Nickel-containing precursor, nickel-containing composite material, and preparation methods and applications of nickel-containing precursor and nickel-containing composite material

A technology of composite materials and precursors, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of lithium-ion battery capacity, poor rate cycle performance, etc., to improve capacity and rate cycle performance, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

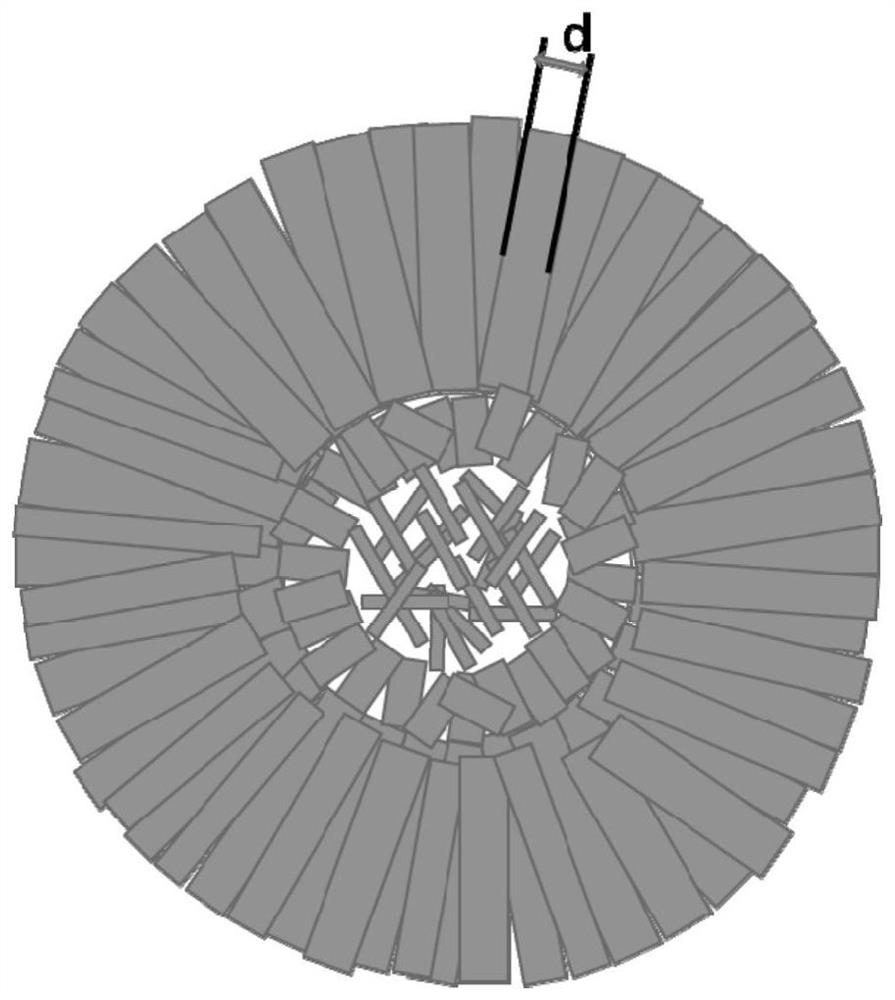

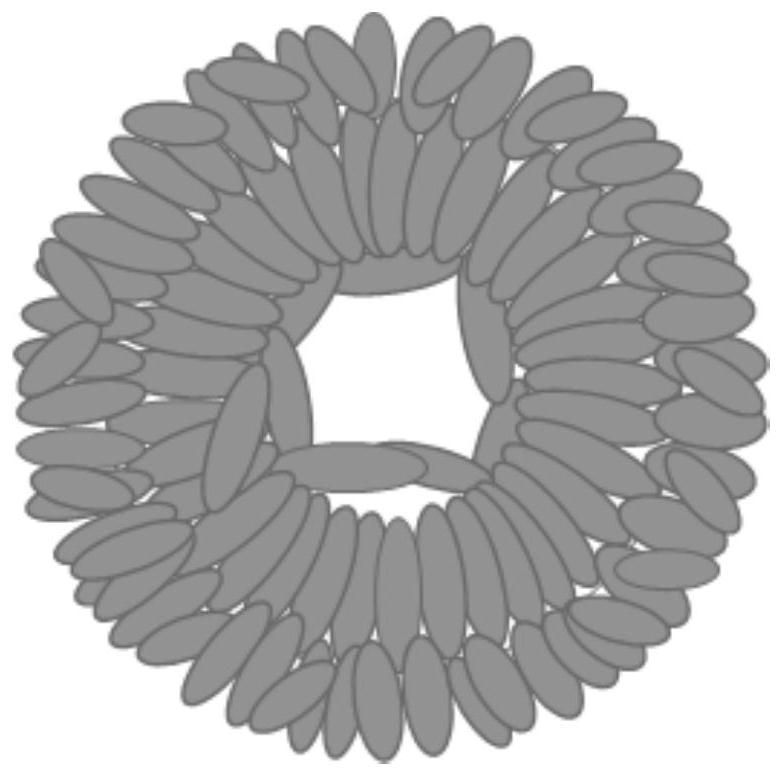

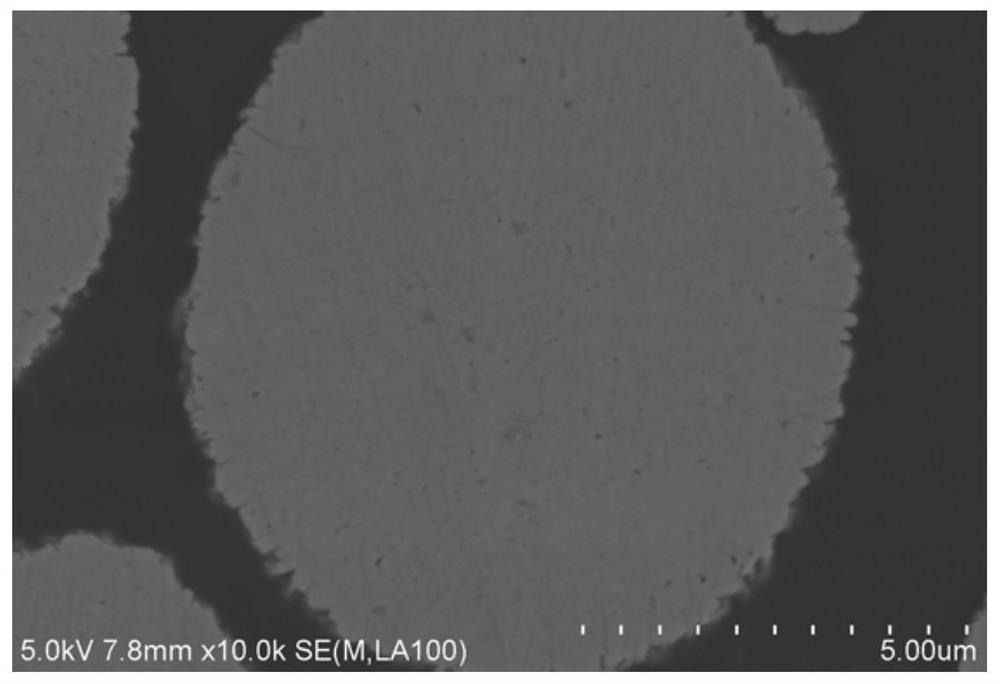

[0053] (1) Preparation of nickel-containing precursor:

[0054] S1, nickel sulfate, cobalt sulfate, manganese sulfate are dissolved in water according to the ratio of Ni:Co:Mn molar ratio 83:11:6 and are formulated with the metal salt solution that the total concentration of metal salt is 2mol / L, and sodium hydroxide is dissolved in The aqueous sodium hydroxide solution (lye) with a concentration of 4 mol / L is prepared in water, and the aqueous ammonia solution with a concentration of 4 mol / L is prepared with ammonia water.

[0055] S2. Pass the metal salt solution, lye and ammonia solution into the reaction kettle equipped with half a pot of deionized water at the same time, and the feeding rate of the metal salt solution is controlled at 10L h -1 , the initial feed rate of ammonia solution was controlled at 1.3L h -1 , the initial lye feed rate was controlled at 3.0L h -1 , the temperature in the reactor is controlled at 60°C, the stirring frequency is controlled at 20Hz, ...

Embodiment 2

[0059] (1) Preparation of nickel-containing precursor:

[0060] S1, nickel sulfate, cobalt sulfate, manganese sulfate are dissolved in water according to the ratio of Ni:Co:Mn molar ratio 83:11:6 and are formulated with the metal salt solution that the total concentration of metal salt is 2mol / L, and sodium hydroxide is dissolved in The aqueous sodium hydroxide solution (lye) with a concentration of 4 mol / L is prepared in water, and the aqueous ammonia solution with a concentration of 4 mol / L is prepared with ammonia water.

[0061] S2. Pass the metal salt solution, lye and ammonia solution into the reaction kettle equipped with half a pot of deionized water at the same time, and the metal salt solution feed rate is controlled at 12L h -1 , the initial feed rate of ammonia solution was controlled at 1.3L h -1 , the initial lye feed rate was controlled at 3.3L h -1 , the temperature in the reactor is controlled at 60°C, the stirring frequency is controlled at 20Hz, the pH val...

Embodiment 3

[0067] (1) Preparation of nickel-containing precursor:

[0068] S1. Dissolve nickel sulfate, cobalt sulfate, manganese sulfate, and aluminum nitrate in water according to the ratio of Ni:Co:Mn:Al molar ratio 83:11:5:1 to prepare a metal salt solution with a total concentration of metal salt of 2mol / L , Sodium hydroxide is dissolved in water to be prepared as a 4mol / L aqueous sodium hydroxide solution (lye), and ammonia water is prepared as a 4mol / L ammonia solution.

[0069] S2. Pass the metal salt solution, lye and ammonia solution into the reaction kettle equipped with half a pot of deionized water at the same time, and the metal salt solution feed rate is controlled at 15L h -1 , the initial feed rate of ammonia water was controlled at 1.7L h -1 , the initial lye feed rate was controlled at 4.0L h -1 , the temperature in the reactor is controlled at 60°C, the stirring frequency is controlled at 20Hz, the pH value is controlled at 11.6±1.0, and the feeding speed of the lye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com