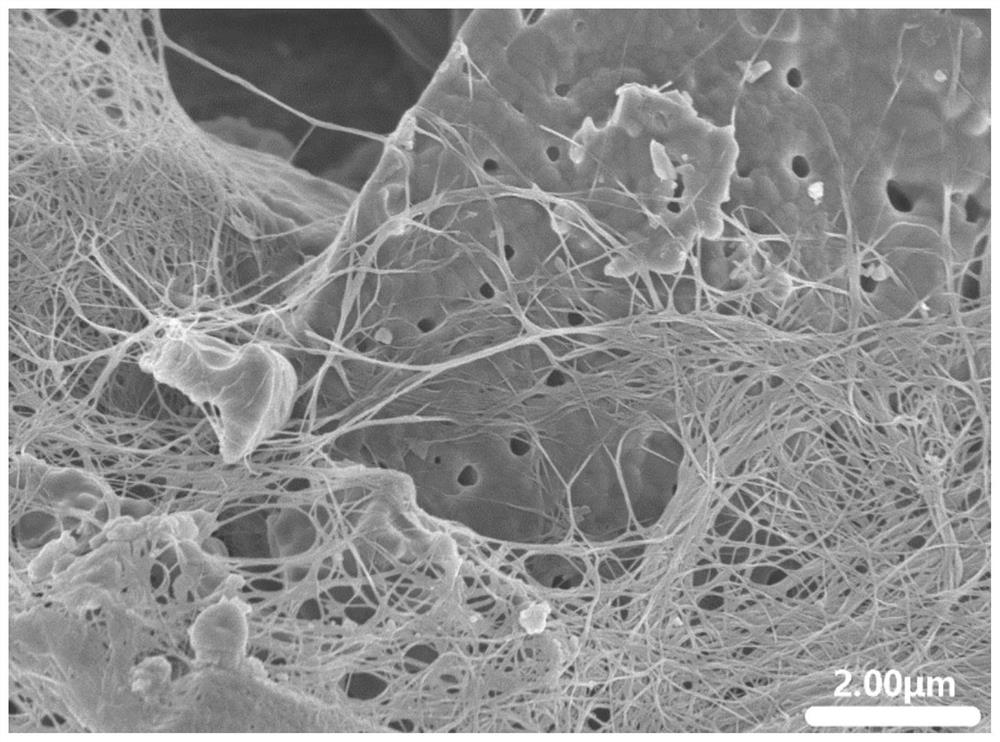

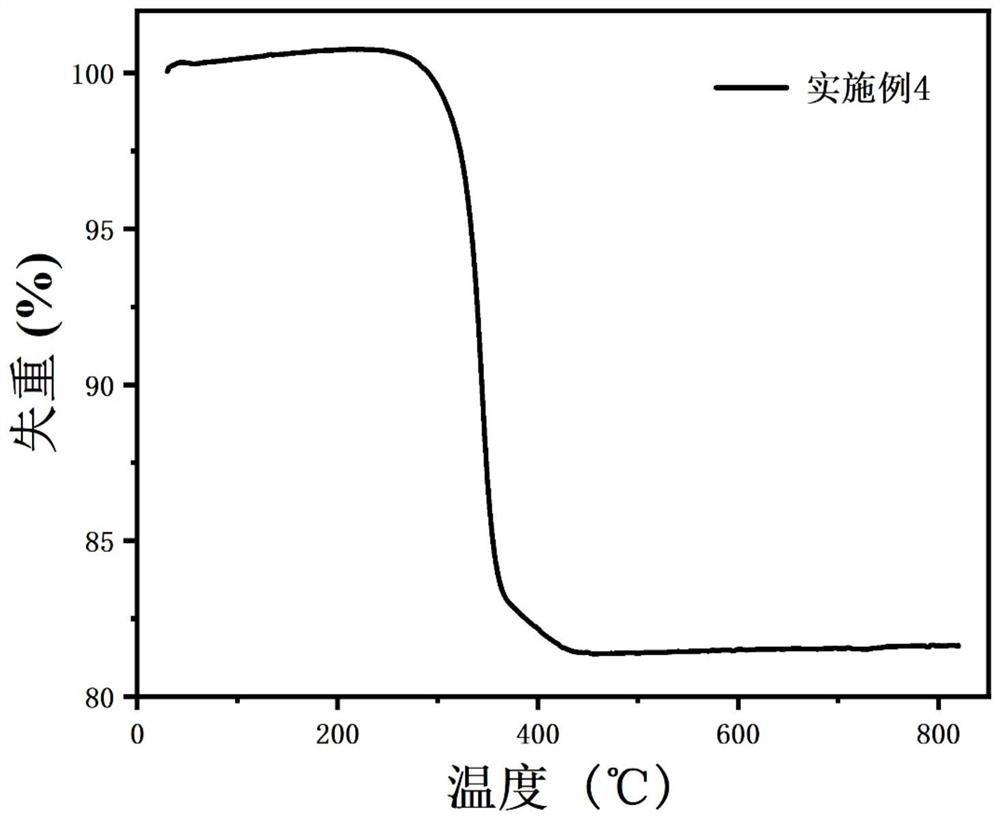

Cellulose inorganic composite membrane, high-temperature-resistant battery diaphragm as well as preparation method and application of high-temperature-resistant battery diaphragm

PendingCN114256560ADoes not affect normalityAdjustable thicknessSecondary cellsCell component detailsPhysical chemistryLithium-ion battery

The invention provides a cellulose inorganic composite membrane, a high-temperature-resistant battery diaphragm as well as a preparation method and application of the high-temperature-resistant battery diaphragm, and belongs to the field of lithium ion battery manufacturing. The cellulose inorganic composite membrane comprises bacterial cellulose and composite powder. The composite powder comprises an organic high-molecular compound and an inorganic substance; the mass ratio of the bacterial cellulose to the composite powder is (5-50): (25-200); the mass ratio of the organic high-molecular compound to the inorganic matter is (10-300): (100-300). The preparation method of the battery diaphragm is simple, pollution-free in process and low in commercialization cost. The battery diaphragm is high in porosity and liquid absorption rate, and electrolyte infiltration and ion migration are facilitated; the thermal stability is excellent, so that the safety performance of the lithium ion battery is greatly improved; and when being applied to the lithium ion battery diaphragm, the lithium ion battery diaphragm shows better long cycle performance and rate cycle performance, and is a lithium ion battery diaphragm with great potential.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

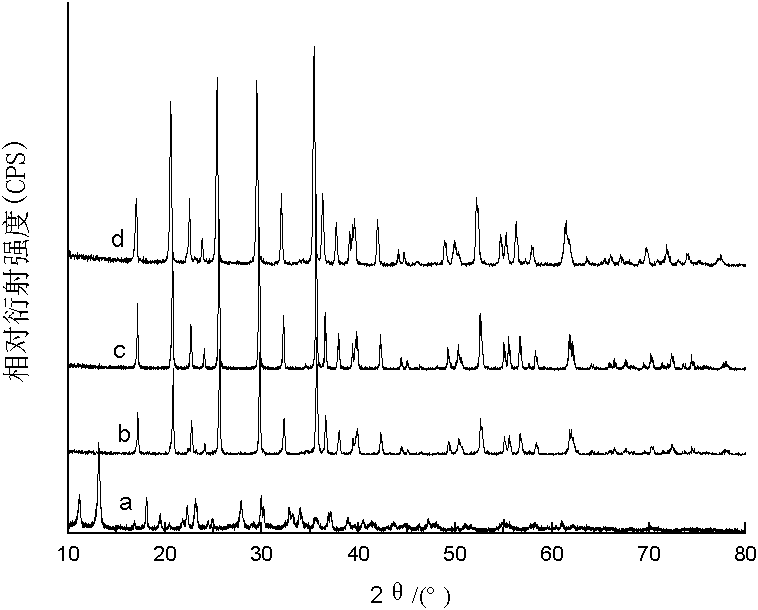

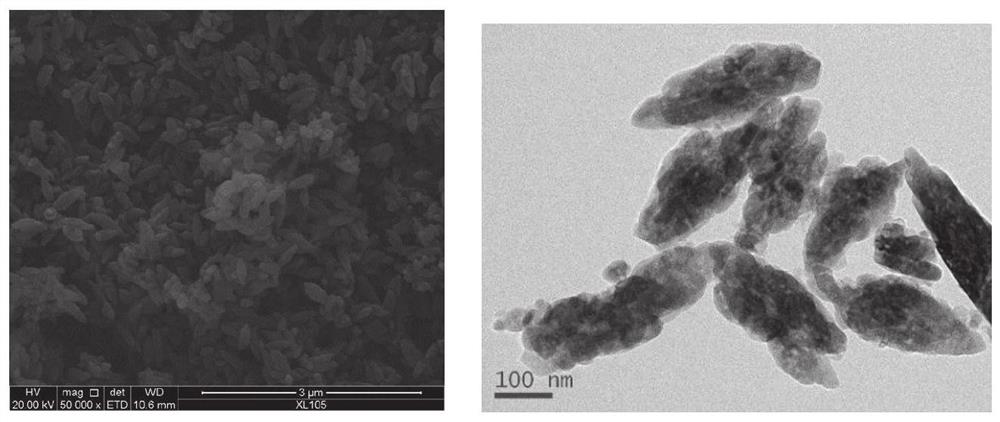

Preparation method of nano-micron lithium manganese phosphate/carbon composite positive electrode material

The invention belongs to the technical field of batteries, and particularly discloses a preparation method of a nano-micron lithium manganese phosphate / carbon composite positive electrode material. The method comprises the steps of carrying out the thermal treatment on a raw material solution containing a manganese source, a lithium source, a phosphorus source, the hexamethylenetetramine and the ethylene glycol at 70-80 DEG C in advance, then carrying out the thermal treatment on the solvent at 160-200 DEG C, mixing the prepared nano-micron lithium manganese phosphate with a macromolecule carbon source, drying and calcining at 500-650 DEG C in a protective atmosphere. The primary particles of the prepared material are nano-scale, grow preferentially and are distributed uniformly, so that the diffusion of the lithium ions in the material is facilitated. The secondary particles are micron-scale, so that the structure stability is facilitated, and the prepared material has the relativelyhigher charge-discharge capacity, excellent cycling stability and good rate capability.

Owner:CENT SOUTH UNIV

A preparation method of nano-micro graded manganese phosphate lithium/carbon composite positive electrode material

ActiveCN110492060BStable structureInterface stabilityPhosphatesCell electrodesCarbon compositesPhosphate

The invention belongs to the technical field of batteries, and specifically discloses a preparation method of a lithium manganese phosphate / carbon composite material with a nano-micro hierarchical structure, which will contain a manganese source, a lithium source, a phosphorus source, hexamethylenetetramine, ethylene glycol The raw material solution is heat-treated at 70°C to 80°C in advance, and then solvothermally obtained at 160°C to 200°C. The prepared lithium manganese phosphate material with nano-micro hierarchical structure is mixed with a polymer carbon source, dried and calcined at 500°C to 650°C in a protective atmosphere. The primary particles of the material prepared by the invention are nano-scale, have preferential growth and uniform distribution, and are beneficial to the diffusion of lithium ions in the material. The size of the secondary particles is at the micron level, which is conducive to the stability of the structure. The prepared material has a high charge and discharge capacity, excellent cycle stability, and good rate performance.

Owner:CENT SOUTH UNIV

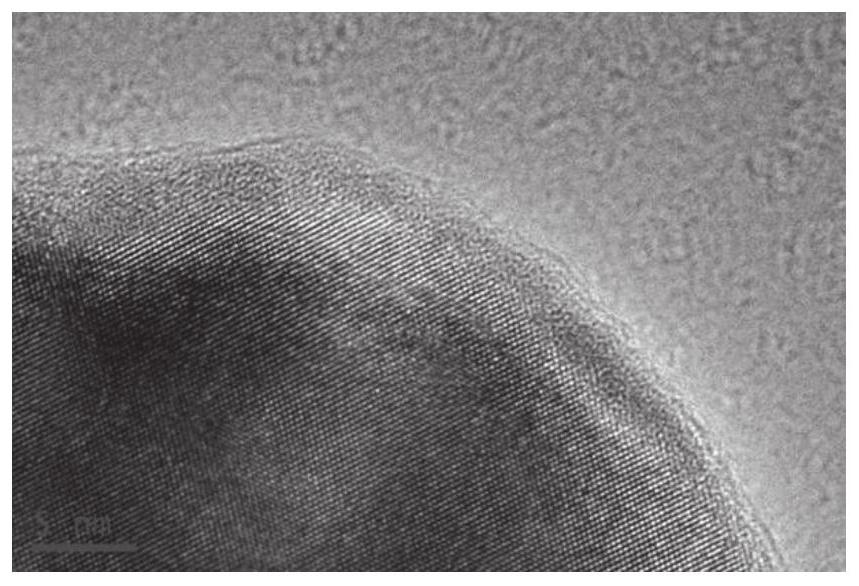

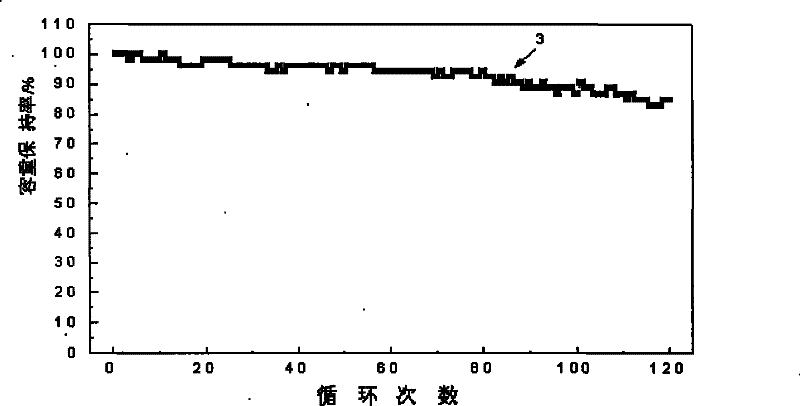

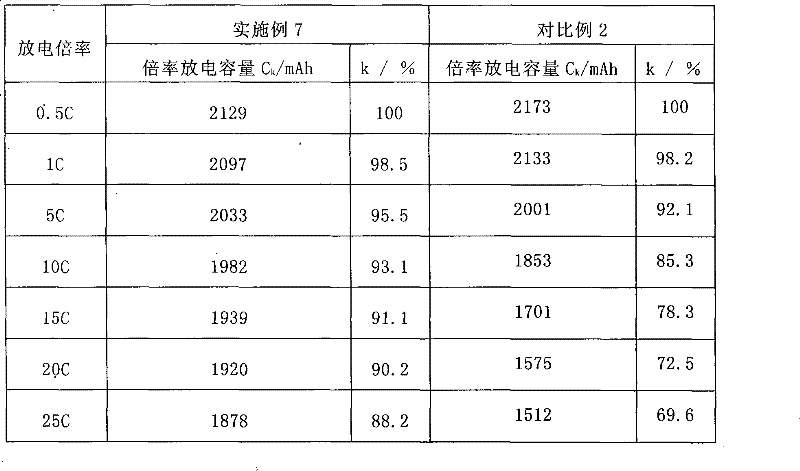

Positive plate of high power lithium ionic cell and lithium ionic cell containing the same

ActiveCN101388449BLow costHigh specific capacityElectrode manufacturing processesActive material electrodesSodium-ion batteryCobalt

The invention relates to the technical field of lithium ion batteries, in particular to a high-power lithium ion battery positive plate and a lithium ion battery thereof. The invention discloses a high-power lithium ion battery positive plate, which comprises a current collector and cathode material, wherein the cathode material comprises positive active substances, bonding agent and conductive agent, and is characterized in that the positive active substance is formed by layered lithium cobalt oxide and layered nickel cobalt lithium manganese oxide, and the proportion by weight of lithium cobalt oxide and nickel cobalt lithium manganese oxide is 1-7:1-9. The invention further provides a lithium ion battery which contains the positive plate. The invention solves the problems of bad heavy-current discharge and poor performance high circulation generated after layered nickel cobalt lithium manganese oxide material is used on a high-power lithium ion battery owing to the weaknesses existing in the nickel cobalt lithium manganese oxide material of lower electric conductivity and tap density. The lithium ion battery disclosed by the invention has excellent heavy-current discharge performance and high circulation performance, wherein the25 C continuous discharge capacity is 88% of the 0.5C discharge capacity, and the capacity conservation rate is 85% after 20 C cell multiplying power circulates 120 cycles.

Owner:HANGZHOU NARADA BATTERY +1

Porous hard carbon lithium ion battery negative electrode material and preparation method thereof and lithium ion battery

ActiveCN106450313BEasy to watch and controlHigh reversible capacityCell electrodesSecondary cellsAluminium-ion batteryVegetable oil

The invention discloses a porous hard-carbon lithium ion battery anode material, a preparation method thereof and a lithium ion battery. The method comprises steps as follows: hydrogenated vegetable oil powder is prepared firstly and then is subjected to low-temperature carbonizing treatment in inert gas, a precursor is prepared, the precursor is subjected to organic carbon source coating treatment with a solvent and an organic carbon source, material particles are prepared, finally, the material particles are subjected to high-temperature carbonizing treatment, and the porous hard-carbon lithium ion battery anode material is prepared. The method adopts a simple process, a synthesis path is simple and controllable, micro-control for morphology and size of the material is easy, and the prepared porous hard-carbon lithium ion battery anode material is high in reversible capacity and good in rate capability cycle performance and low-temperature performance.

Owner:博尔特新材料(银川)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com