Synthesis method and application of hard carbon coated sodium ion battery nano composite material

A nanocomposite material, sodium-ion battery technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of poor battery cycle and rate performance, low conductivity, etc., and achieve convenient operation. , the effect of mild reaction conditions and high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 0.005mol of LiNO 3 , 0.095mol NaNO 3 , 0.3mol of NH 4 h 2 PO 4 Dissolve in deionized water respectively, mix and stir.

[0035] (2) Take 0.205mol of Ti(OC 4 h 9 ) 4 Add an appropriate amount of ethanol drop by drop using a rubber dropper and stir.

[0036] (3) Add the solution in (2) to step (1) dropwise.

[0037] (4) Weigh 0.005mol of sodium lignosulfonate, add to step (3) and stir at 65°C for 120min.

[0038] (5) Transfer the mixture in step (4) to a hydrothermal reaction kettle and keep it at 120°C for 36h.

[0039] (6) Take out the mixture in step (5), put it into a beaker, dry it in an oven at 70°C, and then grind it into powder to obtain a precursor.

[0040] (7) Under the protection of argon atmosphere, the precursor obtained in step (6) was kept at 350°C for 240 minutes, continued to heat up to 650°C, kept at 600 minutes, and naturally cooled to room temperature to obtain Li 1-X NaxTi 2 (PO 4 ) 3 / NaTi 2 (PO 4 ) 3 nanocomposites.

[0...

Embodiment 2

[0049] (1) Weigh 0.005mol of LiNO 3 , 0.095mol NaNO 3 , 0.3mol of NH 4 h 2 PO 4 Dissolve in deionized water respectively, mix and stir.

[0050] (2) Take 0.205mol of Ti(OC 4 h 9 ) 4 Add an appropriate amount of ethanol drop by drop using a rubber dropper and stir.

[0051] (3) Add the solution in (2) to step (1) dropwise.

[0052] (4) Weigh 0.005mol of sodium lignosulfonate, add to step (3) and stir at 65°C for 120min.

[0053] (5) Transfer the mixture in step (4) to a hydrothermal reaction kettle and keep it at 120°C for 36h.

[0054] (6) Take out the mixture in step (5), put it into a beaker, dry it in an oven at 70°C, and then grind it into powder to obtain a precursor.

[0055] (7) Under the protection of argon atmosphere, the precursor obtained in step (6) is kept at 350°C for 240min, then heated to 750°C, kept at 600min, and naturally cooled to room temperature to obtain Li 1-X NaxTi 2 (PO 4 ) 3 / NaTi 2 (PO 4 ) 3 composite material.

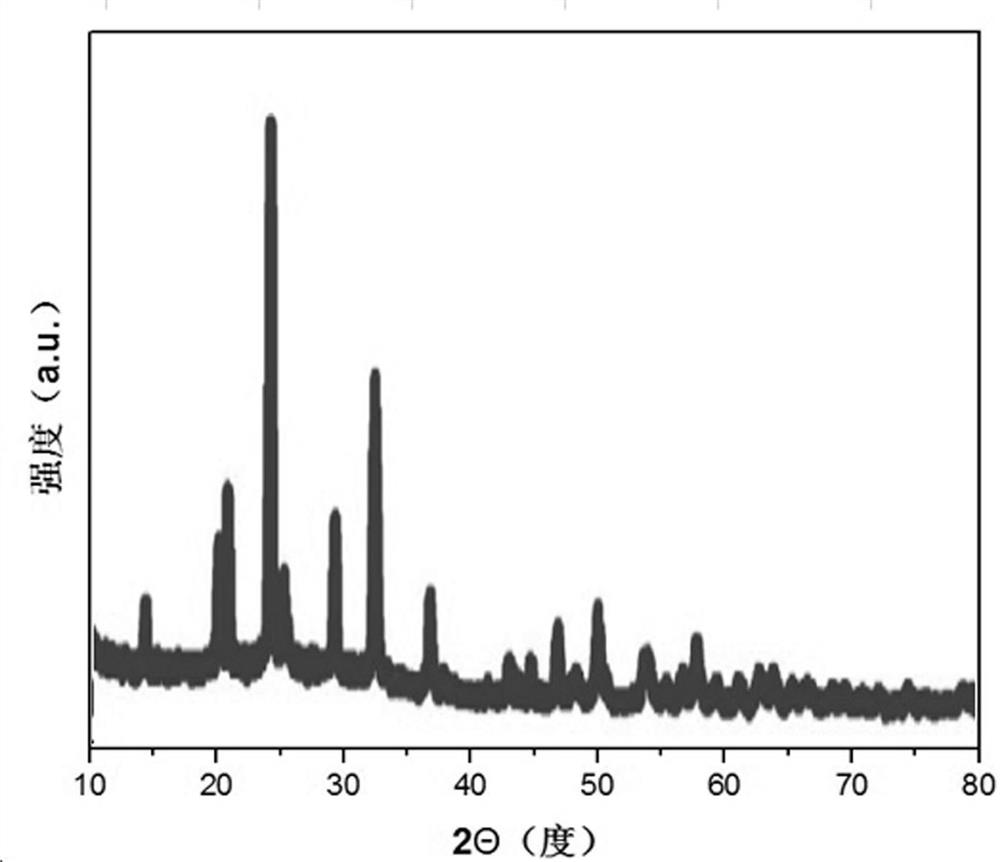

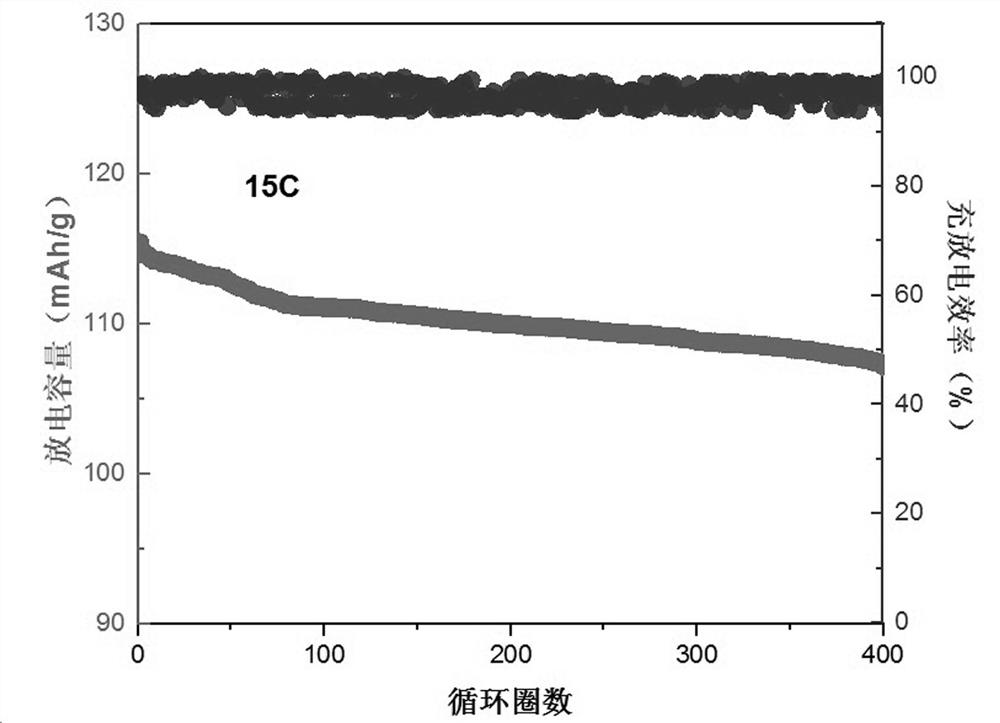

[0056] figure 1 L...

Embodiment 3

[0064] (1) Weigh 0.005mol of LiNO 3 , 0.095mol NaNO 3 , 0.3mol of NH 4 h 2 PO 4 Dissolve in deionized water respectively, mix and stir.

[0065] (2) Take 0.205mol of Ti(OC 4 h 9 ) 4 Add an appropriate amount of ethanol drop by drop using a rubber dropper and stir.

[0066] (3) Add the solution in (2) to step (1) dropwise.

[0067] (4) Weigh 0.005mol of sodium lignosulfonate, add to step (3) and stir at 65°C for 120min.

[0068] (5) Transfer the mixture in step (4) to a hydrothermal reaction kettle and keep it at 120°C for 36h.

[0069] (6) Take out the mixture in step (5), put it into a beaker, dry it in an oven at 70°C, and then grind it into powder to obtain a precursor.

[0070] (7) Under the protection of argon atmosphere, the precursor obtained in step (6) was kept at 350°C for 240 minutes, then heated to 850°C, kept at 600 minutes, and naturally cooled to room temperature to obtain Li 1-X NaxTi 2 (PO 4 ) 3 / NaTi 2 (PO 4 ) 3 composite material.

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com