Bifunctional water decomposition nano material based on metal oxide and preparation method thereof

A technology of nano-materials and oxides, applied in the field of nano-materials, can solve the problems of low catalytic hydrogen evolution efficiency and achieve the effects of good order, easy promotion and application, and large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

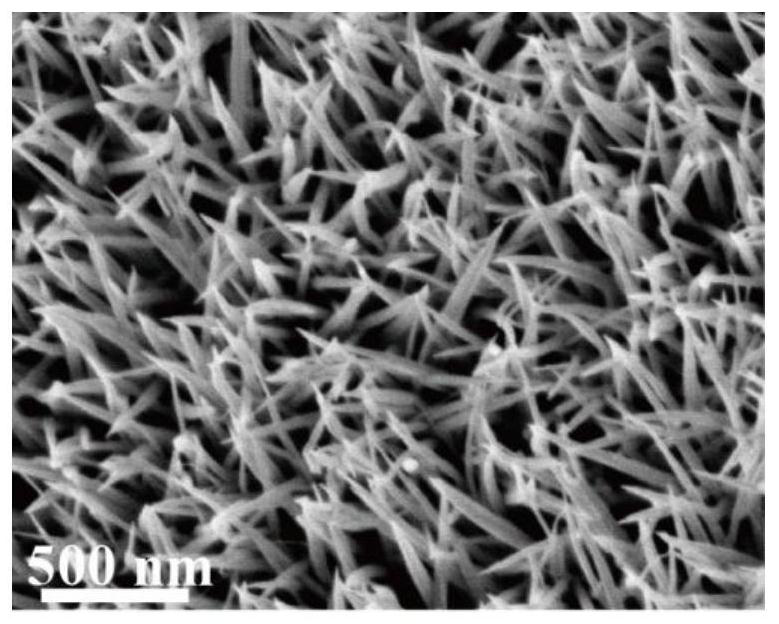

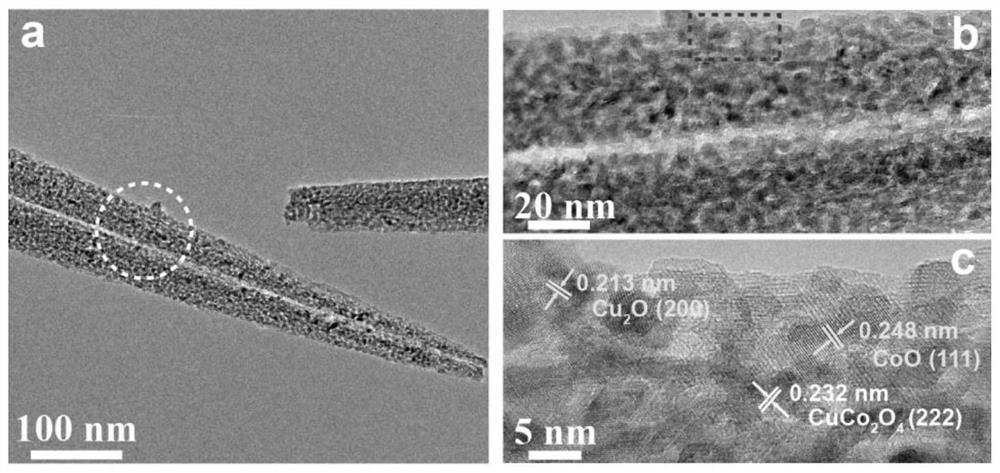

[0029] A preparation method based on metal oxide dual-function water splitting catalyst, the specific steps are as follows:

[0030] (A) Preparation of metal hydroxide precursor

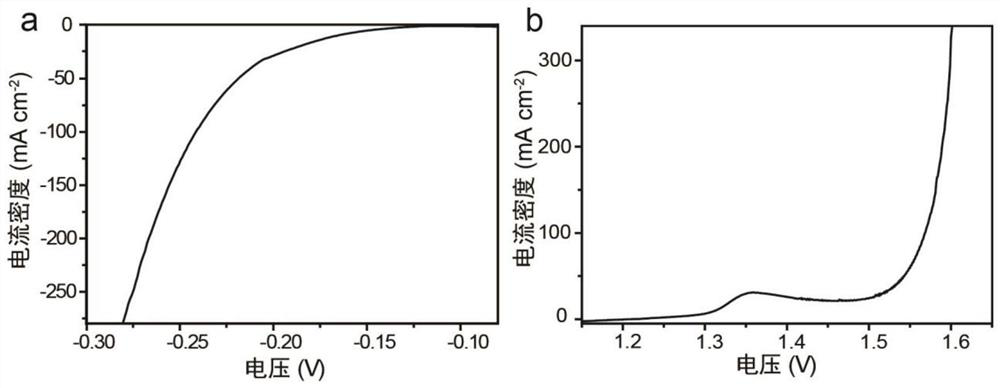

[0031] The commercial nickel foam substrate is washed in dilute acid solution and deionized water to remove impurities on the surface, and finally dried with inert gas for use. Add 1.0 mmol Co(NO 3 ) 2 , 0.5mmol Cu(NO 3 ) 2 , 6 mmol urea was dissolved in 40 mL of deionized water solution and stirred for 15 min to obtain a dispersed mixed solution. Then put the cleaned foamed nickel substrate into a high-temperature hydrothermal reactor. The above dispersion solution was added to a high temperature hydrothermal reaction kettle with a foamed nickel substrate, and reacted at 120 ℃ for 6 h. After the reaction is finished, it is naturally cooled, and the substrate on which the metal hydroxide precursor is grown is taken out and washed with deionized water and ethanol for several times, and then dried in a va...

Embodiment 2

[0037] A preparation method based on a metal oxide dual-function water splitting catalyst is the same as in Example 1, wherein:

[0038] In step (a), Co(NO 3 ) 2 .6H 2 O and Cu (NO 3 ) 2 .6H 2 The molar ratio of O is 1:0.1; the hydrothermal reaction temperature is 100 ℃ and the reaction time is 1 h; in step (b), the high temperature heat treatment temperature is 300 ℃, the heating rate is 0.5 ℃ / min, and the reaction time is 2 h . The copper-cobalt-based oxide nanomaterials prepared in this embodiment obtained 10 mA cm in the total water splitting reaction. -2 The current density requires a voltage of 1.65 V.

Embodiment 3

[0040] A preparation method based on a metal oxide dual-function water splitting catalyst is the same as in Example 1, wherein:

[0041] In step (a), Co(NO 3 ) 2 .6H 2 O and Cu (NO 3 ) 2 .6H 2 The molar ratio of O is 1:10; the hydrothermal reaction temperature is 200 ℃, and the reaction time is 24 h; in step (b), the high temperature heat treatment temperature is 600 ℃, the heating rate is 50 ℃ / min, and the reaction time is 5 h . The copper-cobalt-based oxide nanomaterials prepared in this embodiment obtained 10 mA cm in the total water splitting reaction. -2 The current density requires a voltage of 1.82 V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com