Method for preparing cobalt oxide coated ternary positive electrode material

A cathode material and cobalt oxide technology, which is applied in the field of preparation of cobalt oxide-coated ternary cathode materials, can solve the problems of increased irreversible capacity, morphology damage, and unfavorable commercial utilization of materials, and achieves improved rate cycle performance, The effect of alleviating the interface reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

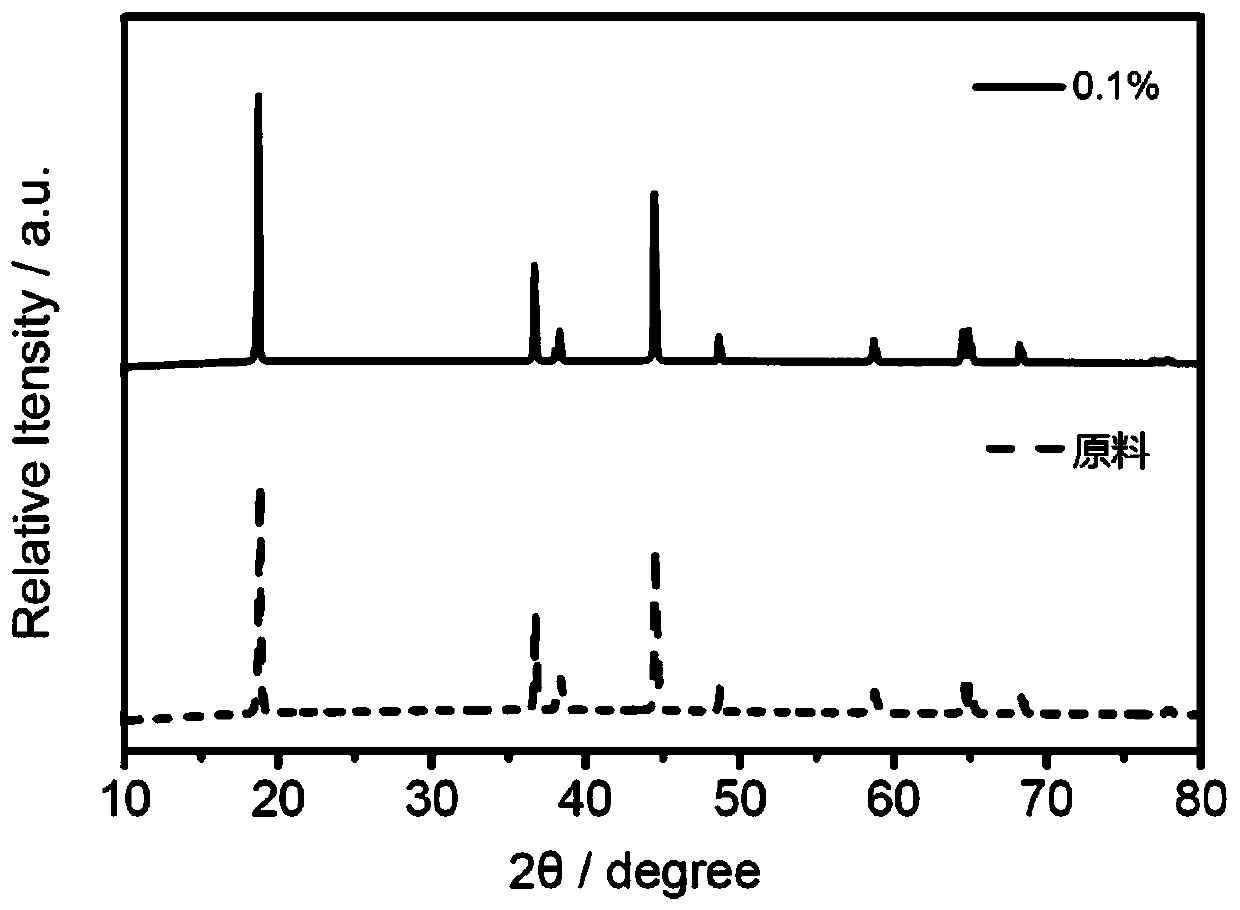

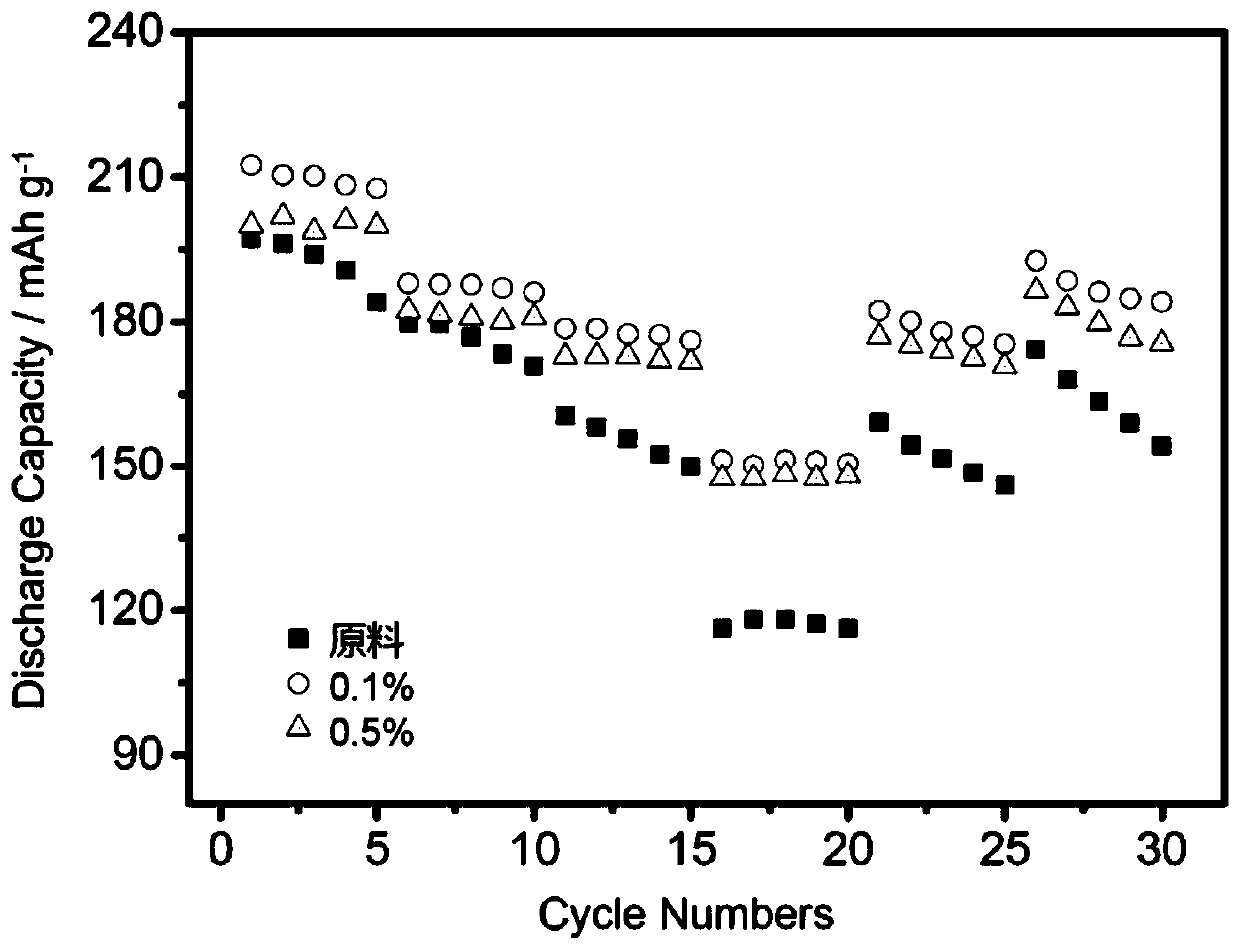

[0022] Weigh 0.0115g of cobalt oxalate and 10g of LiNi 0.8 co 0.15 Al 0.05 o 2 Put the material into the beaker, the particle size of cobalt oxalate is 100 μm ~ 300 μm, then, at a speed of 300 rpm (rev / min), perform magnetic stirring for 30 minutes to mix evenly, and then transfer the evenly mixed phase to the ceramic material boat, Move the material boat into a tube furnace, raise the temperature to about 350°C in an air atmosphere, and carry out low-temperature solid-phase calcination treatment for 3 hours. After the end, a small amount of Co is obtained after natural cooling. 3 o 4 coated LiNi 0.8 co 0.15 Al0.05 o 2 material, here for the obtained material Co 3 o 4 Coating amount is LiNi 0.8 co 0.15 Al 0.05 o 2 About 0.1wt% can also be obtained indirectly from the addition of cobalt oxalate and raw material LiNi 0.8 co 0.15 Al 0.05 o 2 The ratio of the amount of material can basically also explain that only a small amount of Co in the material obtained in th...

Embodiment 2

[0027] Weigh 0.0575g of cobalt oxalate and 10g of LiNi 0.8 co 0.15 Al 0.05 o 2 Put the material into the beaker, the particle size of cobalt oxalate is 100 μm ~ 300 μm, then, at a speed of 300 rpm (rev / min), perform magnetic stirring for 30 minutes to mix evenly, and then transfer the evenly mixed phase to the ceramic material boat, Move the material boat into a tube furnace, raise the temperature to about 350°C in an air atmosphere, and carry out low-temperature solid-phase calcination treatment for 3 hours. After the end, a small amount of Co is obtained after natural cooling. 3 o 4 coated LiNi 0.8 co 0.15 Al 0.05 o 2 material, here for the obtained material Co 3 o 4 Coating amount is LiNi 0.8 co 0.15 Al 0.05 o 2 0.5wt% or so.

[0028] Similarly, the small amount of Co obtained in this example 3 o 4 coated LiNi 0.8 co 0.15 Al 0.05 o 2 Material, there is no obvious cobalt oxide diffraction peak in the XRD spectrum, indicating that its coating amount is sma...

Embodiment 3

[0030] Weigh 0.0221g of cobalt acetate, 10g of LiNi 0.8 co 0.15 Al 0.05 o 2 Put the material into the beaker, the particle size of cobalt acetate is 100 μm ~ 200 μm, then stir it with a magnetic force at a speed of 200 rpm for 60 minutes to mix evenly, then transfer the evenly mixed phase to a ceramic material boat, and move the material boat into a tube furnace calcination at 300°C for 4h in an air atmosphere, and after the end, the cobalt oxide-coated LiNi was obtained after natural cooling. 0.8 co 0.15 Al 0.05 o 2 material, where the coating amount of cobalt oxide is cobalt oxide coated LiNi 0.8 co 0.15 Al 0.05 o 2 About 0.2 wt% of the mass of the material.

[0031] Similarly, the cobalt oxide coated LiNi obtained in this example 0.8 co 0.15 Al 0.05 o 2 There is no obvious cobalt oxide diffraction peak in the XRD pattern of the material, which also shows the characteristics of its small amount of coating, while the shape of the material shown in the SEM image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com