Preparation method and application of nitrogen-doped porous carbon negative electrode material

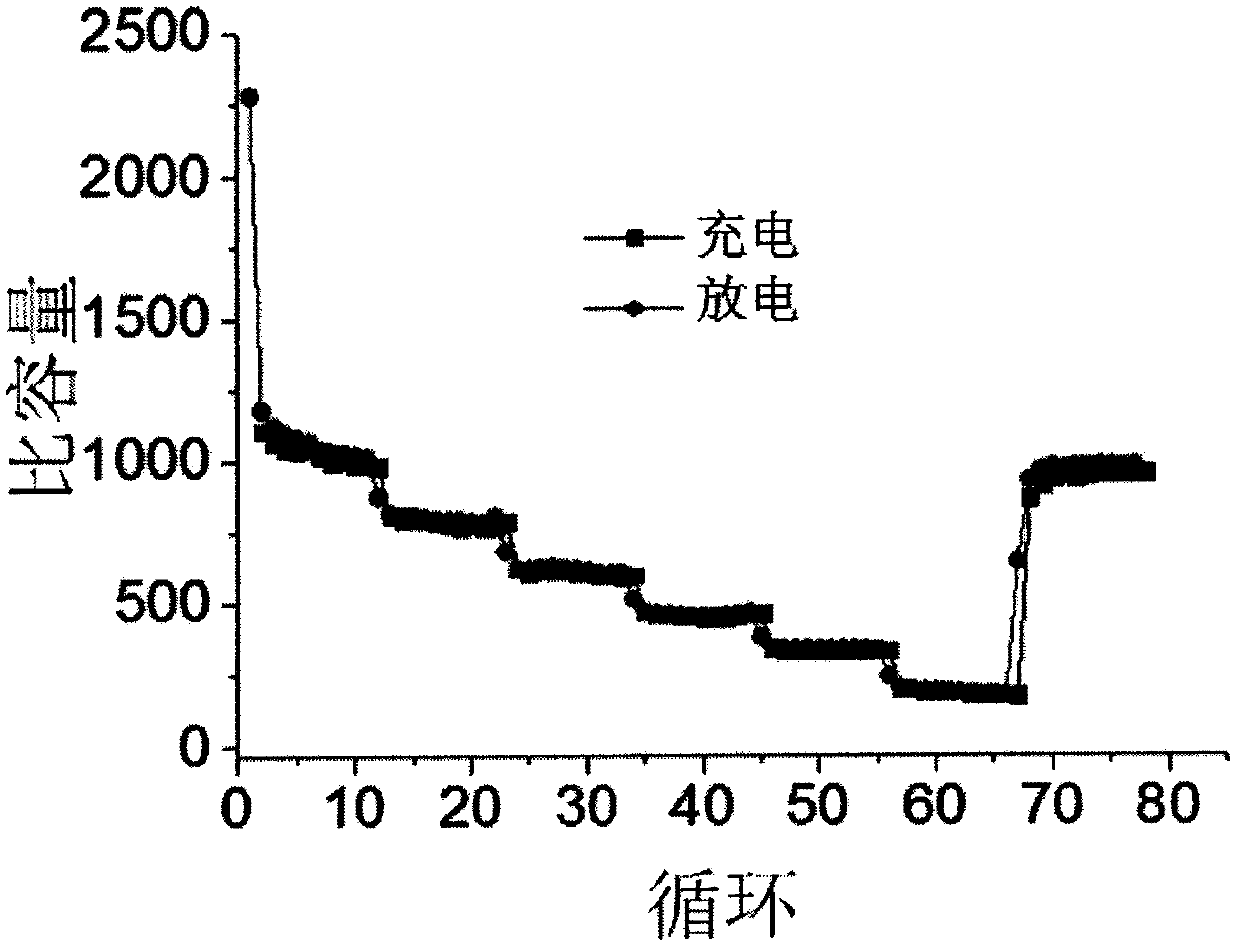

A negative electrode material and porous carbon technology, which is applied in the field of preparation of nitrogen-doped porous carbon negative electrode materials, can solve the problems of reduced battery life, insufficient specific capacity potential, and difficult lithium intercalation process, achieving easy preparation, good cycle stability, Structured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix and grind one of the carbon sources in 1-34 and sodium hydroxide at a mass ratio of 1:1 for 10 minutes; in a tube furnace, under an argon atmosphere of 20ml / min, at a heating rate of 1°C / min Raise the temperature to 600°C, carbonize for 2 hours, wash and dry with water, and obtain the nitrogen-doped porous carbon negative electrode material.

Embodiment 2

[0030] Mix and grind one of the carbon sources in 1-34 and sodium sulfate at a mass ratio of 1:1 for 10 minutes; in a tube furnace, raise the temperature at a rate of 1°C / min under an argon atmosphere of 20ml / min carbonization at 600°C for 2 hours, washed with water and dried to obtain nitrogen-doped porous carbon negative electrode material.

Embodiment 3

[0032] Mix and grind one of the carbon sources in 1-34 and sodium chloride at a mass ratio of 1:1 for 10 minutes; in a tube furnace, under an argon atmosphere of 20ml / min, at a heating rate of 1°C / min Raise the temperature to 600°C, carbonize for 2 hours, wash and dry with water, and obtain the nitrogen-doped porous carbon negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com