Iron-chromium-cobalt permanent magnetic alloy compounding vanadium and tungsten and deformation processing technology thereof

A permanent magnet alloy, deformation processing technology, used in metal processing equipment, magnetic materials, electrical components and other directions, to achieve good machinability, reduce solid solution temperature, reduce the effect of cobalt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The specific implementation, composition, features and effects provided by the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

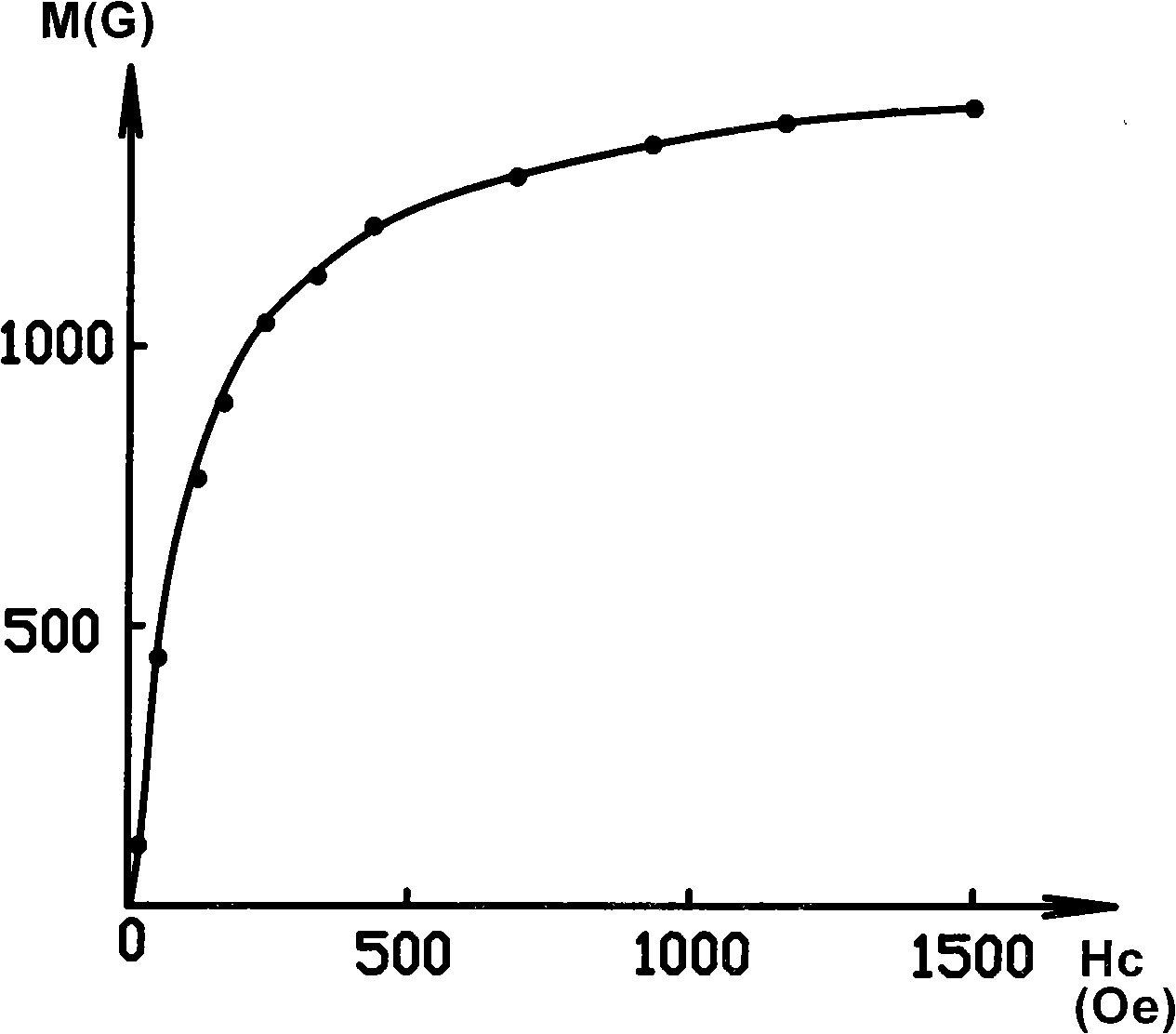

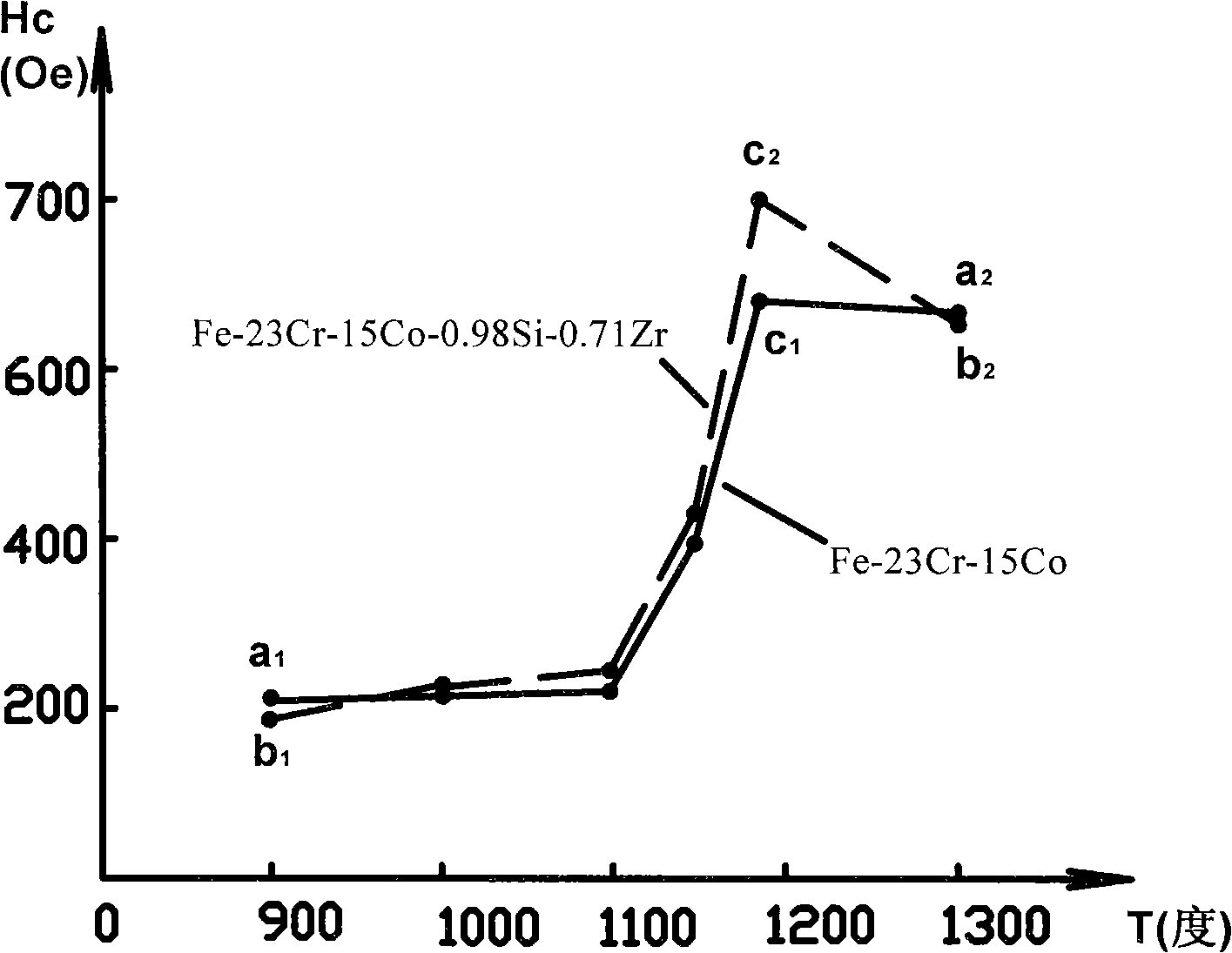

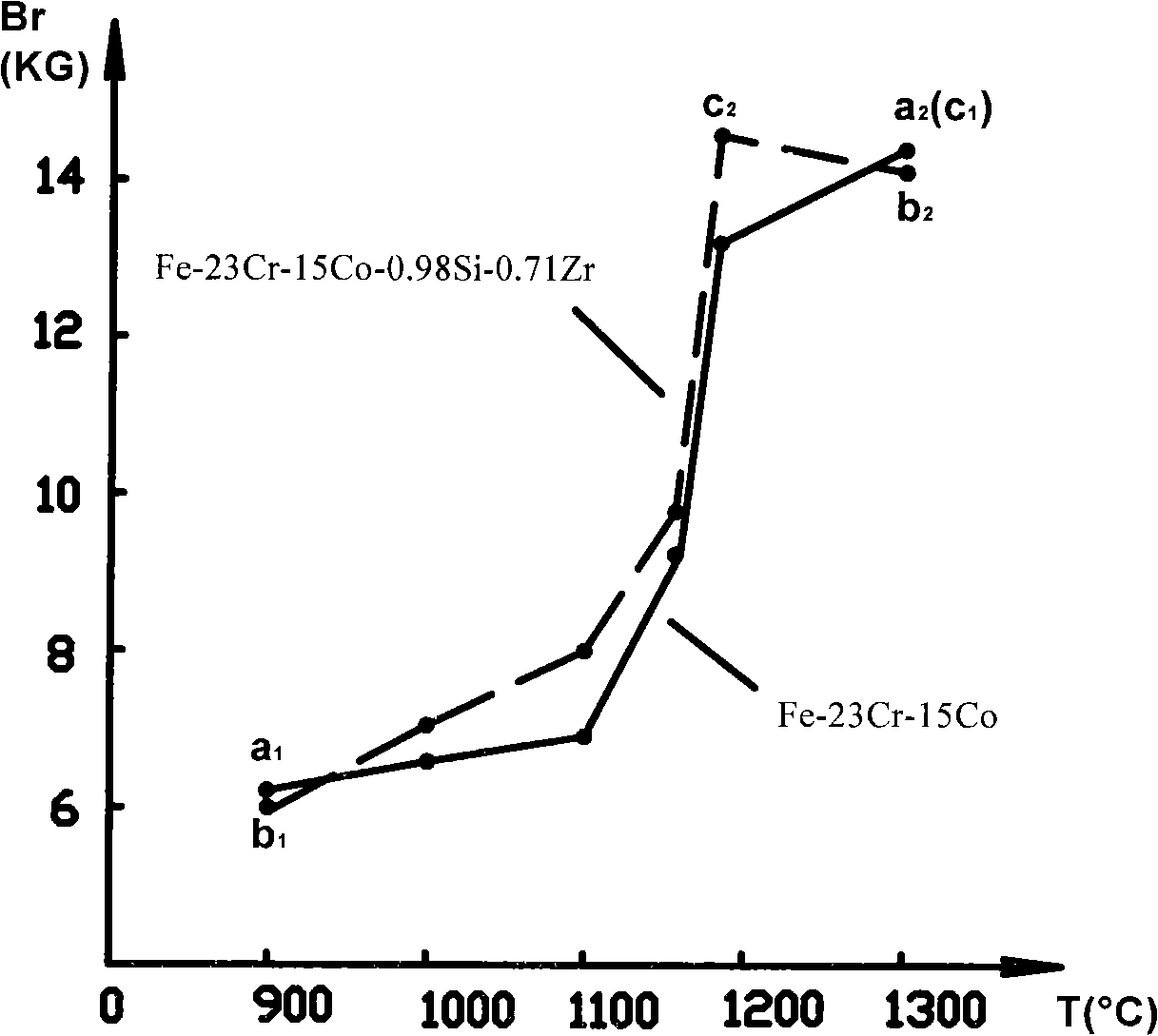

[0071] See Figure 2-3 , a Fe-23Cr-15Co-Si-Zr iron-chromium-cobalt permanent magnet alloy compounded with silicon and zirconium elements, its weight percentage composition is: chromium (Cr) 22-27%, cobalt (Co) 10-16%, silicon (Si) 0.8%-1%, zirconium (Zr) 0.2%-0.8%, the rest is iron and unavoidable impurities;

[0072] The preferred composition weight percentage is: chromium (Cr) 23.1%, cobalt (Co) 14.9%, Si (silicon) 0.98% Zr (zirconium) 0.71%, the rest are iron and unavoidable impurities;

[0073] Since the main component of the Fe-23Cr-15Co alloy is iron (Fe), adding body-centered cubic structural elements silicon and zirconium can expand the α phase region of iron, and the α phase is more stable, thereby effectively reducing the solid solution of the material. temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com