Preparation for interconnected nanowire core-shell structure material

A core-shell structure and structural material technology, applied in nanotechnology, structural parts, electrical components, etc., can solve the problems of destroying electrode structure, electrical contact deterioration, material crushing, etc., to reduce diffusion resistance, good conductivity, high The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

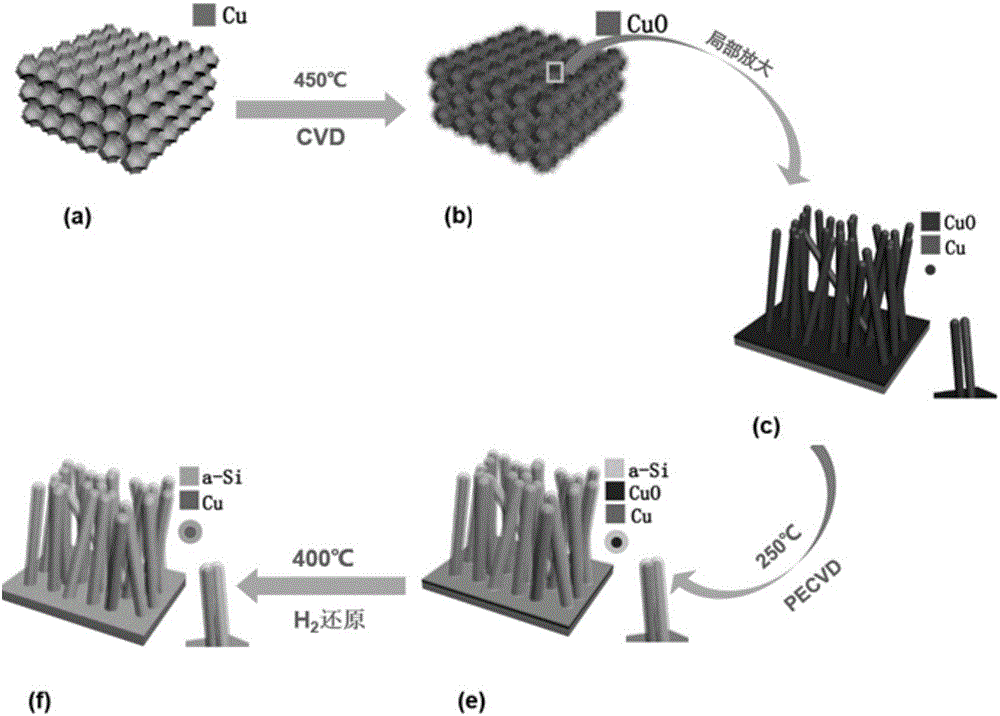

[0018] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended figure 1 , to further describe the present invention in detail.

[0019] 1) Use a three-dimensional porous copper foam with a thickness of 0.5mm as the current collector (such as a), and clean the surface normally, soak it with hydrochloric acid to remove the oxide layer, and then dry it with a nitrogen gun.

[0020] 2) Using a CVD furnace and calcining in the atmosphere, CuO nanowires with a diameter of about 30nm and a length of 7-10um can be prepared on the three-dimensional copper foam.

[0021] 3) Depositing amorphous Si(Ge) for 30 minutes by PECVD under the conditions of power 20W and temperature 250°C, an interconnected core-shell nanowire structure with a diameter of about 100nm can be obtained.

[0022] 4) Use H 2 , reduce the core CuO in PECVD (atmospheric pressure 200Pa, fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com