A kind of multi-tooth-head cemented carbide composite column tooth and its preparation method

A cemented carbide and composite column technology, which is used in metal processing equipment, drill bits, earthwork drilling, etc., can solve the problem of insufficient wear resistance, cemented carbide column teeth cannot take into account wear resistance and toughness at the same time, and low drilling speed. and other problems to achieve the effect of improving wear resistance, enhancing wear resistance and prolonging service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

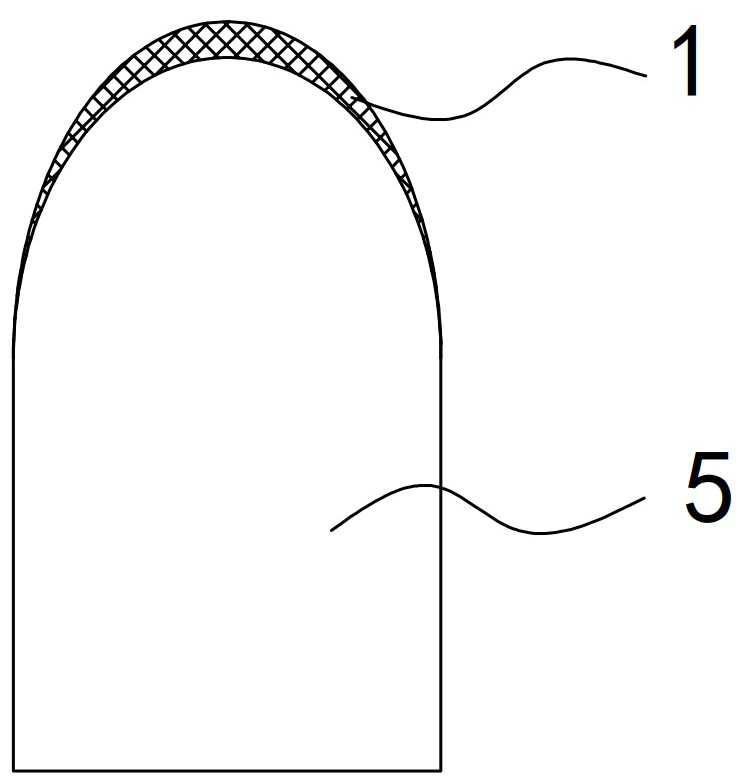

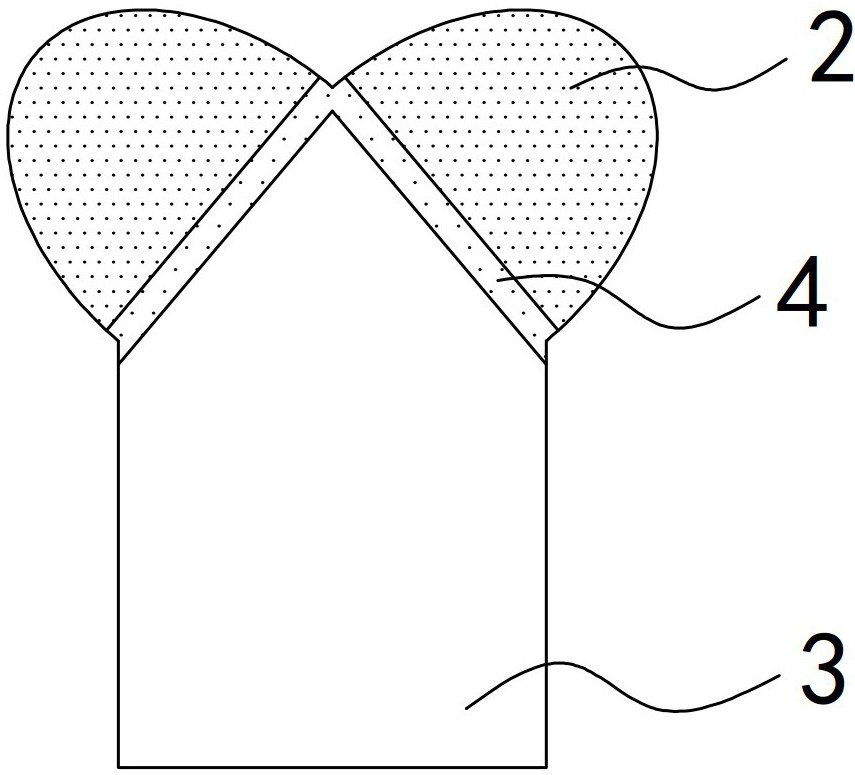

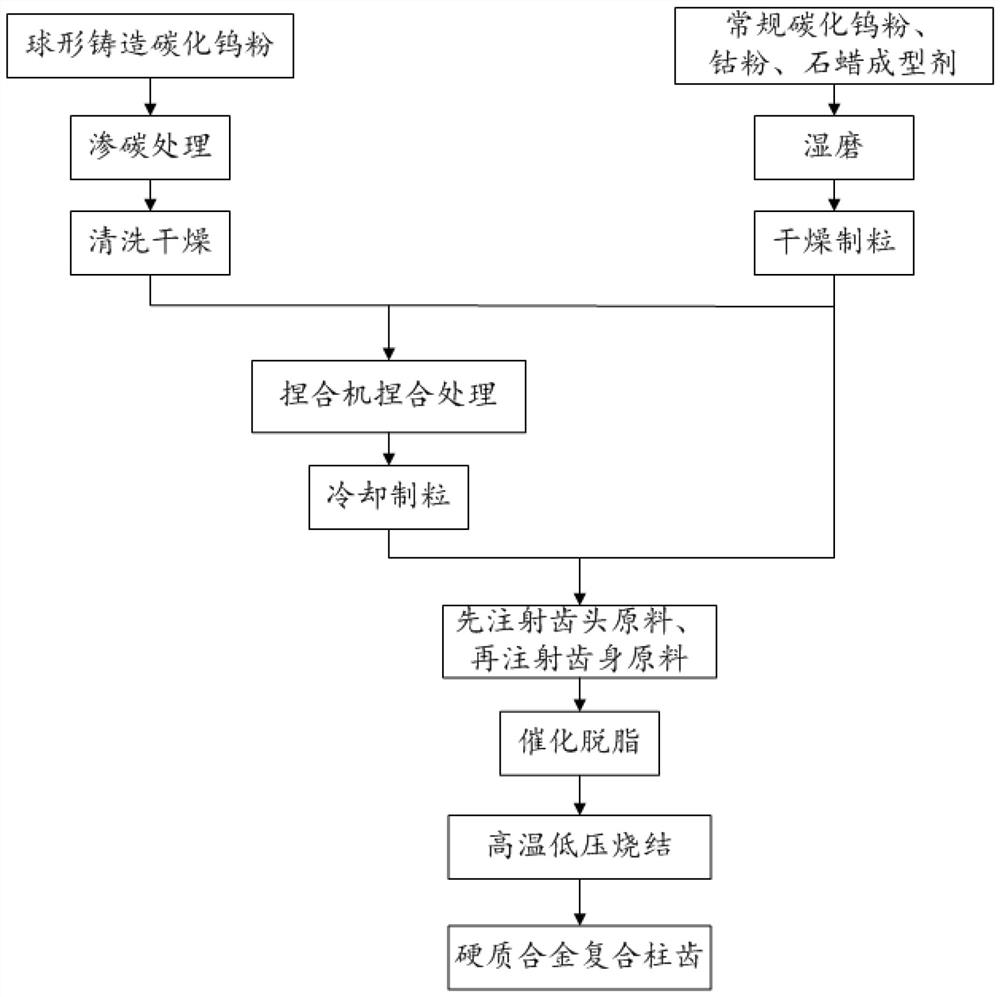

[0060] A method for preparing a multi-head cemented carbide composite column tooth, the preparation process is shown in the appendix image 3 , the preparation method comprises the following steps:

[0061] Step 1. Prepare raw materials for tooth body 3 and tooth head 2;

[0062] The tooth body 3 includes the following components by weight: 6wt% cobalt powder, 2wt% paraffin wax molding agent, and the balance is conventional tungsten carbide powder; each component is weighed by weight, and then wet-milled and dried. The raw material of the tooth body 3 is obtained through particle processing; the particle size of the conventional tungsten carbide powder is 3 μm.

[0063] The tooth head 2 includes the following components by weight: 10wt% carbonized spherical cast tungsten carbide particles, 6wt% wax-based composite molding agent, and the balance is the raw material of the tooth body 3; The components are first placed in a kneader for kneading treatment, the kneading temperatu...

Embodiment 2

[0070] A method for preparing a multi-head cemented carbide composite column tooth, the preparation process is shown in the appendix image 3 , the preparation method comprises the following steps:

[0071] Step 1. Prepare raw materials for tooth body 3 and tooth head 2;

[0072] The tooth body 3 includes the following components by weight: 8wt% cobalt powder, 2wt% paraffin wax molding agent, and the balance is conventional tungsten carbide powder; each component is weighed according to weight content, and then wet-milled and dried. The raw material of the tooth body 3 is obtained through particle processing; the particle size of the conventional tungsten carbide powder is 6 μm.

[0073] The tooth head 2 includes the following components by weight: 20wt% carbonized spherical cast tungsten carbide particles, 5wt% wax-based composite molding agent, and the balance is the raw material of the tooth body 3; The components are first placed in a kneader for kneading treatment, the ...

Embodiment 3

[0080]A method for preparing a multi-head cemented carbide composite column tooth, the difference from Example 1 is that the tooth head 2 includes 20wt% carbonized spherical cast tungsten carbide particles, and other raw materials, process parameters, steps, etc. are the same . Compared with the traditional single-head cemented carbide column, the prepared multi-head cemented carbide composite column has a hardness of 0.7HRA and a 75% increase in wear resistance. The toughness is equivalent to that of traditional cemented carbide columns, and the fracture toughness of the prepared multi-head cemented carbide composite columns is 16.4MPa m 1 / 2 , The drilling speed is increased by 35%, which significantly improves the service life and drilling efficiency of the drilling tool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com