Additive and electrolyte and lithium ion battery using same

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of low rapid discharge capacity, increased self-discharge of lithium-ion batteries, and low oxidation potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

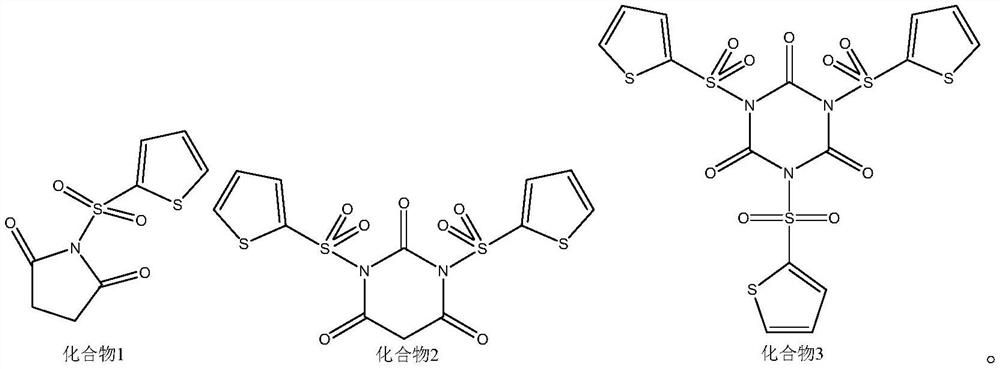

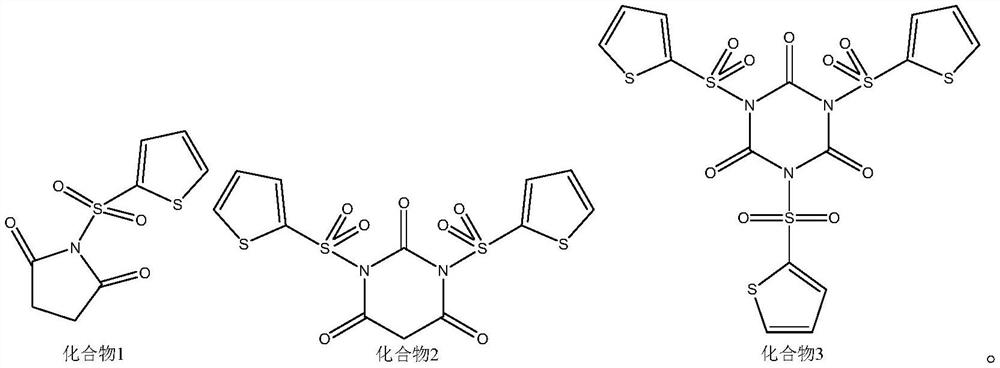

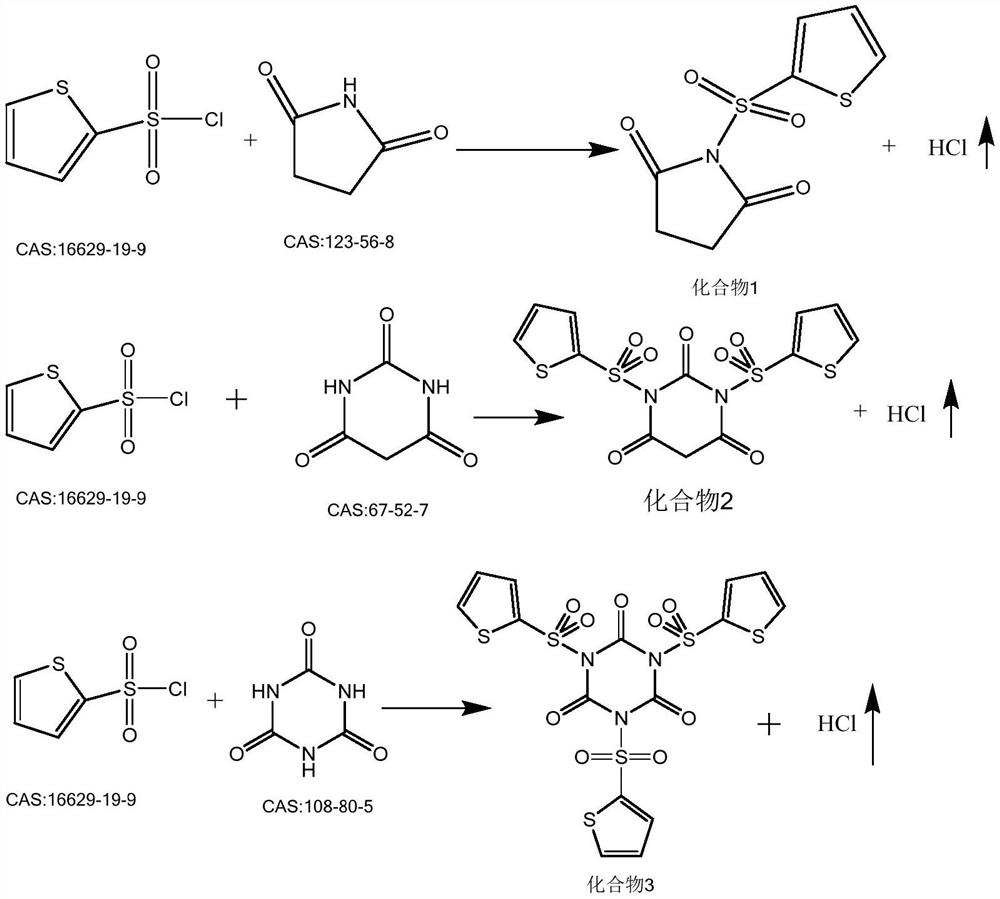

Method used

Image

Examples

Embodiment 1

[0028] In a nitrogen-filled glove box (O 2 2 (02 2 (0<1ppm), slowly add 20g of lithium hexafluorophosphate into the mixed solution, and mix well to make an electrolyte solution.

[0029] The components of the electrolyte solutions of Examples 2-16 and Comparative Examples 1-6 are shown in Table 1, and the preparation methods of the electrolyte solutions of Examples 2-16 and Comparative Examples 1-6 refer to the preparation method of Example 1.

[0030] Table 1 Electrolyte formula

[0031]

[0032]

[0033] Using LCO with a maximum charging voltage of 4.5V as the positive electrode material and natural graphite as the negative electrode material, the electrolytes of Examples 1 to 16 and Comparative Examples 1 to 6 were used to make lithium ion batteries with reference to the conventional lithium battery preparation method, and carried out 5C respectively. Rate discharge test, 3C rate cycle test, high temperature storage test, the test results are shown in Table 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com