Sea urchin-like lithium titanate microsphere preparation method

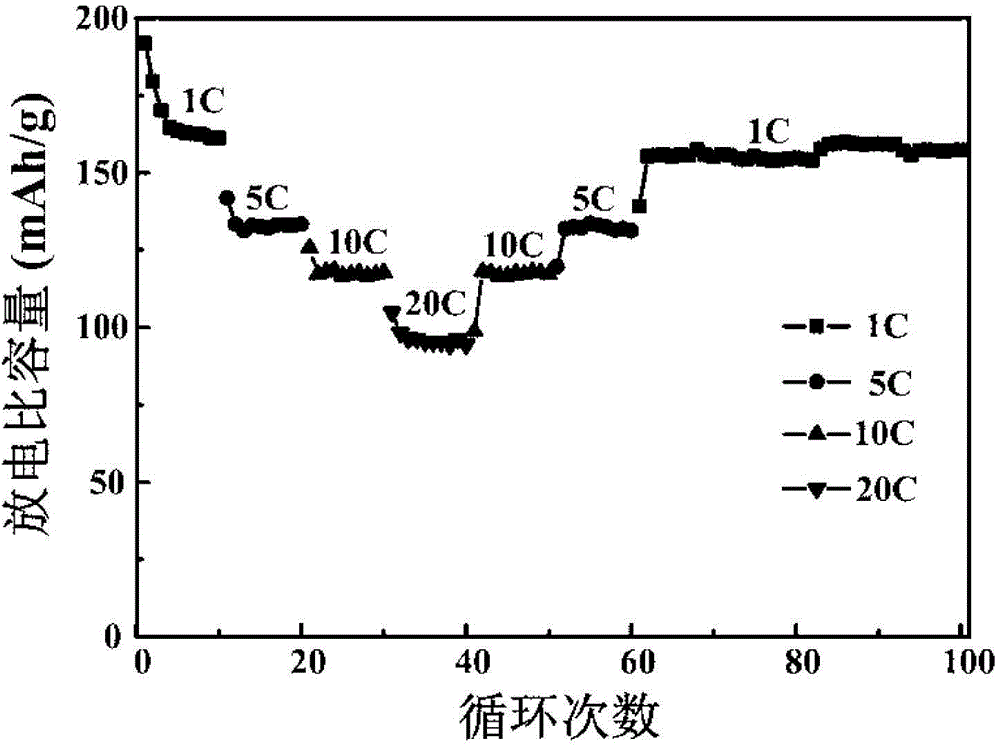

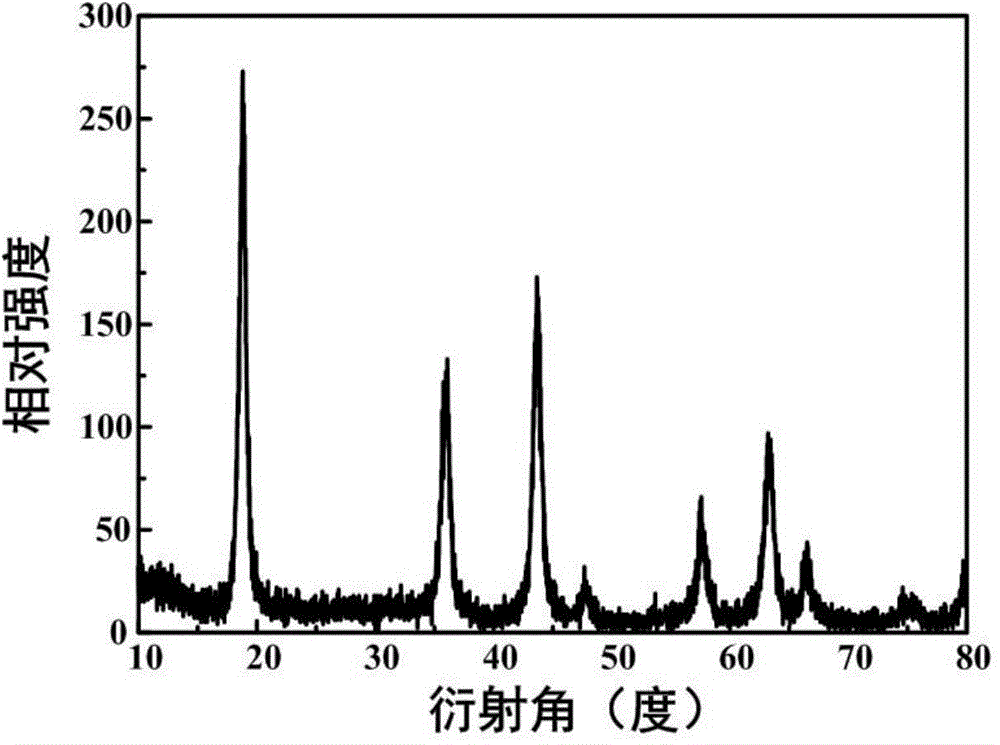

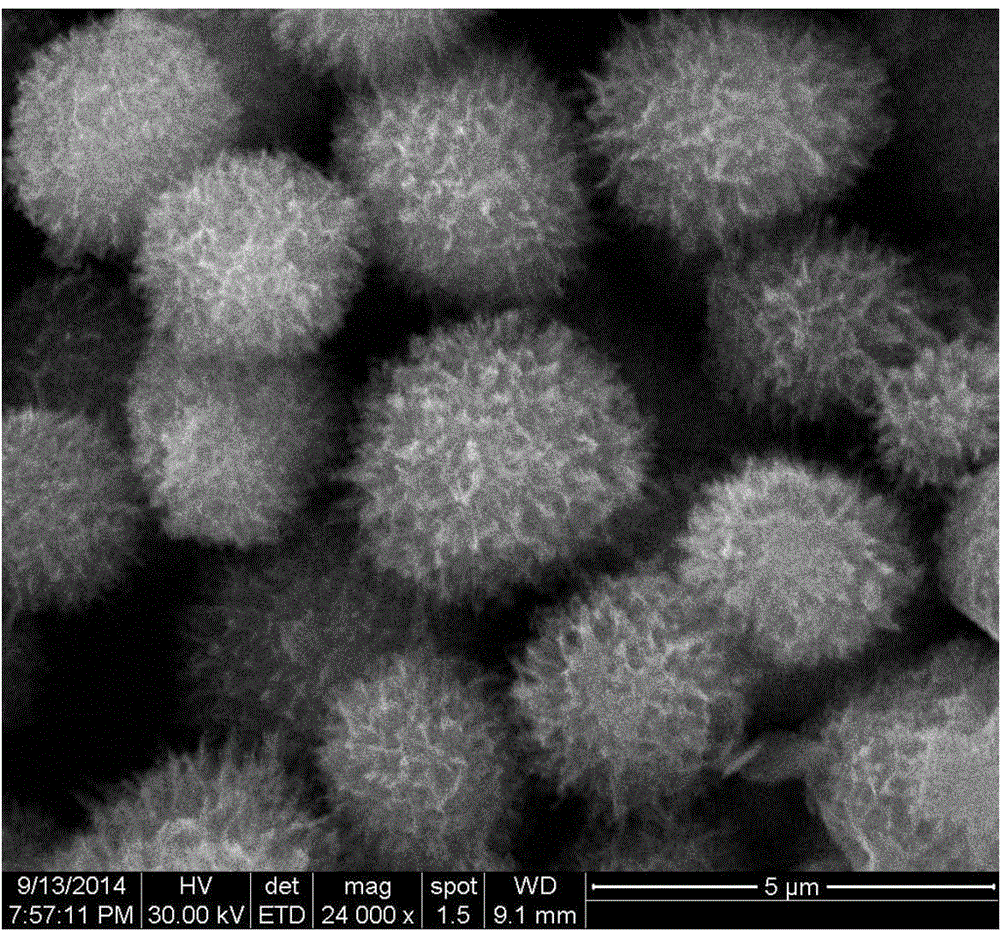

A lithium titanate, sea urchin-shaped technology, applied in the field of preparation of sea urchin-shaped lithium titanate microspheres, can solve the problems of fast capacity decay and low conductivity of lithium titanate, and achieve high discharge specific capacity and excellent rate cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add metal titanium powder to 5mol / L sodium hydroxide solution, wherein the amount of metal titanium powder added is 0.1g / L, stir magnetically for 1-100 minutes, and then transfer the mixed solution into polytetrafluoroethylene Lined stainless steel reaction kettle, sealed and placed in an oven, hydrothermal reaction at 80-220°C for 1-48 hours.

[0039] (2) After the reaction, cool to room temperature, centrifuge the obtained precipitate, wash until the pH value is 7.0, and then dry the precipitate in an oven at 60-90° C. to obtain a titanium dioxide precursor.

[0040] (3) Take a certain amount of lithium nitrate according to the atomic ratio Li / Ti=0.8-1.3, join in the mixed solution of ethanol and deionized water together with the titanium dioxide precursor of step (2) gained (the ratio of ethanol and deionized water The volume ratio is 1:2-3:1), magnetically stirred for 1-100 minutes, and then the obtained emulsion was transferred to a polytetrafluoroethylene-line...

Embodiment 2

[0045] (1) Add metal titanium powder to 7mol / L sodium hydroxide solution, wherein the amount of metal titanium powder added is 0.2g / L, stir magnetically for 1-60 minutes, and then transfer the mixed solution into polytetrafluoroethylene Lined stainless steel reaction kettle, sealed and placed in an oven, hydrothermal reaction at 100-220°C for 1-36 hours.

[0046] (2) After the reaction, cool to room temperature, centrifuge the obtained precipitate, wash until the pH value is 7.0, and then dry the precipitate in an oven at 70-90° C. to obtain a titanium dioxide precursor.

[0047] (3) Take a certain amount of lithium acetate according to the atomic ratio Li / Ti=0.8-1.2, join in the mixed solution of ethanol and deionized water together with the titanium dioxide precursor of step (2) gained (the ratio of ethanol and deionized water The volume ratio is 1:3-3:1), magnetically stirred for 5-100 minutes, and then the obtained emulsion was transferred to a polytetrafluoroethylene-line...

Embodiment 3

[0051] (1) Add metal titanium powder to 5mol / L sodium hydroxide solution, wherein the amount of metal titanium powder added is 0.2g / L, stir magnetically for 5-60 minutes, and then transfer the mixed solution into polytetrafluoroethylene Lined stainless steel reaction kettle, sealed and placed in an oven, hydrothermal reaction at 100-200°C for 1-30 hours.

[0052] (2) After the reaction, cool to room temperature, centrifuge the obtained precipitate, wash until the pH value is 7.0, and then dry the precipitate in an oven at 70-85°C to obtain a titanium dioxide precursor.

[0053] (3) Take a certain amount of lithium hydroxide by weighing according to the atomic ratio Li / Ti=0.8-1.1, and join in the mixed solution of ethanol and deionized water together with the titanium dioxide precursor obtained in step (2) (ethanol and deionized water The volume ratio is 1:3-2:1), magnetically stirred for 5-80 minutes, and then the obtained emulsion was transferred to a polytetrafluoroethylene-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com