Patents

Literature

101results about "Nickel halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

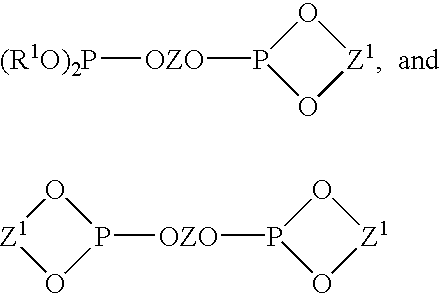

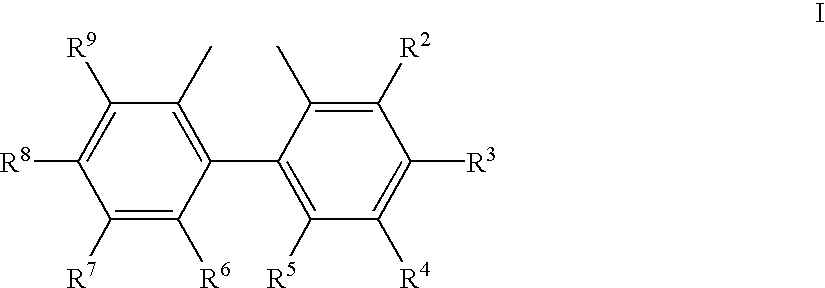

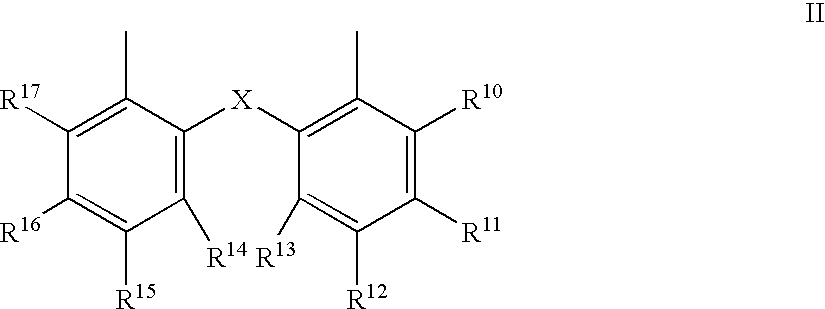

Process for the preparation of a nickel/phosphorous ligand catalyst for olefin hydrocyanation

A process for preparing a hydrocyanation catalyst comprising contacting a bidentate phosphorous-containing ligand with a molar excess of nickel chloride in the presence of a nitrile solvent and a reducing metal which is more electropositive than nickel. Preferably, the nickel chloride is dried before use.

Owner:INVISTA NORTH AMERICA R L

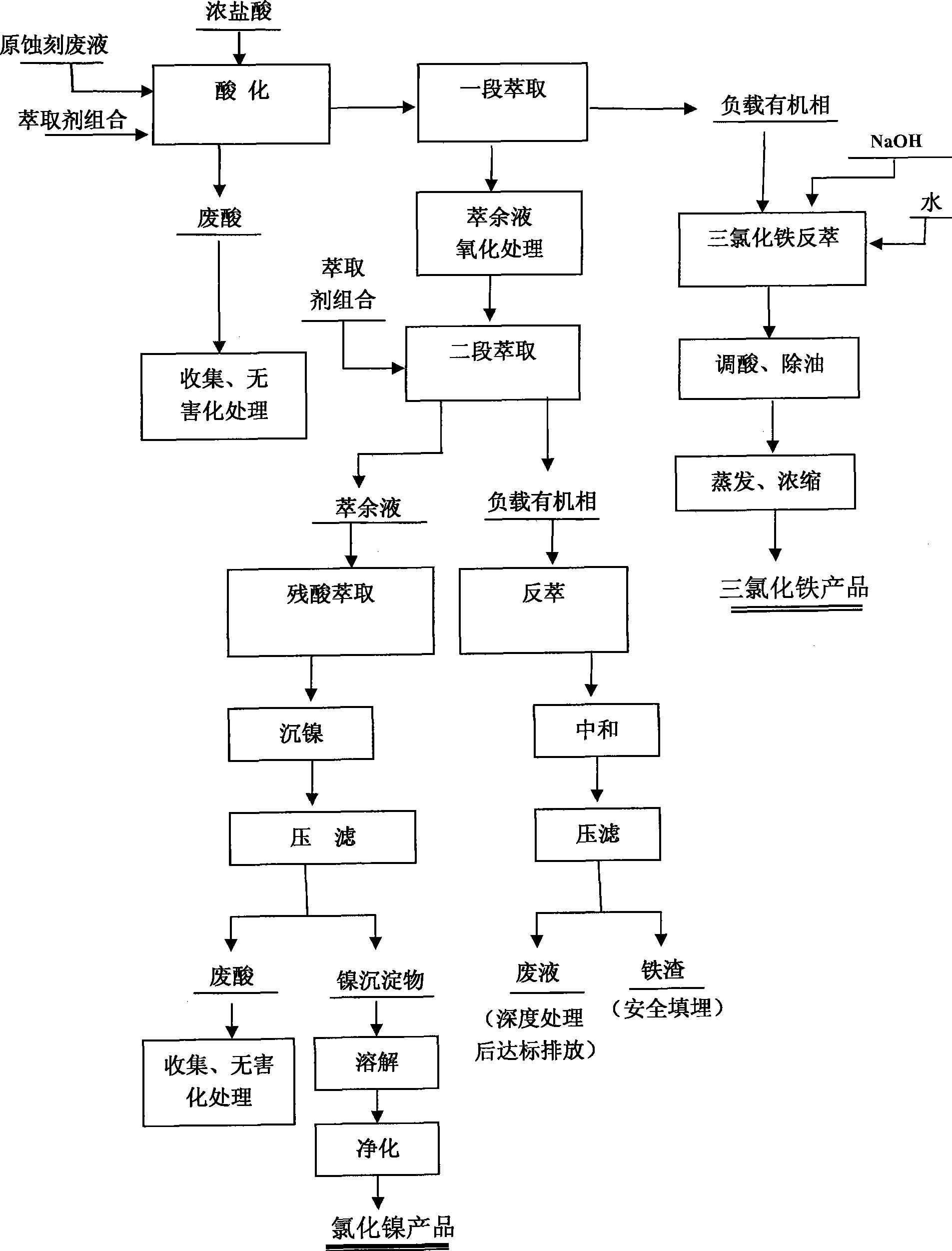

Method for treating ferric trichloride etching waste liquor

ActiveCN101497484AEasy to separateImprove efficiencyMultistage water/sewage treatmentNickel halidesLiquid wasteLiquid state

The invention relates to a method for treating ferric trichloride etching waste liquor, in particular to a method for treating the ferric trichloride etching waste liquor containing nickel, which mainly adopts a two-stage extraction method to remove iron so as to achieve the complete separation of the nickel and the iron, wherein a first stage extraction organic phase combination comprises 15 to 40 percent of extractant, 10 to 20 percent of synergist and 40 to 75 percent of diluent agent according to the volume ratio; a second stage extraction organic phase combination comprises 20 to 50 percent of extractant, 5 to 10 percent of synergist and 40 to 75 percent of diluent agent according to the volume ratio; the extractants and the synergists used in the two stages have various selections; and under the condition that the technological parameters are controlled strictly, with the two stages of extractions, the iron contained in the etching waste liquor is regenerated into a liquid state ferric trichloride product, and the nickel is regenerated into a nickel chloride product. The method overcomes various defects of the prior art, has good iron and nickel separation effect, high efficiency and low cost, achieves the resource recycling of valuable metals to the utmost extent while achieving the decontamination of the ferric trichloride etching waste liquor, and has board technique application prospect.

Owner:DONGJIANG ENVIRONMENTAL

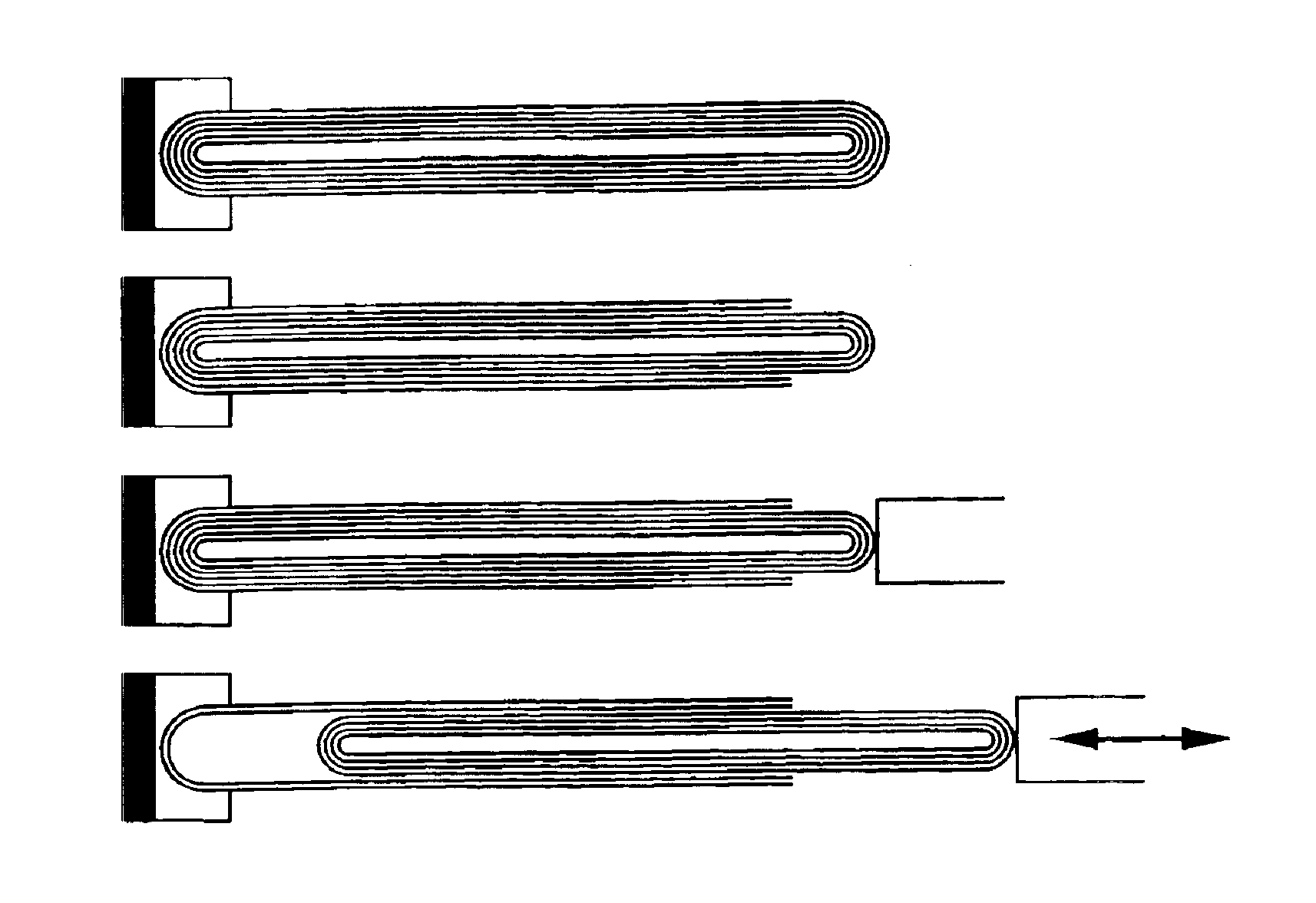

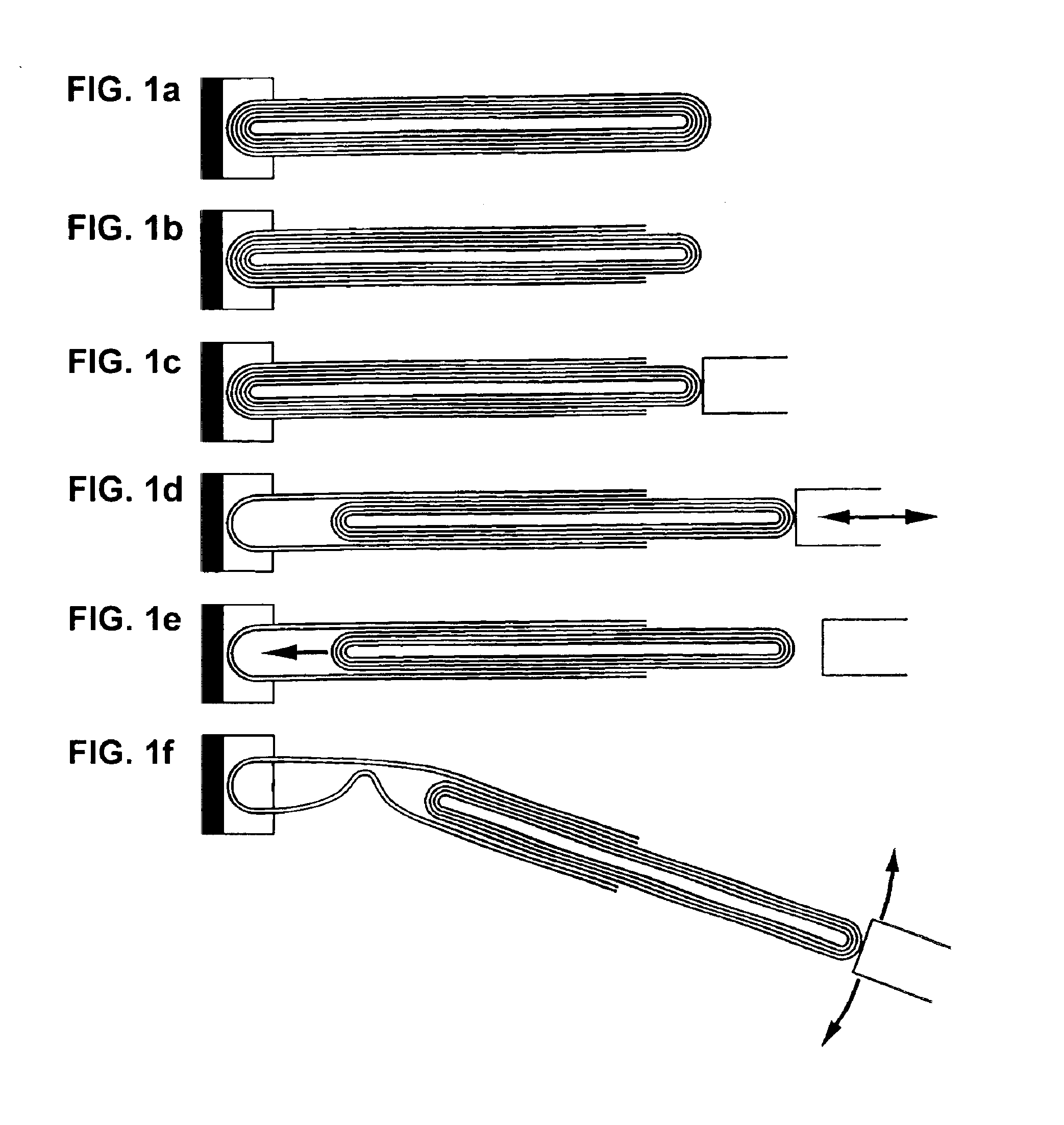

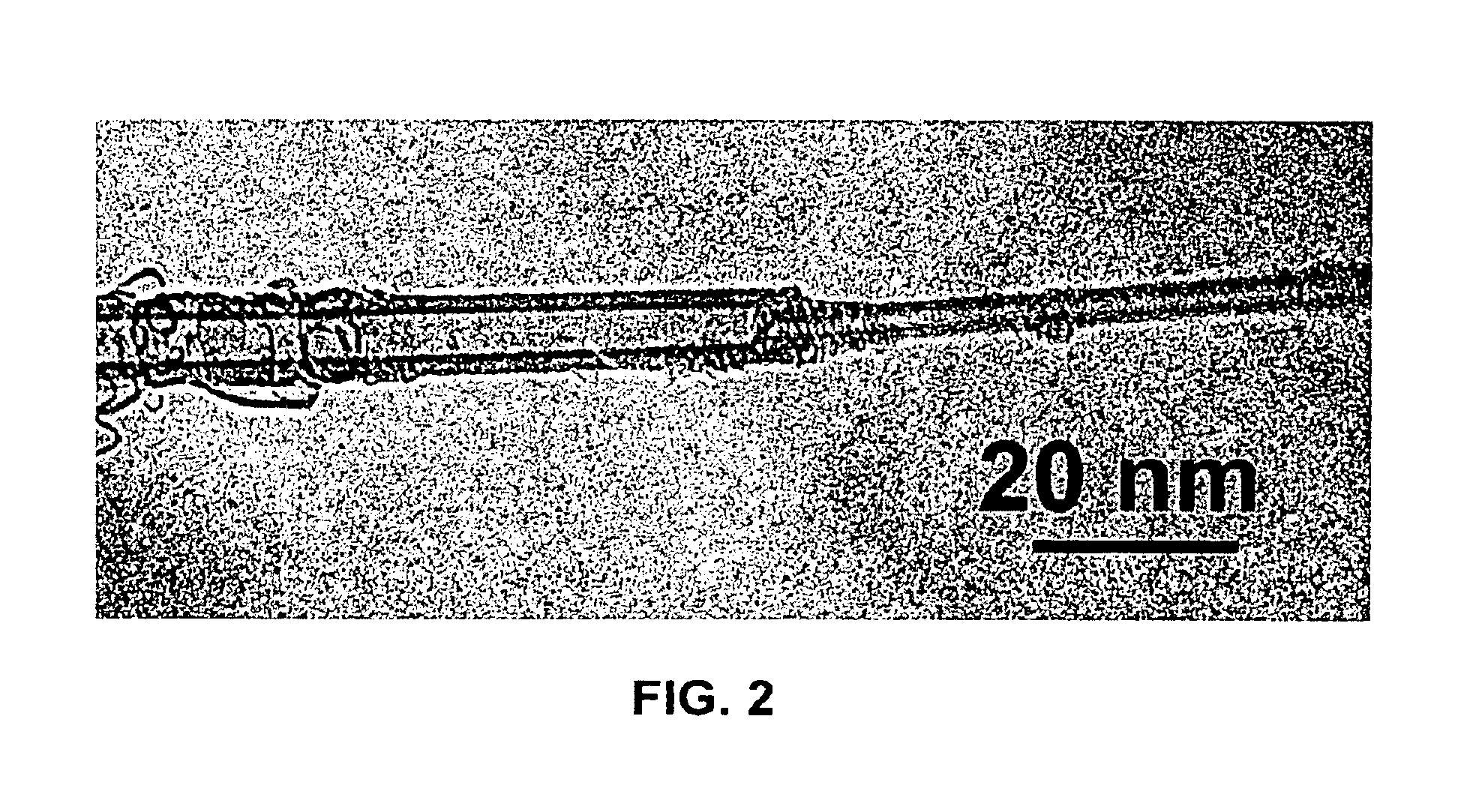

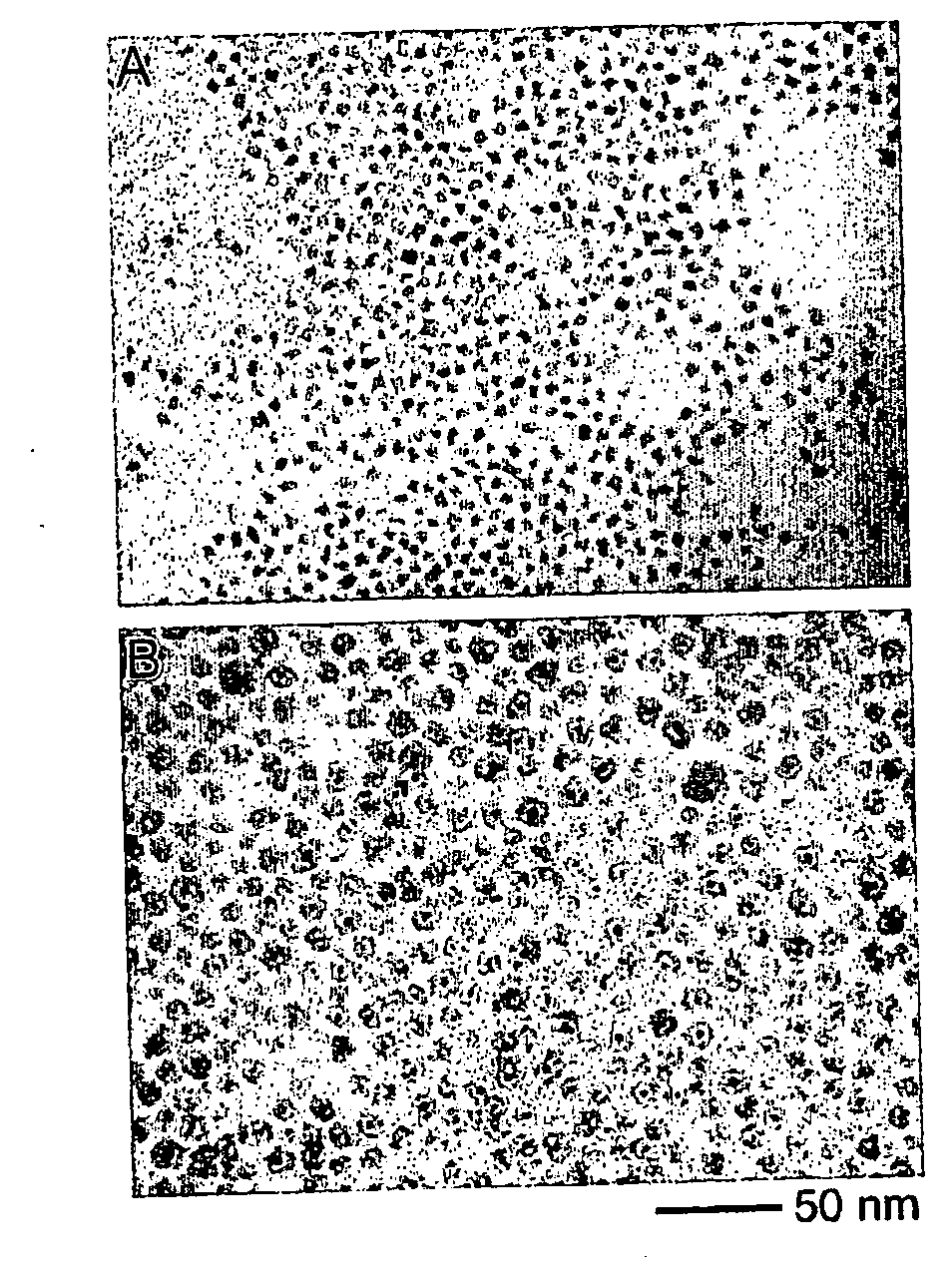

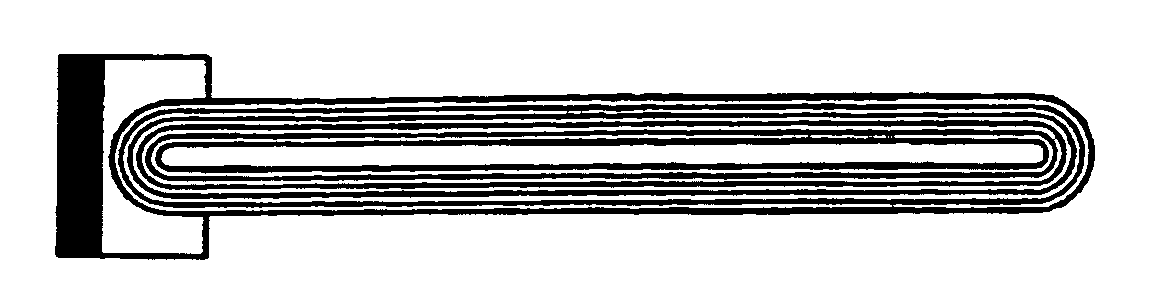

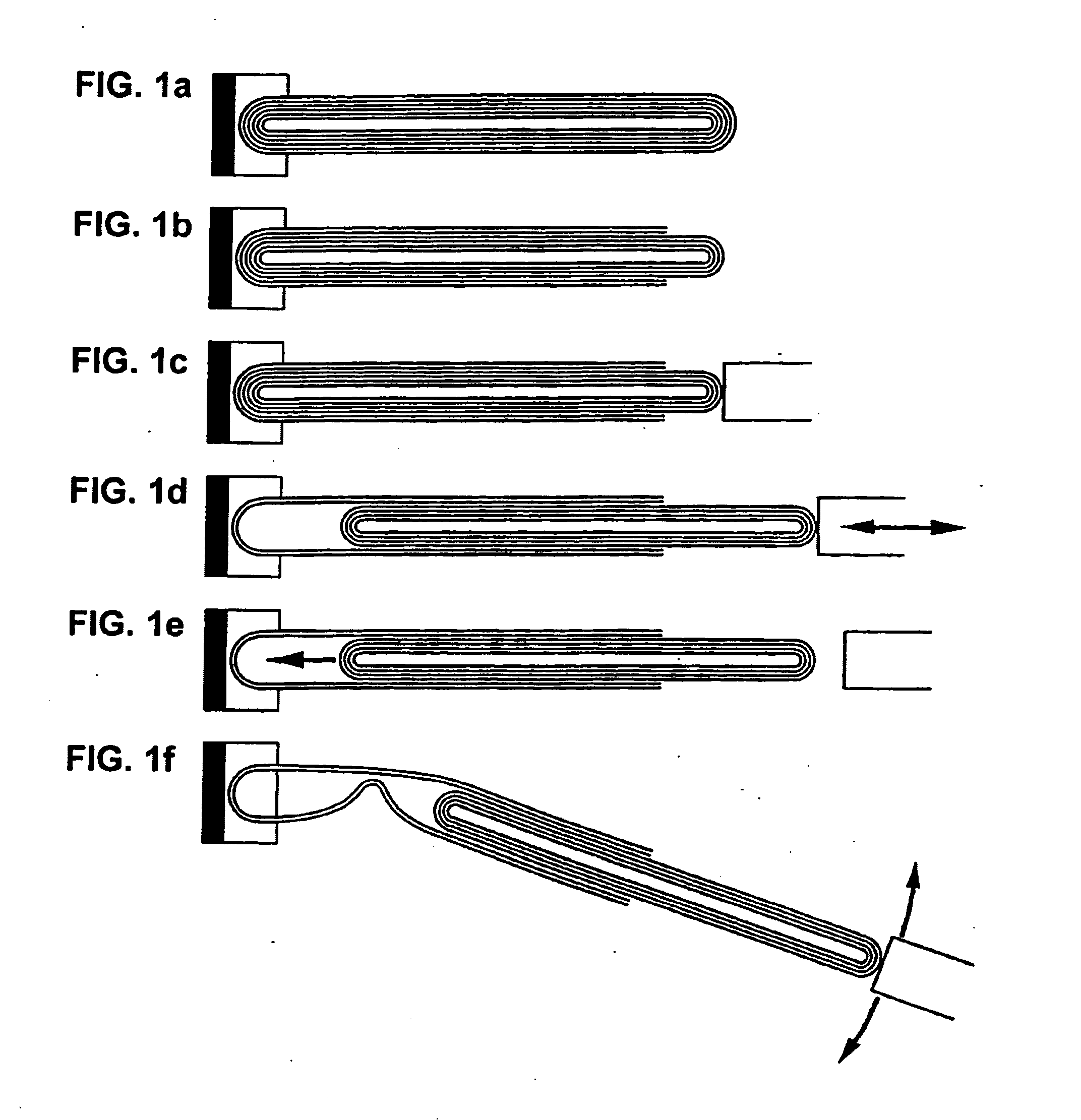

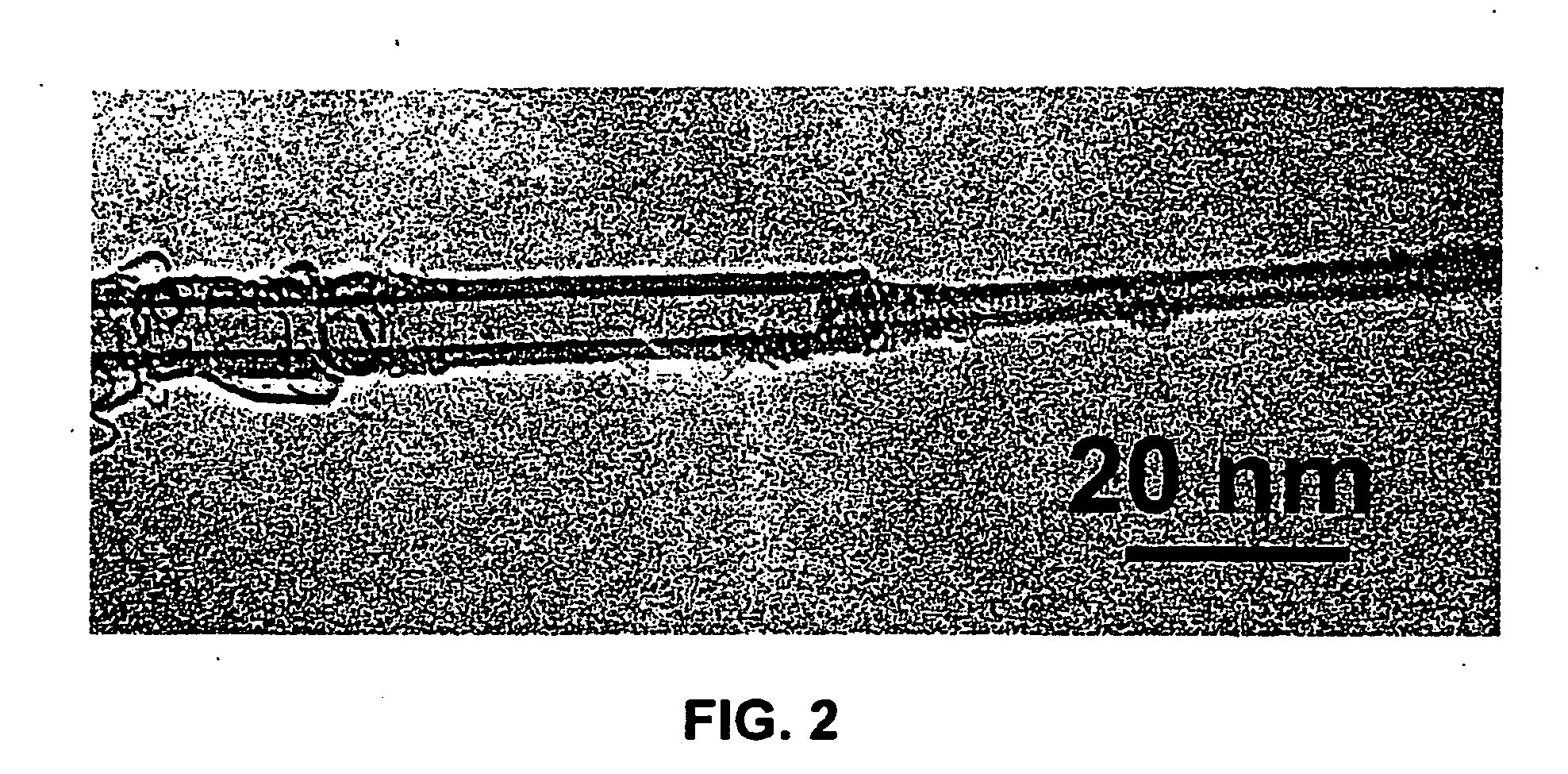

Telescoped multiwall nanotube and manufacture thereof

InactiveUS6874668B2Overcome disadvantagesMaterial nanotechnologyNitrogen compoundsNanomanipulatorConstant force

The invention relates to a method for forming a telescoped multiwall nanotube. Such a telescoped multiwall nanotube may find use as a linear or rotational bearing in microelectromechanical systems or may find use as a constant force nanospring. In the method of the invention, a multiwall nanotube is affixed to a solid, conducting substrate at one end. The tip of the free end of the multiwall nanotube is then removed, revealing the intact end of the inner wall. A nanomanipulator is then attached to the intact end, and the intact, core segments of the multiwall nanotube are partially extracted, thereby telescoping out a segment of nanotube.

Owner:RGT UNIV OF CALIFORNIA

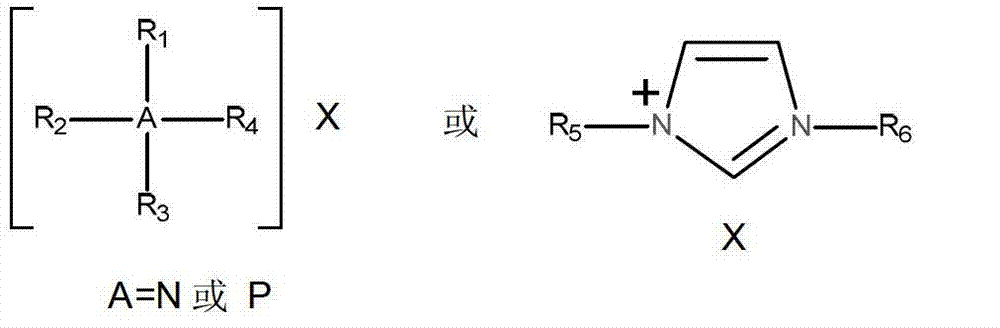

Three-ingredient eutectic ionic liquid and preparation method thereof

InactiveCN103193711ALow costWill not emitZinc halidesUrea derivatives preparationOrganic synthesisToxic material

The invention relates to three-ingredient eutectic ionic liquid and a preparation method thereof. The three-ingredient eutectic ionic liquid consists of ILX, MH and HBD, wherein ILX is ionic liquid with negative-monovalent halogen ions which serve as negative ions, MH is transition metal haloid, and HBD is a compound with multiple hydrogen bonds. The preparation method comprises the following steps of: uniformly mixing ILX, MH and HBD according to the molar ratio of 1: 1: n (n= 0.5-4), heating up to the temperature of 100-140 DEG C, and then, carrying out heat preservation for 2-4 hours until a mixture is completely dissolved. According to the ionic liquid disclosed by the invention, the melting point is extremely low, the viscosity is low, the conductivity is high, the dissolution performance is good, and the ionic liquid has Lewis acidity and catalysis performance, so that the ionic liquid can be widely applied to organic synthesis reaction, the preparation of nano and mesoporous materials, gas absorption and the like; and the preparation process is simple, the raw materials are readily available, the cost is low, no organic solvents are used and no toxic substances are emitted during reaction, no byproducts are produced, and the ionic liquid is biodegradable, so that the ionic liquid is suitable for industrial production.

Owner:DONGHUA UNIV

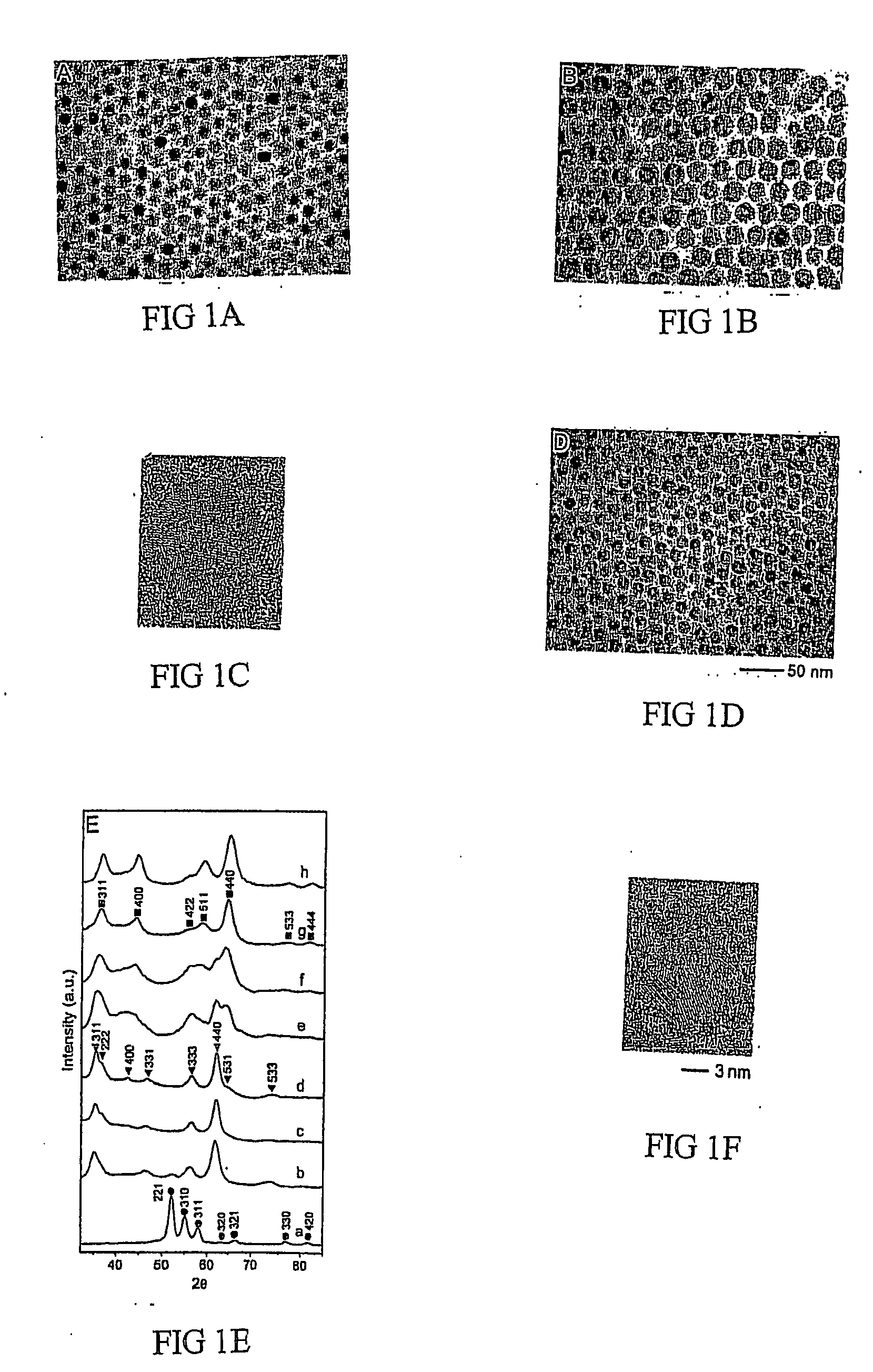

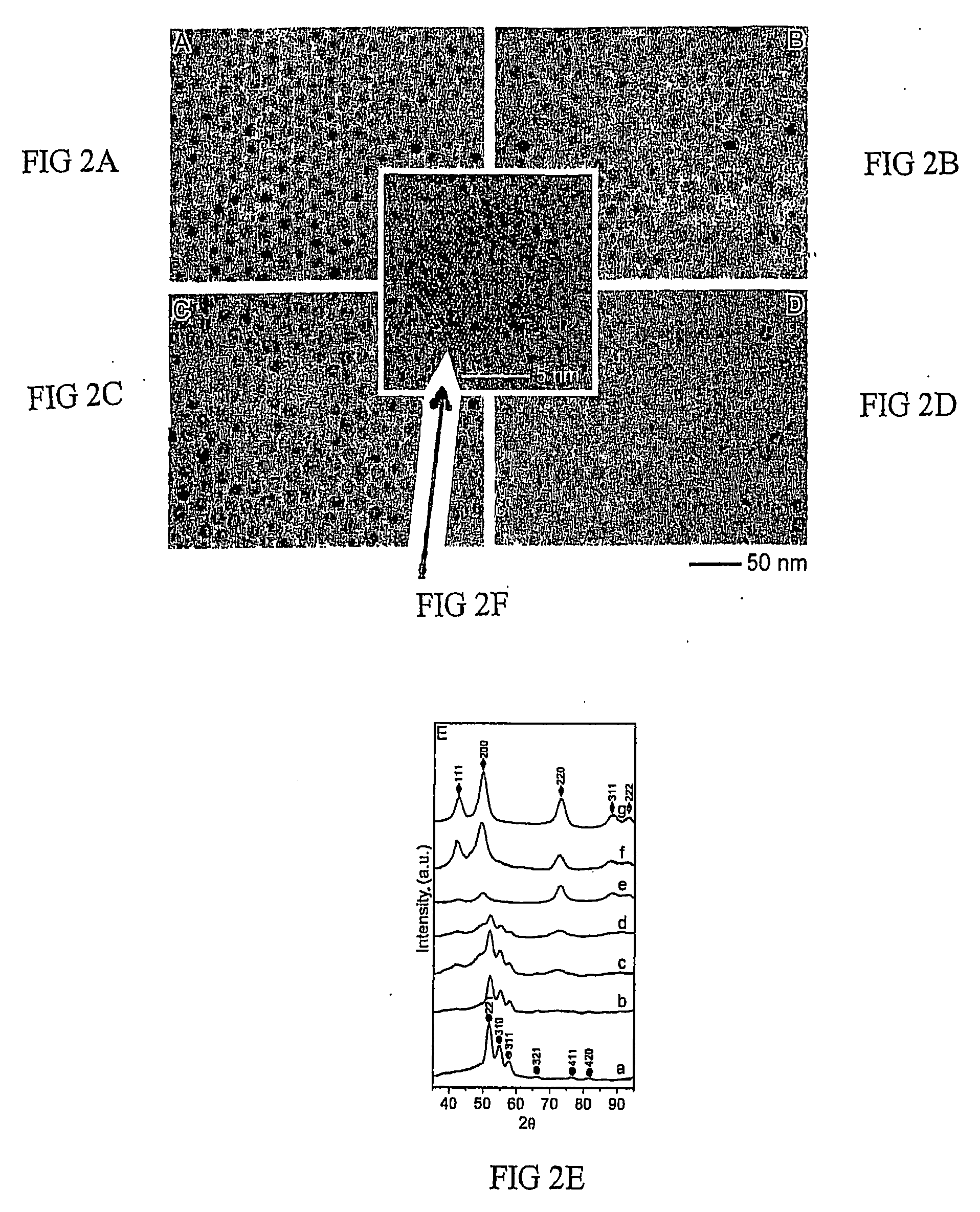

Hollow nanocrystals and method of making

Owner:RGT UNIV OF CALIFORNIA

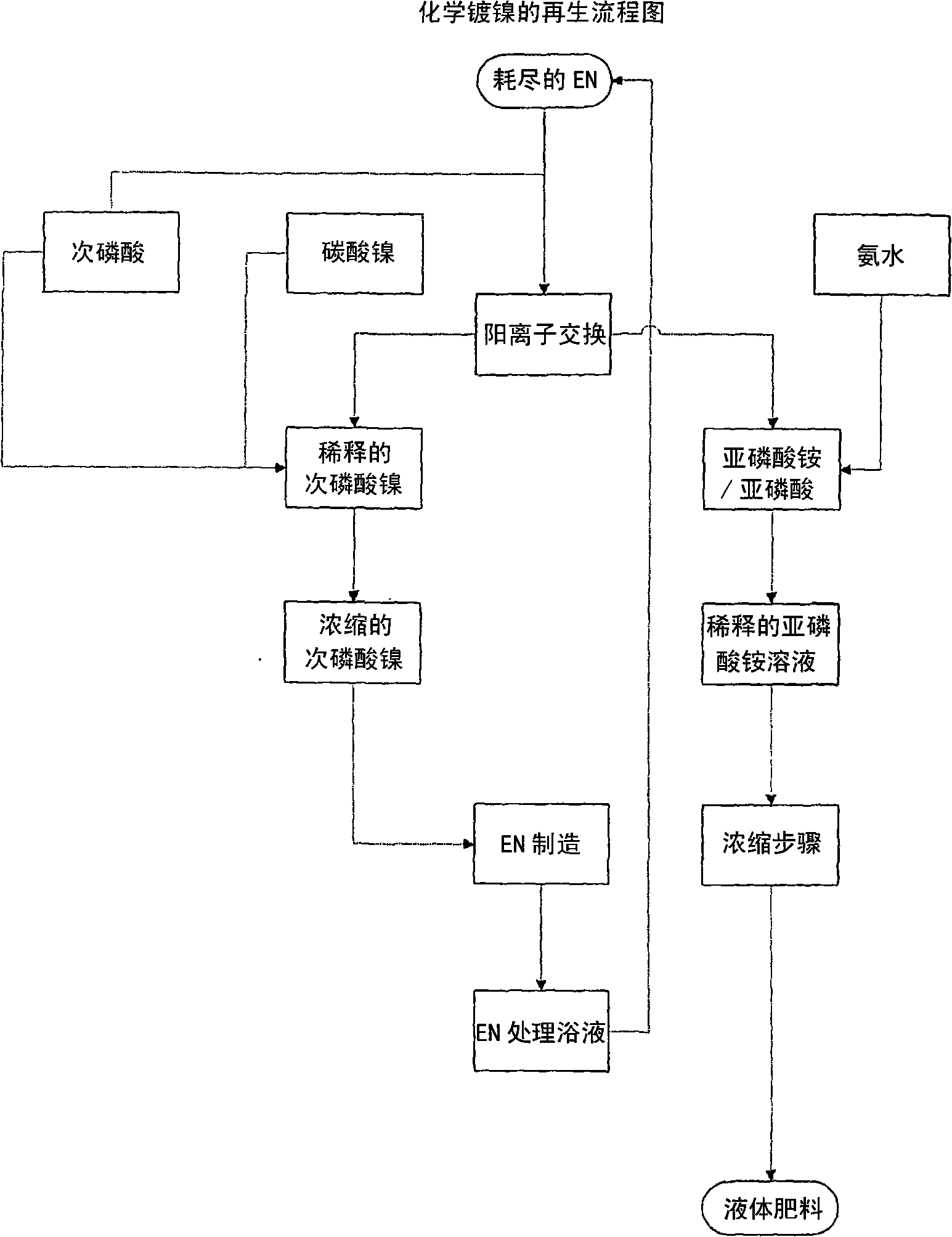

Method of recycling electroless nickel waste

InactiveCN101636353AEliminate processingAvoid it happening againNickel compounds preparationLiquid/solution decomposition chemical coatingElectroless nickelSULFATE ION

An electroless nickel plating bath is provided that utilizes hypophosphite ions as a reducing agent and is substantially free of sulphate and sodium ions. Spent nickel in the plating bath is removed using an ion exchange resin and the remaining effluent solution is usable for manufacturing fertilizer compositions. The nickel is processed for inclusion back into the plating bath. Thus, the process of the invention allows for the indefinite use of the solutions without discharging hazardous waste.

Owner:MACDERMID ACUMEN INC

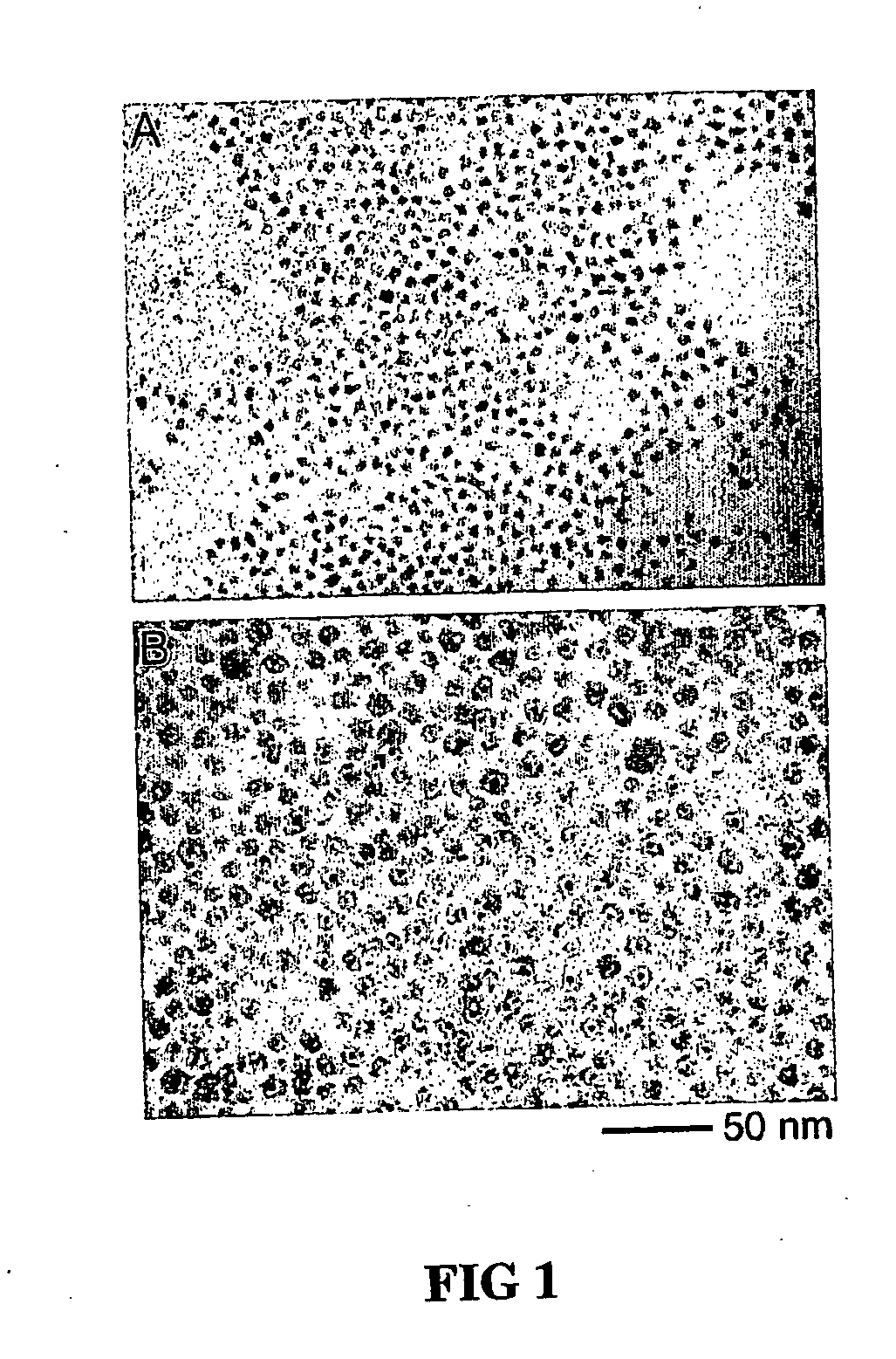

Nanoreactors and Method of Making

Described herein are nanoreactors having various shapes that can be produced by a simple chemical process. The nanoreactors described herein may have a shell as thin as 0.5 nm and outside diameters that can be controlled by the process of making and have a nanoparticle enclosed therein. The nanoreactors have catalytic activity and may be used to catalyze a variety of chemical reactions.

Owner:RGT UNIV OF CALIFORNIA

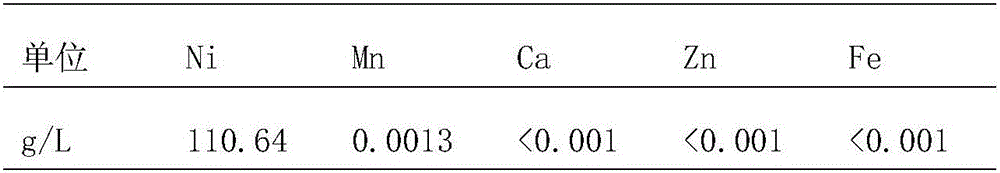

Method for preparing nickel salt through direct leaching of nickel oxide at normal pressure

InactiveCN107935063AImprove qualityEasy to produceNickel halidesNickel sulfatesSulfateDistilled water

The invention discloses a method for preparing nickel sulfate or nickel chloride through normal-pressure leaching of a nickel oxide. The method comprises the following steps: mixing a dilute sulfuricacid solution with a nickel oxide, and carrying out a stirring reaction at 50 to 100 DEG C for 1 to 5 h so as to gradually produce a yellow-green solid; carrying out solid-liquid separation, washing the yellow-green solid with distilled water until the solid is weakly acid and then dissolving the solid with distilled water or with an aqueous hydrogen peroxide solution with a concentration of 1 to5% so as to produce a corresponding nickel sulfate solution; and mixing a hydrochloric acid solution with the nickel oxide and carrying out a stirring reaction at 50 to 100 DEG C for 1 to 3 h so as togradually produce a green nickel chloride solution. A nickel salt solution prepared by using the method has nickel content of 110 g / L or above. According to the method, direct leaching reaction at normal pressure is carried out so as to obtain nickel sulfate and nickel chloride, so production flow of nickel sulfate and nickel chloride is effectively simplified, and cost is lowered; and impurity introduction is reduced from the source, so the quality of nickel sulfate is effectively improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nickel-contained materials abstraction and type-reverting production method of nickel salt

InactiveCN101139112AReduce demandRelieve production pressureNickel halidesNickel ammonia complexesNickel saltSulfamic acid

An extraction and transformation method to produce nickel salt with material containing nickel relates to an extraction and transformation technology with nickel salt medium solution in the preparation process of nickel salt products, in particular to the preparation of nickelous chloride and nickel sulfamic acid. The present invention is characterized in that the nickel salt solution after purified is extracted by P204 extracting agent and the main metal nickel is led into an organic phase and then the organic phase is back extracted by various acid solution. The nickel is transferred into outer nickel salt solution and then produced to other nickel salt products after the procedures of depth decontamination, evaporating and crystallization. The present invention can enlarge the material range of nickel salt products, greatly improve working environment and save production cost.

Owner:JINCHUAN GROUP LIMITED

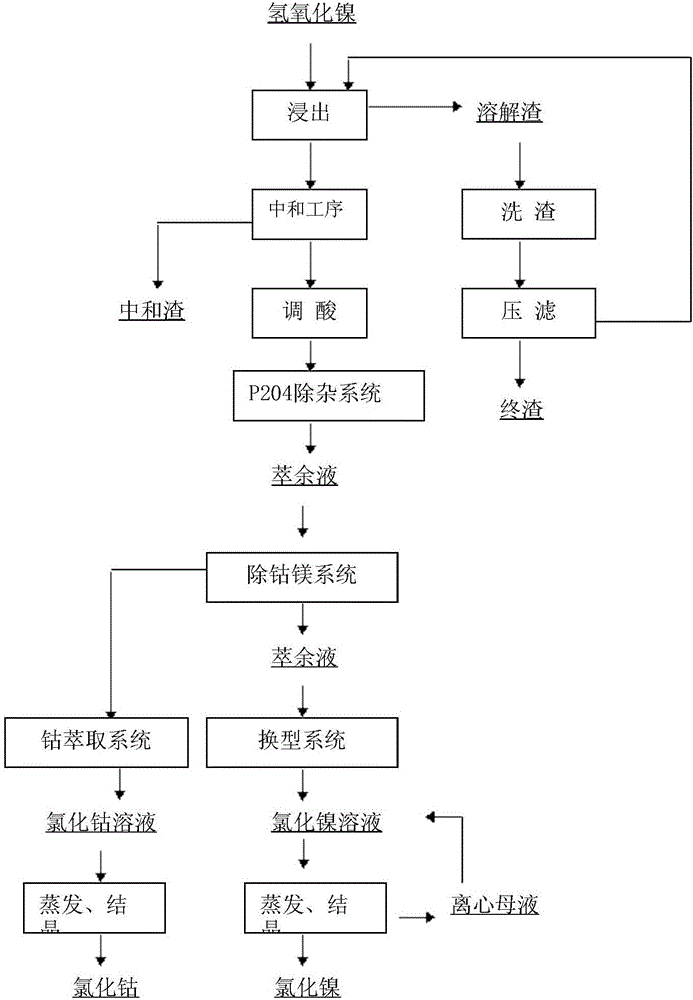

Method for preparing nickel chloride through sulfuric acid leaching of crude nickel hydroxide

ActiveCN106745342AReduce usageAvoid pollutionNickel compounds preparationNickel halidesNickel oxide hydroxideSulfate

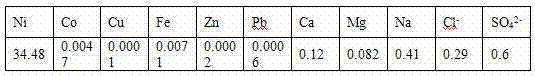

The invention provides a method for preparing nickel chloride through sulfuric acid leaching of crude nickel hydroxide, and belongs to the technical field of hydrometallurgy. The method comprises the following steps: carrying out concentrated sulfuric acid leaching on the crude nickel hydroxide to obtain a nickel sulfate solution, removing silicon and iron from the nickel sulfate solution, and allowing the obtained solution to enter an extraction system; carrying out extraction to remove Mn, Zn, Ca, Mg and other impurities from the nickel sulfate solution and recover Co, wherein the content of Mn, Zn, Ca and Co is reduced to 0.001 g / L or below, and the content of Mg is reduced to 0.05 g / L or below; carrying out extraction to convert the nickel sulfate solution into a nickel chloride solution; and carrying out evaporation, crystallization and centrifuge packaging to obtain the nickel chloride product. The method has the advantages of simplicity, effective control of the content of the impurities in the nickel chloride, obtaining of the high-quality nickel chloride product, and wide application.

Owner:JILIN JIEN NICKEL IND

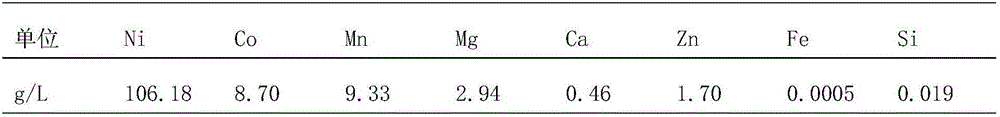

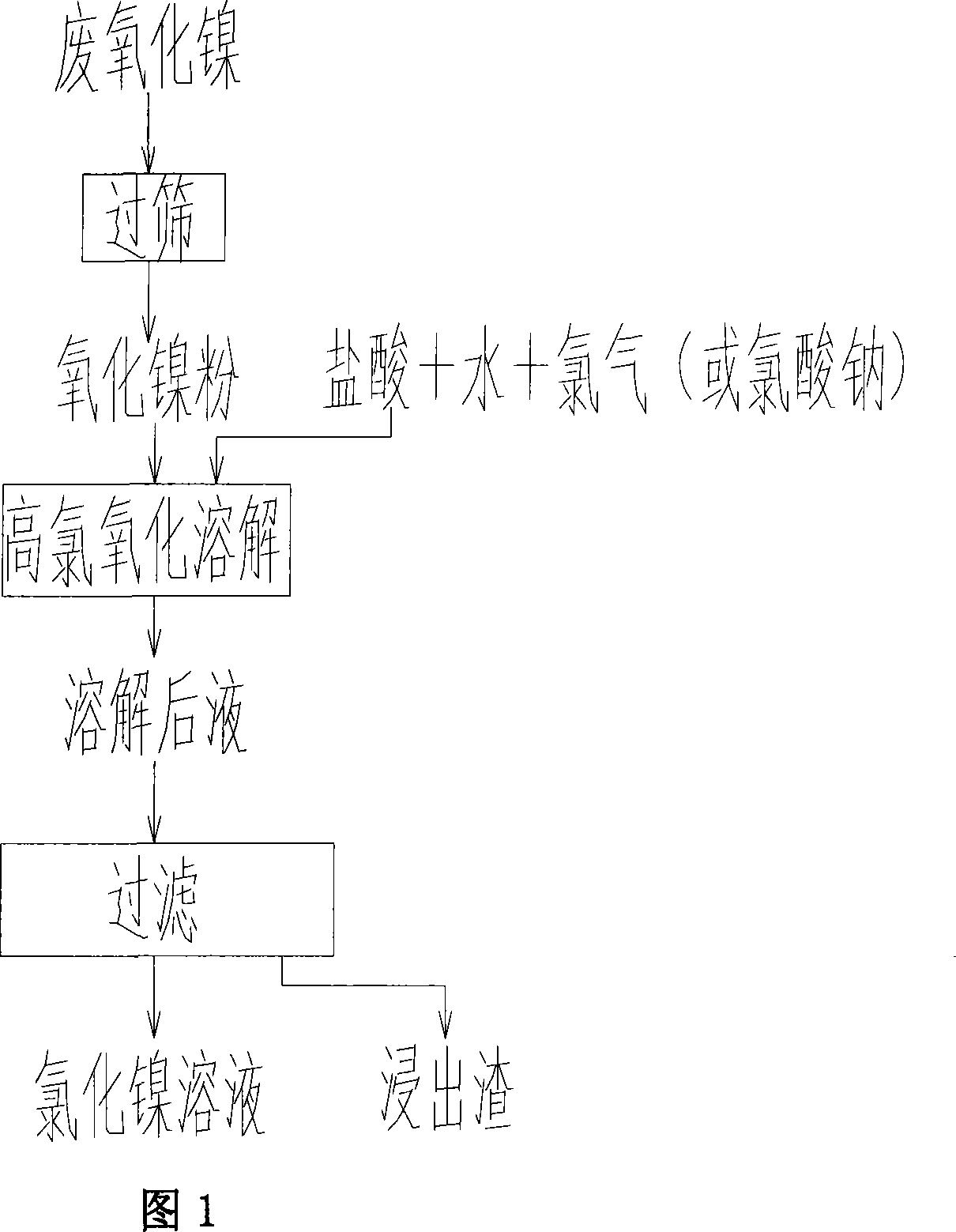

Nickelous oxide dead catalyst dissolution processing method

ActiveCN101219814AEfficient recyclingEnhanced leaching processNickel halidesChemical recyclingElectrolysisSodium chlorate

The invention relates to a dissolution method for treating nickel oxide waste catalyst, which is characterized in that the dissolution treatment process comprises the steps: the nickel oxide waste catalyst which is screened blocky material such as scree and slag is put into the hydrochloric acid solution with a concentration above 5N / L; under a temperature ranging from 85 DEG C to 100 DEG C and under a stirring condition, the oxidant sodium chlorate is added or the chorine is implanted and the oxidation potential is controlled to be 0.5-1.0V; the dissolution reaction is carried out for 1-5 hours to obtain green nickel chloride solution. The method of the invention has high leaching rate and dissolution ratio; high temperature treatment and pressure treatment are not required, which reduces cost and solves the difficult problem of production technology. Combined with prior process of nickel electrolysis, the nickel in the waste catalyst can be effectively recycled.

Owner:JINCHUAN GROUP LIMITED

Porous material and method for producing the same

InactiveCN1798703AExcellent fluorination catalytic abilityHigh porosityMagnesium fluoridesCobalt halidesHydrogen fluoridePhysical chemistry

The present invention provides a raw material composition suitably used for synthesizing a porous metal fluoride having a large surface area and being stable even in a corrosive gas environment or the like. The porous metal fluoride obtained by reacting this raw material composition with anhydrous hydrogen fluoride has a larger surface area and is stable in a corrosive gas environment, etc., and can be used, for example, as a fluorination catalyst.

Owner:权恒道

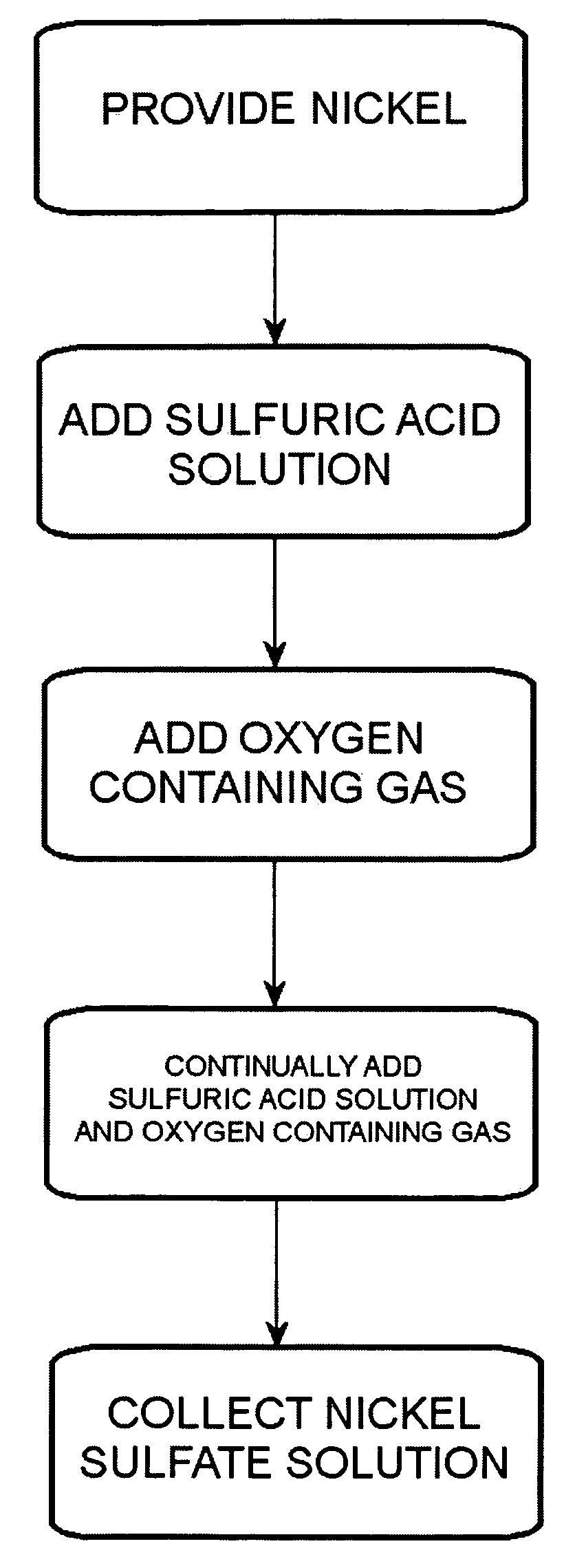

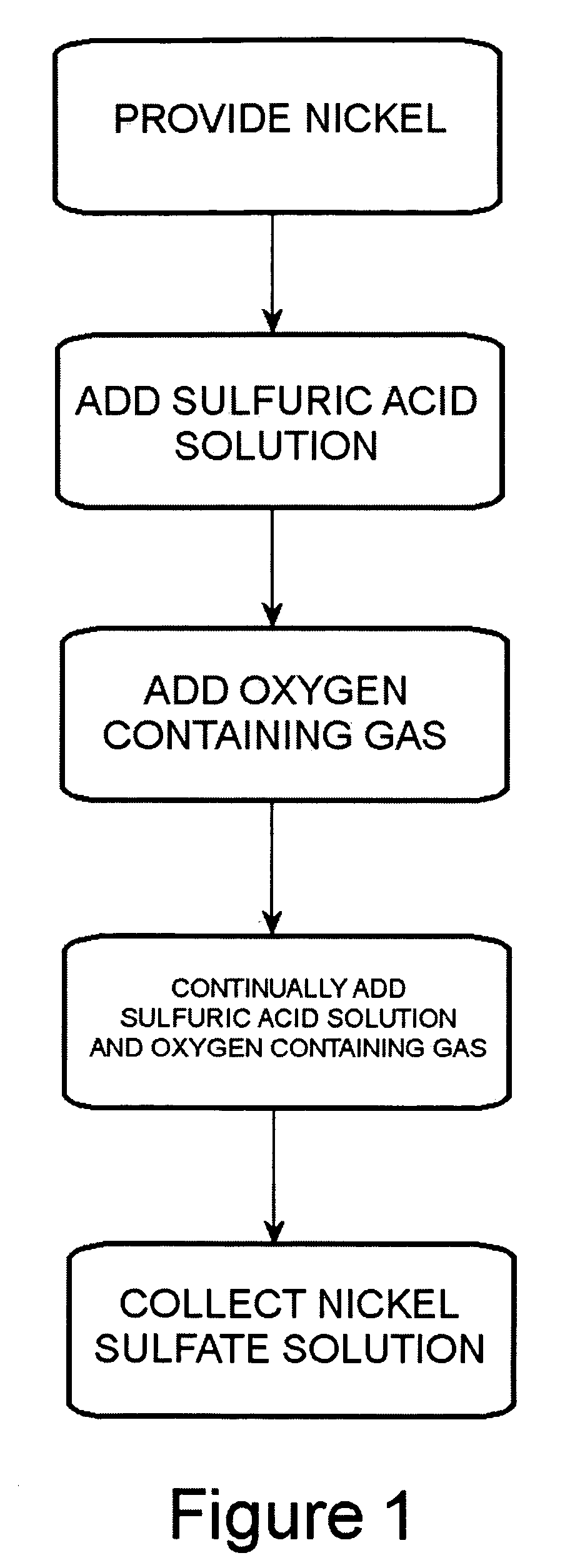

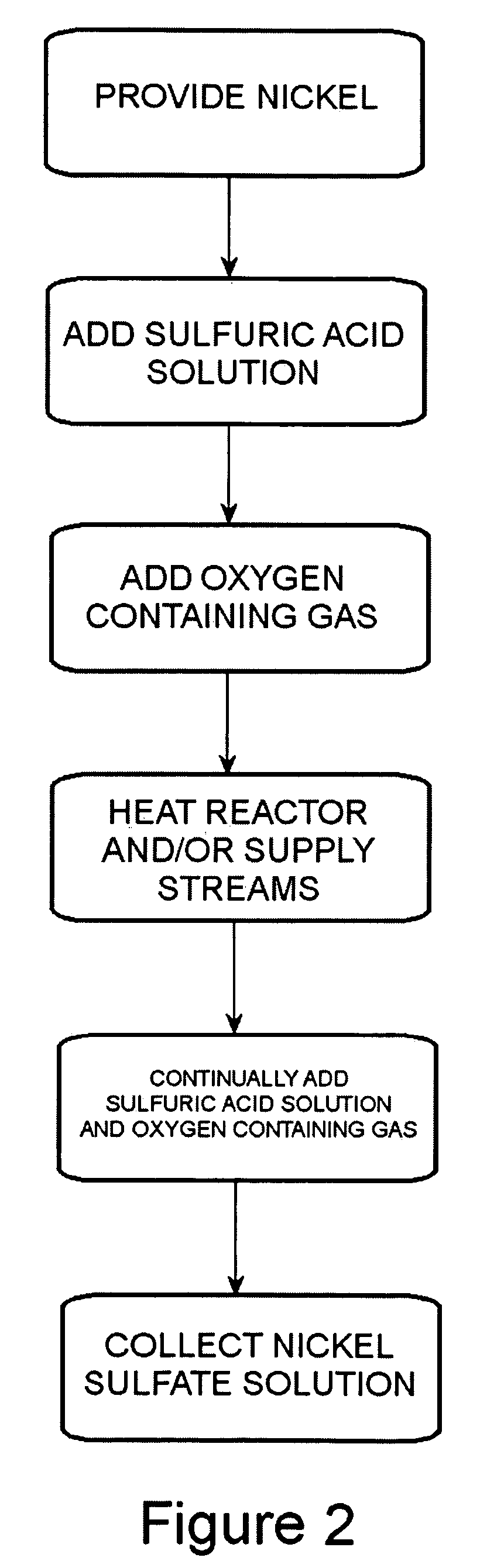

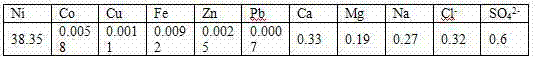

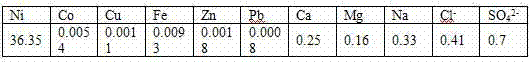

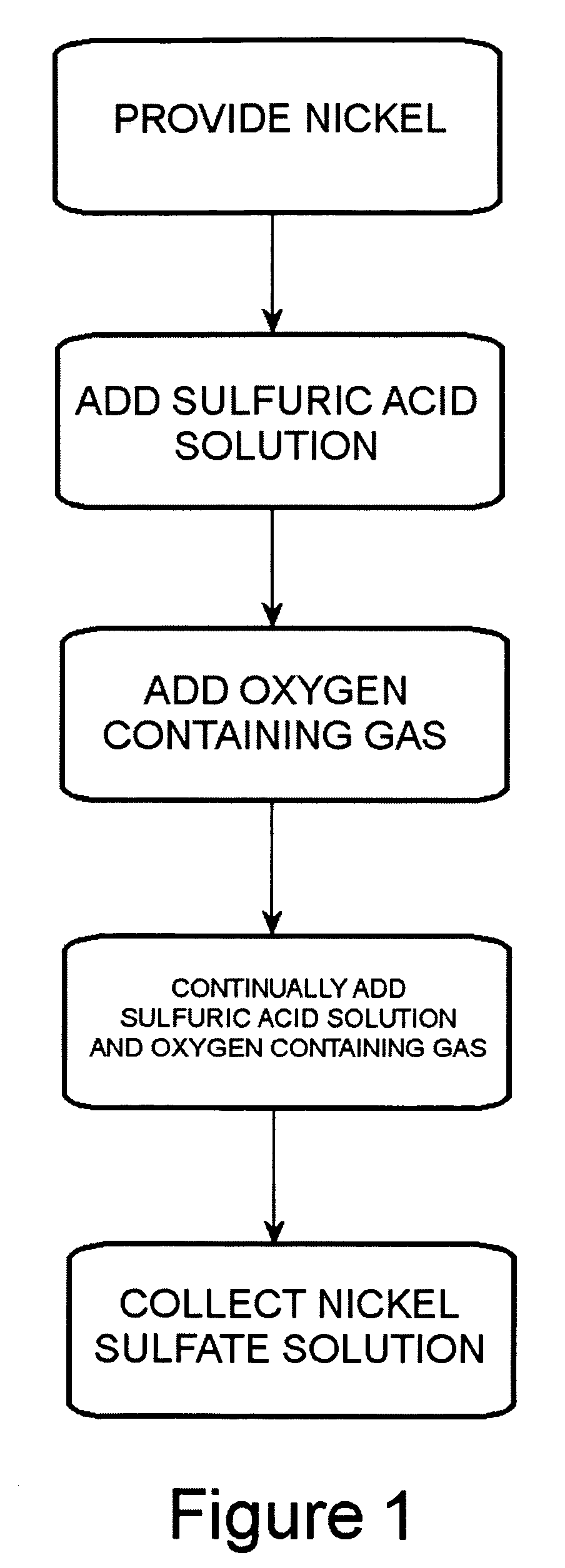

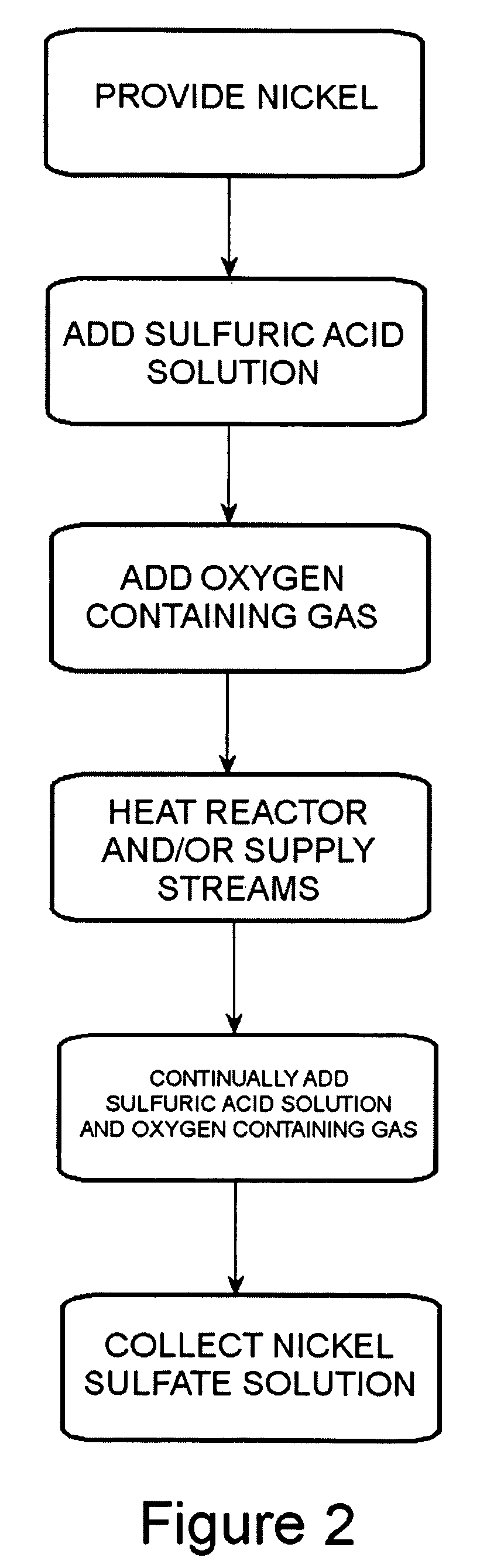

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base: Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

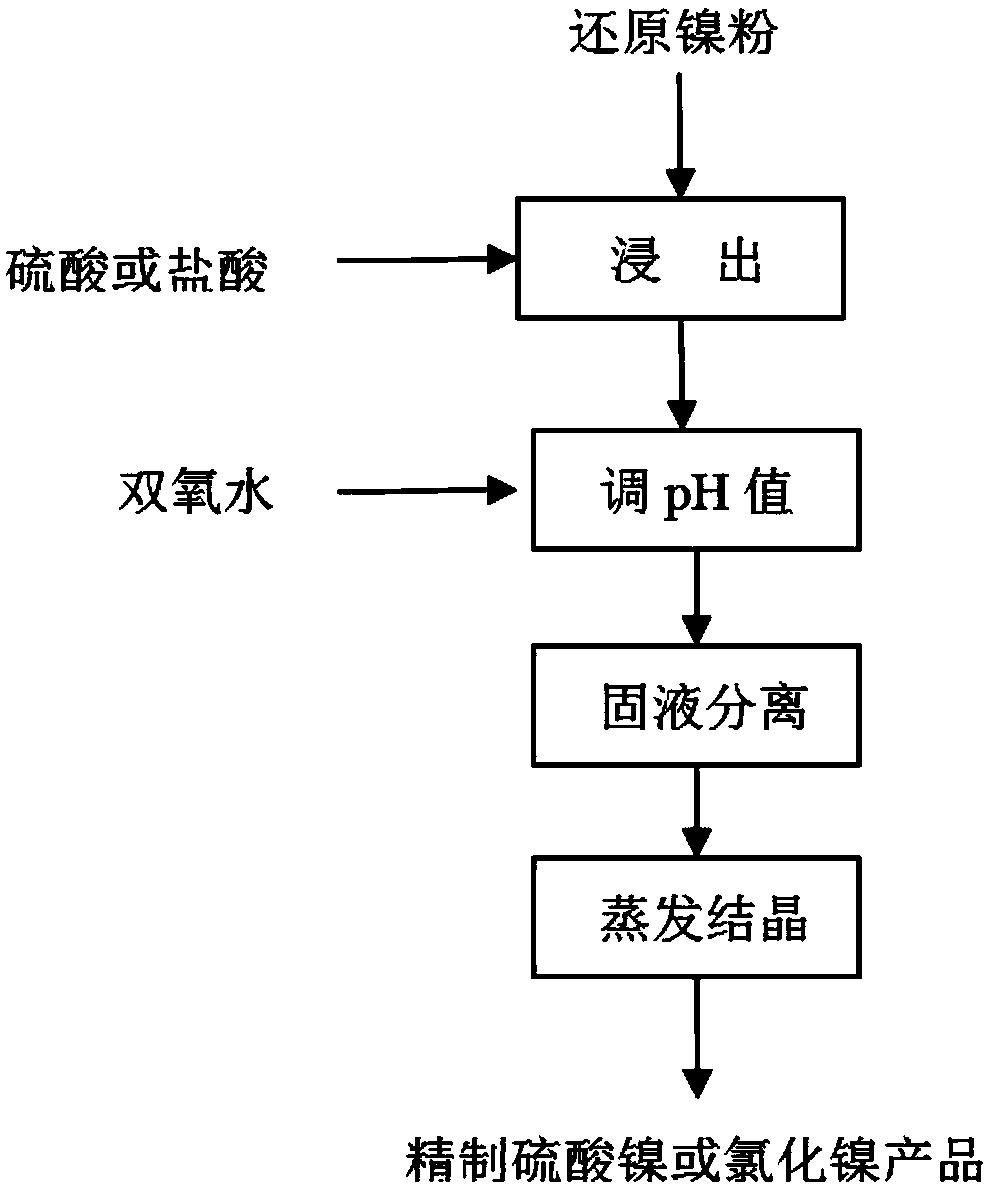

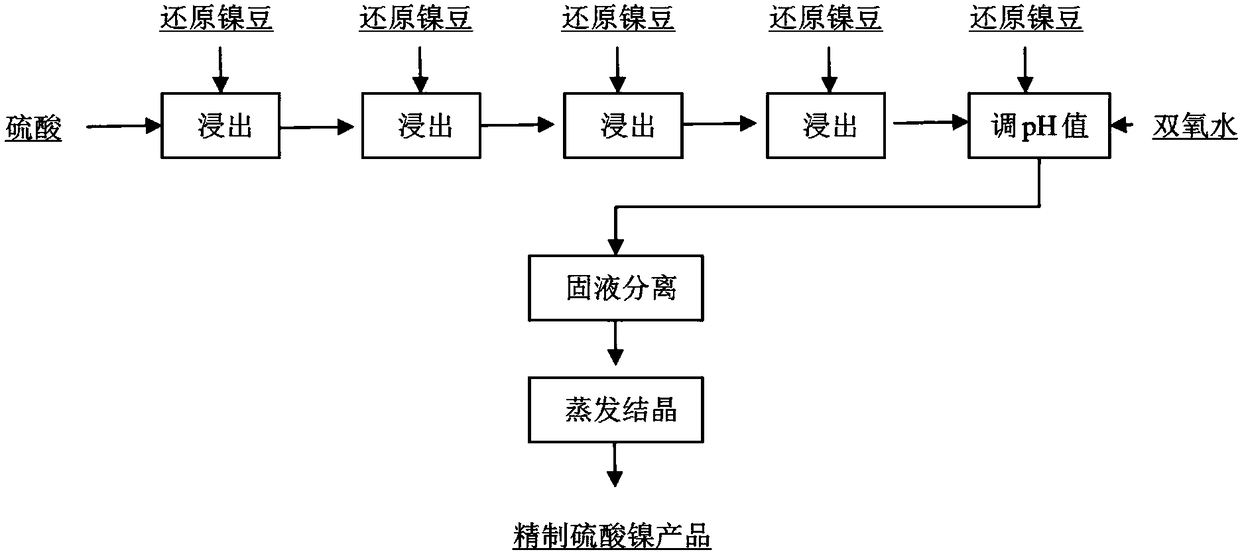

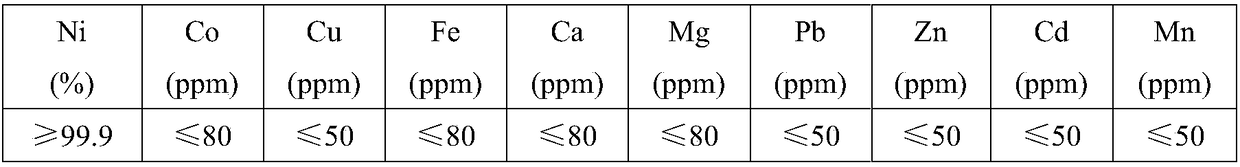

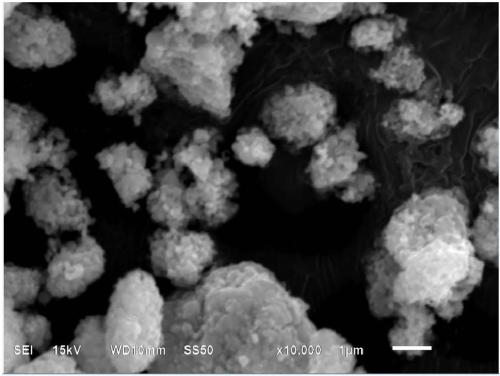

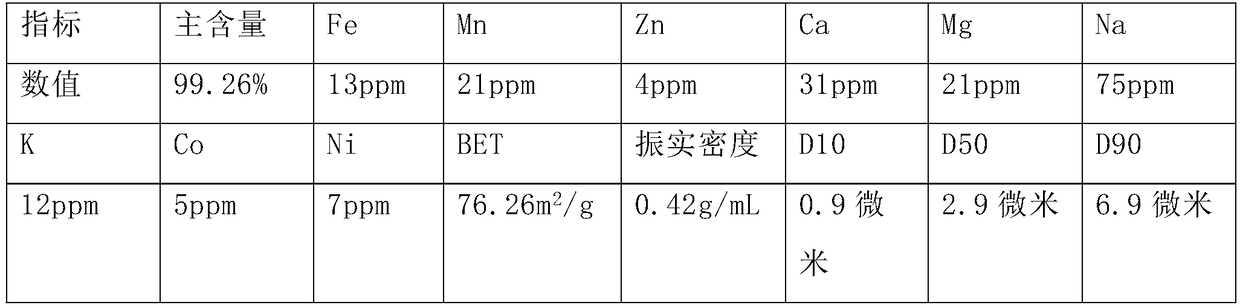

Method for preparing refined nickel salt from reduced nickel powder as raw material and nickel salt prepared with method

InactiveCN108423716AThe process steps are simpleEasy to controlNickel halidesNickel sulfatesManganeseLithium-ion battery

The invention belongs to the technical field of inorganic fine chemical products and discloses a method for preparing refined nickel salt from reduced nickel powder as a raw material and the nickel salt prepared with the method. The method comprises following steps: (1), the reduced nickel powder is leached by acid liquor, and a nickel salt solution is obtained; (2), hydrogen peroxide is added tothe nickel salt solution, and pH is regulated to 4.0-5.5; (3), solid-liquid separation is performed, a liquid is subjected to evaporative crystallization, and the refined nickel salt is obtained. Theinvention further provides the refined nickel salt prepared with the method. The preparation method adopts simple technological steps, the production process is easy to control, an obtained product ishigh in purity, impurities such as calcium, magnesium, iron, copper, zinc and cadmium in the nickel salt product are smaller than 10 ppm, and the product can be used for preparing binary precursors (nickel-cobalt hydroxide and nickel-manganese hydroxide) and a ternary precursor (nickel-cobalt-manganese hydroxide) of a lithium ion battery. According to the method for preparing the refined nickel salt from the reduced nickel powder as the raw material, a new way is provided for preparation of the refined nickel salt.

Owner:HUNAN BRUNP RECYCLING TECH +1

Method of preparing nickel salt from nickel-contained mixed acid waste liquid

InactiveCN1923709AReduce processImprove purification effectNickel halidesNickel sulfatesImpurity ionsMetal

The invention discloses a preparing method of nickel salt (NiSO4 or NiCl2) through waste liquid with compound nickel acid, which comprises the following steps: removing impurity ion such as Cu2+, Co2+, Fe2+, Ca2+ and Mg2+ in the waste liquid; extracting through P2O4; adding metal nickel in the organic phase; draining the extracting phase; adopting acid to proceed back extraction for organic phase; transmitting nickel into clear nickel salt; evaporating; crystallizing to produce metal nickel salt.

Owner:JINCHUAN GROUP LIMITED

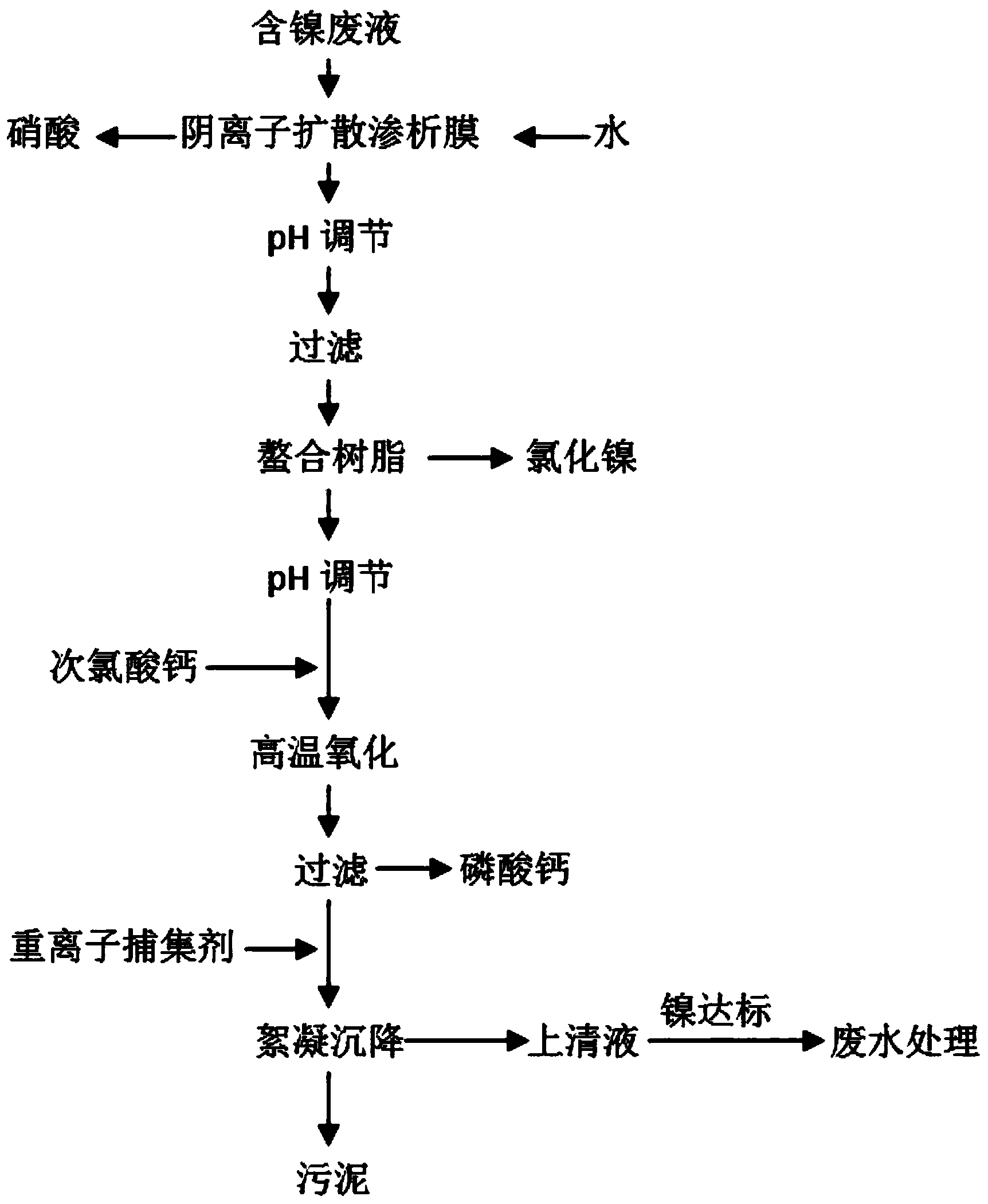

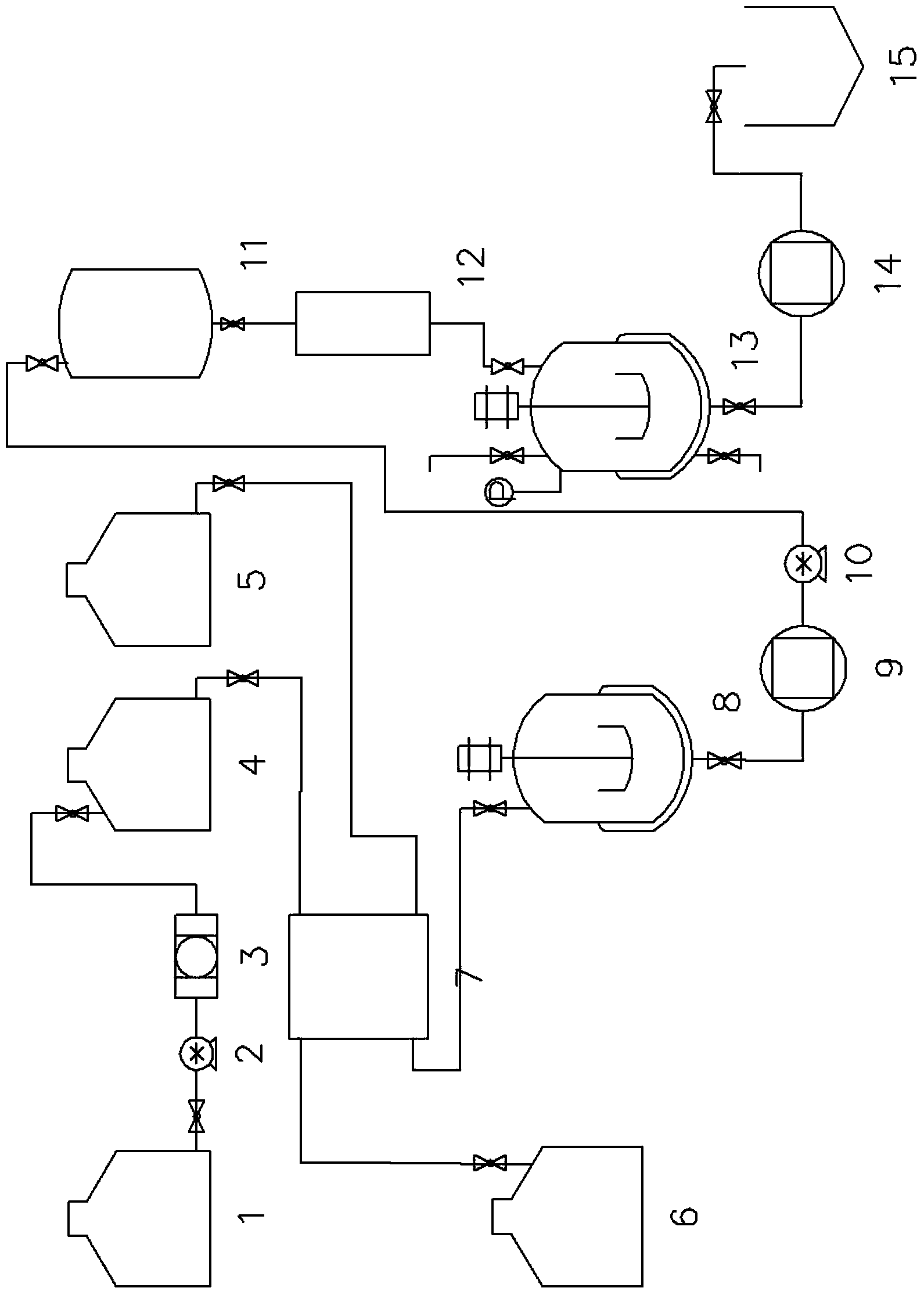

Processing method and corresponding processing system for chemical nickel plating waste liquid containing nitric acids

ActiveCN104291498AReduce CODAchieve recyclingWater contaminantsWater/sewage treatment by ion-exchangeLiquid wasteDialysis membranes

The invention discloses a processing method for chemical nickel plating waste liquid containing nitric acids, and particularly relates to an environmentally-friendly processing method. Considerable integrated environment and economic benefits are generated. The method comprises the following steps: (1) the waste liquid containing nickel is filtered to remove mechanical impurities; (2) the nitric acids are separated from the waste liquid containing the nickel through a diffusion dialysis membrane; (3) the pH of the waste liquid containing the nickel passing through the membrane is adjusted, the pH is adjusted to 3.5-4.0, and then the waste liquid containing the nickel, of which the pH is adjusted, is filtered; (4) the waste liquid containing the nickel passes through chelate resin, so that the nickel is recovered, and then the nickel adsorbed on the resin is eluted by hydrochloric acids to obtain nickel chloride; (5) oxidizers are added to the waste liquid passing through the resin, high-temperature oxidation and dephosphorization are performed, then filtration is performed, precipitates formed by calcium and phosphate are filtered, and calcium phosphate is recovered; (6) heavy metal ion trapping agents are added to filtrate, and a reaction is performed for 30-40 minutes; (7) flocculants PAC and PAM are added to the filtrate for flocculation and sedimentation, and then supernatant which reaches a set standard is discharged.

Owner:昆山市千灯三废净化有限公司

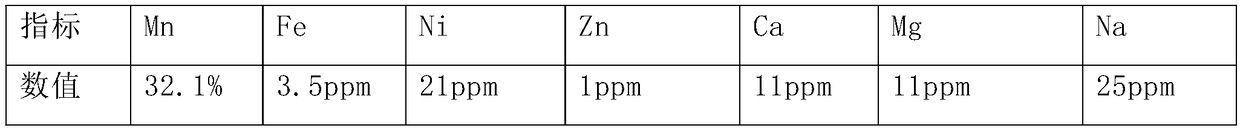

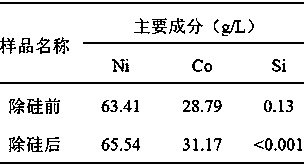

Method for producing nickel chloride solution through leaching nickel hydroxide cobalt with hydrochloric acid

ActiveCN104310495AInhibitionSuppress overflowNickel halidesProcess efficiency improvementPregnant leach solutionChloride

The invention provides a method for producing a nickel chloride solution through leaching nickel hydroxide cobalt with hydrochloric acid. The method comprises the following steps: step one, carrying out two-stage leaching, namely, firstly adding a nickel chloride solution into a reaction kettle, then adding hydrochloric acid and one-stage leaching residue for leaching, always controlling the concentration of [H<+>] of the solution in the reaction kettle to 0.1-0.8mol / L, then filtering the solution by a filter press so as to produce a second-stage leaching liquid and second-stage leaching residue; and step two, carrying out one-stage leaching, namely, adding the second-stage leaching liquid into a one-stage leaching kettle, adding nickel hydroxide cobalt into the one-stage leaching kettle for adjusting the pH value of the solution, after the pH value reaches 3.5-4.0, carrying out filter pressing, so as to produce one-stage leaching liquid and one-stage leaching residue, and eliminating impurities of the one-stage leaching liquid so as to obtain the product nickel chloride solution. The method can effectively prevent generation and overflowing of chlorine in leaching; furthermore, the second-stage leaching residue formed in the leaching process contains little nickel, so that the method can effectively improve the leaching rate of the nickel.

Owner:金川集团镍盐有限公司

Method for treating lithium nickel manganese cobalt oxide ternary waste

The invention discloses a method for treating lithium nickel manganese cobalt oxide ternary waste. The method is as below: dissolving ternary waste with alkali, dissolving amphoteric aluminum in the solution to separate the aluminum from other components, and then reducing the solid after aluminum separation in a reduction furnace; then adding reduced materials to pure water for washing; dissolving lithium oxide in hot pure water to obtain lithium hydroxide, thereby realizing separation of lithium from nickel-cobalt-manganese; controlling addition amount of sulfuric acid and pH value at a final process and an end point to separate highly active metal manganese from nickel and cobalt; pulpifying slag after separation of manganese, conducting electromagnetic separation to obtain electromagnetic separation materials, and then dissolving the electromagnetic separation materials in hydrochloric acid; and introducing chlorine gas into the obtained nickel-cobalt solution at a certain temperature and pressure to oxidize and hydrolyze cobalt ions into trivalent cobalt precipitates, thereby achieving the separation of nickel and cobalt. The method has the advantages of a short process, a small amount of waste water generation and high material recovery rate; and the obtained products are all battery grade, and have high added value.

Owner:中燃能环保能源(山东)有限公司

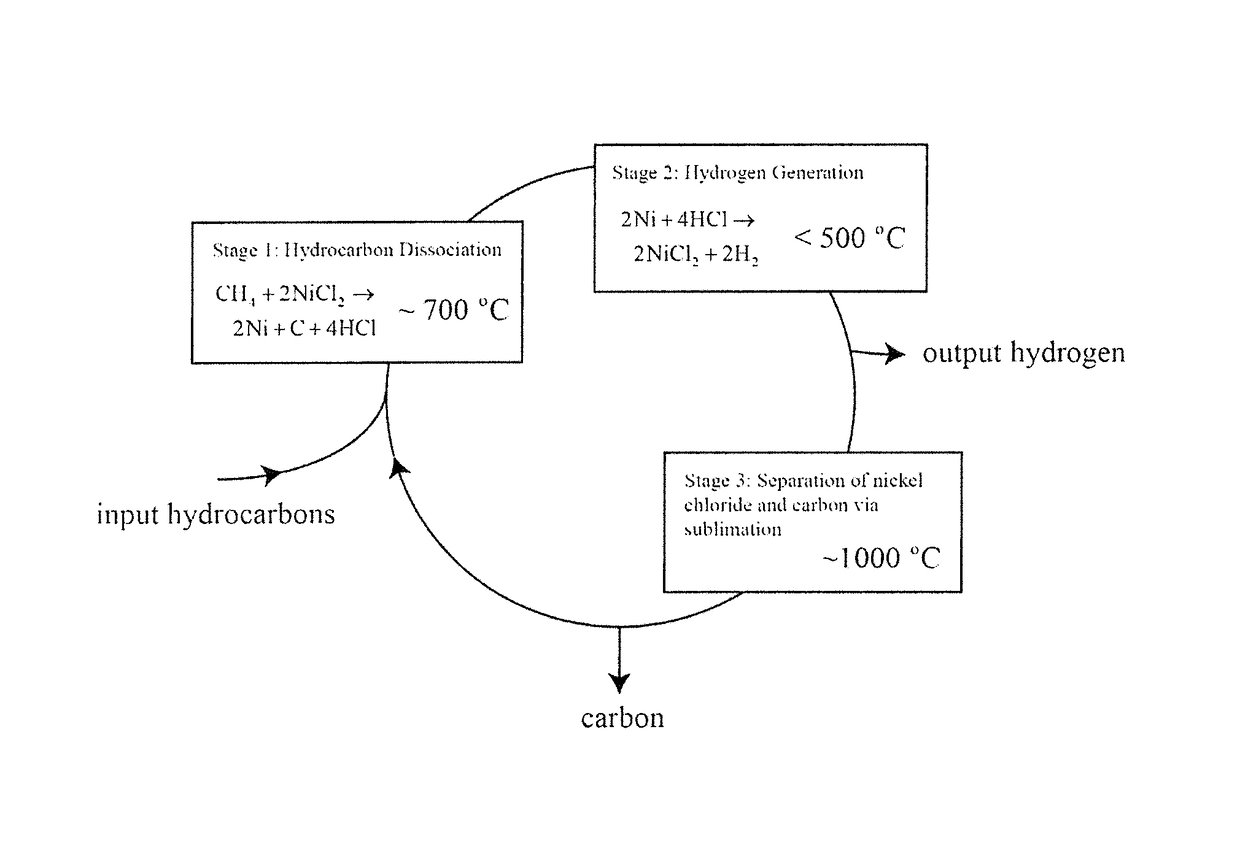

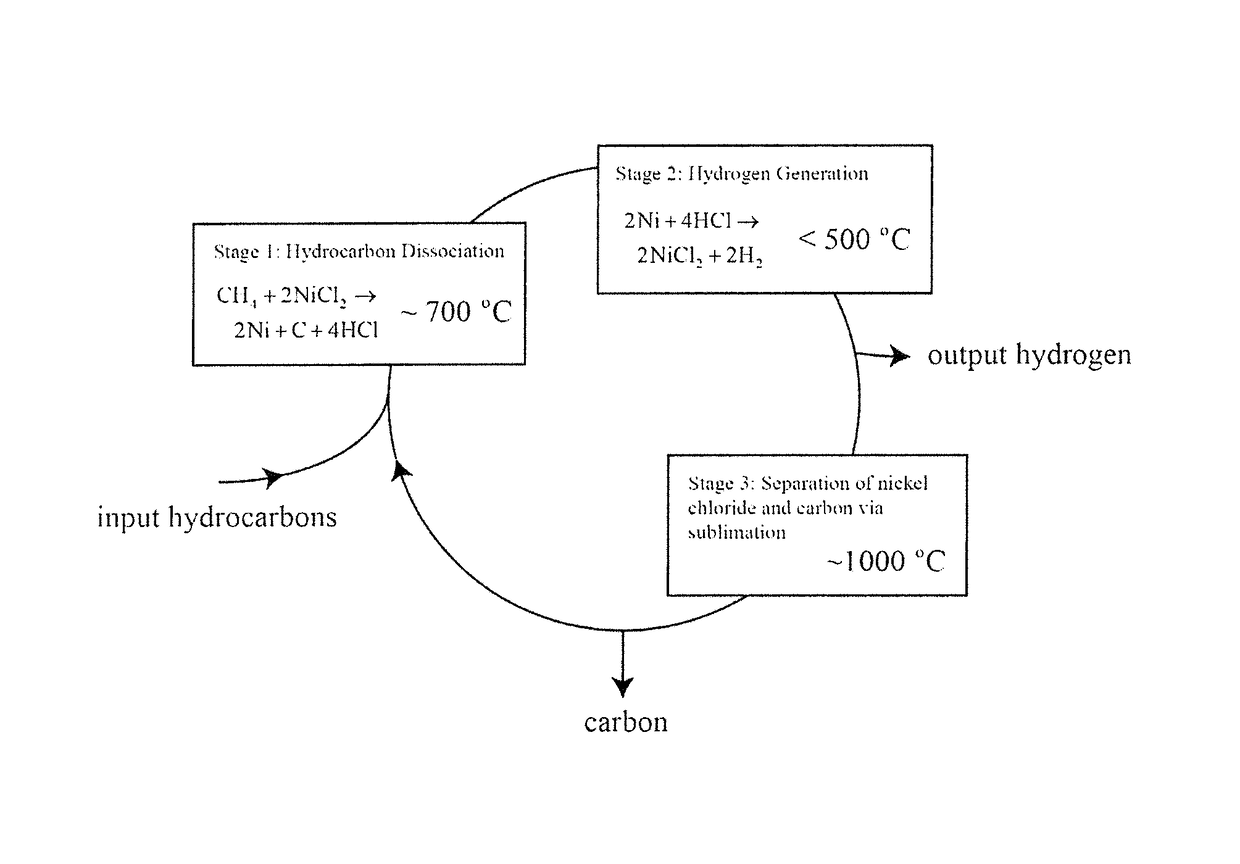

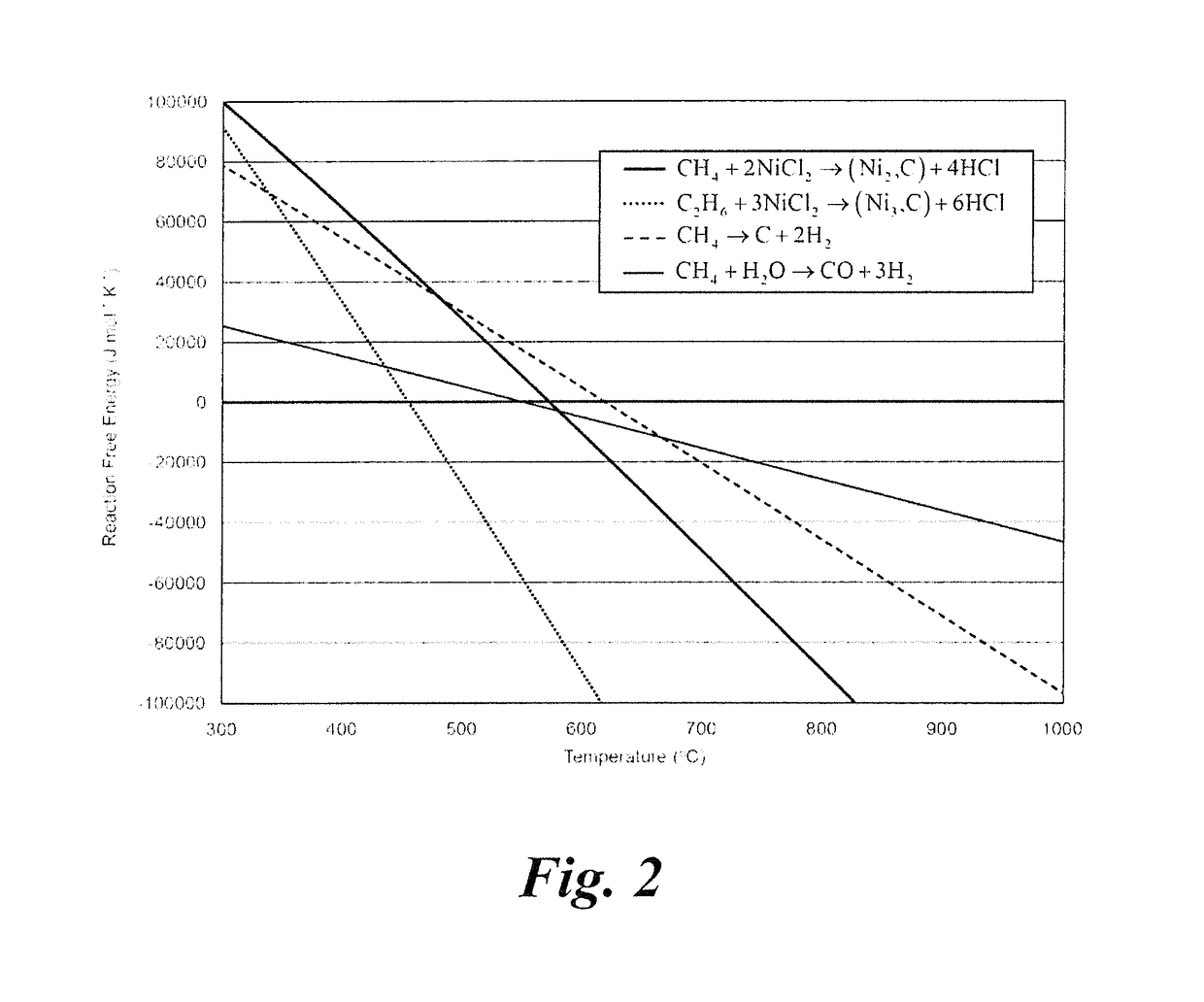

Method of carbon dioxide-free hydrogen production from hydrocarbon decomposition over metal salts

A process to decompose methane into carbon (graphitic powder) and hydrogen (H2 gas) without secondary production of carbon dioxide, employing a cycle in which a secondary chemical is recycled and reused, is disclosed.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

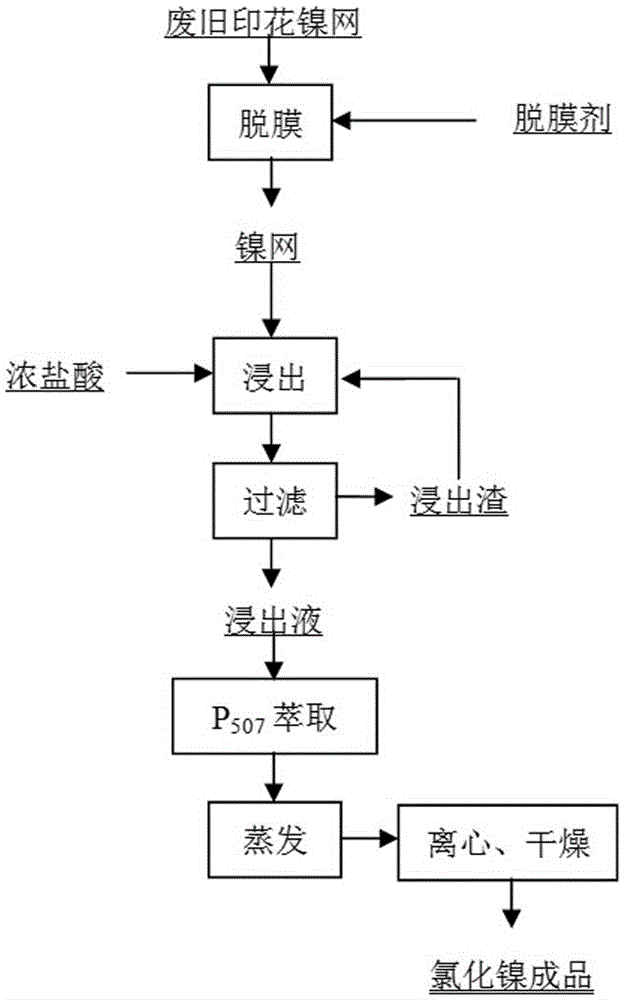

Method used for producing nickel chloride products taking waste printing nickel screens as raw materials

The invention relates to a method used for producing nickel chloride products taking waste printing nickel screens as raw materials, and belongs to the field of hydrometallurgy. According to the method, cyclic utilization of waste printing nickel screens is realized, and the waste printing nickel screens are taken as the raw materials to produce the nickel chloride products. The mehod comprises following steps: the waste printing nickel screens are processed with a release agent so as to remove photoresist on the surfaces of the waste printing nickel screens, and then are subjected to leaching treatment with industrial hydrochloric acid; an obtained leached solution is subjected to extraction with P507 extraction agent so as to remove impurities until the content of impurities in an obtained extraction raffinate is capable of satisfying requirements on the content in nickel chloride product production; and the extraction raffinate is subjected to evaporation, crystallization, centrifugalization, and drying so as to obtain the qualified nickel chloride products. The method is capable of realizing cyclic utilization of the waste printing nickel screens, and broadening the sources of raw materials used for producing the nickel chloride products.

Owner:JINCHUAN GROUP LIMITED

Process for chlorinating resources containing recoverable metals

A process for chlorinating ore, slag, mill scale, scrap, dust and other resources containing recoverable metals from the groups 4-6, 8-12, and 14 in the periodic table. The process comprises: a) forming a liquid fused salt melt consisting essentially of aluminum chloride and at least one other metal chloride selected from the group consisting of alkali metal chlorides and alkaline earth metal chlorides, wherein the aluminum chloride content in the liquid salt melt exceeds 10% by weight; b) introducing the recoverable metal resources into said liquid salt melt: c) reacting the aluminum chloride as chlorine donor with said recoverable metal resource to form metal chlorides, which are dissolved in the salt melt; and d) recovering the formed metal chlorides from the salt melt.

Owner:P M TECH

Telescoped multiwall nanotube and manufacture thereof

The invention relates to a method for forming a telescoped multiwall nanotube. Such a telescoped multiwall nanotube may find use as a linear or rotational bearing in microelectromechanical systems or may find use as a constant force nanospring. In the method of the invention, a multiwall nanotube is affixed to a solid, conducting substrate at one end. The tip of the free end of the multiwall nanotube is then removed, revealing the intact end of the inner wall. A nanomanipulator is then attached to the intact end, and the intact, core segments of the multiwall nanotube are partially extracted, thereby telescoping out a segment of nanotube.

Owner:RGT UNIV OF CALIFORNIA

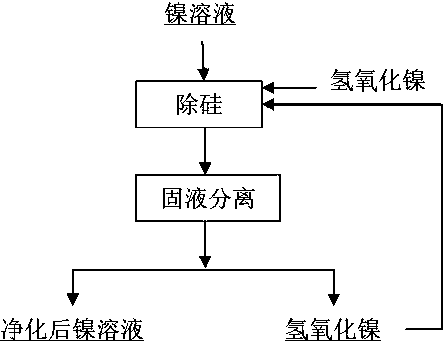

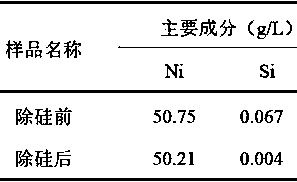

Method for adsorbing and removing silicon from nickel solution

InactiveCN110812888ASolve the problem of deep silicon removalStable pHIon-exchange process apparatusIon-exchanger regenerationSilicone GelsSorbent

The invention relates to a method for adsorbing and removing silicon from a nickel solution. According to the method, a prefabricated colloidal nickel hydroxide precipitate is used as an adsorbent, and adsorbs a silica gel in a nickel solution under a certain condition, and solid-liquid separation is performed to achieve the purpose of deep silicon removal, wherein the silicon content in the nickel solution can be reduced to less than 0.005 g / L from about 1 g / L, and the yield of the valuable metal nickel is more than 99%. According to the invention, the method for deep purification and siliconremoval is simple and easy to implement, other impurities cannot be introduced, the direct recovery rate of the valuable metal is high, the next procedure is facilitated, and the industrial continuous production can be achieved.

Owner:JINCHUAN GROUP LIMITED +1

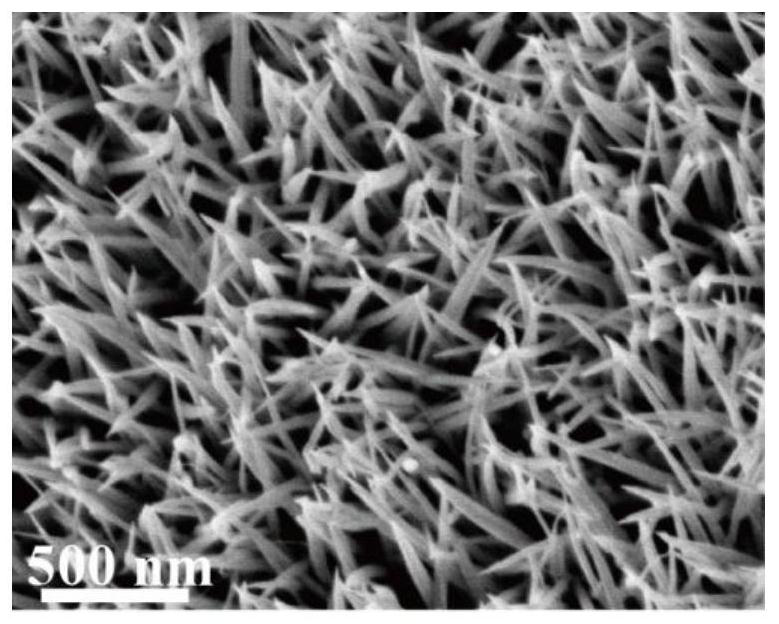

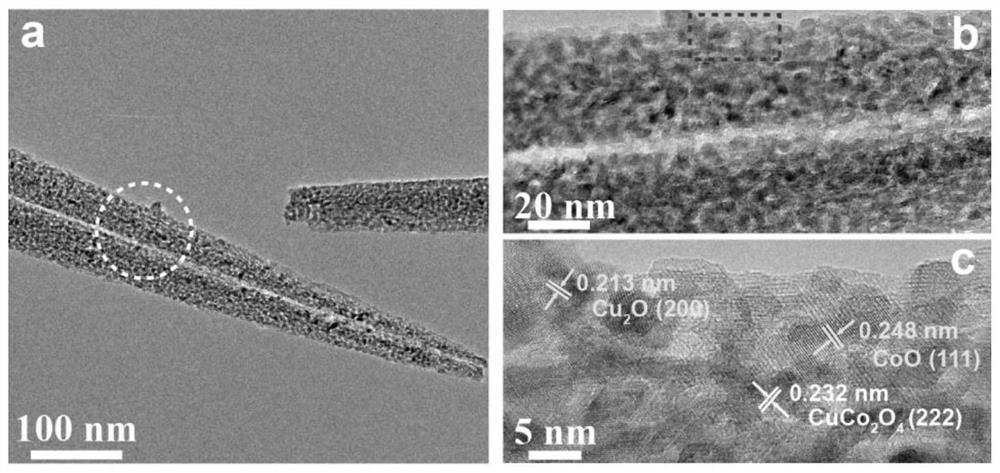

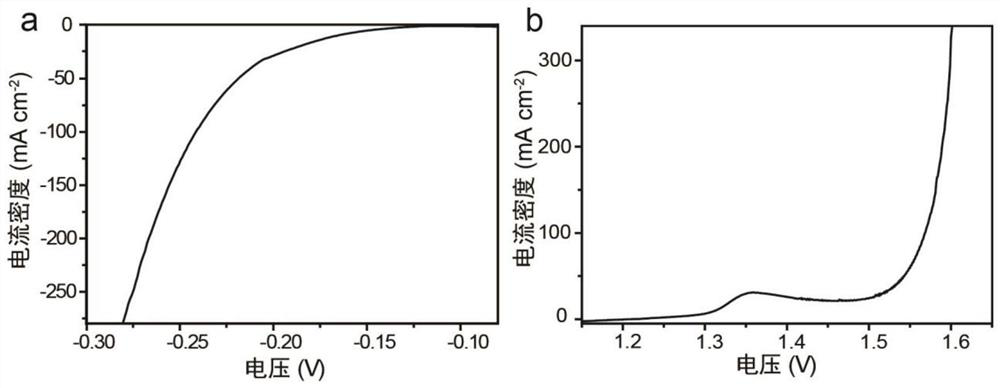

Bifunctional water decomposition nano material based on metal oxide and preparation method thereof

InactiveCN111777102ARegular structureStable structureNanotechnologyIron compoundsCatalytic decompositionPhysical chemistry

The invention belongs to the technical field of nano-materials, and particularly relates to a bifunctional water decomposition nano material based on metal oxide and a preparation method thereof. A commercial current collector is selected as a substrate, a chemical coprecipitation method is used for preparing a nano material precursor containing two or more metal ions, and then the corresponding metal oxide nano material is obtained through a thermal conversion method according to different thermal decomposition properties of different metal precursors. According to the prepared material, themetal oxide with high H * adsorption capacity can be integrated into a material system with excellent electrocatalytic oxygen production property so that the material finally has the capacity of catalytically decomposing water for hydrogen evolution and producing oxygen at the same time, and thus the purpose of completely decomposing water in an alkaline environment is achieved. The material prepared in the invention has the advantages of strong binding force with a current collector, regular and ordered structure, excellent conductivity and good mechanical and chemical stability, and the method has the advantages of simple process, low energy consumption, safety, reliability, convenience in large-scale preparation, and facilitation of popularization and application.

Owner:FUDAN UNIV

Nickel fluoride preparation method

The invention relates to a nickel fluoride preparation method, and relates to a hydrometallurgy nickel fluoride preparation method, and the method is characterized in that: in the preparation process, nickel fluoride is prepared from nickel carbonate and ammonium fluoride as raw materials by four steps of nickel carbonate slurrying, synthesis preparation, purification and impurity removal, and filtering and washing and drying. The specific method is as follows: the nickel fluoride is prepared from the nickel carbonate and the ammonium fluoride as the raw materials by four steps of nickel carbonate slurrying, synthesis preparation, purification and impurity removal, and filtering and washing and drying, in the preparation process, an auxiliary material is a soluble carbonate, no fluorine gas, hydrofluoric acid and other strong corrosive materials is used, and compared with the traditional process, the method has high safety, low equipment requirement, simple operation, high product quality and other advantages.

Owner:JINCHUAN GROUP LIMITED

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base:Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

Treatment method of fluorine-containing nickel slag generated in nitrogen trifluoride preparation process

ActiveCN112645396AImprove solubilityEasy to operateIron oxides/hydroxidesNickel halidesFerric hydroxideSlag

The invention relates to a treatment method of fluorine-containing nickel slag generated in a nitrogen trifluoride preparation process, and belongs to the technical field of harmless treatment of nickel-containing hazardous wastes. The method comprises the following steps: (1) crushing the fluorine-containing nickel slag into solid powder; (2) dissolving the fluorine-containing nickel slag solid powder by using a hydrofluoric acid solution, performing stirring at 30-60 DEG C, and adding an oxidizing substance in the stirring dissolution process until the fluorine-containing nickel slag is completely dissolved to obtain a mixed solution a; (3) adjusting the pH value of the mixed solution a to 3.5-4.5 by using ammonia water, and performing filtering to obtain ferric hydroxide precipitate and a mixed solution b; and (4) continuing to adjust the pH value of the mixed solution b to 6.5-7.5 with the ammonia water, performing filtering to obtain nickel fluoride and a mixed solution c, heating and concentrating the mixed solution c, and performing cooling crystallizing to obtain ammonium fluoride and a mixed solution d. The method realizes recovery and cyclic utilization of nickel metal resources and ammonium fluoride, and can significantly reduce the production cost of nitrogen trifluoride.

Owner:PERIC SPECIAL GASES CO LTD

Preparation method of transition metal fluoride

ActiveCN109081383AHigh crystallinityEasy to operateCobalt halidesNickel halidesHigh volume manufacturingPhysical chemistry

The invention discloses a preparation method of a transition metal fluoride, comprising: mixing a transition metal precursor and ammonium fluoride in a mass ratio of 1:(5-20) or placing them with oneupstream and the other downstream, pyrolyzing at 250 DEG C and above, washing with water, filtering, and drying to obtain the transition metal fluoride. The preparation method is simple to perform; afluorine source and transition metal material herein are simple; the cost is low; the transition metal fluoride has good crystallizing performance and is suitable for batch production.

Owner:YANGZHOU UNIV

Method of removing iron from nickel chloride leachate

A method to remove iron in nickelous chloride lixivium relates to a method to remove impurities from chlorination medium, in particular to a method to remove iron in nickelous chloride lixivium, which is characterized in that: the chlorination lixivium is heated to 85-95 DEG C, chlorine is pumped into the chlorination lixivium, oxidation-reduction potential is controlled to be 650-750mv, Fe2+ in the chlorination lixivium is oxidized into Fe3+, pH value of the solution is adjusted to 3.0-4.0 by nickel carbonate, then the nickel carbonate is stopped to added and Fe(OH)3 is generated, the reaction lasts for 2-4 hours and the nickelous chloride solution containing less than 0.006g / l iron is obtained after the separation of solid and liquid. The method of the invention realizes that the complete degree of iron removal is not affected by the iron concentration of the chlorination solution and meets the requirements of deep purifying iron in nickelous chloride solution.

Owner:JINCHUAN GROUP LIMITED

Popular searches

Organic-compounds/hydrides/coordination-complexes catalysts Nickel organic compounds Catalyst activation/preparation Catalytic reactions Preparation by hydrogen cyanide addition Iron halides Water/sewage treatment by extraction Water/sewage treatment by oxidation Selenium/tellurium compunds Titanium oxides/hydroxides

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com