Method for treating ferric trichloride etching waste liquor

A technology for ferric chloride corrosion and waste liquid, which is applied in chemical instruments and methods, ferric halide, water/sewage treatment, etc. It can solve the problems of increasing the amount of chlorine gas, high processing cost, complicated equipment, etc., and achieve cost saving in processing , Good separation effect and wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

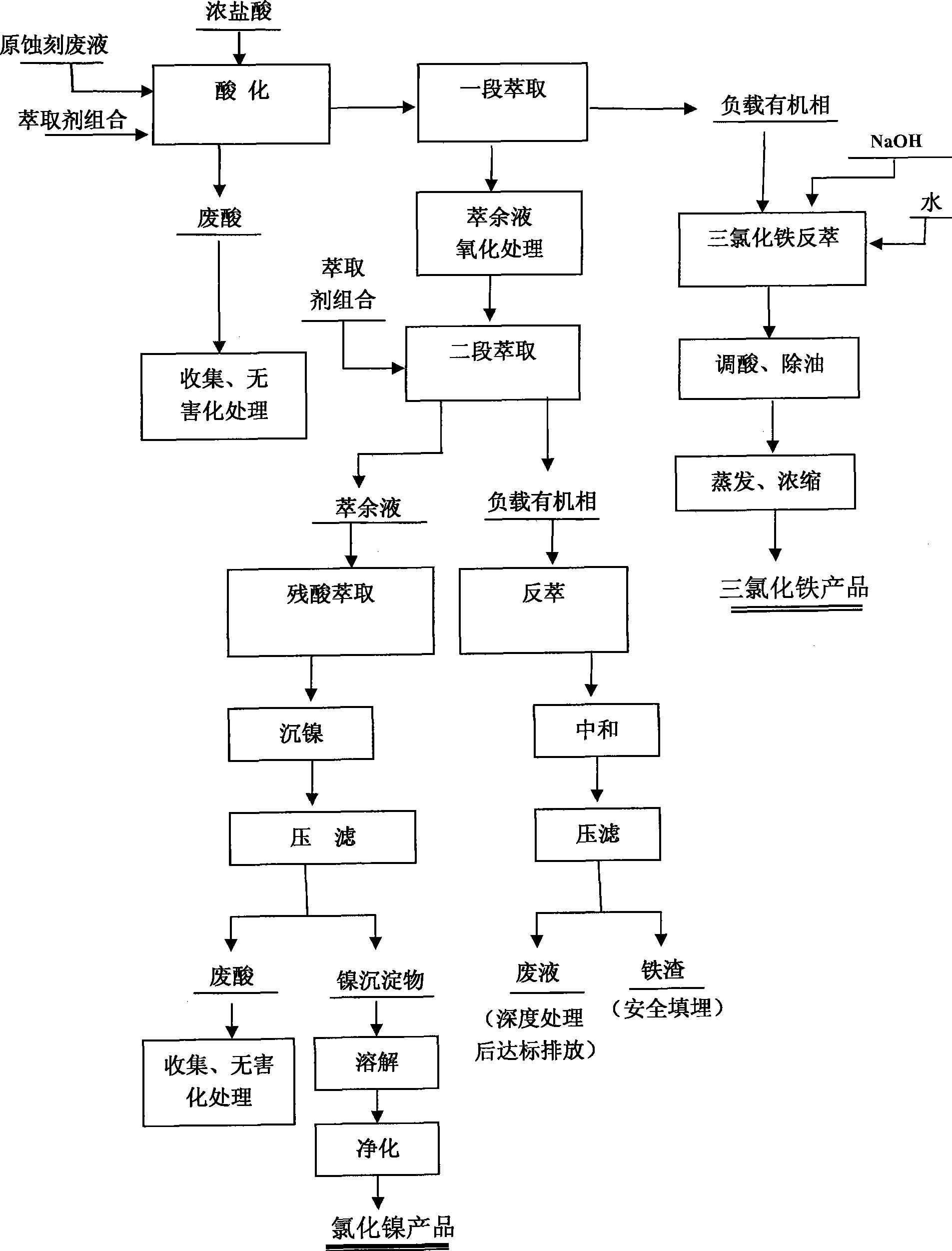

Method used

Image

Examples

example 1

[0055] A kind of nickel-containing ferric chloride etching waste liquid from A circuit board factory is dark brown red and has a density of 1.48. The chemical analysis composition is as follows:

[0056] Table-2 Chemical Composition and Content of Nickel-Containing Ferric Chloride Etching Waste Liquid

[0057] Element Concentration(g / L) Fe 3+ 216.30 Fe 2+ 2.57 Ni 2+ 19.75 Cl - 436.4 H + 0.22mol / L

[0058] The organic phase combination of one-stage extraction is: 15% bis-octyl methyl tertiary amine + 10% N-hexyl isooctylamide + 70% kerosene, and the organic phase combination of second-stage extraction is: 20% 2-hydroxy-4-sec-octyl - Benzophenone oxime + 5% trialkylphosphine oxide + 75% kerosene.

[0059] Add 5% of its volume of hydrochloric acid to the organic phase combination of "15% bis-octylmethyl tertiary amine + 10% N-hexyl isooctylamide + 70% kerosene" to carry out 3-stage countercurrent acidification, collect the waste a...

example 2

[0065] A nickel-containing ferric chloride etching waste solution from B circuit board factory is dark brown red and has a density of 1.53. The chemical analysis composition is as follows:

[0066] Table-3 Chemical Composition and Content of Nickel-Containing Ferric Chloride Etching Waste Liquid

[0067] Element Concentration(g / L) Fe 3+ 245.50 Fe 2+ 6.45 Ni 2+ 25.75 Cl - 475.60 H + 0.46mol / L

[0068] The organic phase combination of one-stage extraction is: 30% sec-octyl alcohol + 15% N-octyl caprolactam + 55% kerosene, and the organic phase combination of second-stage extraction is: 35% 2-hydroxy-4-sec-octyl-benzophenone Oxime + 8% trioctylphosphine oxide + 57% kerosene.

[0069] Add 10% hydrochloric acid by volume to the organic phase combination of "30% 2-octanol + 15% N-n-octyl caprolactam + 55% kerosene" for 4-stage countercurrent acidification treatment, collect waste acid and perform harmless treatment.

[0070] Perform...

example 3

[0075] A kind of nickel-containing ferric chloride etching waste liquid from C circuit board factory is dark brown red and has a density of 1.49. The chemical analysis composition is as follows:

[0076] Table-4 Chemical Composition and Content of Nickel-Containing Ferric Chloride Etching Waste Liquid

[0077] Element Concentration(g / L) Fe 3+ 228.50 Fe 2+ 4.65 Ni 2+ 35.50 Cl - 455.60 H + 0.30mol / L

[0078] The organic phase combination of one-stage extraction is: 40% sec-octylphenoxyacetic acid + 10% N-n-octyl caprolactam + 50% kerosene, and the organic phase combination of second-stage extraction is: 40% 2-hydroxy-4-sec-octyl-di Benzophenone oxime + 5% trioctylphosphine oxide + 55% kerosene.

[0079] Add 15% hydrochloric acid by volume to the organic phase combination of "40% sec-octylphenoxyacetic acid + 10% N-n-octyl caprolactam + 50% kerosene" for two-stage countercurrent acidification treatment, collect waste acid and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com