Preparation method of transition metal fluoride

A transition metal and transition metal salt technology, applied in metal material coating process, nickel halide, iron halide and other directions, can solve the problem of uncontrollable purity of synthetic materials, and achieve the effects of low cost, simple raw materials and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of cobalt fluoride supported on nickel foam: deposit 100mg of cobalt hydroxide precursor on nickel foam, and place 2g of ammonium fluoride upstream and downstream, place it in an inert atmosphere tube furnace, and conduct pyrolysis treatment at 350°C for 120 Minutes later, the mixture was washed with deionized water, filtered and dried to obtain cobalt fluoride supported on nickel foam.

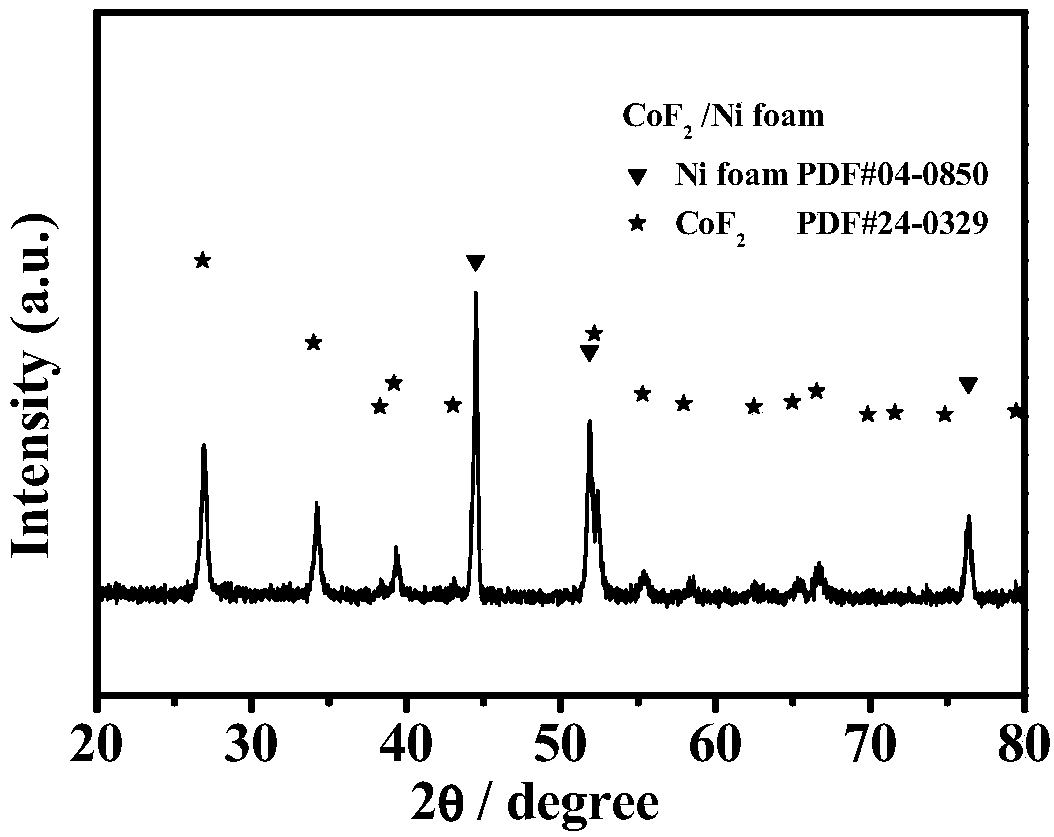

[0024] figure 1 This is the XRD pattern of the nickel foam material loaded with cobalt fluoride. It can be seen from the figure that only the characteristic peaks of cobalt fluoride and nickel foam exist, and there are no other impurity phases, which proves that the cobalt fluoride material has been successfully synthesized.

Embodiment 2

[0026] Preparation of cobalt fluoride / nickel fluoride: place 100mg of transition metal precursor (cobalt nitrate and nickel nitrate molar ratio is 1:1) and 2g of ammonium fluoride upstream and downstream, and place them in an inert atmosphere tube furnace at 350°C After pyrolysis treatment for 120 minutes, the mixture was washed with deionized water, filtered and dried to obtain a cobalt fluoride / nickel fluoride mixture.

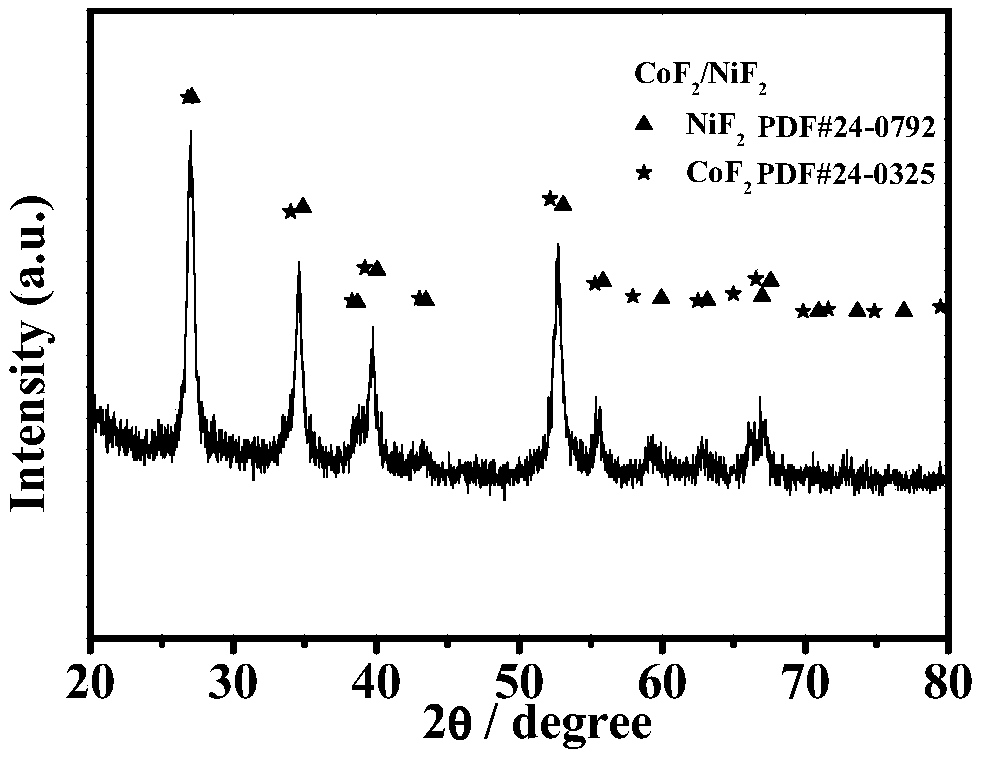

[0027] figure 2 is the XRD pattern of the cobalt fluoride / nickel fluoride mixture material obtained, it can be seen from the figure that only the characteristic peaks of the cobalt fluoride / nickel fluoride mixture exist, and the cobalt fluoride / nickel fluoride mixture material is synthesized in one step.

Embodiment 3

[0029] Preparation of cobalt fluoride: mix 100mg of cobalt oxide precursor and 500mg of ammonium fluoride, place in an inert atmosphere tube furnace, and after pyrolysis treatment at 350°C for 120 minutes, wash the mixture with deionized water, filter and dry Cobalt fluoride can be obtained.

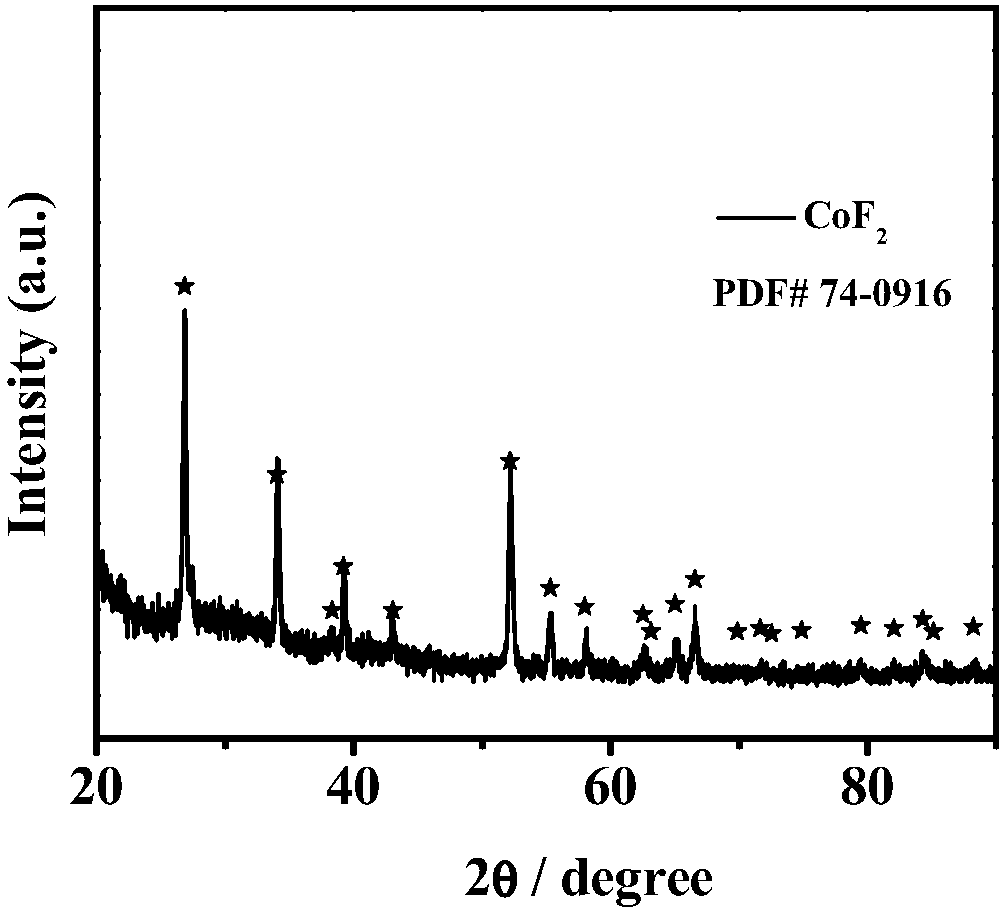

[0030] image 3 It is the XRD figure of the prepared cobalt fluoride, it can be seen from the figure that only the characteristic peaks of cobalt fluoride exist.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com