High-performance silicon monoxide/amorphous carbon/graphite composite negative electrode material and preparation method thereof

A silicon monoxide and negative electrode material technology, applied in the field of electrochemical power supply, can solve the problems of cycle stability and capacity performance to be improved, nanoparticles are easy to agglomerate, and the preparation process is complicated, and achieves excellent rate cycle performance and low preparation cost. , the effect of improving the contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the Si / C / G mass ratio of 5:1:4, accurately weigh a certain amount of SiO powder, glucose and natural flake graphite, and perform heat treatment after mechanical ball milling for 5 hours under the protection of argon. The ball milling process and heat treatment conditions refer to the above specific implementation. The obtained 5Si / 1C / 4G composites were prepared as electrodes for electrochemical tests. The electrode preparation method, battery assembly and test conditions are the same as in Comparative Example 1.

[0034] Through the test, the first lithium intercalation capacity of the material is 889.7mAh g -1 , the delithiation capacity is 420.8mAh·g -1 ; The lithium intercalation capacity of 100 cycles is 637.1mAh g -1 , the delithiation capacity is 635.7mAh g -1 , its capacity retention rate is 151.1%, the capacity has a gradual upward trend, and its capacity performance and cycle stability have been significantly improved compared with SiO raw mate...

Embodiment 2

[0036]According to the Si / C / G mass ratio of 5:2:3, accurately weigh a certain amount of SiO powder, glucose and natural flake graphite, and perform heat treatment after mechanical ball milling for 5 hours under the protection of argon. The ball milling process and heat treatment conditions are the content of the invention Specific implementations described in . Then, the obtained 5Si / 2C / 3G composite material was used to prepare electrodes for electrochemical testing. The electrode preparation method, battery assembly and test conditions were the same as in Comparative Example 1.

[0037] Through the test, the first lithium intercalation capacity of the material is 1176.7mAh g -1 , the delithiation capacity is 684.6mAh·g -1 , the lithium intercalation capacity of 100 cycles is 724.6mAh·g -1 , the delithiation capacity is 722.9mAh·g -1 , the capacity retention rate is 105.6%, and the capacity basically has no attenuation, which is significantly improved compared with SiO raw ...

Embodiment 3

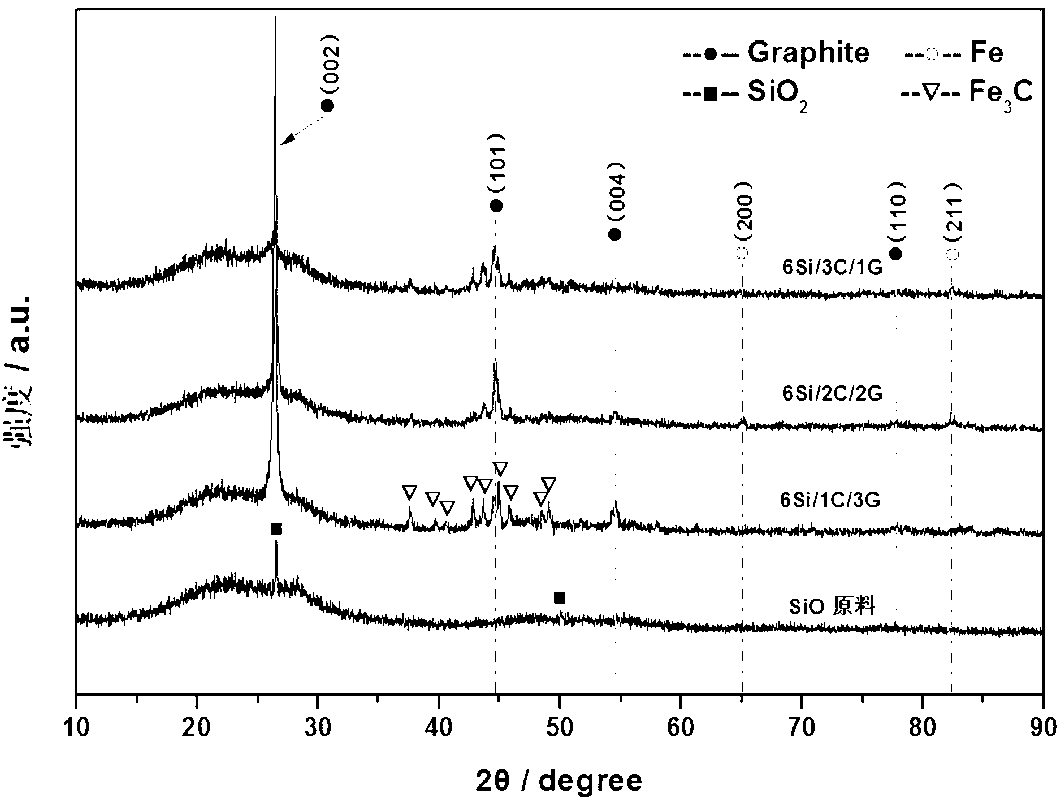

[0039] According to the Si / C / G mass ratio of 6:1:3, accurately weigh a certain amount of SiO powder, sucrose and natural flake graphite, and perform heat treatment after mechanical ball milling for 5 hours under the protection of argon. The ball milling process and heat treatment conditions refer to the above specific implementation. The obtained 6Si / 1C / 3G composites were used to prepare electrodes for electrochemical tests. The electrode preparation method, battery assembly and test conditions are the same as in Comparative Example 1.

[0040] Through the test, the first lithium intercalation capacity of the material is 1156.8mAh g -1 , the delithiation capacity is 628.6mAh·g -1 , the lithium intercalation capacity of 100 cycles is 822.6mAh·g -1 , the delithiation capacity is 817.3mAh g -1 , the capacity retention rate is 130%, and the capacity has a gradual upward trend, which has been significantly improved compared with SiO raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com