Porous hard carbon lithium ion battery negative electrode material and preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, which is applied in battery electrodes, carbon preparation/purification, secondary batteries, etc., and can solve problems such as poor low-temperature performance, cumbersome operation, and many synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) pulverizing the hydrogenated vegetable oil to obtain a hydrogenated vegetable oil powder with a particle size of less than 100 mesh;

[0035] (2) The hydrogenated vegetable oil powder is heated from 20°C to 350°C at a heating rate of 2°C / min in helium, subjected to low-temperature carbonization treatment for 5 hours, then cooled naturally until the temperature of the calcined product is 20°C, and then pulverized to produce get the precursor;

[0036] (3) Dispersing 100 parts by weight of the precursor in water, then adding 5 parts by weight of polyvinyl alcohol, stirring at a speed of 400 rpm for 7 hours to obtain a slurry, and then drying to obtain material particles;

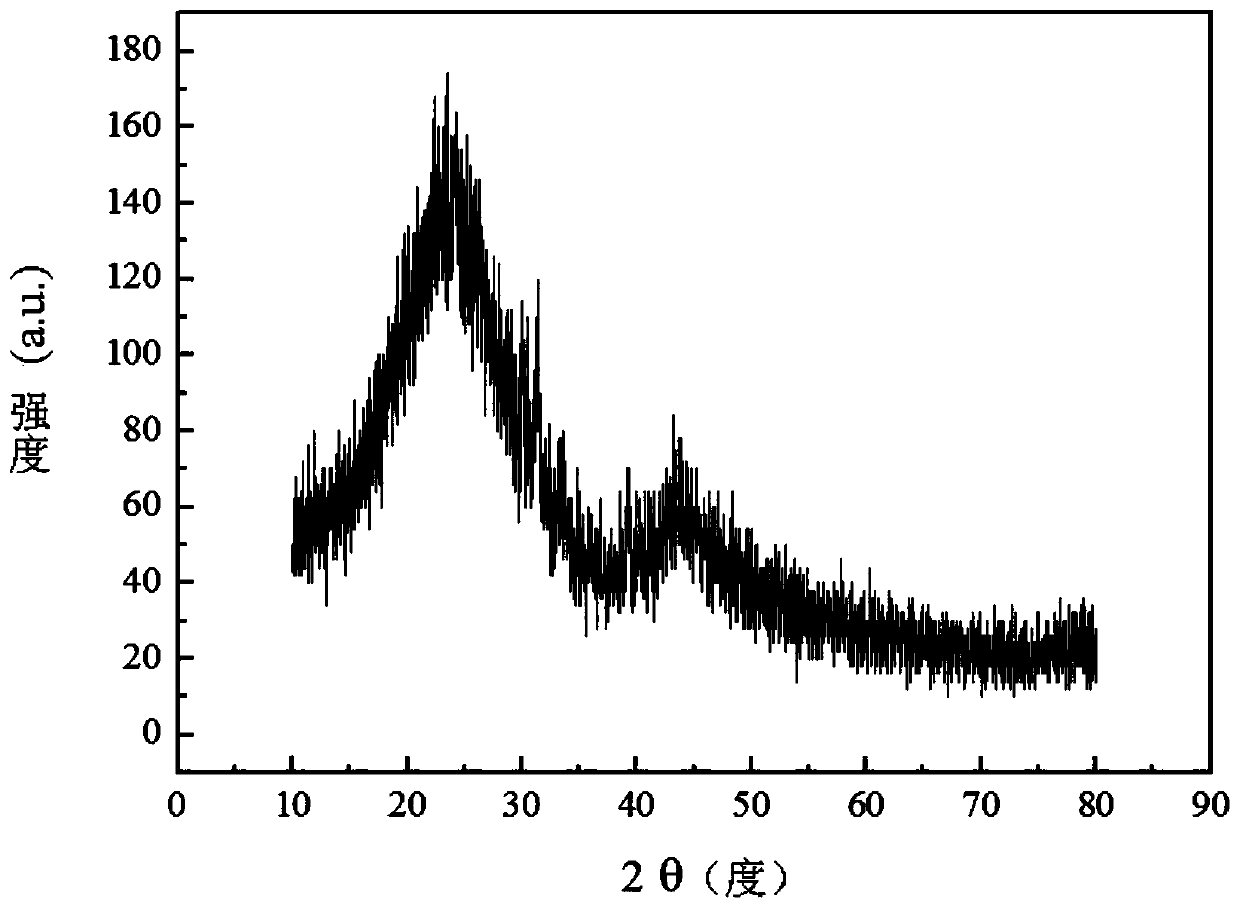

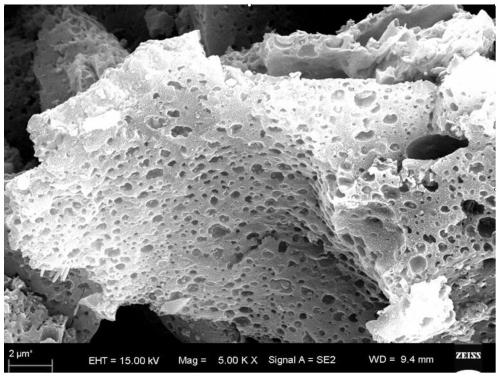

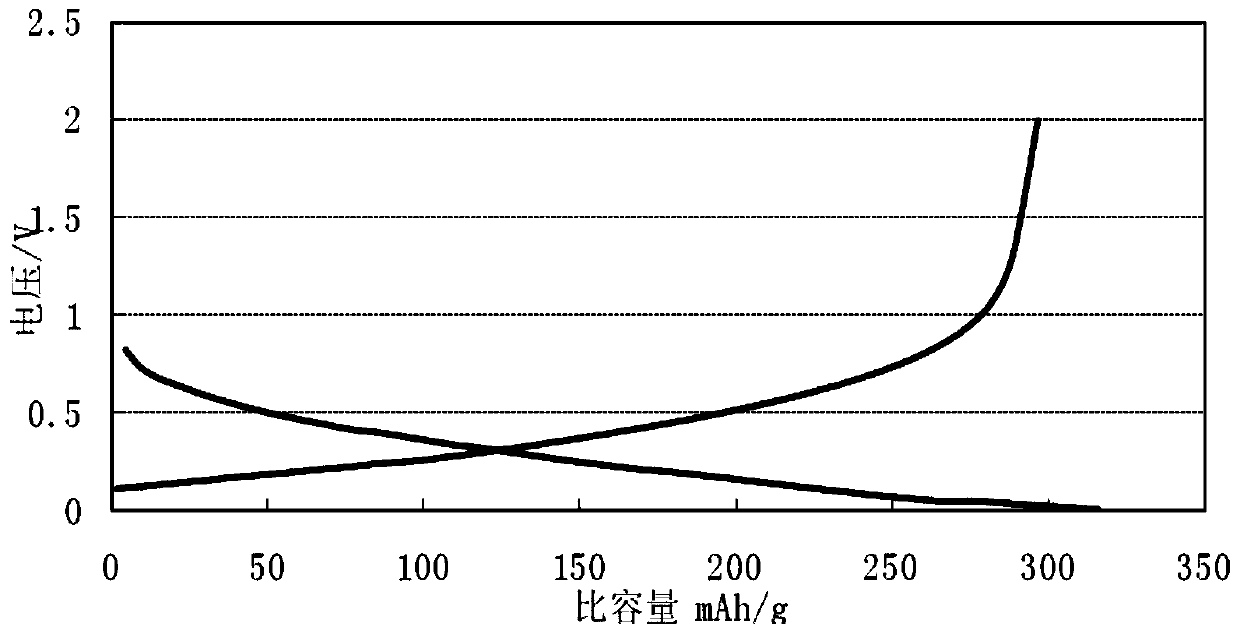

[0037] (4) Heat the material particles from 20°C to 950°C at a heating rate of 6°C / min in helium, perform high-temperature carbonization treatment for 10 hours, and then cool naturally until the temperature of the calcined product is 20°C, then pulverize and shake To make porous hard carbon lithium...

Embodiment 2

[0039] (1) pulverizing the hydrogenated vegetable oil to obtain a hydrogenated vegetable oil powder with a particle size of less than 100 mesh;

[0040] (2) The hydrogenated vegetable oil powder is heated from 25°C to 250°C at a heating rate of 2°C / min in argon, subjected to low-temperature carbonization treatment for 10 hours, then cooled naturally until the temperature of the calcined product is 25°C, and then pulverized to produce get the precursor;

[0041] (3) Dispersing 100 parts by weight of the precursor in dichloromethane, then adding 20 parts by weight of asphalt, stirring at a speed of 1000 rpm for 0.5 h to obtain a slurry, followed by drying to obtain material particles;

[0042] (4) Raise the temperature of the material particles from 25°C to 650°C at a rate of 2°C / min in nitrogen, perform high-temperature carbonization treatment for 20 hours, then cool naturally until the temperature of the calcined product is 25°C, then pulverize and compact Porous hard carbon ...

Embodiment 3

[0044] (1) pulverizing the hydrogenated vegetable oil to obtain a hydrogenated vegetable oil powder with a particle size of less than 100 mesh;

[0045] (2) Heat the hydrogenated vegetable oil powder from 30°C to 600°C at a heating rate of 2°C / min in argon, perform low-temperature carbonization treatment for 2 hours, then cool naturally until the temperature of the calcined product is 30°C, and then pulverize to produce get the precursor;

[0046](3) Disperse 100 parts by weight of the precursor in a mixed solvent of ethanol and water with a volume ratio of 1:1, then add 1 part by weight of methyl cellulose, and stir at a speed of 50 rpm for 10 h to prepare a slurry , followed by drying treatment to obtain material particles;

[0047] (4) Raise the temperature of the material particles from 30°C to 1400°C at a rate of 10°C / min in nitrogen, perform high-temperature carbonization treatment for 3 hours, then cool naturally until the temperature of the calcined product is 30°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com