High-rate electrolyte of lithium iron phosphate power battery and preparation method thereof and battery

A power battery and lithium iron phosphate technology, which is applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problem of low transfer rate, achieve the effects of reducing impedance, reducing decomposition, and improving rate cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

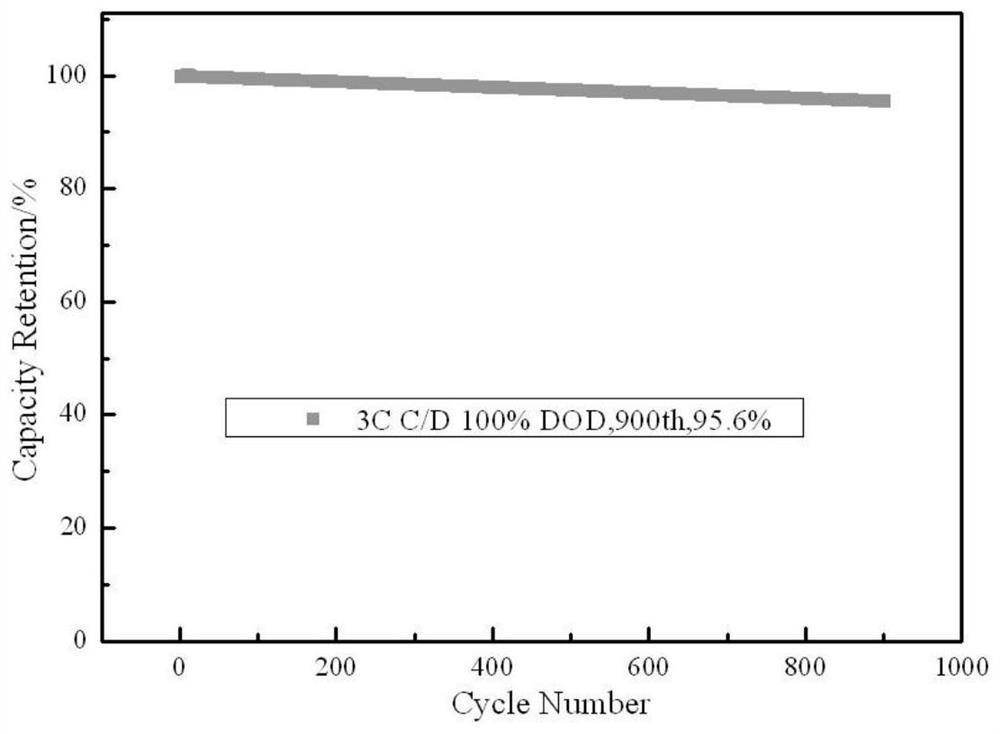

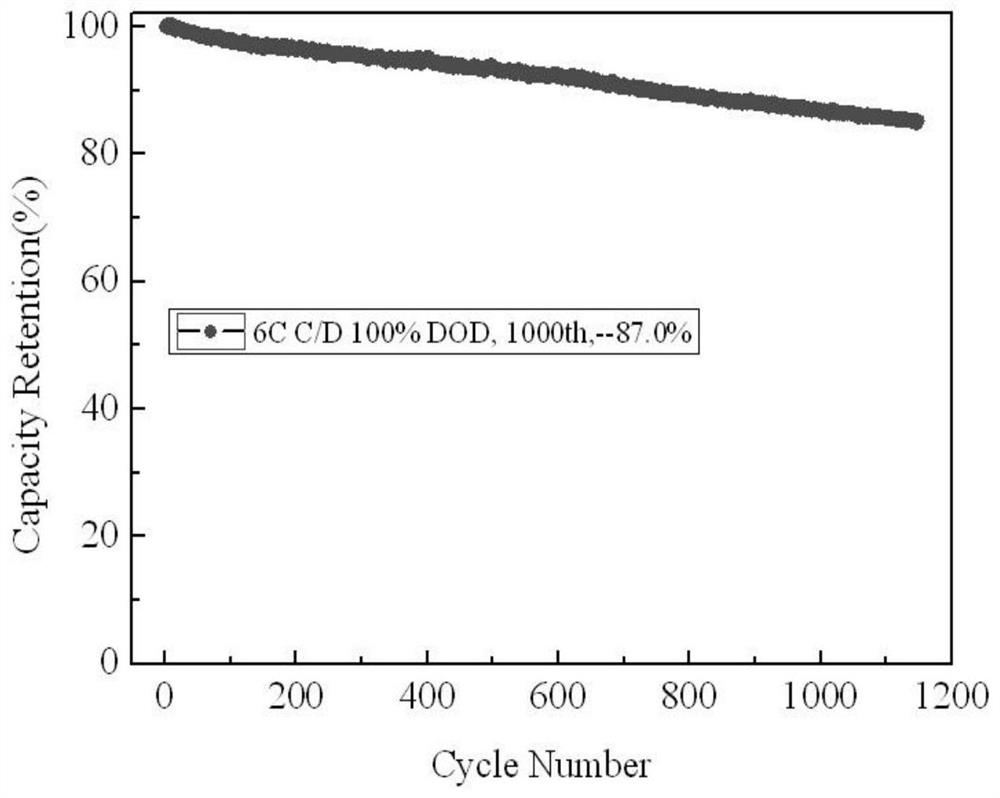

Examples

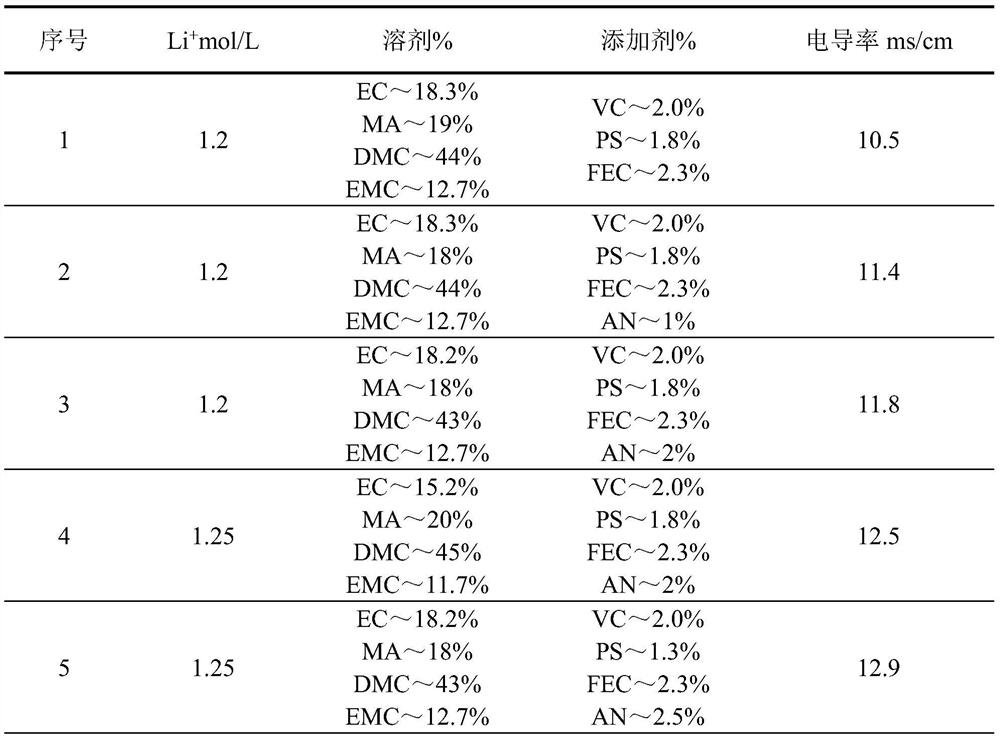

Embodiment 1

[0032] A high-rate electrolyte solution for lithium iron phosphate power batteries, comprising lithium salts, organic solvents, organic solvents include non-aqueous organic solvents and functional additives, wherein LiPF content is 1.2mol / L, and non-aqueous organic solvents include ethylene carbonate ( EC) 18.3%, chain carboxylate (MA) 18%, dimethyl carbonate (DMC) 44%, ethyl methyl carbonate (EMC) 12.7%, functional additives including vinylene carbonate (VC) 2.0%, 1 , 3-propane sultone (PS) 1.8%, fluoroethylene carbonate (FEC), acetonitrile (AN) 1%.

Embodiment 2

[0034] A high-rate electrolyte solution for lithium iron phosphate power batteries, comprising lithium salts, organic solvents, organic solvents include non-aqueous organic solvents and functional additives, wherein LiPF content is 1.2mol / L, and non-aqueous organic solvents include ethylene carbonate ( EC) 18.2%, chain carboxylate (MA) 18%, dimethyl carbonate (DMC) 44%, ethyl methyl carbonate (EMC) 12.7%, functional additives including vinylene carbonate (VC) 2.0%, 1 , 3-propane sultone (PS) 1.8%, fluoroethylene carbonate (FEC) 2.3%, acetonitrile (AN) 2%.

Embodiment 3

[0036] A high-rate electrolyte solution for lithium iron phosphate power battery, comprising lithium salt, organic solvent, organic solvent comprises non-aqueous organic solvent and functional additive, wherein, LiPF The content is 1.25mol / L, and non-aqueous organic solvent comprises ethylene carbonate ( EC) 15.2%, chain carboxylate (MA) 20%, dimethyl carbonate (DMC) 43%, ethyl methyl carbonate (EMC) 11.7%, functional additives including vinylene carbonate (VC) 2.0%, 1 , 3-propane sultone (PS) 1.8%, fluoroethylene carbonate (FEC) 2.3%, acetonitrile (AN) 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com