Multiplying power type ternary battery and preparation method thereof

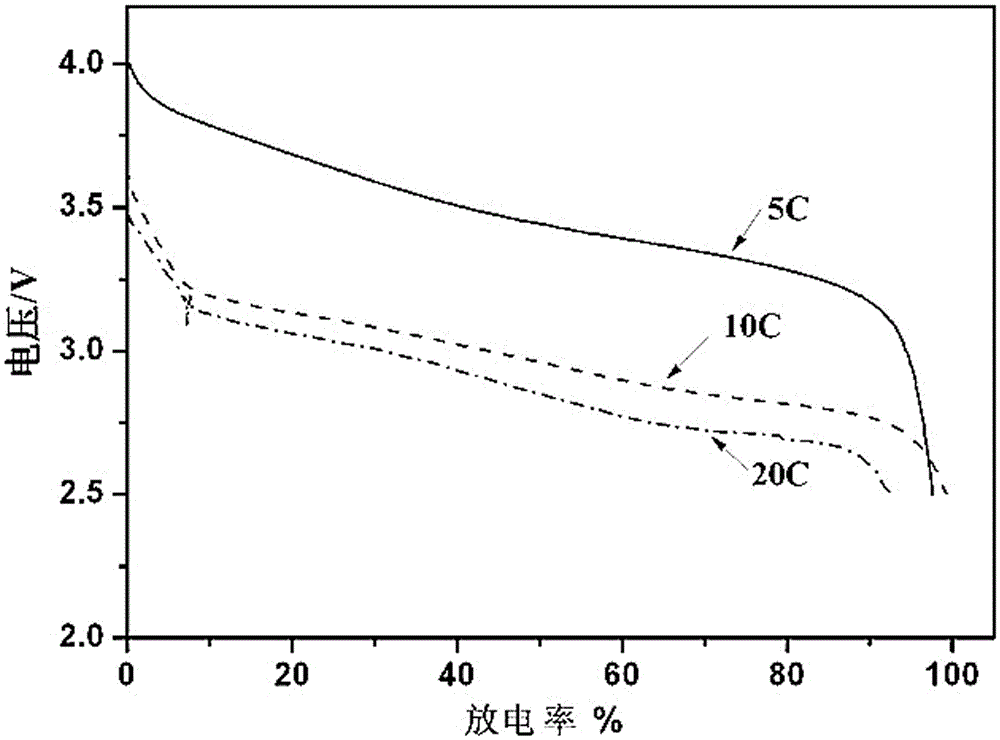

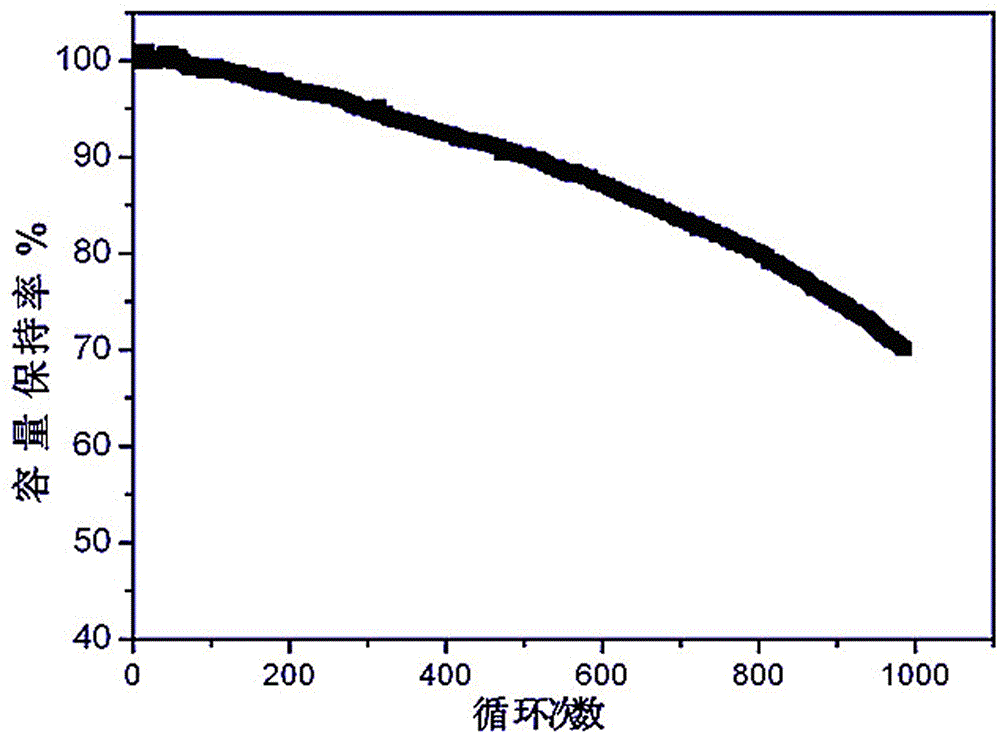

A ternary battery and rate performance technology, which is applied to secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of high battery surface temperature, potential safety hazards, poor rate cycle performance, etc., achieve strong discharge capacity, improve Conductivity, effect of increasing movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Production of positive electrode sheet: Add 111-type ternary material, carbon nanotubes, carbon fiber and PVDF into NMP at a mass ratio of 88:3:3:6 to prepare a slurry, and then coat the slurry on the aluminum foil. After drying, rolling, slitting and sheeting in sequence, a positive electrode sheet containing 2 tabs is obtained, and the density of both sides of the electrode sheet is controlled to be 400g / m2 during coating. 2 , the compacted density of the pole piece is 3.2g / cm when rolling 3 ;

[0024] (2) Production of negative electrode sheet: Add artificial graphite, mesophase carbon microspheres, carbon nanotubes, carbon fibers, CMC and SBR into water to prepare slurry according to the mass ratio of 78.3:8.7:3.25:3.25:5.5:2, and then put The slurry is coated on the copper foil, followed by drying, rolling, slitting and sheeting to obtain a negative electrode sheet with 2 tabs, in which the density of both sides of the electrode sheet is controlled to be 210g / ...

Embodiment 2

[0028] (1) Production of positive electrode sheet: Add 532-type ternary material, carbon nanotubes, carbon fiber and PVDF into NMP at a mass ratio of 95:1:0.5:3.5 to prepare slurry, and then coat the slurry on aluminum foil, After drying, rolling, cutting and sheeting in sequence, a positive electrode sheet containing 2 tabs was obtained, and the density of both sides of the electrode sheet during coating was controlled to be 320g / m 2 , the compaction density of the pole piece is 3.5g / cm when rolling 3 ;

[0029] (2) Production of negative electrode sheet: Add artificial graphite, mesocarbon microspheres, carbon nanotubes, carbon fibers, CMC and SBR into water to prepare slurry according to the mass ratio of 65.1:27.9:1.5:1.5:2:2, and then put The slurry is coated on the copper foil, followed by drying, rolling, slitting and sheeting to obtain a negative electrode sheet with 3 tabs, and the density of both sides of the electrode sheet during coating is controlled to be 160g / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com