Method for removing silicon from nickel solution through deep purification

A technology of deep purification and nickel solution, applied in the direction of improving process efficiency, can solve the problem of lack of nickel solution deep silicon removal method, etc., and achieve the effect of good impurity removal effect, cost reduction and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

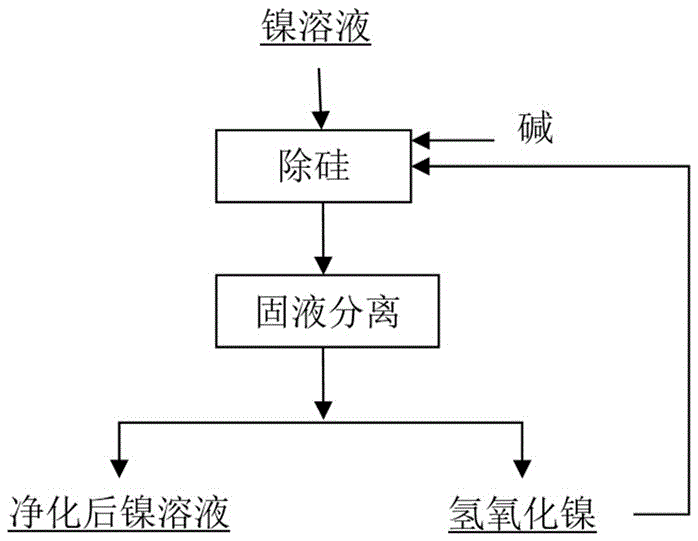

Method used

Image

Examples

Embodiment 1

[0019] Weigh 5 g of sodium hydroxide, add 20 mL of water to prepare a 250 g / L sodium hydroxide solution, and take 1 L of silicon-containing nickel sulfate solution.

[0020] Solution heating: Put the silicon-containing nickel sulfate solution in a container and heat it to 50°C.

[0021] Adjust the pH value: add an appropriate amount of alkaline substances, and stir evenly during the addition of alkaline substances until the pH value of the solution remains at 4. When the pH value of the solution is stable, continue to stir for 2 hours.

[0022] Separation of reactants: vacuum suction filtration is performed on the substance that has been operated in step B to obtain purified nickel solution and nickel hydroxide slag. The nickel hydroxide slag can be reused 3 to 4 times after being washed 2 to 3 times with hot pure water. The nickel hydroxide slag is all added to the solution to be removed before adding the sodium hydroxide solution.

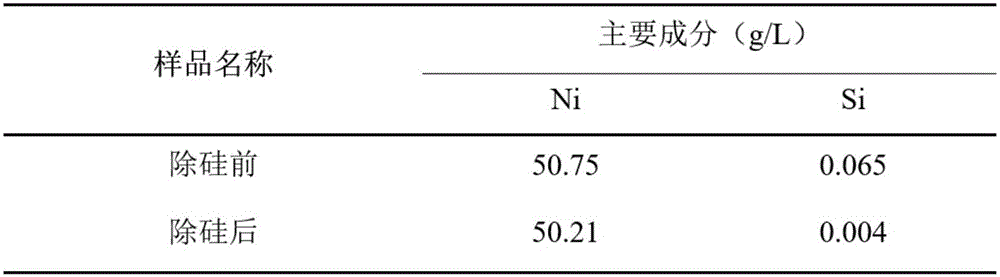

[0023] The comparison of solution indica...

Embodiment 2

[0027] Weigh 8 g of sodium hydroxide, add 20 mL of water to prepare a 400 g / L sodium hydroxide solution, and take 2 L of silicon-containing nickel chloride solution.

[0028] Solution heating: Put the silicon-containing nickel chloride solution in a container and heat it to 80°C.

[0029] Adjust the pH value: add an appropriate amount of alkaline substances, the process of adding alkaline substances is accompanied by uniform stirring, until the pH value of the solution remains at 5, when the pH value of the solution is stable, continue to stir for 10 hours.

[0030] Separation of reactants: vacuum suction filtration is performed on the substance that has been operated in step B to obtain purified nickel solution and nickel hydroxide slag.

[0031] The nickel hydroxide slag can be reused 3 to 4 times after being washed 2 to 3 times with hot pure water. The nickel hydroxide slag is all added to the solution to be removed before adding the sodium hydroxide solution.

[0032] Th...

Embodiment 3

[0036] Weigh 150 g of sodium hydroxide, add 375 mL of water to prepare a 400 g / L sodium hydroxide solution, and take 70 L of silicon-containing nickel-cobalt sulfate solution.

[0037] Solution heating: Put silicon-containing nickel-cobalt sulfate in a container and heat to 70°C.

[0038] Adjust the pH value: add an appropriate amount of alkaline substances, and the process of adding alkaline substances is accompanied by uniform stirring until the pH value of the solution remains at 5.5. When the pH value of the solution is stable, continue to stir for 5 hours.

[0039] Separation of reactants: press-filter the material that has been operated in step B to obtain purified nickel solution and nickel hydroxide slag.

[0040] The nickel hydroxide slag can be reused 3 to 4 times after being washed 2 to 3 times with hot pure water. The nickel hydroxide slag is all added to the solution to be removed before adding the sodium hydroxide solution.

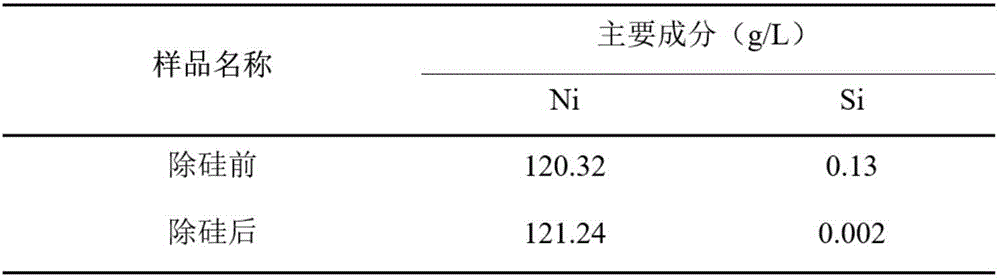

[0041] The comparison of solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com