Method for improving poor back sealing pinholes of large-diameter semiconductor silicon wafer

A semiconductor and large-diameter technology, applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, crystal growth, etc., can solve problems such as poor back-sealing pinholes and silicon chip pinholes, and improve back-sealing pinhole defects , reduce the surface impurities of incoming materials, and improve the effect of equipment maintenance methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The experimental method of the present embodiment comprises the following steps:

[0030] Pre-LTO cleaning is carried out through the Pre-cvd cleaning machine, and the secondary distribution personnel are linked to increase the frequency conversion fan with harmful exhaust air. After the harmful exhaust air of the equipment is stabilized, the general exhaust air is adjusted to finally ensure the pressure balance of the equipment cavity, and the frequency conversion exhaust air can be added. Stabilize the fluctuation of harmful exhaust air, prevent the dust from falling on the silicon wafer due to the fluctuation of exhaust air during the film forming process, and form pinholes. During the filming process, it enters the equipment cavity and falls on the silicon wafer to form a pinhole defect. The linkage production arranges machine cleaning and feeding, and the full inspection is carried out through fluorescent lamp visual inspection.

[0031] In the present embodiment, ...

Embodiment 2

[0044] The difference from Embodiment 1 is that:

[0045] The experimental method of the present embodiment comprises the following steps:

[0046] S1. The first machine: use the Pre-cvd cleaning machine to perform pre-LTO cleaning, link the secondary distribution personnel to increase the frequency conversion fan for harmful exhaust air, adjust the general exhaust air after stabilizing the harmful exhaust air of the equipment, and finally ensure the pressure balance of the equipment cavity. Increasing frequency conversion exhaust air can stabilize the fluctuation of harmful exhaust air, and prevent the dust from falling on the silicon wafer due to the fluctuation of exhaust air during the film forming process, resulting in poor pinholes. Before film formation or during film formation, it enters the equipment cavity and falls on the silicon wafer to form pinholes.

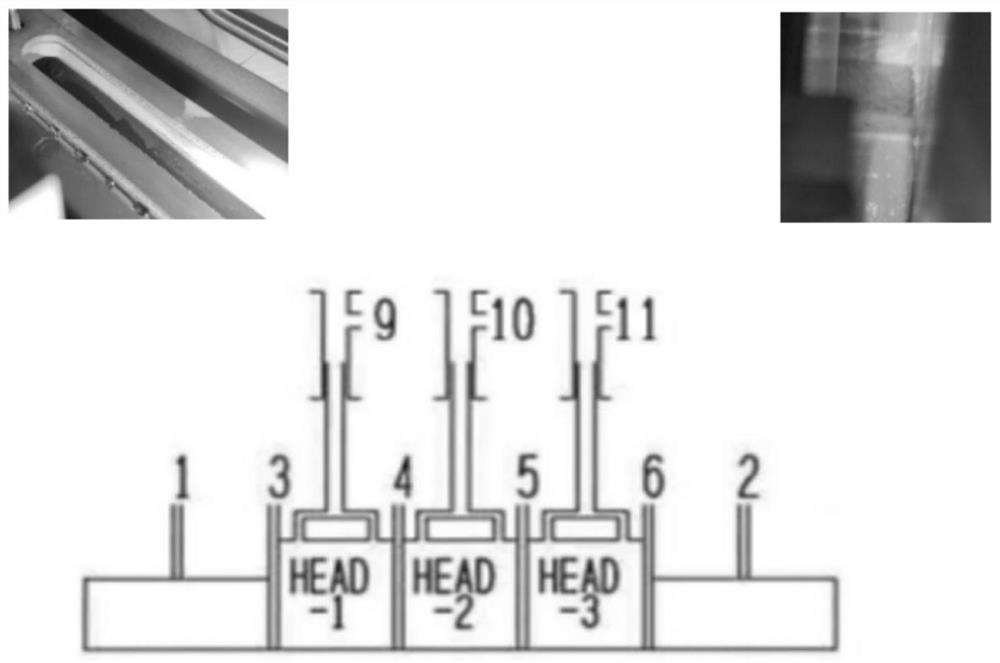

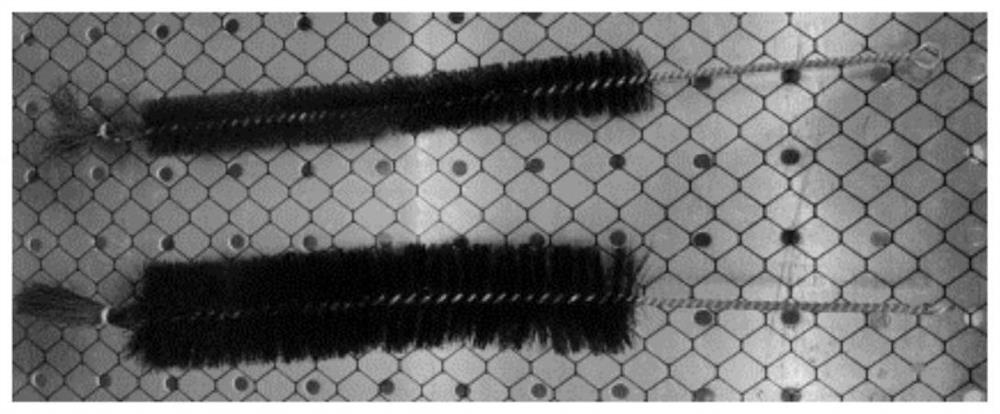

[0047] S2. Next method: Compile the instruction manual for equipment nozzle cleaning and maintenance. According...

Embodiment 3

[0061] The difference with embodiment one and embodiment two is characterized in that:

[0062] The experimental method of the present embodiment comprises the following steps:

[0063] S1. The first machine: use the Pre-cvd cleaning machine to perform pre-LTO cleaning, link the secondary distribution personnel to increase the frequency conversion fan for harmful exhaust air, adjust the general exhaust air after stabilizing the harmful exhaust air of the equipment, and finally ensure the pressure balance of the equipment cavity. Increasing frequency conversion exhaust air can stabilize the fluctuation of harmful exhaust air, and prevent the dust from falling on the silicon wafer due to the fluctuation of exhaust air during the film forming process, resulting in poor pinholes. Before film formation or during film formation, it enters the equipment cavity and falls on the silicon wafer to form pinholes.

[0064] S2. Next method: Compile the instruction manual for equipment nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com