Method for adsorbing and removing silicon from nickel solution

A nickel solution and solution technology, applied in the field of deep silicon removal, can solve the problems of increasing the burden of impurity removal and not being able to achieve deep desiliconization, and achieve the effect of industrialized continuous production, high direct yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

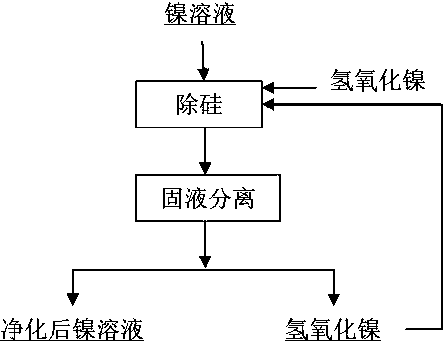

Method used

Image

Examples

Embodiment 1

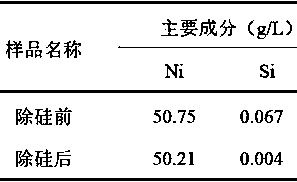

[0016] Weigh 5g of sodium hydroxide, add 20mL of water to prepare a 250g / L sodium hydroxide solution, use nickel sulfate crystals (99% purity) to prepare a nickel sulfate solution with a concentration of 25g / L, take 300mL of nickel sulfate solution, and heat to 50°C , while stirring, add the prepared sodium hydroxide solution, stir and react for 2 hours, carry out vacuum filtration, and wash the nickel hydroxide colloid precipitate with hot pure water for 2 to 3 times after solid-liquid separation. Take 1L of silicon-containing nickel sulfate solution, heat it to 50°C, add the above-mentioned nickel hydroxide colloidal precipitation while stirring, stir and react for 2 hours, perform vacuum filtration, and wash the filter residue after solid-liquid separation with hot pure water 2 to 3 times. The comparison of solution indicators before and after silicon removal is shown in Table 1. The nickel yield calculated from the volume of the solution before and after silicon removal an...

Embodiment 2

[0020] Weigh 8g of sodium hydroxide, add 20mL of water to prepare a 400g / L sodium hydroxide solution, use nickel sulfate crystals to prepare a nickel sulfate solution with a concentration of 20g / L, take 600mL of nickel sulfate solution, heat to 80°C, and stir Add the prepared sodium hydroxide solution, stir and react for 2 hours, then carry out suction filtration under reduced pressure, and wash the nickel hydroxide colloidal precipitate after solid-liquid separation with hot pure water for 2 to 3 times. Take 2L of silicon-containing nickel chloride solution, heat it to 80°C, and add the above-mentioned nickel hydroxide colloidal precipitation while stirring. After stirring and reacting for 3 hours, carry out vacuum filtration, and the filter residue after solid-liquid separation is washed with hot pure water for 2~3 Second-rate. The comparison of solution indexes before and after silicon removal is shown in Table 2. When the reaction temperature is high, the concentration of ...

Embodiment 3

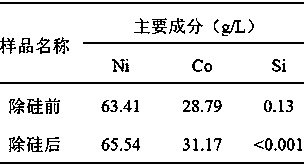

[0024] Weigh 150g of sodium hydroxide, add 375mL of water to prepare a 400g / L sodium hydroxide solution, use nickel sulfate crystals to prepare a nickel solution with a concentration of 25g / L, take 9L of nickel sulfate solution, heat it to 70°C, and add it while stirring After the prepared sodium hydroxide solution was stirred and reacted for 2 hours, vacuum filtration was performed, and the nickel hydroxide colloid precipitate after solid-liquid separation was washed with hot pure water for 2 to 3 times. Take 70L of silicon-containing nickel-cobalt sulfate solution, heat it to 70°C, add the prepared sodium hydroxide solution while stirring, stir and react for 5 hours, then carry out pressure filtration, and wash the filter residue after solid-liquid separation with hot pure water for 2~3 Second-rate. The comparison of solution indexes before and after silicon removal is shown in Table 3. When the reaction temperature is high, the concentration of nickel in the solution after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com