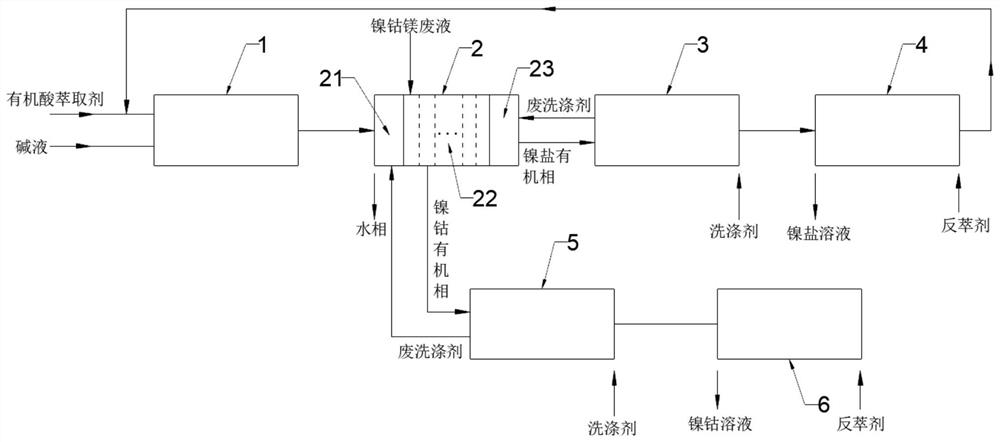

Three-outlet extraction method and system device for obtaining nickel salt solution and nickel-cobalt solution through separation

A system device and three-exit technology, which is applied in the field of three-exit extraction method and system device, can solve the problems of long technical process and high investment cost, and achieve the effect of high extraction rate, high purity and long solution process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] This embodiment provides a three-outlet extraction system device for separating and obtaining nickel salt solution and nickel-cobalt solution. Based on the three-outlet extraction system device provided by the specific embodiment, the saponification tank 1 includes a first-level saponification section, and the pre-extraction section includes a stage extraction section, the middle extraction section includes a first-stage extraction section, the post-extraction section includes a first-stage extraction section, the first washing tank includes two-stage washing sections connected in sequence, the second washing tank includes two-stage washing sections connected in sequence, and the first The extraction tank includes two-stage stripping sections connected in sequence, and the second stripping tank includes two-stage stripping sections connected in sequence.

[0084] This embodiment also provides a method for extracting and separating nickel-cobalt-magnesium waste liquid usi...

Embodiment 2

[0094] This embodiment provides a three-outlet extraction system device for separating and obtaining a nickel salt solution and a nickel-cobalt solution. Based on the three-outlet extraction system device provided by the specific embodiment, the saponification tank 1 includes two successively connected saponification sections. The front section includes a 1-level extraction section, and the middle extraction section includes a 4-level extraction section (the first stage of the extraction middle section is provided with a feed liquid inlet, and the second stage of the extraction middle section is provided with a nickel-cobalt organic phase outlet), and the back section of the extraction includes a first-level extraction section, The first washing tank includes 4-stage washing sections communicated in sequence, the second washing tank includes 4-stage washing sections communicated in sequence, the first stripping tank includes 3-stage stripping sections communicated in sequence, a...

Embodiment 3

[0105] This embodiment provides a three-outlet extraction system device for separating and obtaining nickel salt solution and nickel-cobalt solution. Based on the three-outlet extraction system device provided by the specific embodiment, the saponification tank 1 includes 3-stage saponification sections connected in sequence, and the extraction The front section includes a 2-stage extraction section, and the middle extraction section includes an 8-stage extraction section (the first stage of the extraction middle section is provided with a feed liquid inlet, and the third stage of the extraction middle section is provided with a nickel-cobalt organic phase outlet), and the back section of the extraction includes a 2-stage extraction section, The first washing tank includes 6-stage washing sections communicated in sequence, the second washing tank includes 6-stage washing sections communicated in sequence, the first stripping tank includes 4-stage stripping sections communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com