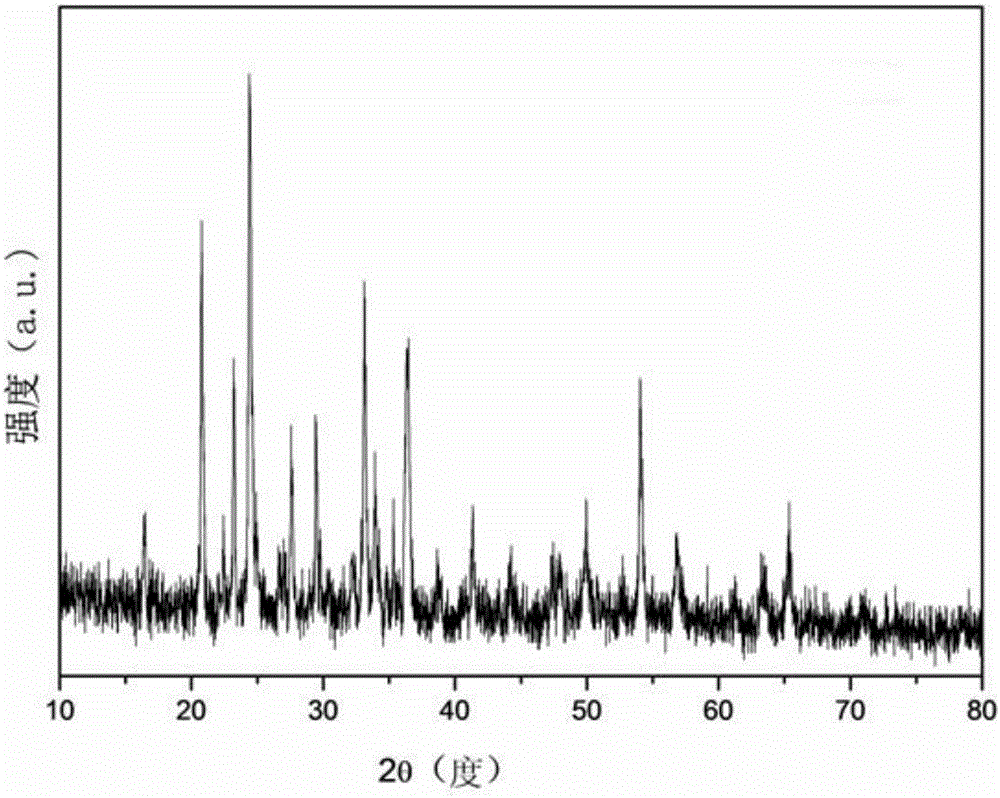

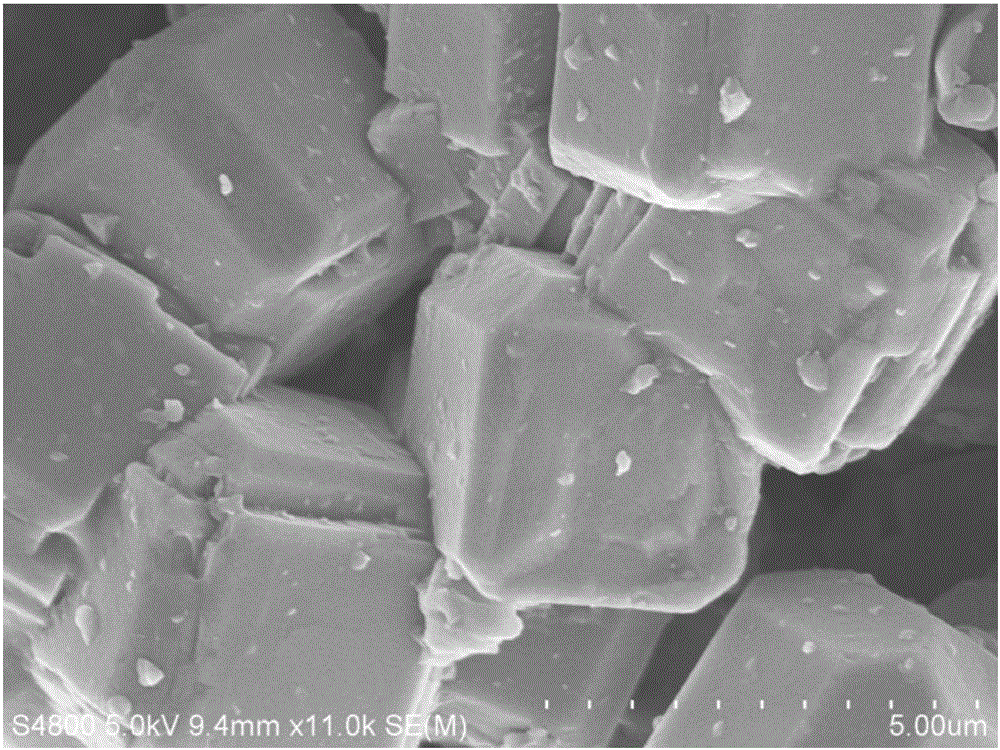

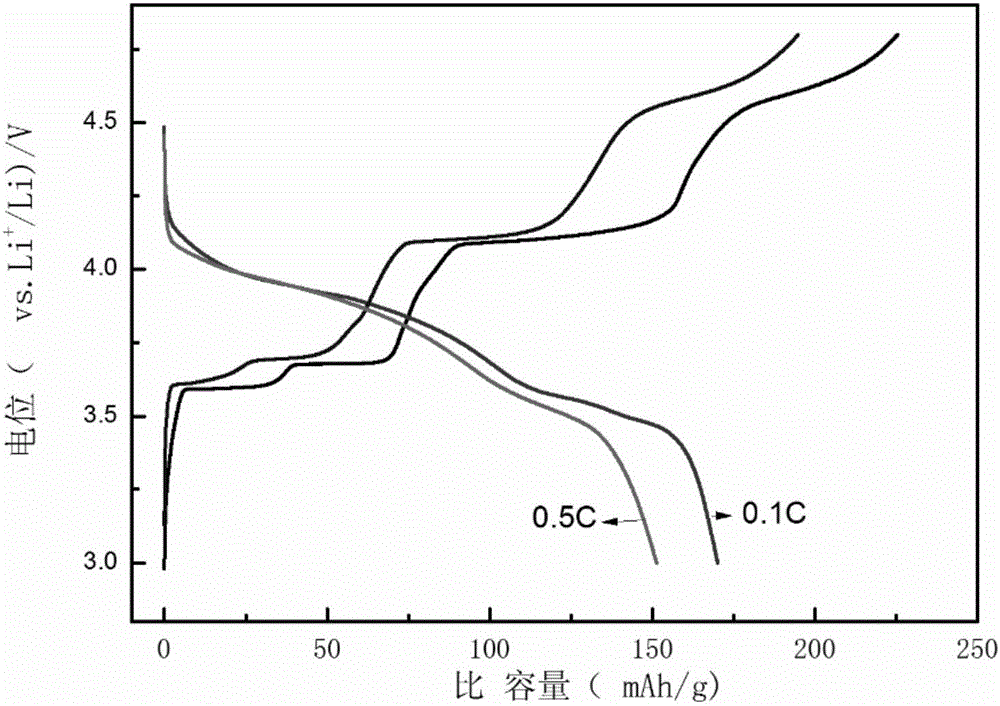

Nearly cubic lithium vanadium phosphate and preparation method thereof, lithium-ion battery and positive electrode of lithium-ion battery

A technology of lithium vanadium phosphate and battery positive electrode, which is applied in the field of preparation and application of new energy materials, and can solve the problems of many synthesis steps and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 1.171g of ammonium metavanadate and 1.89g of oxalic acid into 25ml of deionized water and stir to dissolve, then add 1.725g of ammonium dihydrogen phosphate and 1.03g of lithium nitrate and continue stirring to obtain solution A;

[0033] (2) 1.09g cetyltrimethylammonium bromide (CTAB) was stirred and dispersed into 25ml deionized water to obtain solution B;

[0034] (3) Add solution B dropwise to solution A, then add 30ml ethylene glycol and 3.604g urea and stir for 24h to prepare solution C;

[0035] (4) Put the solution C into a polytetrafluoroethylene reactor and put it in an oven, react at 150°C for 20 hours to prepare the precursor, then centrifuge, wash with water, wash with alcohol and dry;

[0036] (5) The precursor was placed in an argon protective atmosphere, and calcined at a temperature of 800° C. for 4 hours to obtain near-cubic lithium vanadium phosphate A1.

Embodiment 2

[0038] According to the method of embodiment 1, near cubic lithium vanadium phosphate A2 is obtained, the difference is that the amount of urea added in step (3) is 3g.

Embodiment 3

[0040] According to the method of Example 1, near-cubic lithium vanadium phosphate A3 was prepared, except that the amount of ethylene glycol added in step (3) was 20ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com