Preparation method of lithium titanate negative electrode material with nitrogen-doped and carbon-coated layer

A technology of nitrogen-doped carbon and negative electrode materials, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc. Solid density and other issues, to achieve the effect of low cost, improve rate cycle performance, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

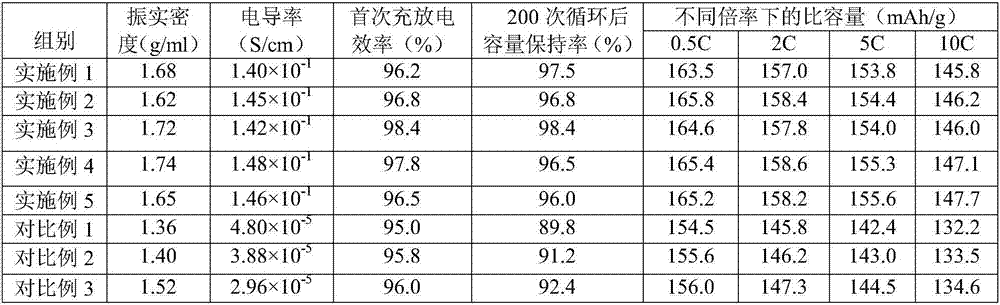

Examples

Embodiment 1

[0025] A method for preparing a lithium titanate negative electrode material with a nitrogen-doped carbon coating layer, which includes the following steps:

[0026] Step 1). Add butyl titanate to the cetyltrimethylammonium bromide solution, stir well, and then slowly add the lithium acetate solution, stir evenly, to obtain a mixed solution, in which, butyl titanate, ten The molar ratio between hexaalkyltrimethylammonium bromide and lithium acetate is 1:0.2:0.8;

[0027] Step 2). Transfer the mixed solution of step 1) to a hydrothermal kettle, conduct a hydrothermal reaction treatment at 180°C for 24 to 48 hours, then dry it at 85°C, and place the dried powder Heat to 700℃ in a tube furnace with argon gas and keep it for 7 hours to obtain the precursor nano lithium carbonate material;

[0028] Step 3). Distribute the nano-lithium carbonate material obtained in step 2 uniformly in an alumina crucible, and place it in a tube furnace filled with argon and acetonitrile steam, the flow r...

Embodiment 2

[0030] A method for preparing a lithium titanate negative electrode material with a nitrogen-doped carbon coating layer, which includes the following steps:

[0031] Step 1). Add butyl titanate to the cetyltrimethylammonium bromide solution, stir well, and then slowly add the lithium hydroxide solution, stir evenly to obtain a mixed solution, wherein, butyl titanate, The molar ratio between cetyltrimethylammonium bromide and lithium hydroxide is 1:0.05:0.1;

[0032] Step 2). Transfer the mixed solution of step 1) to a hydrothermal kettle, conduct a hydrothermal reaction treatment at 160°C for 24 to 48 hours, then dry it at 75°C, and place the dried powder Heat it to 600℃ in a tube furnace with argon gas and keep it for 8 hours to obtain the precursor nano lithium carbonate material;

[0033] Step 3). Distribute the nano-lithium carbonate material obtained in step 2 uniformly in an alumina crucible and place it in a tube furnace filled with argon and acetonitrile steam, the flow rate...

Embodiment 3

[0035] A method for preparing a lithium titanate negative electrode material with a nitrogen-doped carbon coating layer, which includes the following steps:

[0036] Step 1). Add titanium dioxide to the cetyltrimethylammonium bromide solution, stir well, and then slowly add the lithium carbonate solution, stir evenly to obtain a mixed solution, where titanium dioxide, cetyltrimethyl The molar ratio between ammonium bromide and lithium carbonate is 1:0.5:0.9;

[0037] Step 2). Transfer the mixed solution of step 1) to a hydrothermal kettle, conduct a hydrothermal reaction treatment at 200°C for 24 to 48 hours, then dry it at 95°C, and place the dried powder Heat it to 800℃ in a tube furnace with argon gas and keep it for 6 hours to obtain the precursor nano lithium carbonate material;

[0038] Step 3). Distribute the nano-lithium carbonate material obtained in step 2 uniformly in an alumina crucible, and place it in a tube furnace filled with argon and acetonitrile steam, the flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com