A preparation method and application of low cobalt and high nickel ternary lithium

A technology of high nickel and nickel nitrate, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor thermal stability and cycle stability of materials, achieve high thermal stability, reduce cobalt content, and high cycle stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

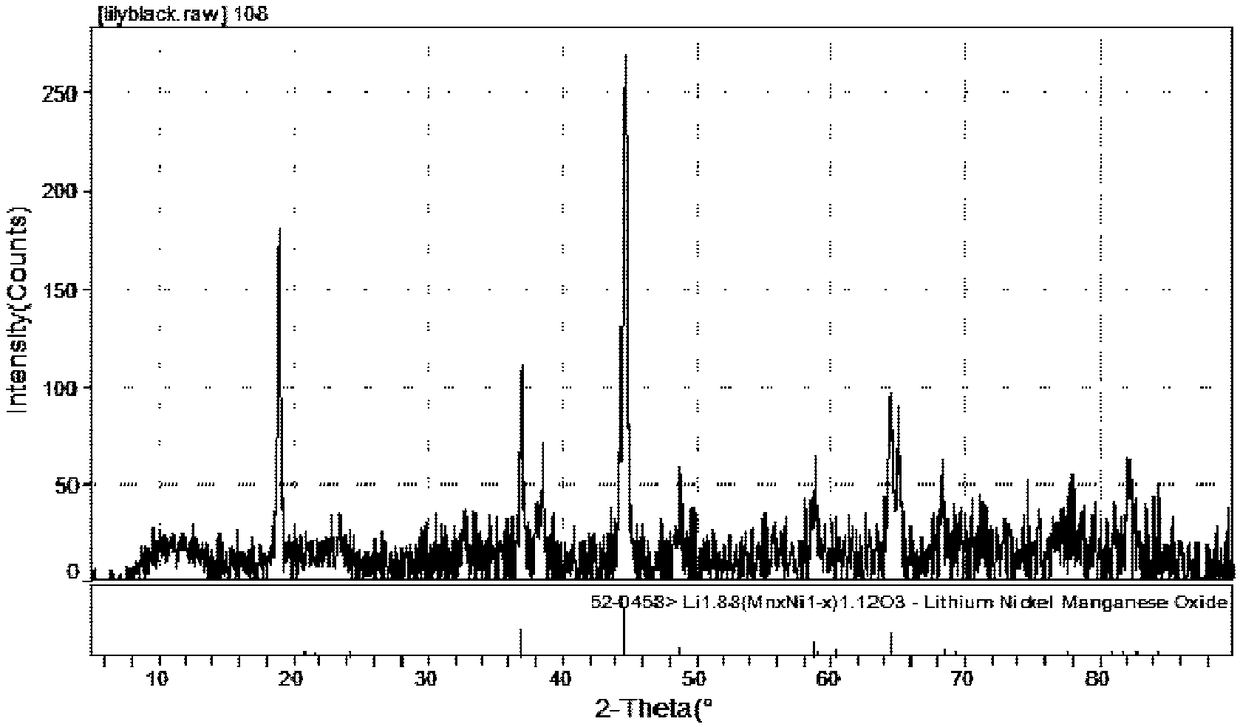

[0030] Example 1 LiNi 0.875 co 0.025 mn 0.1 o 2 Preparation of cathode material

[0031] Include the following steps:

[0032] (1) Accurately weigh 2.25g of lithium acetate and dissolve it in 20mL of absolute ethanol, add 100mL of deionized water, and stir slowly with a magnetic stirrer;

[0033] (2) Slowly add 0.5 mol tetrabutyl titanate dropwise to the solution obtained in step (1) and continue stirring, add a saturated solution containing 1.5 mol cobalt nitrate to obtain a gel;

[0034] (3) Put the above gel at 120° C. for 8 hours, and the gel becomes a solution again;

[0035] (4) The solution obtained in (3) is evaporated and crystallized to obtain the traction agent (LiTi 0.25 co 0.75 o 2 );

[0036] (5) Get 8.75mol nickel nitrate, 0.25mol titanium nitrate, 1mol manganese nitrate dissolved in deionized water, and spray dry to obtain Ni 0.875 Ti 0.025 mn 0.1 (OH) 2 Precursor;

[0037] (6) Take 9mol of Ni 0.875 Ti 0.025 mn 0.1 (OH) 2 Precursor, 0.3mol tra...

Embodiment 2

[0040] Example 2 LiNi 0.875 co 0.025 mn 0.1 o 2 Preparation of cathode material

[0041] Include the following steps:

[0042] (1) Accurately weigh 2.25g of lithium acetate and dissolve it in 20mL of absolute ethanol, add 100mL of deionized water, and stir slowly with a magnetic stirrer;

[0043] (2) Slowly add 0.4 mol tetrabutyl titanate dropwise to the solution obtained in step (1) and continue stirring, add a saturated solution containing 1.2 mol cobalt nitrate to obtain a gel;

[0044](3) Put the above gel at 120° C. for 8 hours, and the gel becomes a solution again;

[0045] (4) The solution obtained in (3) is evaporated and crystallized to obtain the traction agent (LiTi 0.25 co 0.75 o 2 );

[0046] (5) Get 17.5mol nickel nitrate, 0.5mol titanium nitrate, 2mol manganese nitrate dissolved in deionized water, and spray dry to obtain Ni 0.875 Ti 0.025 mn 0.1 (OH) 2 Precursor;

[0047] (6) Take 18mol of Ni 0.875 Ti 0.025 mn 0.1 (OH) 2 Precursor, 0.6mol trac...

Embodiment 3

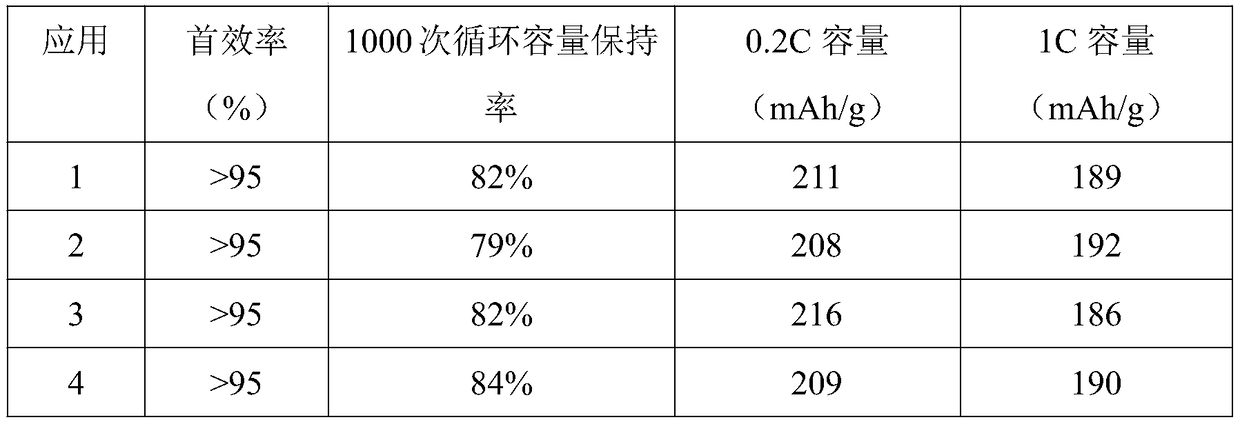

[0050] Example 3 LiNi 0.875 co 0.025 mn 0.1 o 2 Application of Cathode Material as Cathode in Lithium-ion Batteries

[0051] Application 1: Accurately weigh 160 mg of LiNi prepared in Example 1 0.875 co 0.025 mn 0.1 o 2 , 20mgPVDF, 20mgSuper P carbon black, dispersed in 1mLNMP (N-methylpyrrolidone), stirred to dissolve PVDF and mix other materials evenly, and then coated on 12 micron thick double-sided glossy aluminum foil to obtain the required positive electrode aluminum foil , directly assembled with lithium sheets to form a lithium-ion half-cell after cutting. (In this application, LiNi 0.875 co 0.025 mn 0.1 o 2 , polyvinylidene fluoride and super phosphorus carbon black mass ratio is 8:1:1)

[0052] Application 2: Accurately weigh 140 mg of LiNi prepared in Example 1 0.875 co 0.025 mn 0.1 o 2 , 20mgPVDF, 40mgSuper P carbon black, dispersed in 1mLNMP and stirred to dissolve PVDF and mix other materials evenly, and then coated on 5 micron thick double-sided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com