Patents

Literature

53results about How to "Enhanced leaching process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

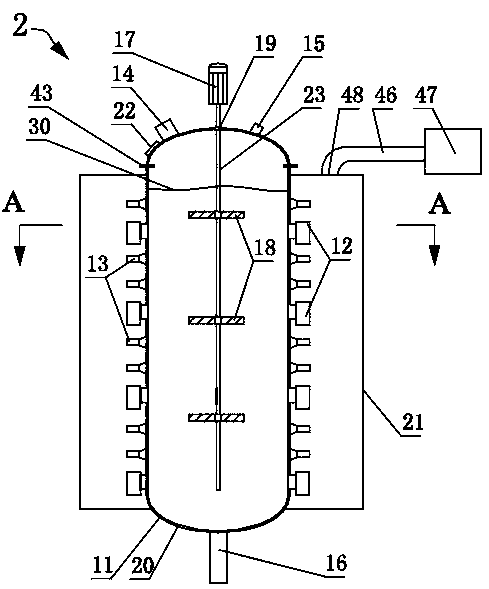

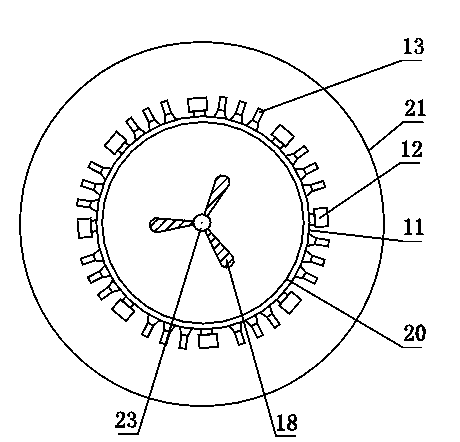

Industrial microwave ultrasonic reaction kettle

InactiveCN103418323ASave operating timeImprove work efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesMicrowaveEngineering

Disclosed is an industrial microwave ultrasonic reactor. The inner wall of the reactor is provided with a liner; a microwave generation device is composed of microwave units distributed over the outer sidewall of the reactor in a spaced manner, or of a microwave pipe provided outside the reactor and microwave units distributed over the microwave pipe in a spaced manner. One end of the microwave pipe is in communication with the bottom of the reactor via a connecting pipe I and the other end is in communication with the top of the reactor via a return pipe. A shield is provided outside the microwave generation device to space the microwave units apart from the outer space, with a heat removal device being provided outside the shield. The microwave generation device is composed of ultrasonic pulse units provided along the outer sidewall of the reactor in a spaced manner; there are 10 - 30 sets of ultrasonic pulse units provided from top to bottom, each set having 10 - 50 members and being distributed along the circumferential direction of the reactor, and a stirring shaft of a stirring device is fixed below a stirring motor and extends into the reactor. The present reactor can shorten the time for chemical leaching, improve the purity of a product extracted and increase operation efficiency.

Owner:SONGXIAN EXPLOITER MOLYBDENUM

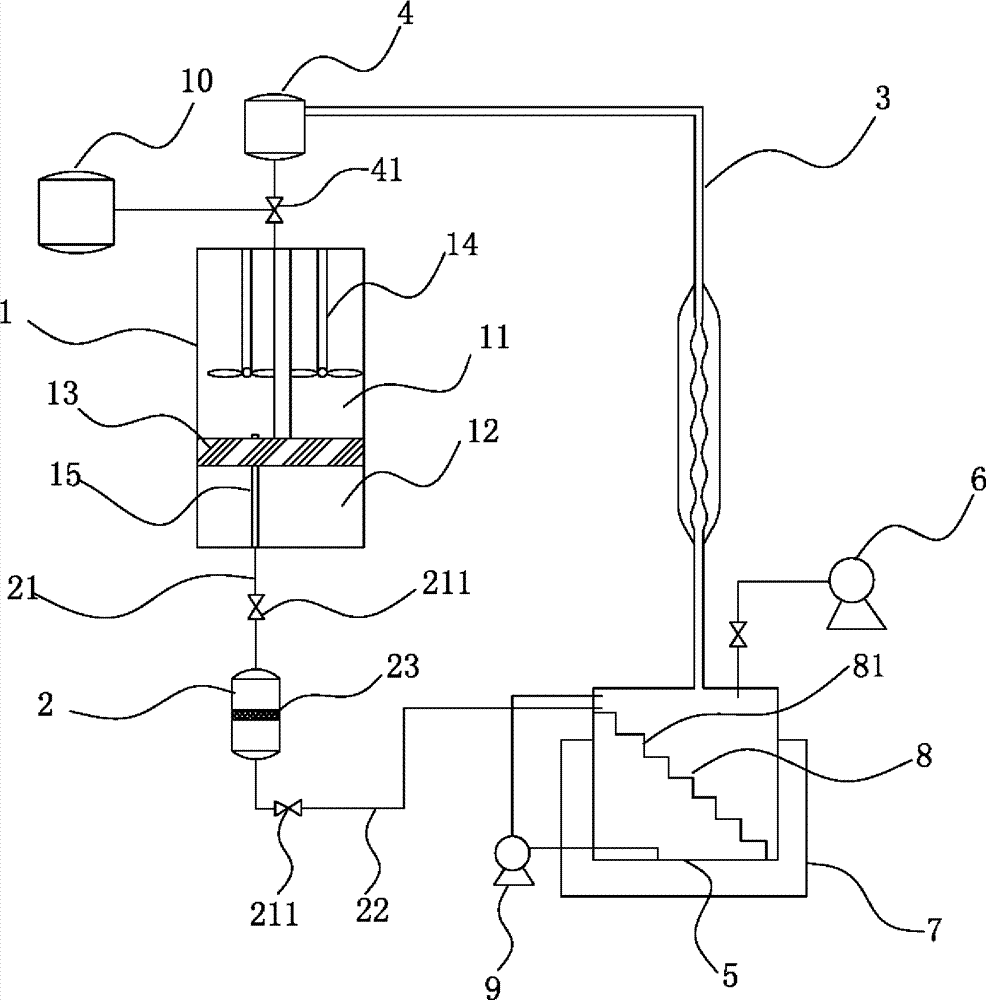

Device and method for extracting and concentrating traditional Chinese medicine

InactiveCN103041614AIncrease pressureIncrease the heat exchange areaEvaporationSolid solvent extractionPharmacy medicineProcess engineering

The invention relates to the technical field of extracting and concentrating of the traditional Chinese medicine, and in particular relates to a method and a device for extracting and concentrating the traditional Chinese medicine. The method for extracting and concentrating structurally comprises an extracting unit and a concentrating unit, wherein the extracting unit comprises an extracting tank and a liquid medicine storage tank, wherein a piston capable of moving up and down is arranged in the extracting tank; when the piston moves upwards under the action of the driving force, dredges of decoction in a pressurizing chamber are pressurized and further squeezed; the concentrating unit comprises a concentrating container, a vacuum pump and a heating device for heating up the concentrating container, wherein a step-shaped evaporation plate assembly of a liquid medicine thin film is formed in the concentrating container, so that the liquid medicine can be circulated and concentrated. Compared with the prior art, the extracting and concentrating efficiency is high, the heating time is short, and the damages to the active ingredients of the medicine are reduced.

Owner:GUANGDONG MEDICAL UNIV

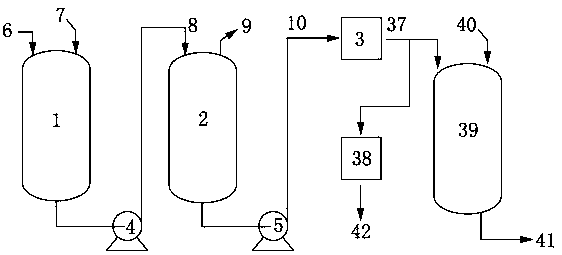

Technology for zinc wet-process clean smelting and resource comprehensive recycling

InactiveCN102978391AEnhanced leaching processHigh recovery ratePhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention belongs to the technical field of zinc smelting of the nonferrous metal smelting industry, in particular relates to a technology for valuable metal comprehensive recycling and iron element separating and concentrating during a zinc clean smelting process. Zinc calcine which is produced through calcinating zinc concentrate is separated out through neutral leaching and low-acid leaching and is then fed into a wet-process reinforced leaching system to separate acid soluble metals from insoluble substances; the separated zinc and soluble impurity-containing liquid enters a valuable metal separating and concentrating system to separate out indium, gallium, germanium and the like, the separated valuable metal sludge enters a special recycling system; and the liquid enters a zinc and iron separating system to completely separate out zinc and iron, iron is output in a high-grade iron ore concentrate mode, zinc enters the next process in a zinc sulfate mode, and the liquid enters an electrolyzing system after deep purification to output metal zinc. The technology has high metal zinc recovery rate, good valuable metal comprehensive recycling effect, a good environment-friendly effect and high iron content of hematite sludge, the hematite sludge can be treated to be used as a raw material for smelting iron, so that 'non-sludge' smelting is realized, and the smelting process is compact.

Owner:HENAN YUGUANG ZINC IND

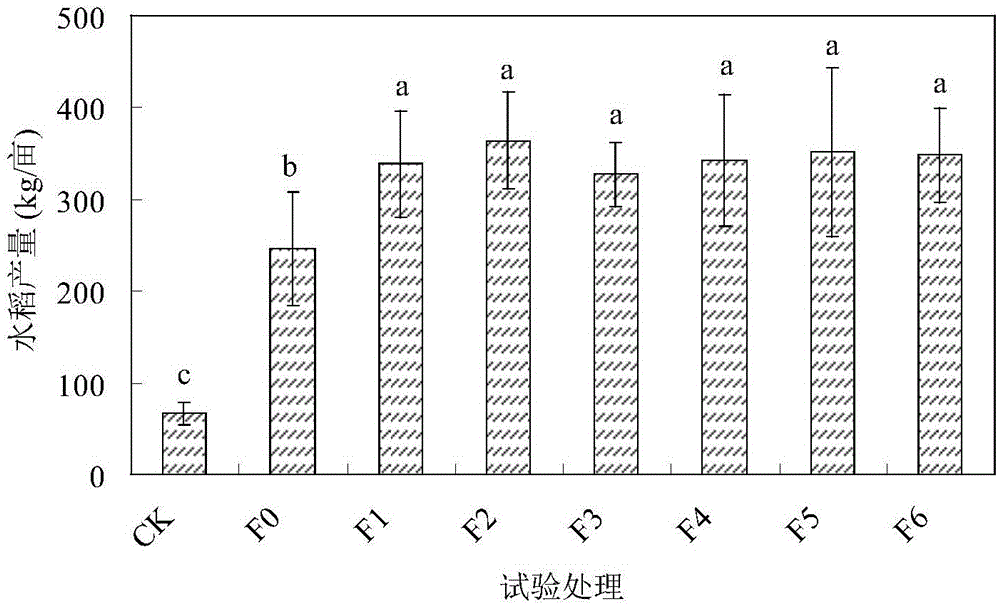

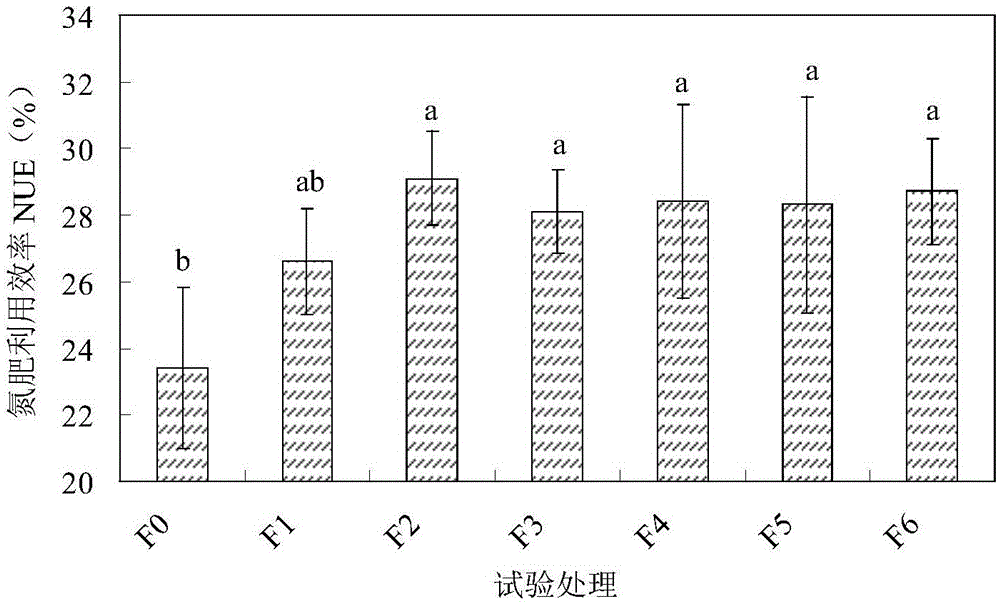

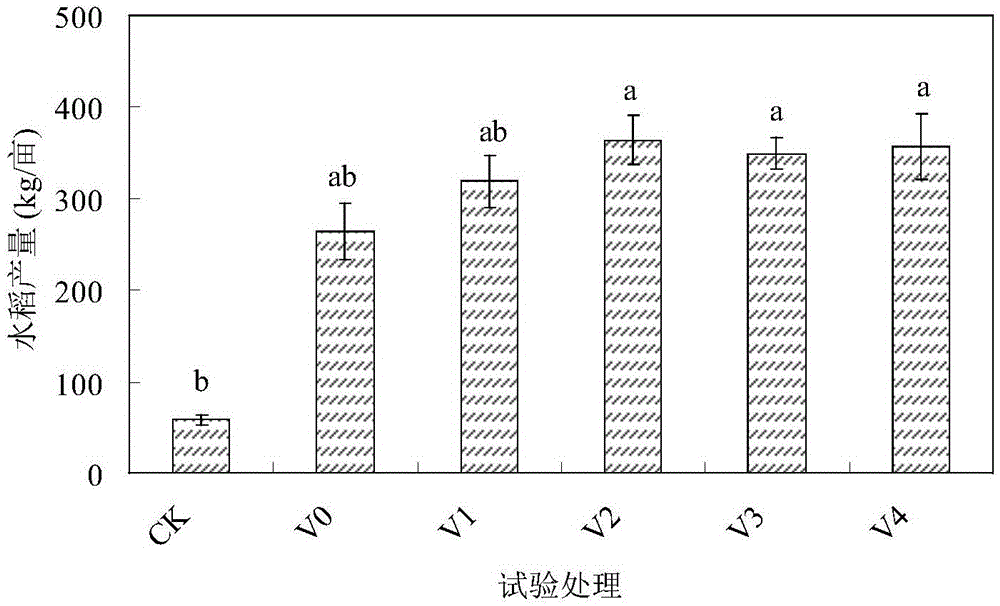

Special rice fertilizer with both soil improvement and fertilizer efficiency functions for coastal saline soil and preparation method and application of special rice fertilizer

ActiveCN105111021AImprove physical and chemical propertiesImprove breathabilityFertilising methodsAgriculture gas emission reductionAlkali soilNitrification inhibitors

The invention discloses a special rice fertilizer with both soil improvement and fertilizer efficiency functions for coastal saline soil and a preparation method and application of the special rice fertilizer. The special rice fertilizer comprises the following components in parts by mass: 35-40 parts of humic acid, 15-20 parts of fulvic acid, 20-25 parts of a composite fertilizer, 15-20 parts of a silicon calcium fertilizer, 1-1.5 parts of a urease inhibitor and 1-1.5 parts of a nitrification inhibitor. According to the invention, the application method combines soil culture, root system activation, crop nourishment and fertilizer efficiency improvement, so the rice fertilizer is low in cost, stable in effect, applicable to mechanical operation, not only applicable to coastal intertidal zones, but also applicable to rice planting in saline-alkali soil in north China or even northwest inland.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

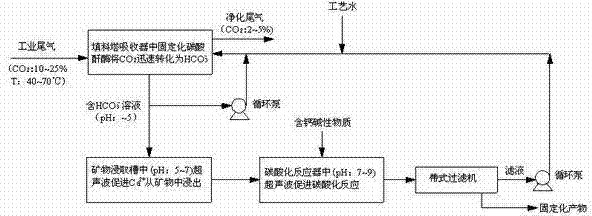

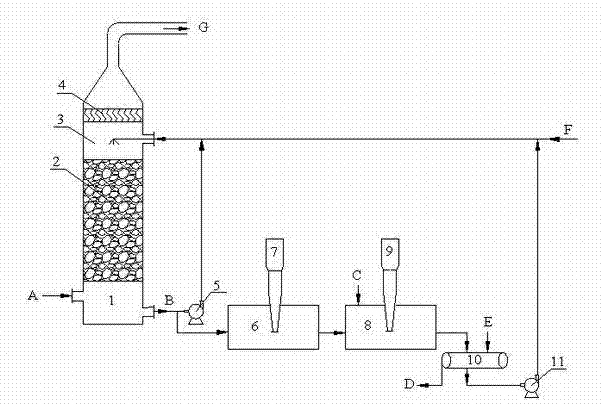

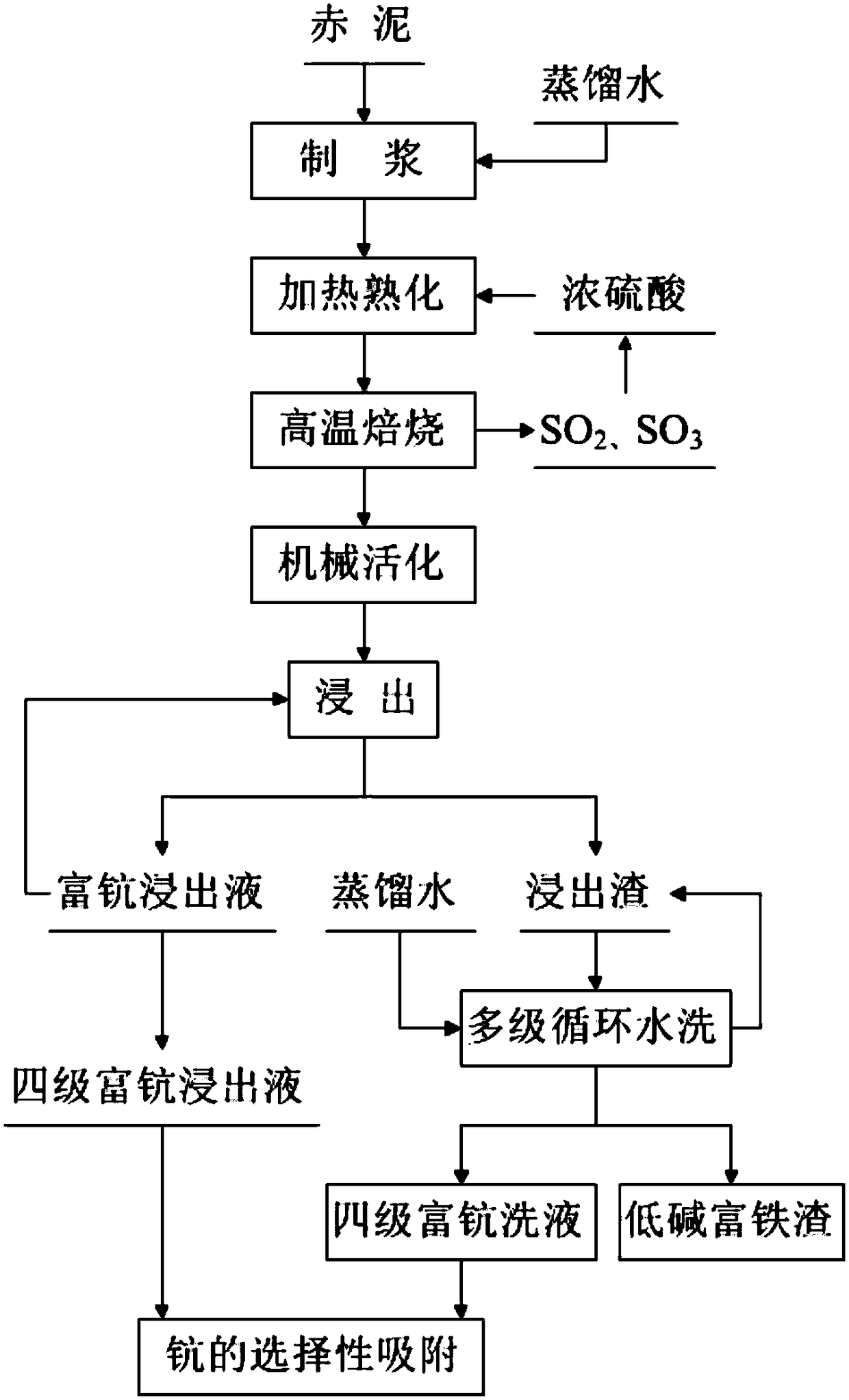

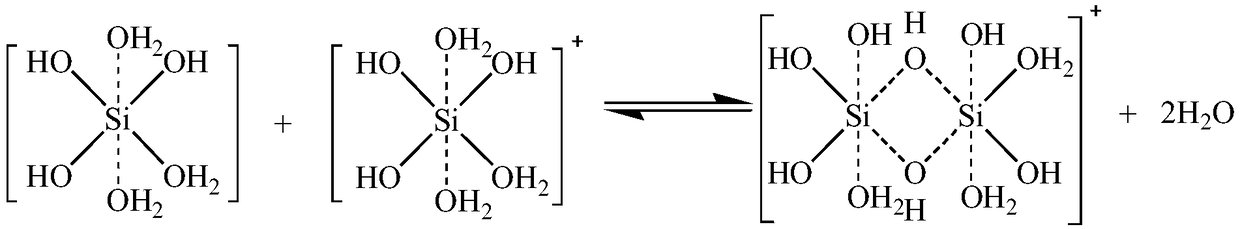

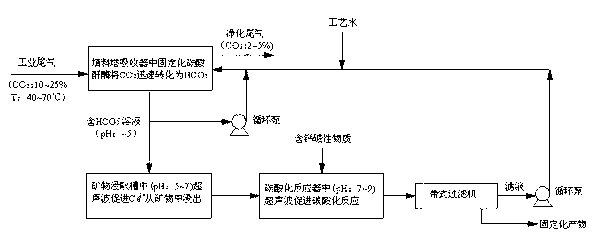

Method and device for immobilizing CO2 by enhancing mineral carbonation

InactiveCN102343199AFast catalytic reaction ratePromotes hydrationDispersed particle separationUltrasound - actionSlurry

The invention discloses a method and device for immobilizing CO2 in industrial tail gas by enhancing mineral carbonation. The device comprises a packed column absorber, a mineral leaching tank, a carbonation reactor and a belt type filter. The method comprises the steps of: enabling the industrial tail gas containing CO2 to enter the packed column absorber filled with immobilization carbonic anhydrase, rapidly transforming the CO2 into HCO3<-> under the catalysis action of the carbonic anhydrase; with a weak acidic solution containing the HCO3<-> as a mineral leaching agent, effectively leaching calcium ions from minerals in the mineral leaching tank under the action of ultrasonic waves to form a slurry enriching Ca<2+>; introducing the slurry enriching Ca<2+> into the carbonation reactor, adding a calcium-containing alkali material, regulating the pH of the slurry to be 7-9 to ensure that the HCO3<-> is transformed into CO3<2->, and generating a carbonation reaction with the Ca<2+> leached from the minerals to generate CaCO3. The invention can promote the CO2 to be rapidly transformed into the HCO3<->, can promote the calcium ions to be leached from the minerals and the carbonation reaction, and further realizes that the CO2 in the industrial tail gas is immobilized through direct carbonation under normal pressure.

Owner:SOUTHEAST UNIV

Wet-process comprehensive recovery and utilization method for zinc replacement residues

InactiveCN106834693AImprove leaching rateEnhanced leaching processProcess efficiency improvementLiquid wasteCopper

The invention discloses a wet-process comprehensive recovery and utilization method for zinc replacement residues. The wet-process comprehensive recovery and utilization method can efficiently recover zinc, germanium, gallium, copper, iron and silicon dioxide in the zinc replacement residues, and the leaching rates of all the metals are all higher than 94%. The wet-process comprehensive recovery and utilization method is conductive to improving the metal comprehensive recovery rate, meanwhile, the energy consumption in the whole technological process is reduced, generated waste liquid is returned for leaching to achieve the purpose of cyclic utilization, the problem of environmental pollution is solved, and the wet-process comprehensive recovery and utilization method is environment-friendly.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

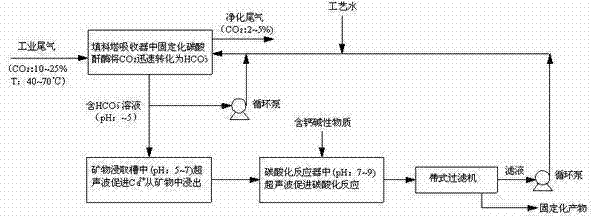

Method for selectively enriching scandium from Bayer process red mud

The invention discloses a method for selectively enriching scandium from Bayer process red mud. The method is characterized in that the Bayer process red mud is used as a raw material, the red mud isfully wet by adding an appropriate amount of water, the red mud is sulphated by using concentrated sulfuric acid and is then calcined at a high temperature, the solid calcined product is mechanicallyactivated by grinding and is then subjected to four-stage water immersion and washing, so that a scandium-rich leaching solution, scandium-rich washing liquid and low-alkali iron-rich slag are obtained. The method enables most of scandium to be leached, but the leaching rates of impurity iron and aluminum are low, and silicon and titanium are not leached substantially, so that the formation of colloidal silicate in the leaching solution is avoided, and the selective absorption and extraction of the scandium in the subsequent leaching solution are facilitated; the generated sulfur dioxide and sulfur trioxide can be reused in the preparation of sulfuric acid, so that the production of a large amount of waste acid is avoided; the pH of the low-alkali iron-rich slag is close to neutral, and can be used in the industries such as iron making, adsorbents, ceramics, construction and the like, so that a new way is provided for the extraction of the scandium and the comprehensive utilization ofthe red mud.

Owner:GUANGXI UNIV

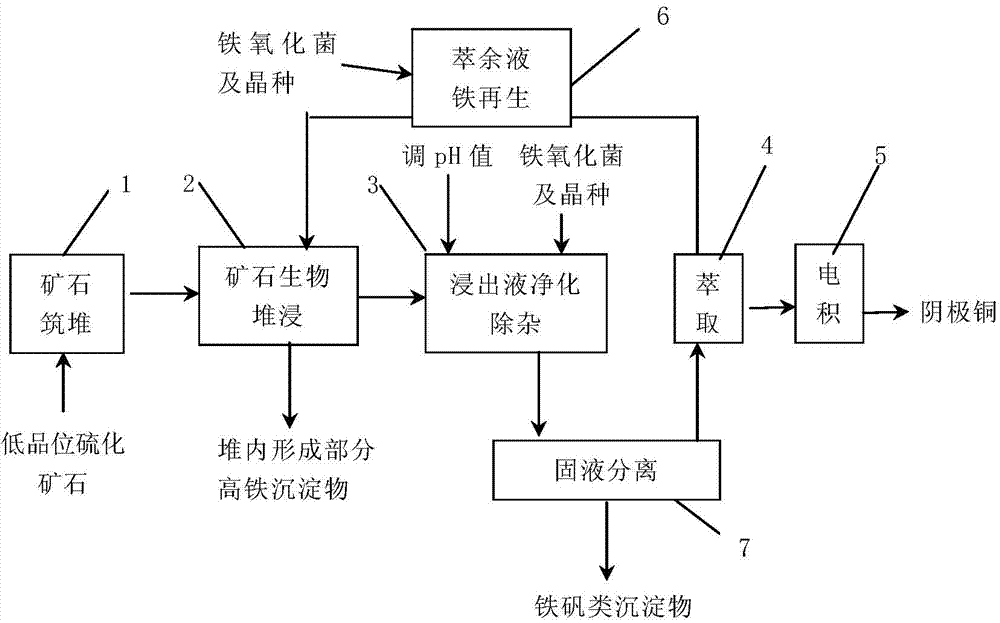

Iron balancing technology in low-grade sulfide ore biological heap leaching-leachate purification-extraction and separation process

InactiveCN104726707APromote rapid formationEnhanced leaching processProcess efficiency improvementPotassiumSulfide

The invention relates to an iron balancing technology in a low-grade sulfide ore biological heap leaching-leachate purification-extraction and separation process. The technology comprises the following steps: firstly dissolving alunite and other potassium-containing minerals in a mineral heap to form one part of iron vitriol type precipitate in the mineral heap; secondly adding lime into a biological leachate to regulate the pH value of the leachate, adding a mixed leaching bacterial solution of ferrous oxide and the like and an iron vitriol seed crystal, and accelerating the formation of the iron vitriol type precipitate by a biological vitriol formation method to realize fast and efficient purification and iron removal; and adding the mixed leaching bacterial solution of iron-oxidizing bacteria and the like before raffinate returns to the mineral heap, regenerating iron in the raffinate, and then returning the raffinate to the mineral heap as spraying liquid. The iron balancing technology provided by the invention is suitable for controlling impurities in the biological leaching process of low-grade sulfide ores, the problems of serious entrainment of valuable elements, high neutralization cost and the like caused by traditional iron removal by neutralizing with the lime are solved, and the leaching and extraction separation efficiency is improved at the same time.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

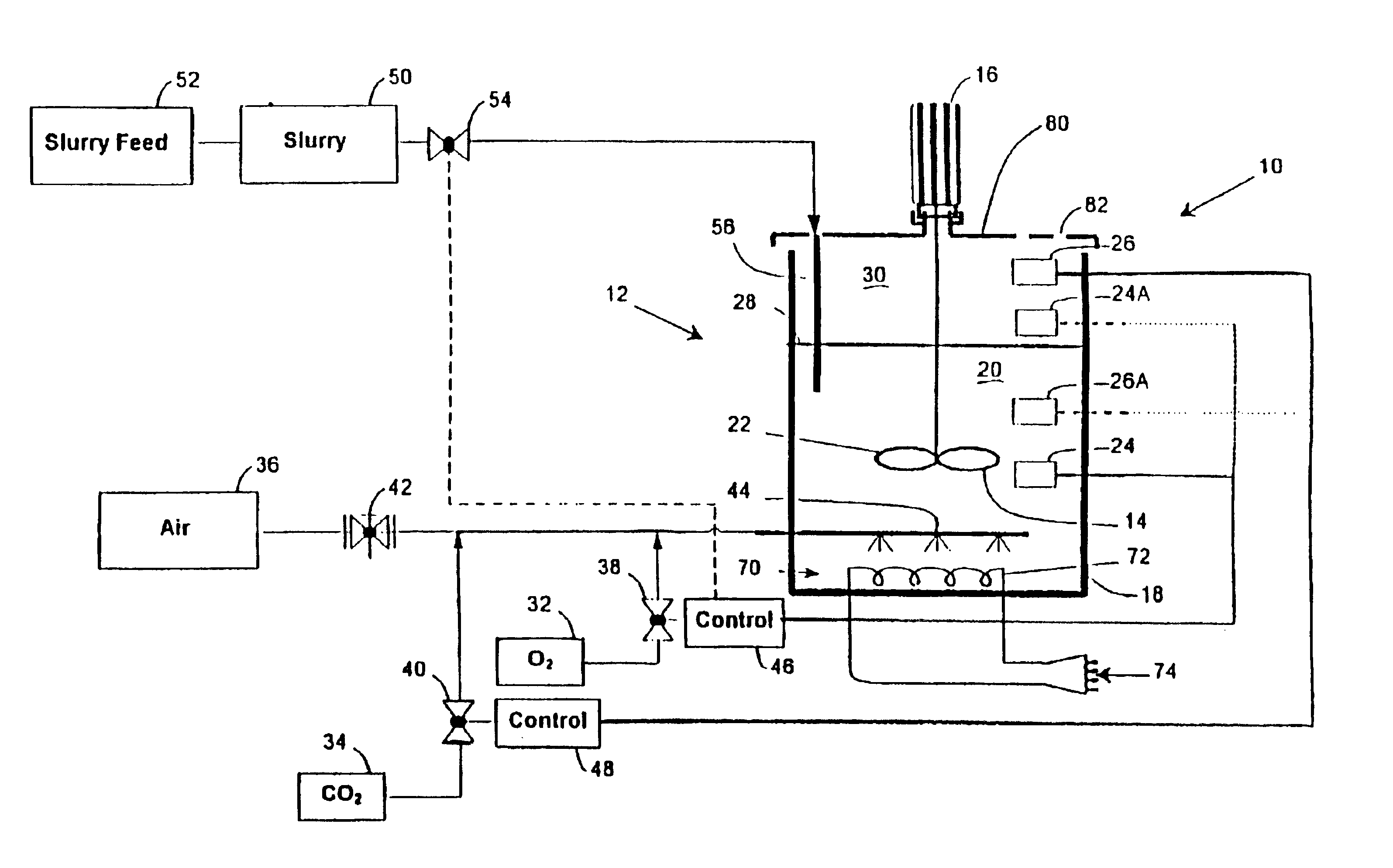

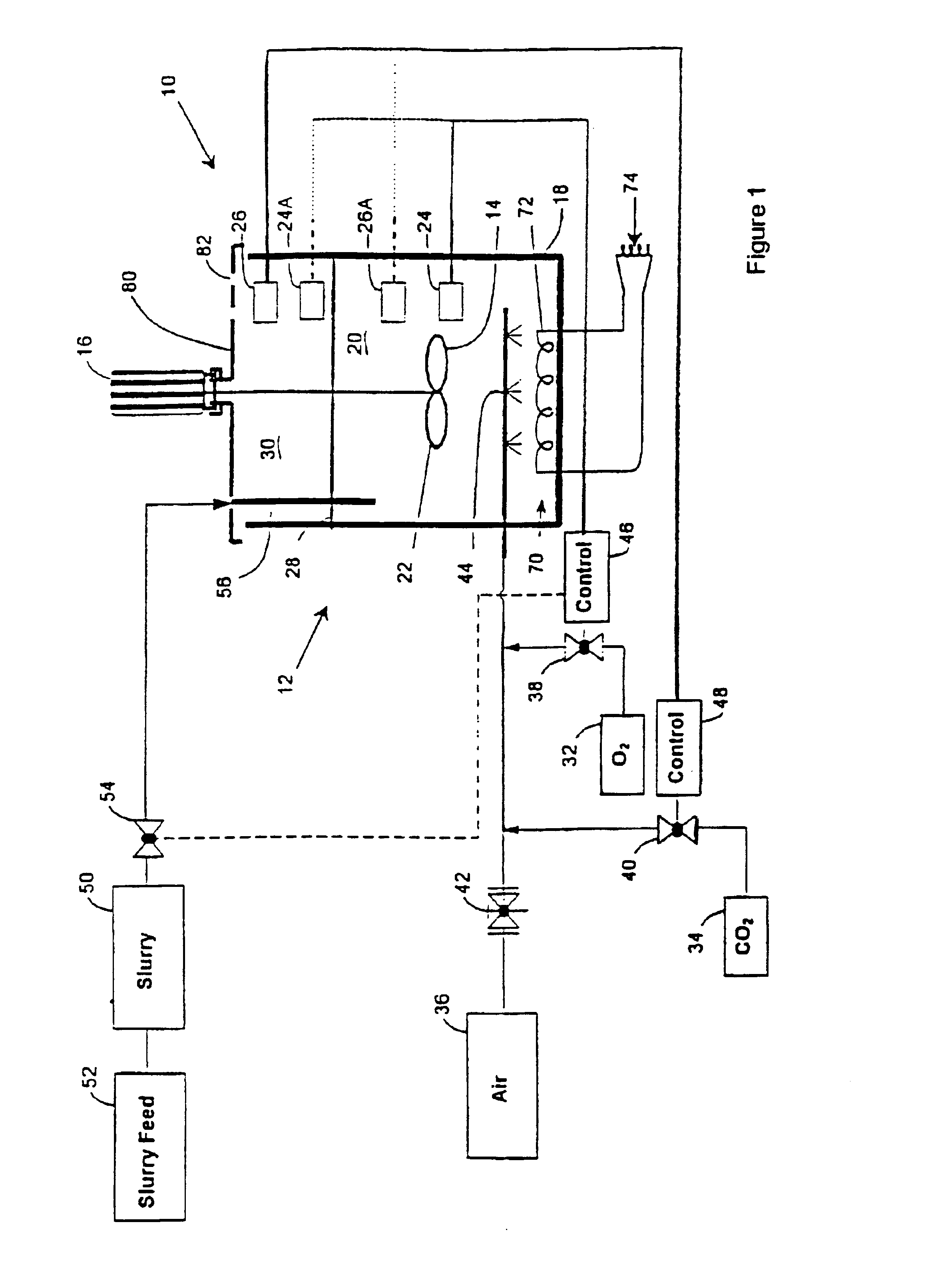

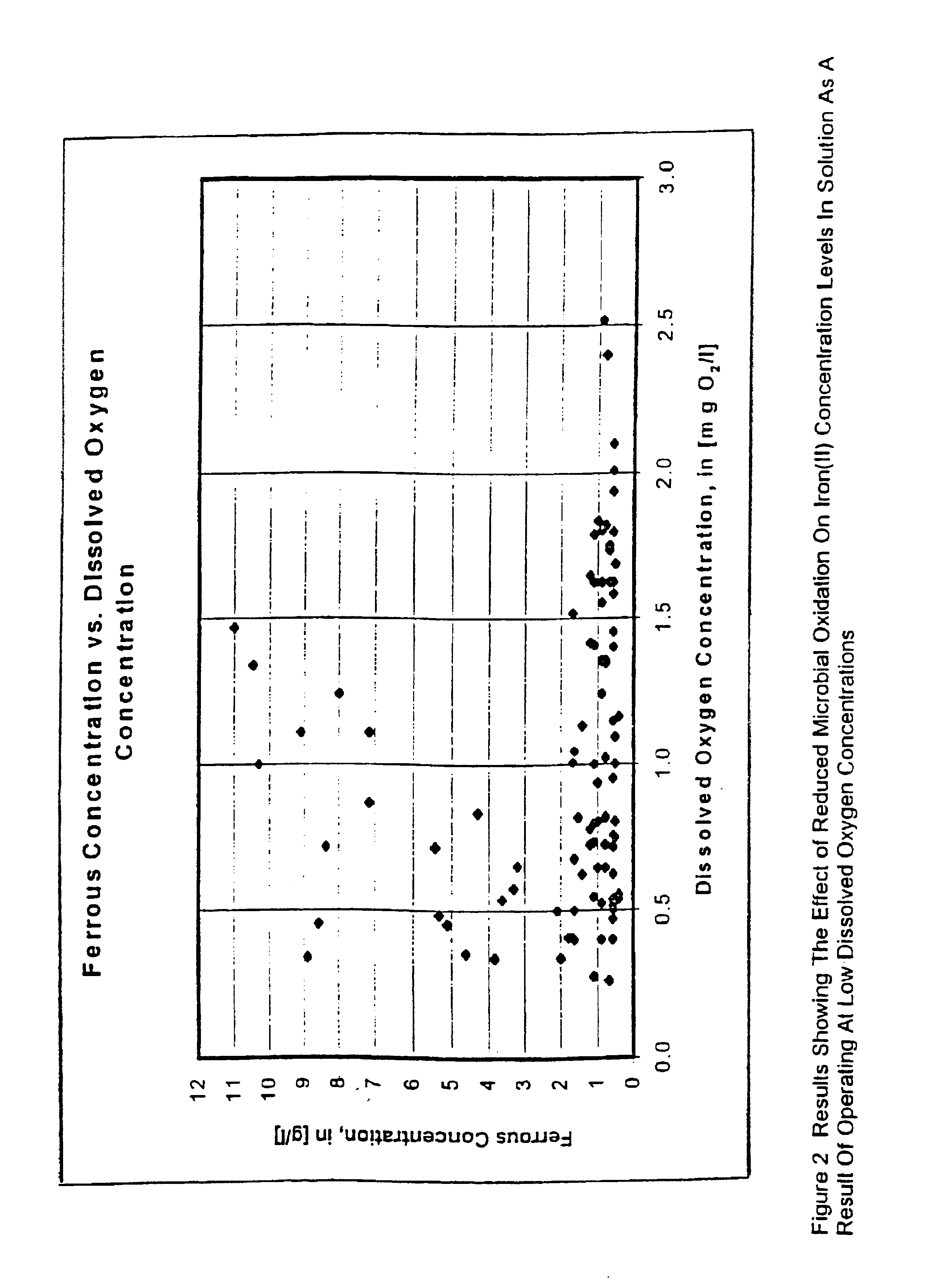

Recovery of precious metal from sulphide minerals by bioleaching

InactiveUS6860919B1Solve the low leaching rateReduced Power RequirementsInorganic chemistryBlast furnace detailsBioleachingSlurry

A method of recovering a precious metal from a sulphide mineral slurry which contains the precious metal which includes the steps of subjecting the slurry to a bioleaching process, supplying a feed gas which contains in excess of 21% oxygen by volume to the slurry, and recovering precious metal from a bioleach residue of the bioleaching process.

Owner:BILLITON INTPROP

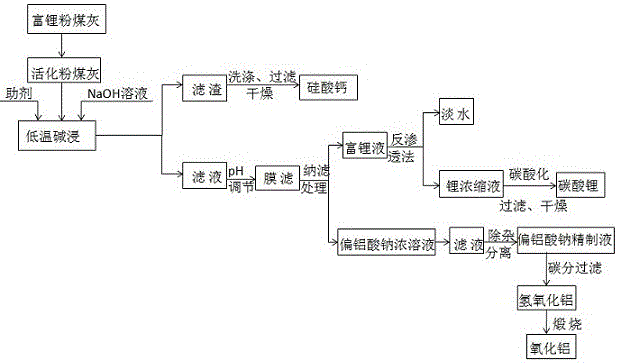

Method for separating and enriching lithium, aluminum and silicon from fly ash

ActiveCN106745016AEasy to recycleImprove leaching rateAlkaline-earth metal silicatesLithium carbonates/bicarbonatesCalcium silicateReverse osmosis

The invention discloses a method for separating and enriching lithium, aluminum and silicon from fly ash. The method comprises the following steps: (1) pretreating fly ash; (2) carrying out low-temperature alkali dip reaction on the treated fly ash, aids and a sodium hydroxide solution, and filtering; (3) washing the filter residue, removing the impurities, filtering, and drying to obtain calcium silicate; (4) regulating the pH value of the filtrate to alkalinity, separating the lithium / aluminum-containing filtrate to obtain a sodium metaaluminate concentrated solution and a lithium-rich solution, carrying out reverse osmosis on the lithium-rich solution to obtain a lithium concentrated solution, and mixing the sodium metaaluminate concentrated solution with the lithium / aluminum-containing filtrate to obtain a refined solution; (5) precipitating the sodium metaaluminate refined solution, filtering to obtain aluminum hydroxide, and calcining to obtain the aluminum oxide finished product; (6) treating the lithium-rich solution to obtain a lithium-rich concentrated solution and fresh water; and (7) carrying out carbonating precipitation on the lithium-rich concentrated solution, filtering, and drying to obtain the lithium carbonate finished product. The method is a short-stage extraction process, reduces the lithium loss, and implements separation, enrichment and extraction of calcium silicate, aluminum oxide and lithium carbonate.

Owner:HEBEI UNIV OF ENG

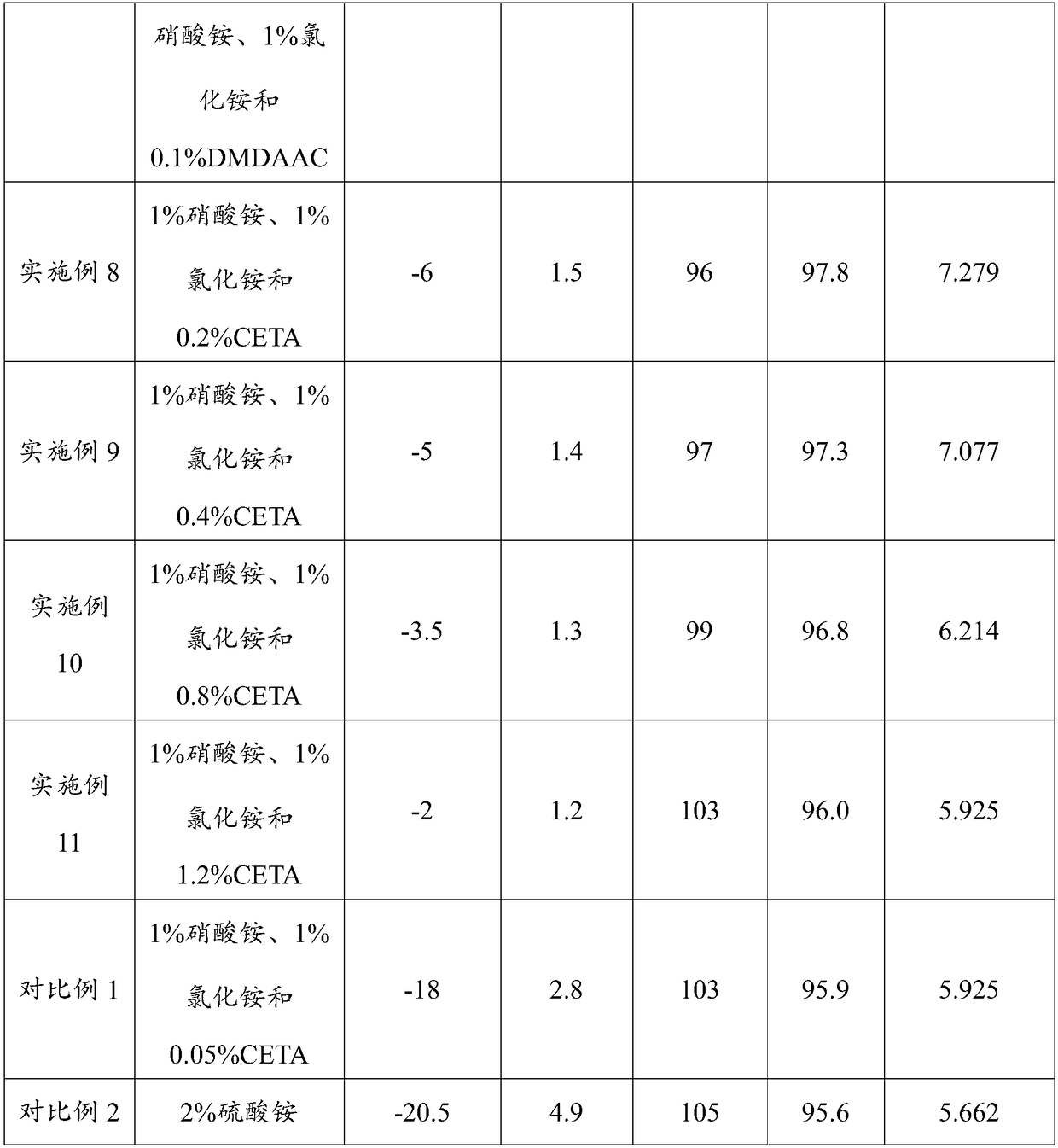

Composite leaching agent for enhanced leaching of weathered crust elution-deposited rare earth ores

ActiveCN109082543AEnhanced leaching processReduce consumptionProcess efficiency improvementClay mineralsRare earth

The invention relates to the field of wet metallurgy, in particular to a composite leaching agent for enhanced leaching of weathered crust elution-deposited rare earth ores and a preparation method thereof and a method for extracting rare earth. The composite leaching agent for enhanced leaching of the weathered crust elution-deposited rare earth ores comprises 1-4 % of an inorganic leaching agentand 0.1-1.2% of one or a combination of more of dimethyl diallyl ammonium chloride, 2-chloroethyl trimetyl ammonium chloride, an acrylamide and dimethyl diallyl ammonium chloride copolymer and acrylamidetrimethyl allyl ammonium chloride according to the mass percentage. The method for extracting the rare earth comprises the step of using the composite leaching agent for enhanced leaching of the weathered crust elution-deposited rare earth ores to leach the rare earth in the rare earth ores. Under the coordination between the inorganic leaching agent and an organic stabilizer, the weathered crust elution-deposited rare earth ores are leached in situ, the permeation of the leaching agent and the leaching process of the rare earth are enhanced, the consumption of the leaching agent is reduced, the expansion of the clay minerals is inhibited, problems that stability of the weathered crust elution-deposited rare earth ores is low and the weathered crust elution-deposited rare earth ores are easy to generate landslide due to the inorganic leaching agent are solved, and the exploration period is also shortened.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

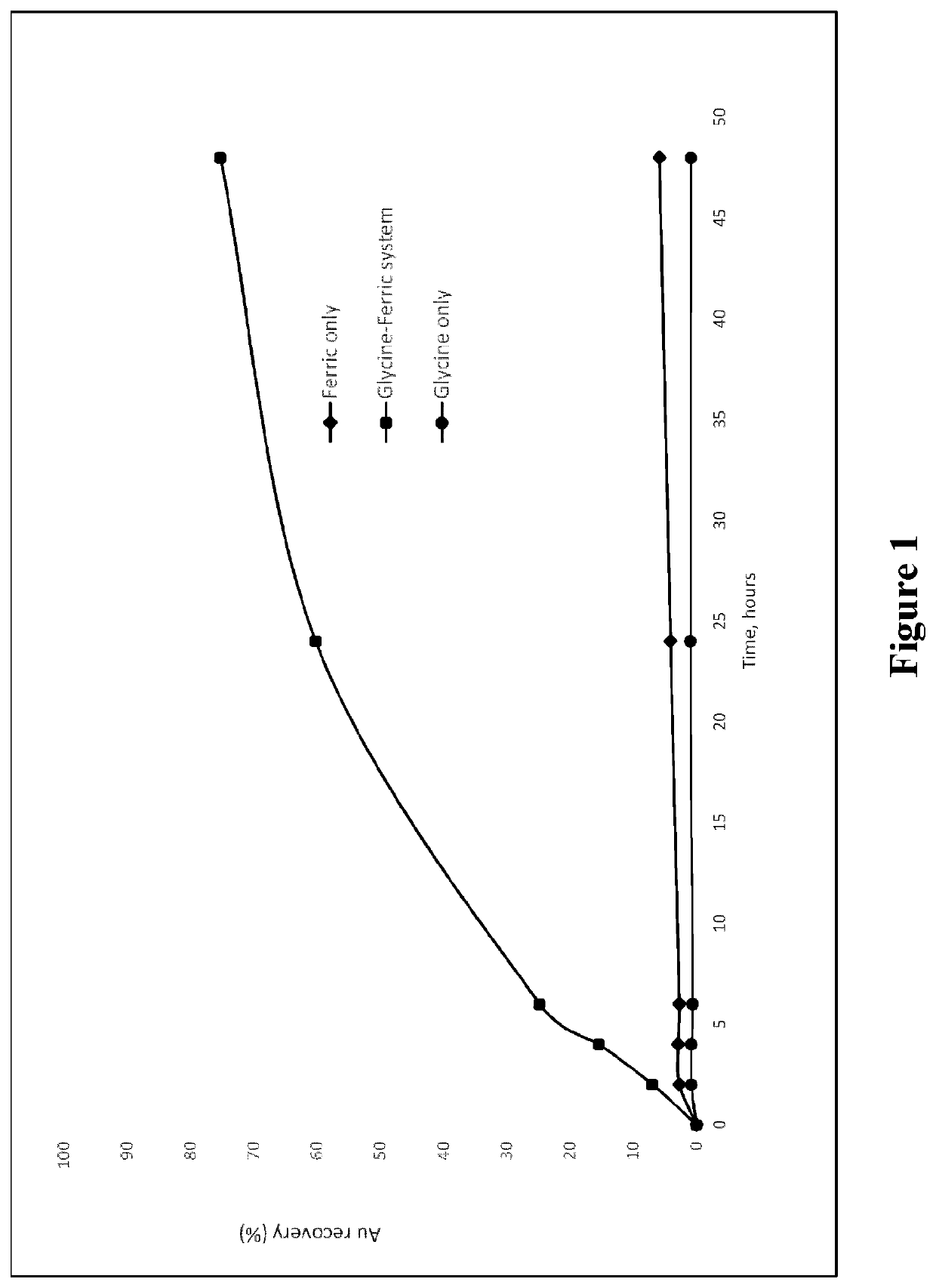

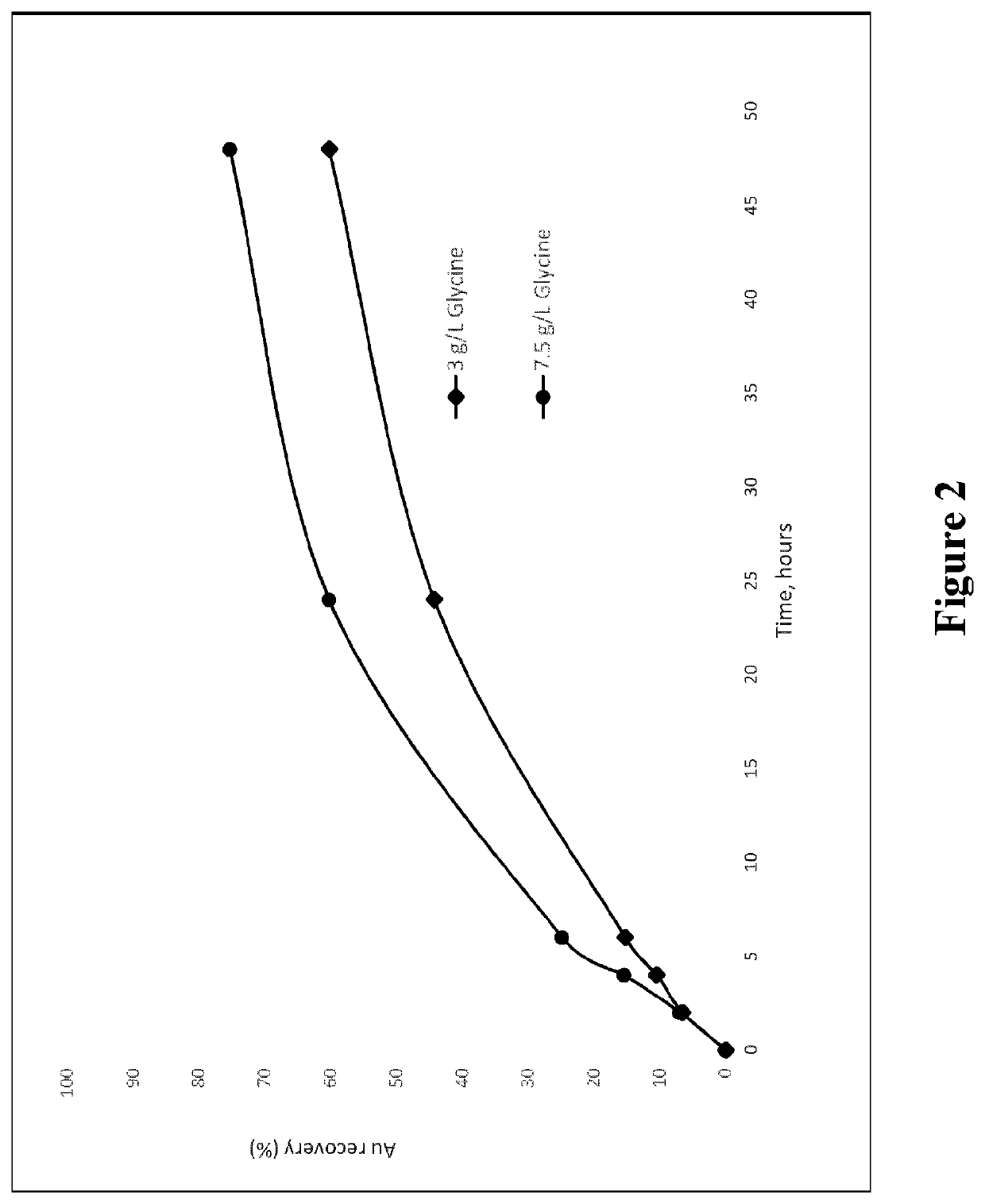

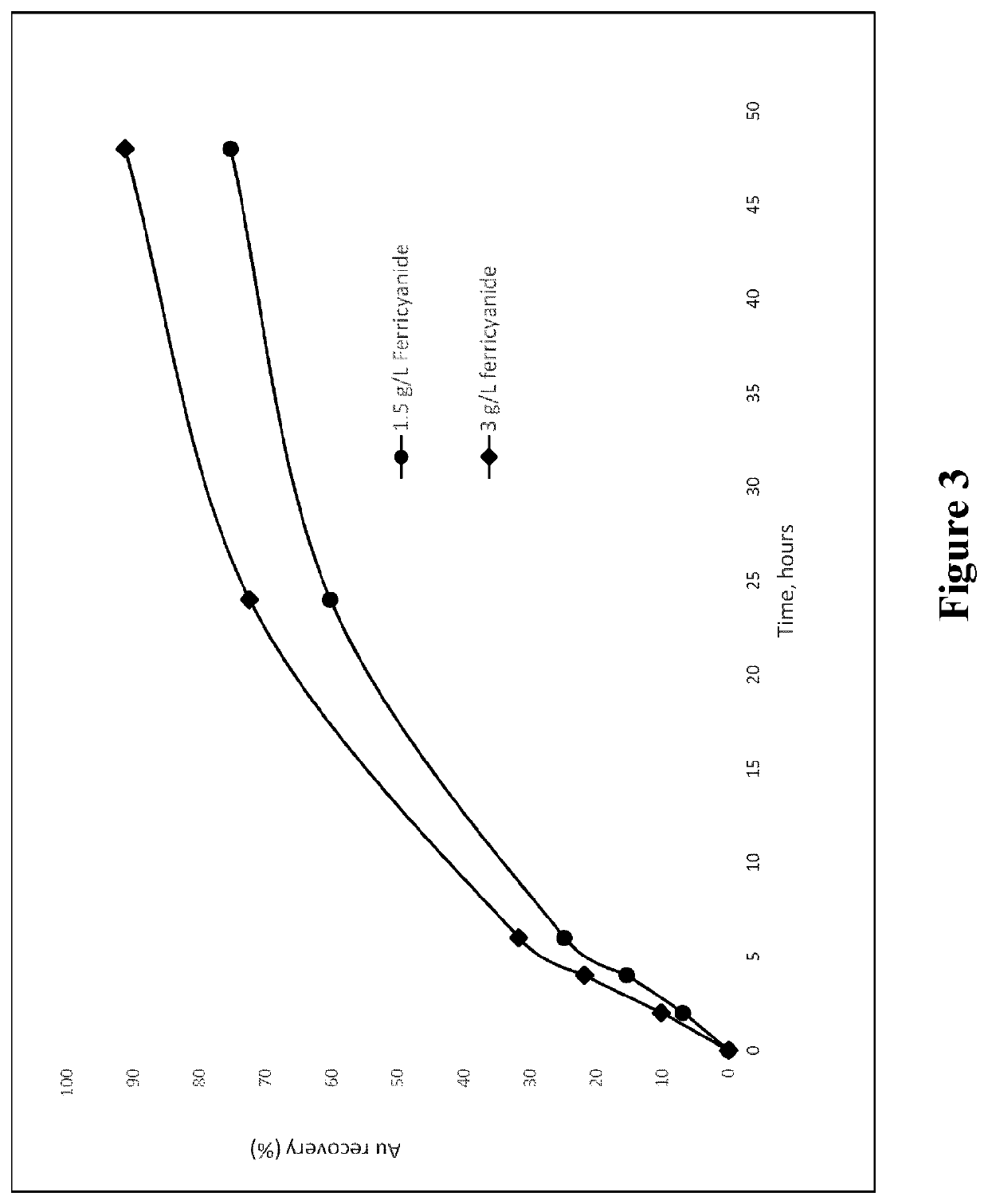

Recovery of precious and chalcophile metals

ActiveUS20200172994A1Limit its contamination in downstream processingPrevent copper contaminationProcess efficiency improvementPregnant leach solutionPhysical chemistry

A process for recovery of one or more elements, selected from precious metals and chalcophile metals, as herein defined, from materials containing precious and / or chalcophile metal / s, said process including: (i) contacting the material with an alkaline solution containing a lixiviant comprising an amino acid, or derivative thereof, and an alkali stable transition metal complex in order to form a leachate containing the precious metal and / or chalcophile metal; and (ii) recovering the precious metal and / or chalcophile metal from the leachate.

Owner:MINING & PROCESS SOLUTIONS PTY LTD

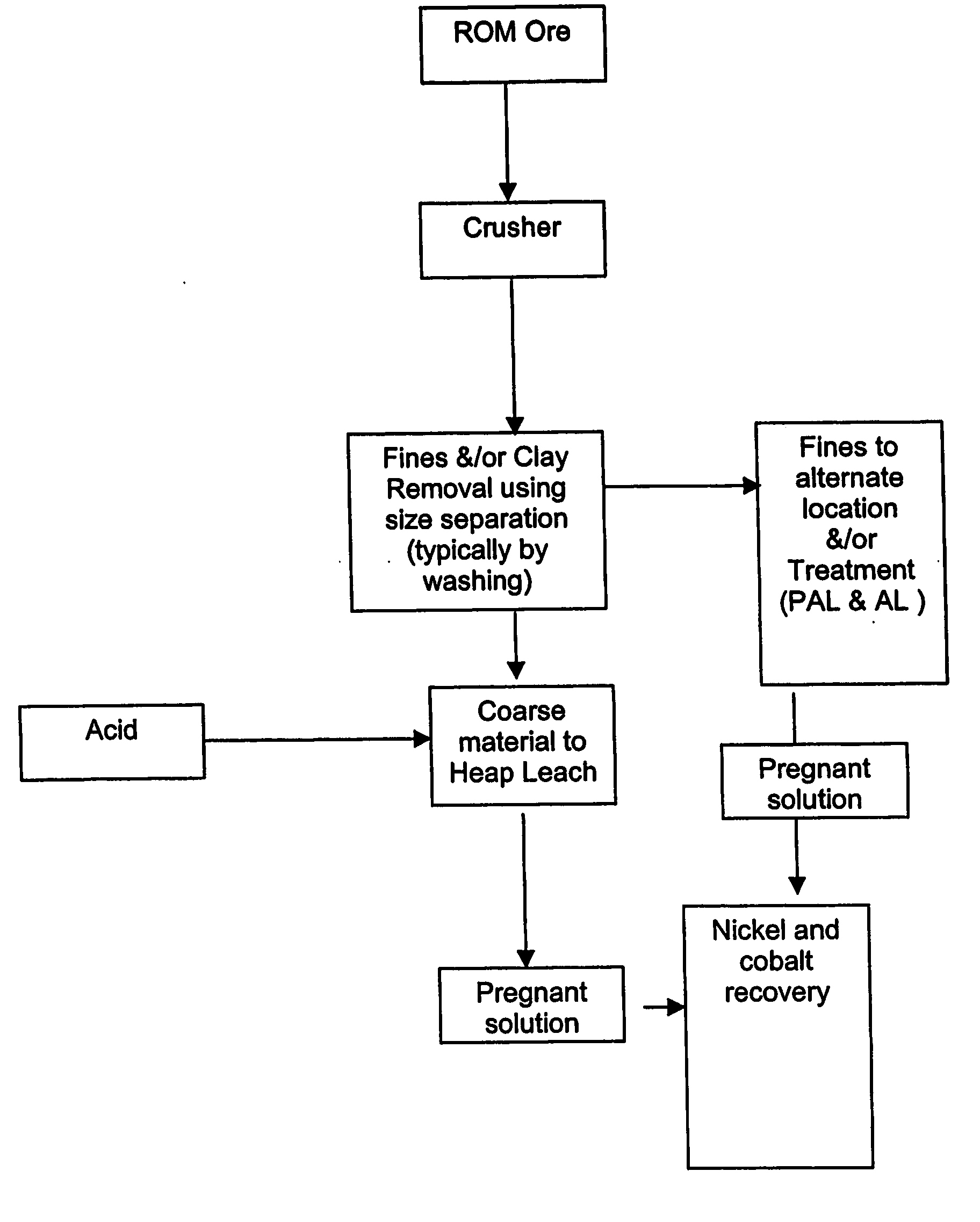

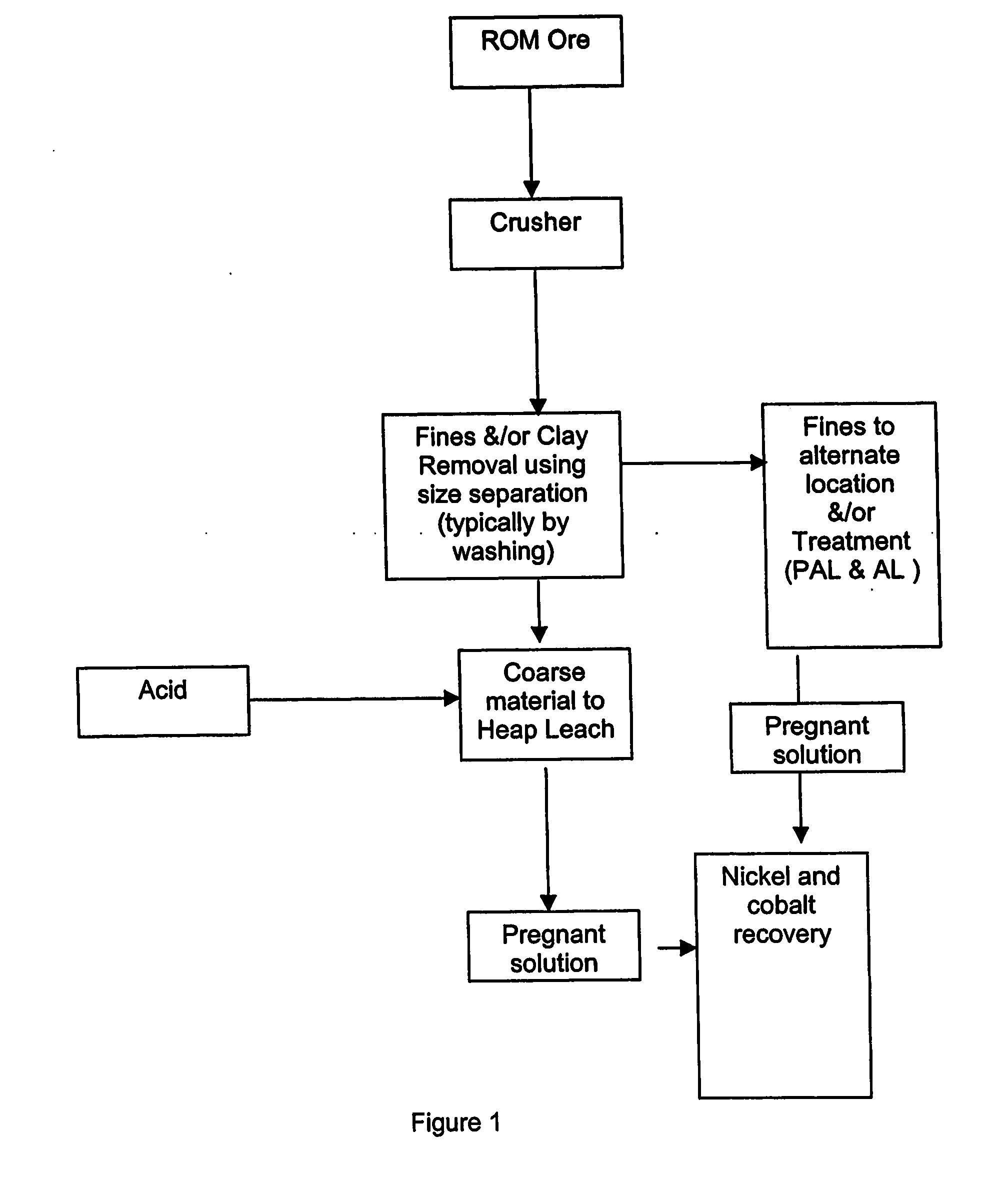

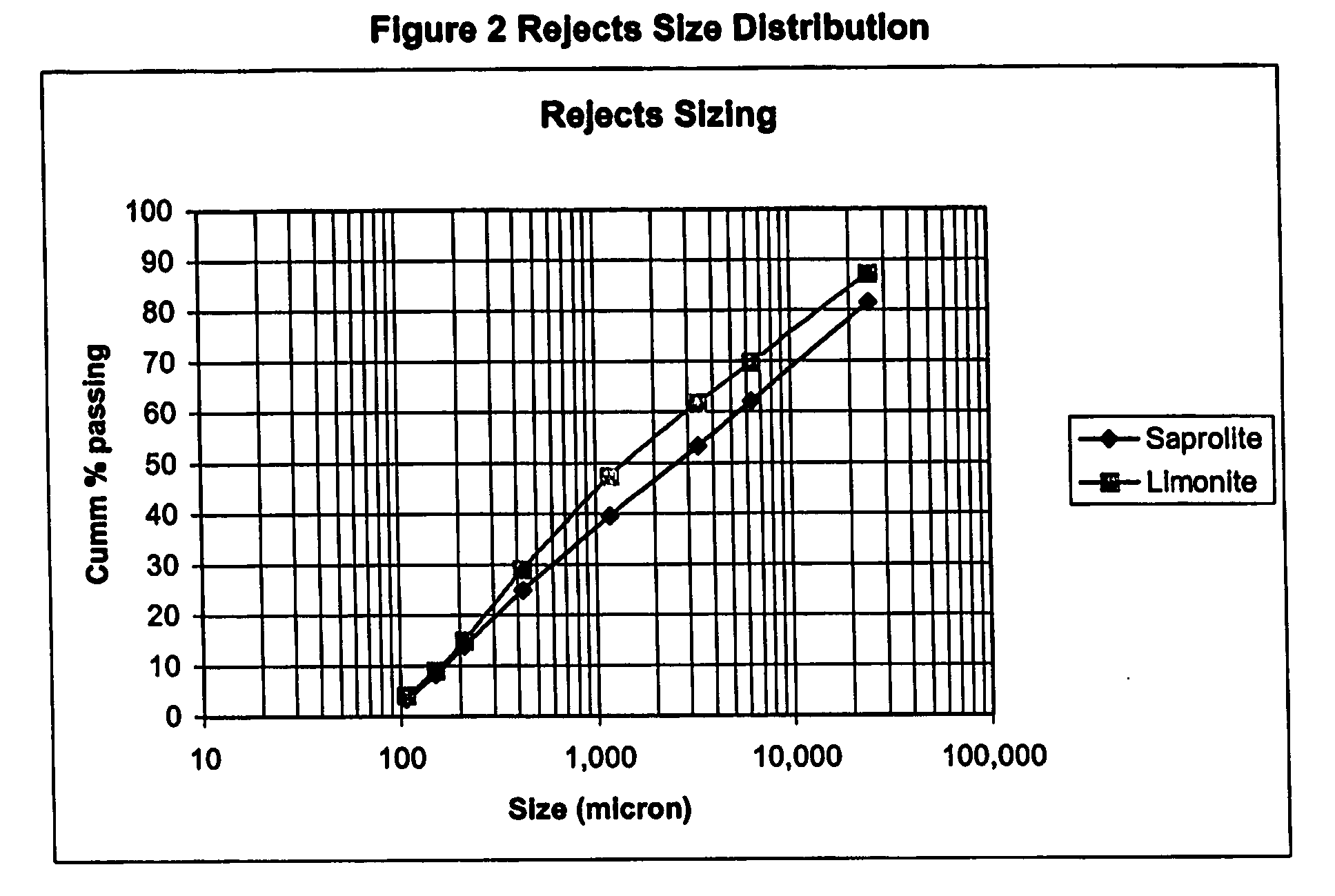

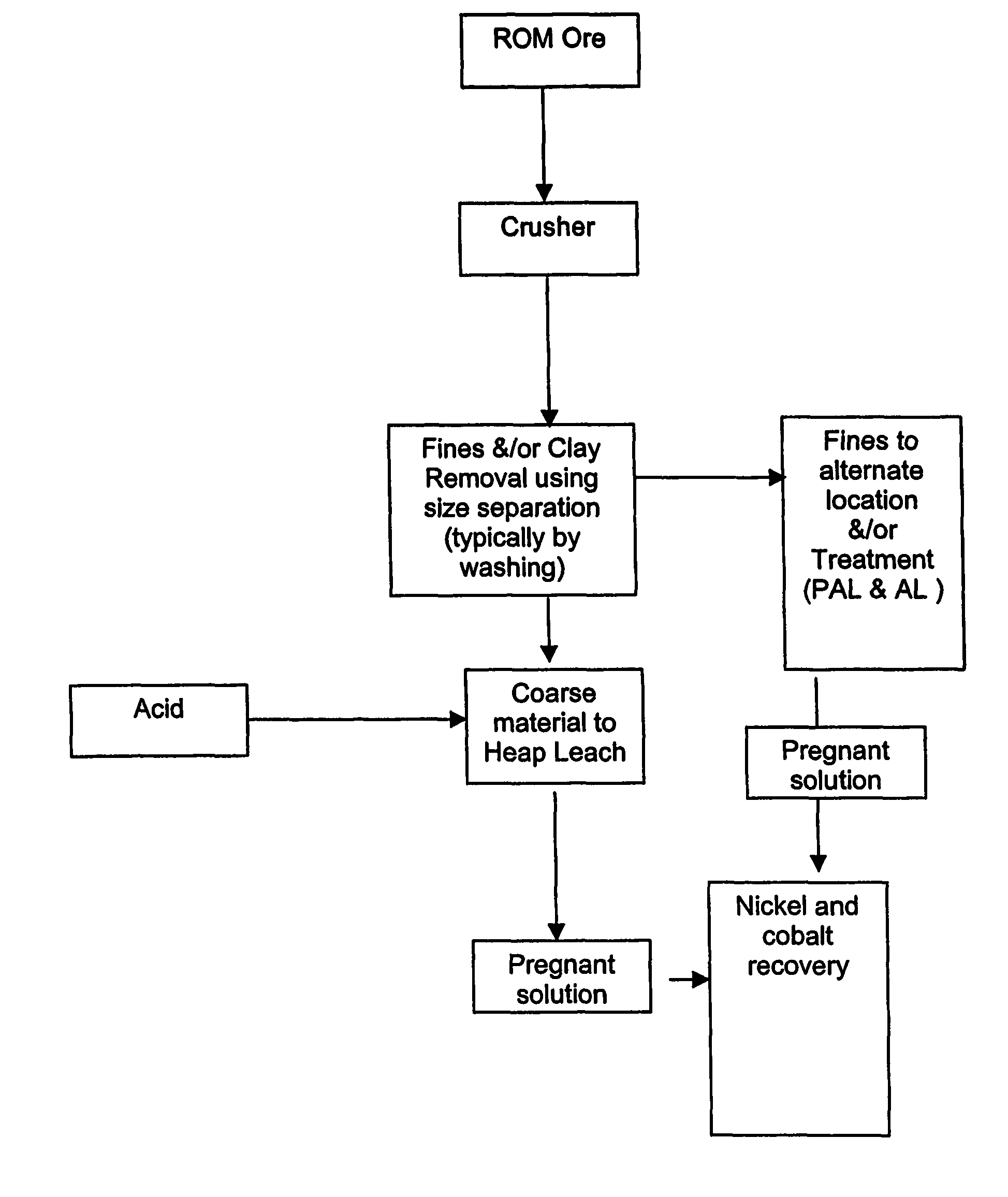

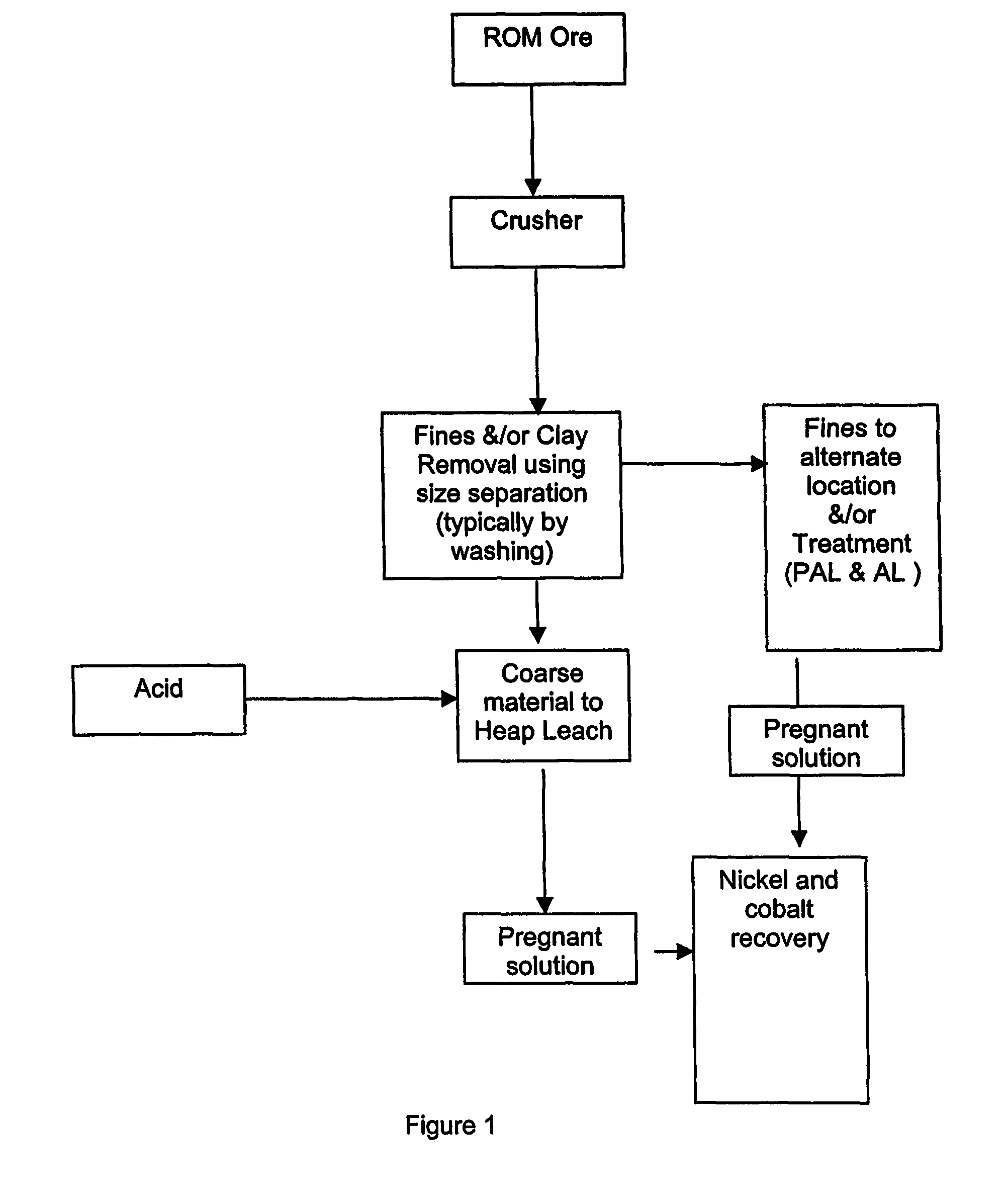

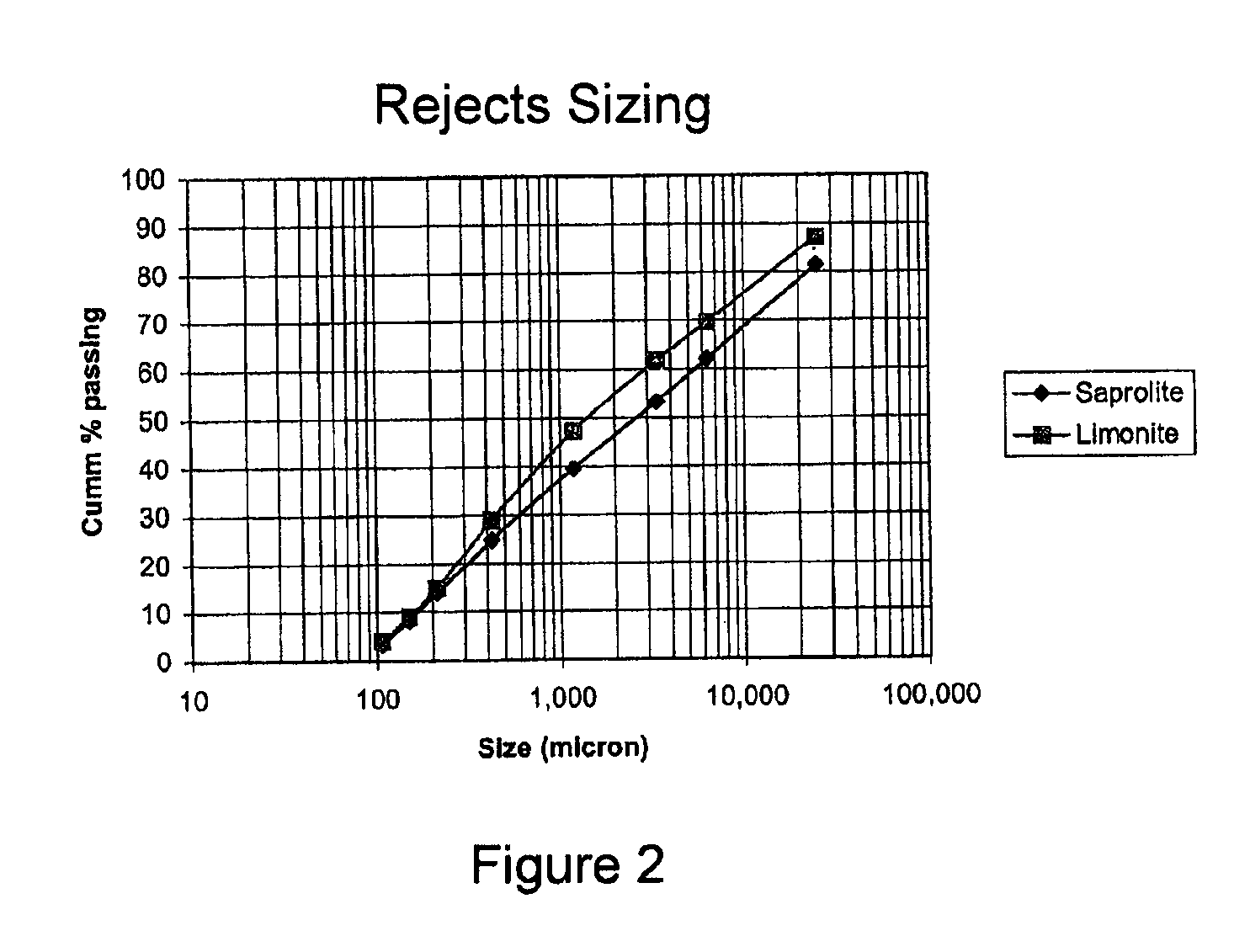

Process for recovery of nickel and cobalt by heap leaching of low grade nickel or cobalt containing material

InactiveUS20070034056A1Enhanced leaching processMaximum recoverySolvent extractionIron compoundsLower gradeLow graded

A process for the recovery of nickel and cobalt from laterite ores, the process including the steps of: a) beneficiating the ore to separate it into a beneficiated upgraded ore fraction and a coarse, siliceous low grade rejects fraction which is substantially free from fines and clay materials; b) separately processing the upgraded ore fraction for the recovery of nickel and cobalt; and c) subjecting the low grade rejects fraction to a heap leach process with an acid supplemented solution to create a heap leachate for further nickel and cobalt recovery processing.

Owner:CERRO MATOSO

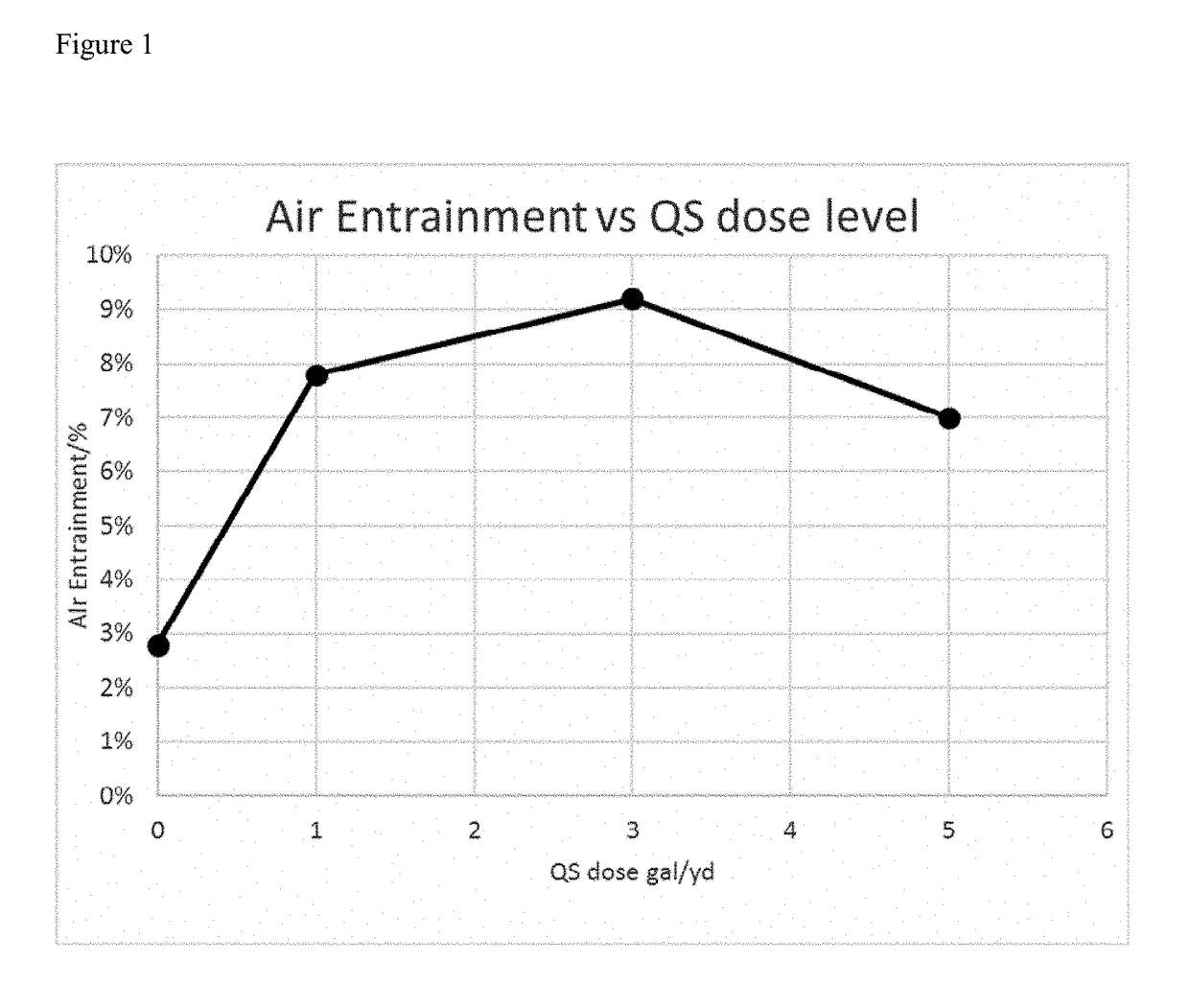

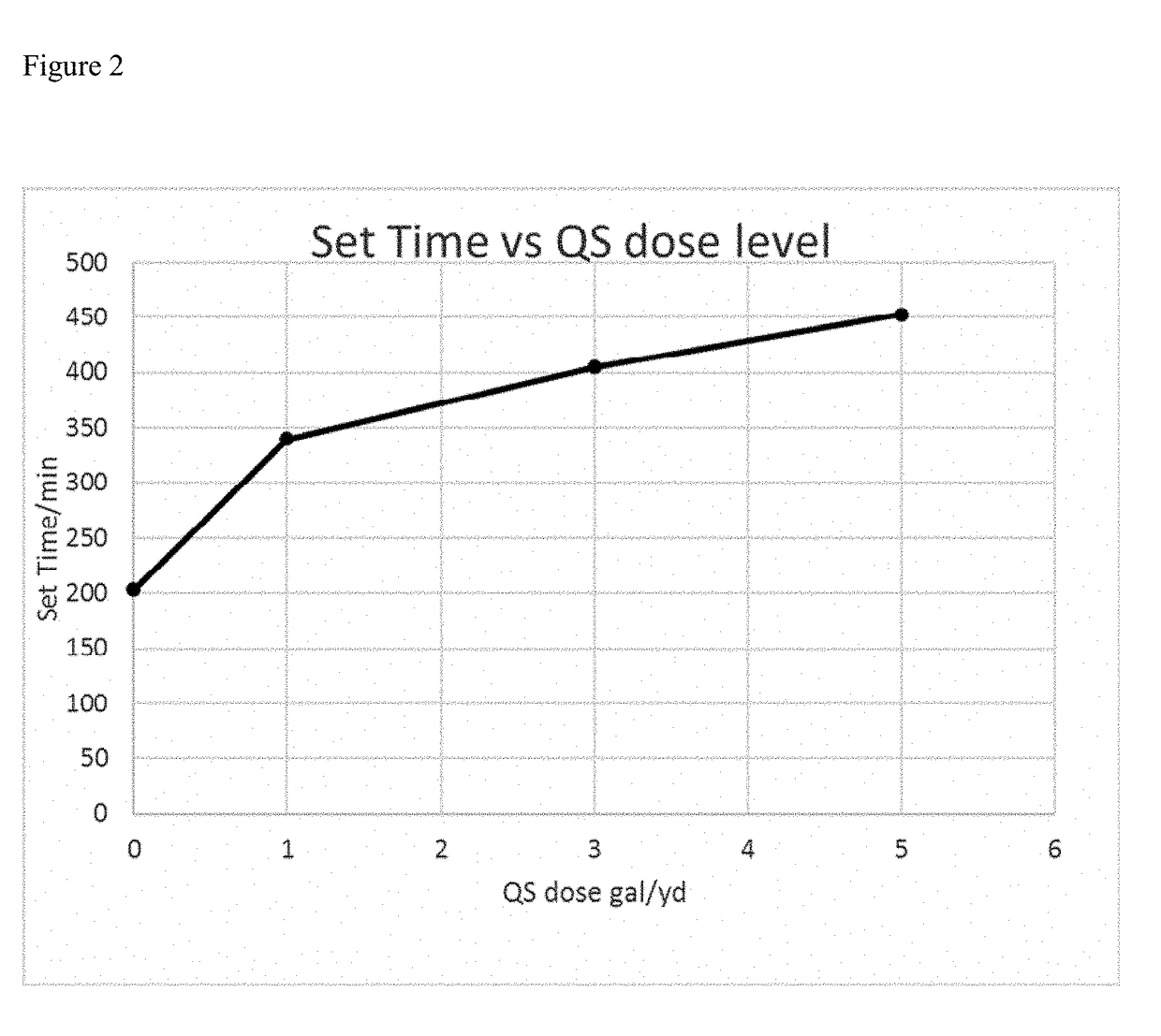

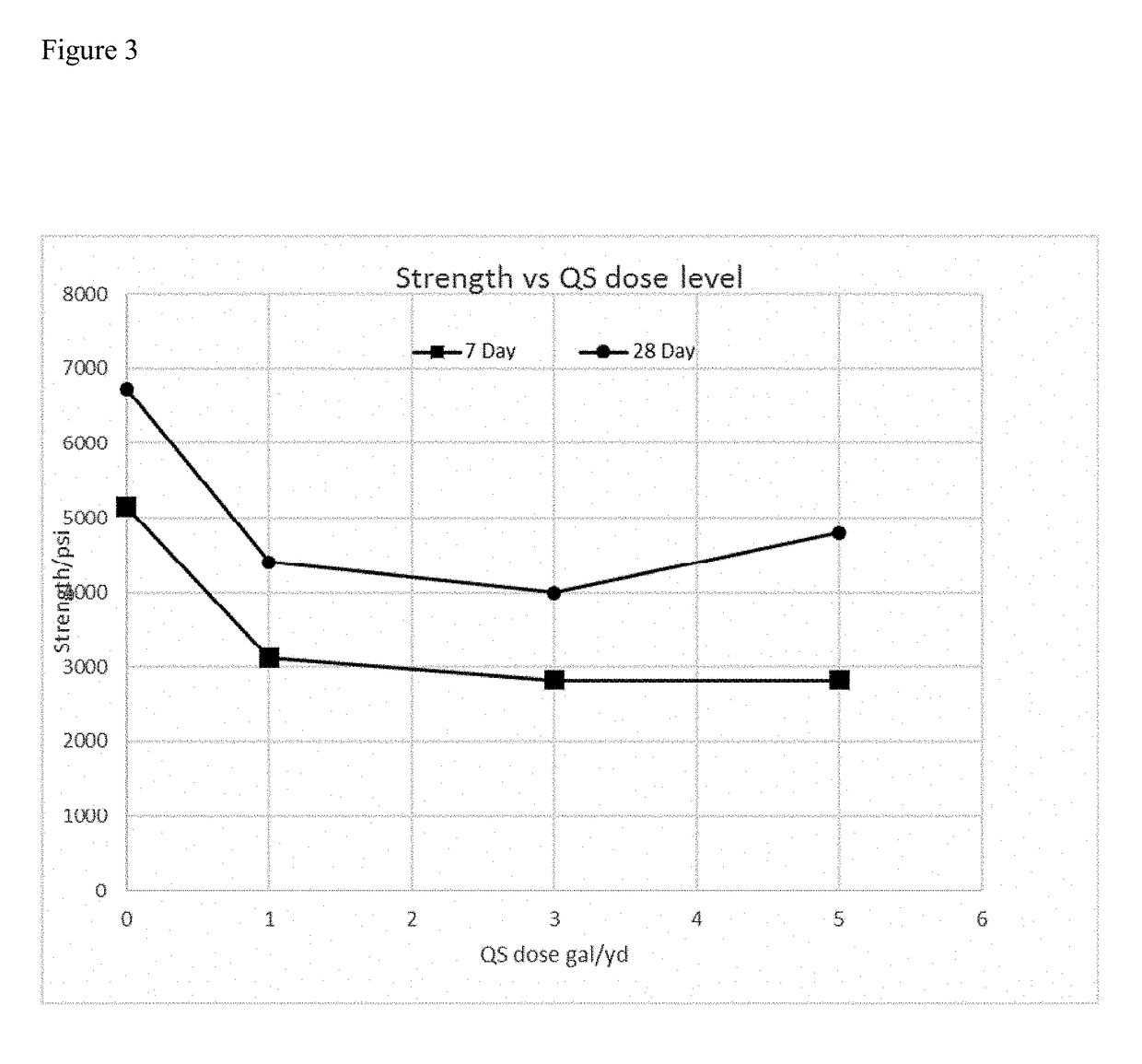

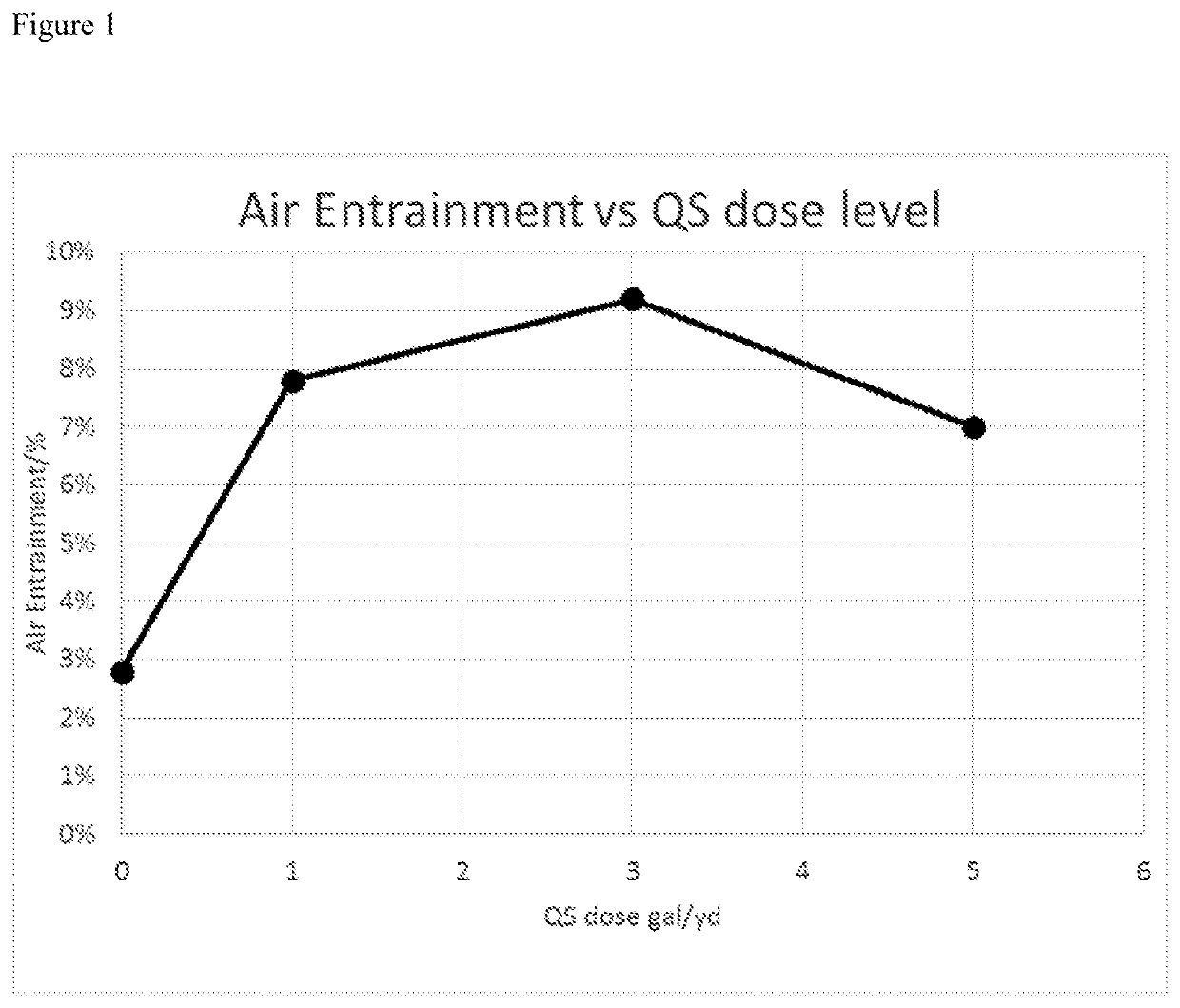

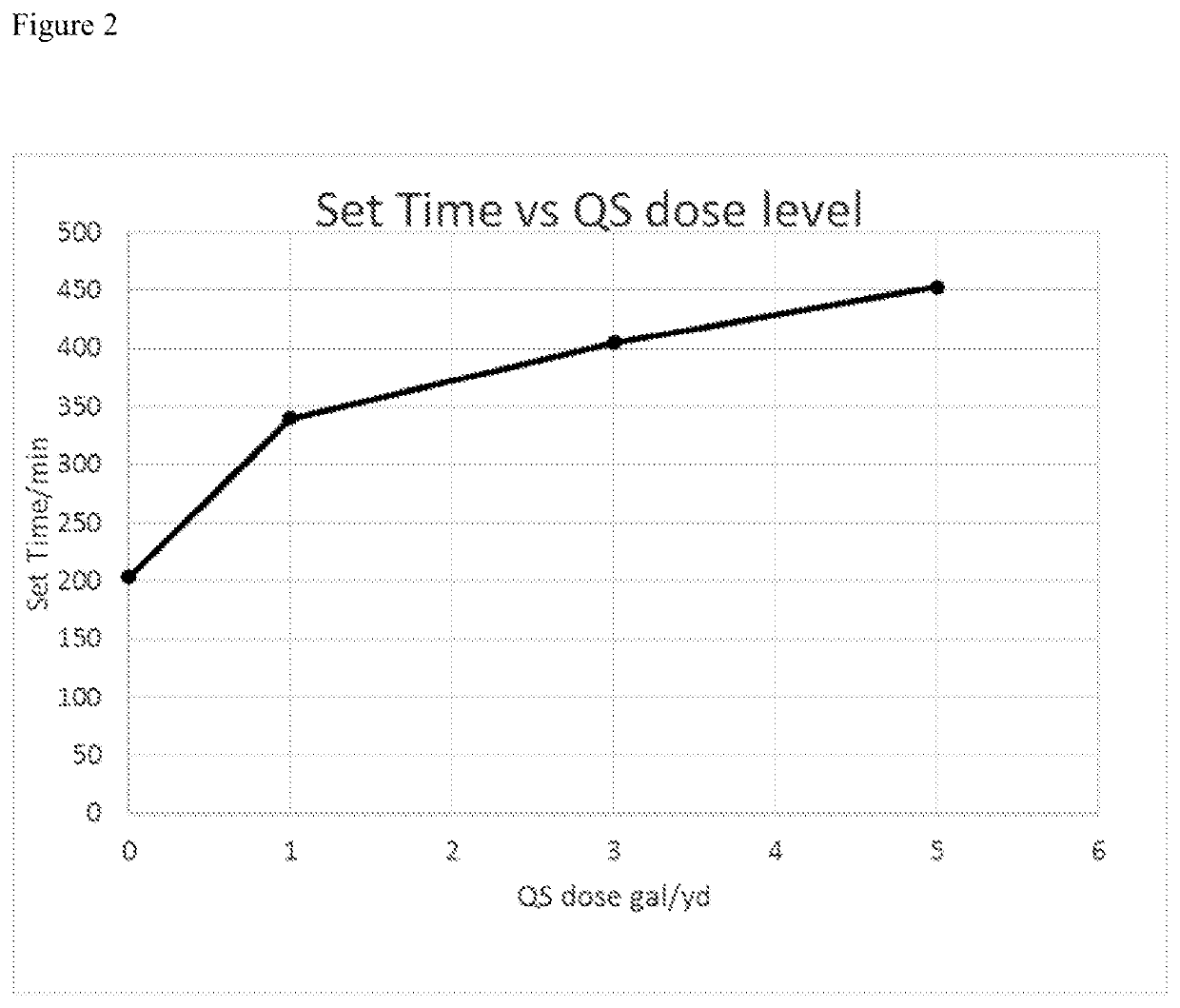

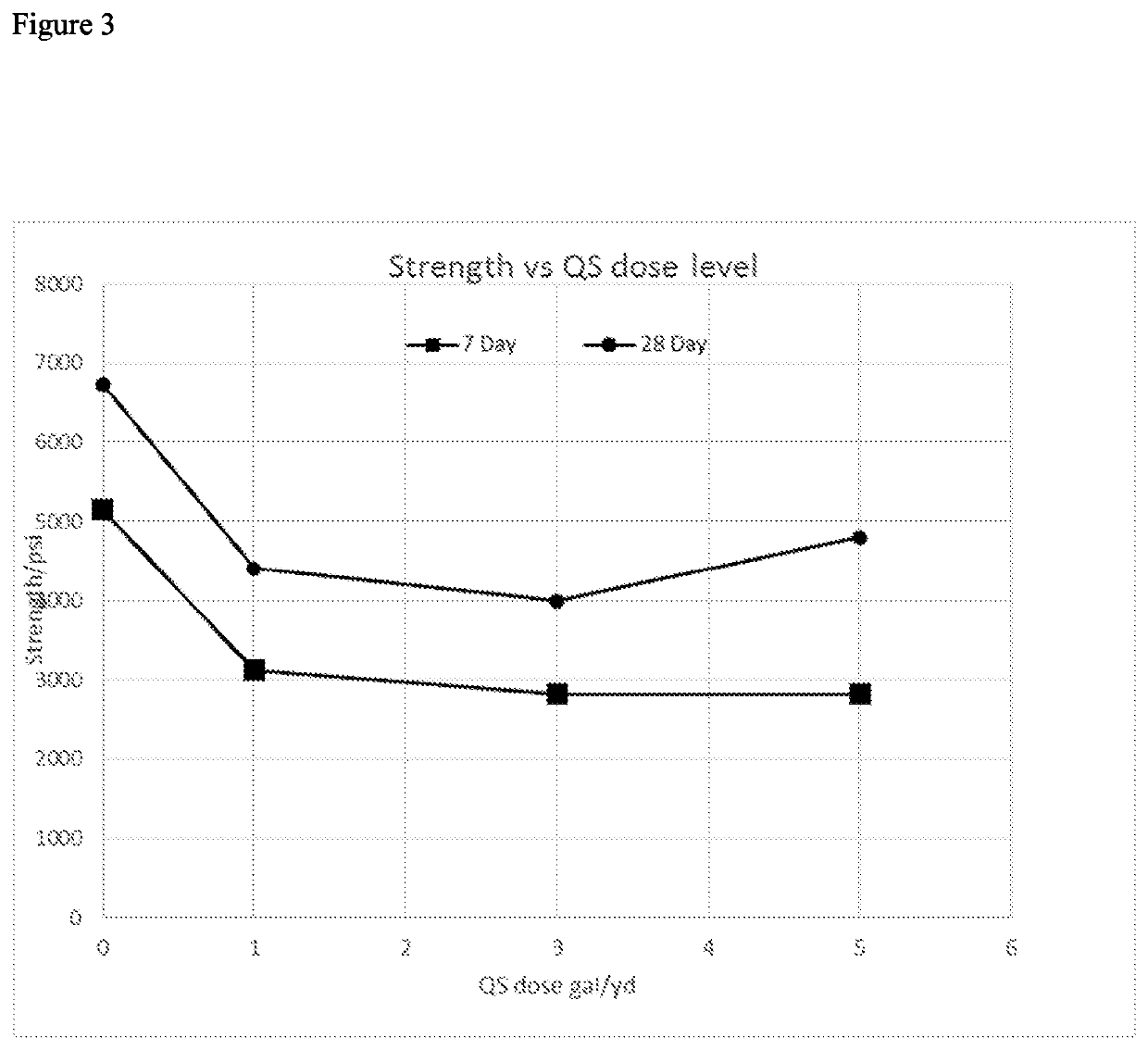

Additive formulation for reduction or prevention of microbially induced corrosion in concrete or cementitious material

An additive formulation for reduction or prevention of microbially induced corrosion in concrete, cementitious material (such as mortar or grout), or a combination thereof. The additive formulation comprises a Quat Silane and a fungicide, wherein the ratio of the Quat Silane to the fungicide in the formulation is in a range of about 10:1 to about 1:10, preferably in a range of about 5:1 to about 1:5.

Owner:MICROBAN PROD CO INC

Method for extracting uranium from acidic, high-specific-gravity or low-concentration uranium ore extraction solution

The invention relates to hydrometallurgical extraction technology of uranium and aims at providing a method for extracting uranium from acidic, high-specific-gravity or low-concentration uranium ore extraction solution, to overcome the difficult concentration problem of an acidic, high-specific-gravity or low-concentration uranium solution, so as to improve the yield and reduce the cost. According to the method provided by the invention, tri-fatty amine is used as an extractant to extract an acidic, high-specific-gravity or low-concentration complicated uranium solution, polyhydric alcohol is used as an additive to perfect the physical properties of the extractant, and the effect of extracting uranium from the acidic, high-specific-gravity or low-concentration uranium ore extraction solution is good.

Owner:CNNC NORTHERN URANIUM IND CO LTD

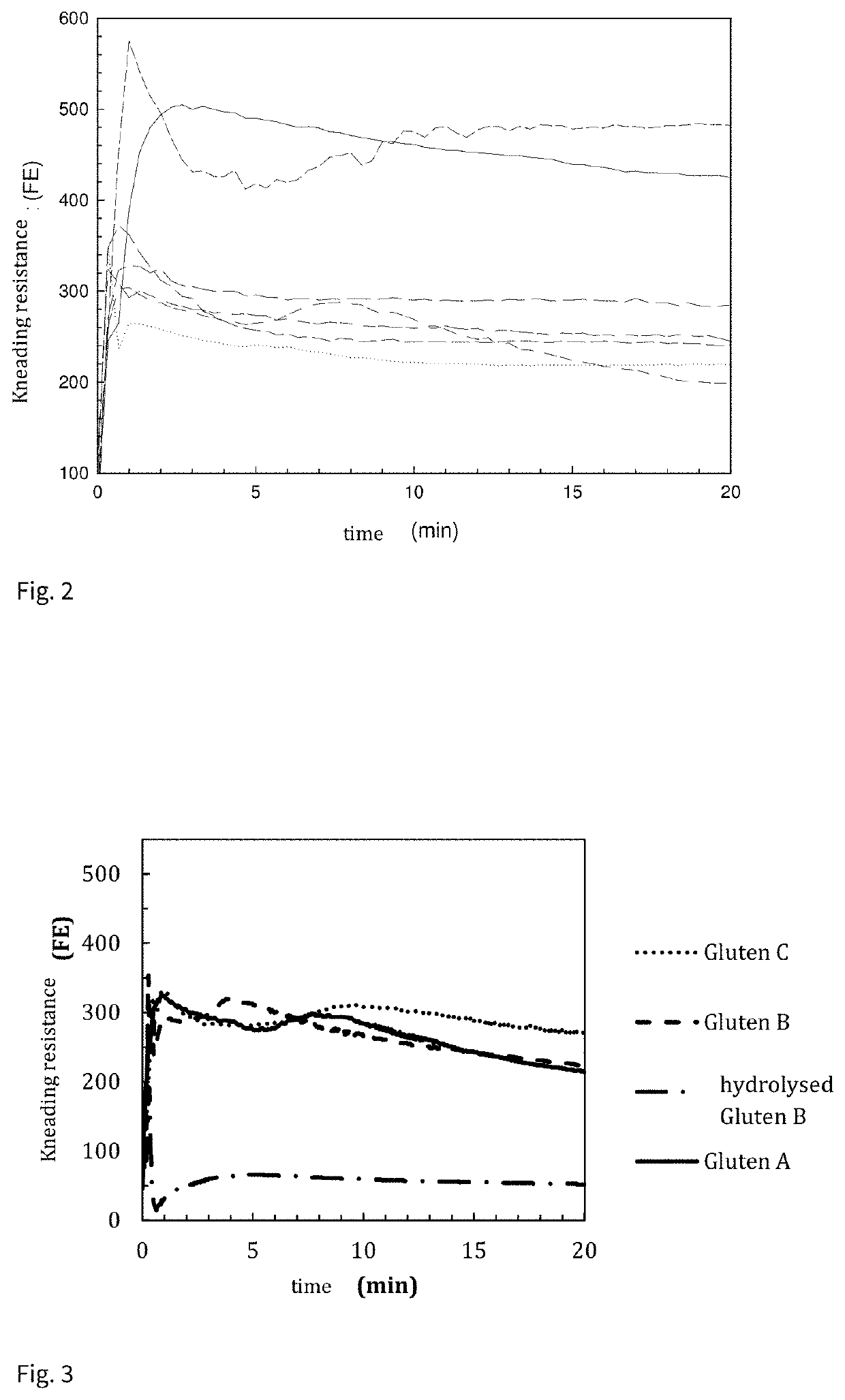

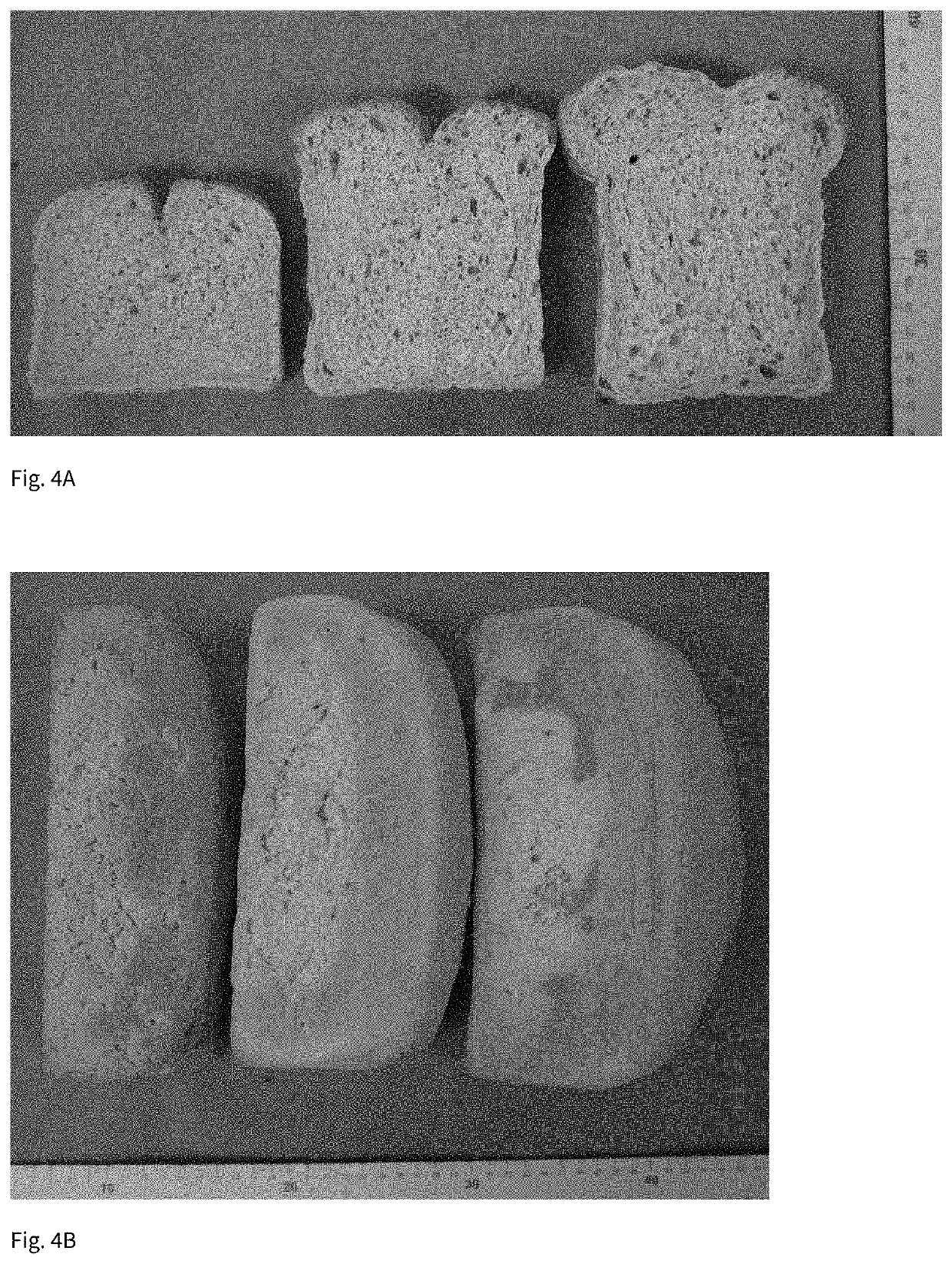

Well-tolerated flour composition

InactiveUS20200214301A1Improve toleranceEnhanced leaching processDough treatmentDough/pre-mixesBiotechnologyFood products

Owner:ERNST BOCKER

Cherry instant drink

InactiveCN107232472AAbundant raw materialsFull of nutritionFood ingredient as taste affecting agentNatural extract food ingredientsEconomic IncomeEnzyme

The invention mainly relates to the technical field of food processing, and discloses a cherry instant drink. The drink is prepared from the following raw materials: cherry, broccoli, tremella, cherry leaves, xylooligosaccharide, complex enzyme, vitamin C, griffonia seed extract and lactobacillus, has the advantages of rich raw materials, comprehensive nutrition, sour and sweet taste and convenience in drinking, the deep processing approach of cherry and cherry leaves is improved, cherry deep-processed products on the market are increased, cherry leaves are sufficiently utilized to change waste into valuable materials, and the economic income of farmer households is increased by 14.2%; color and nutrition of the cherry drink can be enriched by adding broccoli and tremella, and the drink tastes smooth; and cherry mixed slurry is subjected to enzymolysis by the complex enzyme, the tissue structure of raw materials is decomposed, extraction of beneficial ingredients in the raw materials and juice output increase can be promoted, the nutrition and flavoring ingredients of the drink can be improved; and after the cherry leaves are ground and deep-fried, the fragrance is improved, and the tanning taste of cherry leaves can be lightened.

Owner:HEFEI RUNYU AGRI TECH CO LTD

Medicine for treating rhinitis

InactiveCN107334916ARegulate immune responseEnergeticNervous disorderDispersion deliverySide effectExternal application

The invention discloses a medicine for treating rhinitis, belonging to the technical fields of Chinese herbal medicinal preparations and applications of the Chinese herbal medicinal preparations. The medicine adopts the following medicinal materials for external application: flos magnoliae liliflorae, cocklebur fruits, radix angelicae, herba asari, ramulus cinnamomi, garlic bulbs, herba centipedae and borneol; the medicine adopts the following medicinal materials for oral administration: honeysuckle flowers, flos chrysanthemi indici, caulis luffae, herba rhodiolae sacrae, radix acanthopanacis semticosi, radix angelicae sinensis, fructus xanthii, radix angelicae, flos magnoliae officinalis, dandelion, flos carthami, and herba violae. The medicine adopting the prescription is refined and powerful, is simple, and is strong in practicability; after the medicine adopting the prescription is used for treating rhinitis, the relapse of rhinitis seldom occurs, and no side effects exist; the basic purpose of the medicine is to promote the blood circulation and replenish the blood, and improve the body immunity, the external warming the middle warmer and the internal dispelling wind and calming the liver are achieved together, so that the purpose of treating rhinitis is achieved.

Owner:山西金地伟业农林开发有限公司

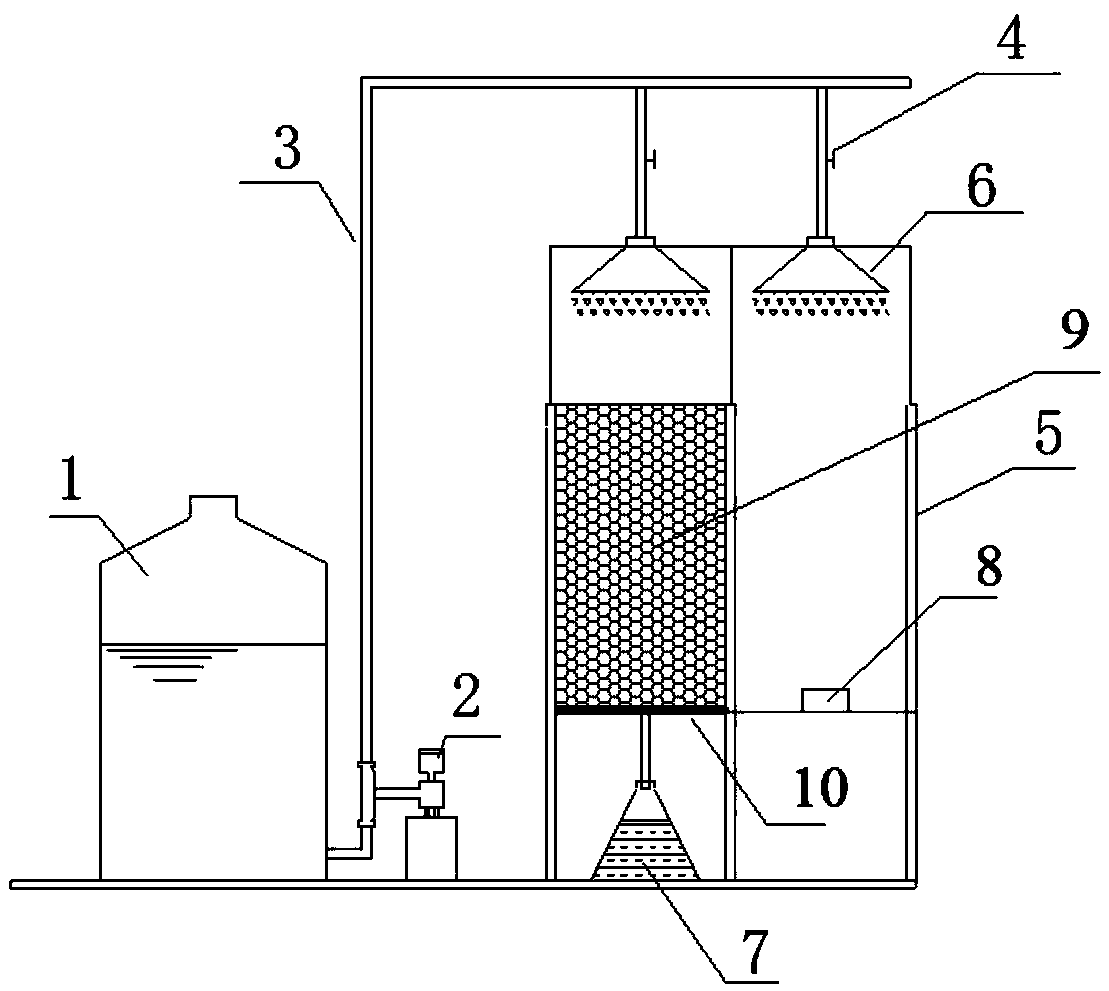

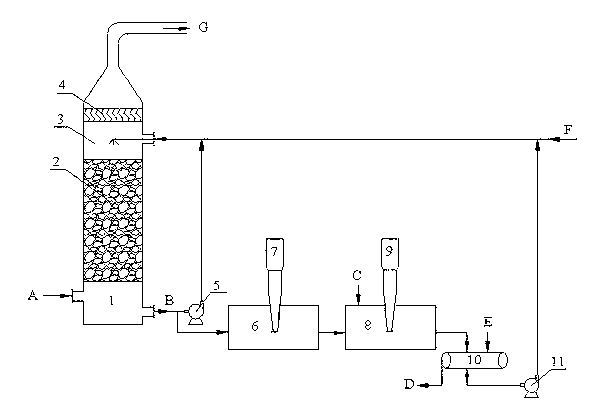

Dynamic leaching system and method

The invention discloses a dynamic leaching system. The dynamic leaching system comprises a container for containing a solvent, a metering pump, a conveying pipeline, at least two columnar containers,spray heads for spraying a leaching solvent into respective columnar containers, a collection container and rain gauges. One end of the conveying pipeline communicates with the container; the meteringpump is arranged on the conveying pipeline close to one end of the container; at least two branch pipelines are arranged at the other end of the conveying pipeline; each branch pipeline communicateswith one corresponding spray head; one columnar container is arranged below each spray head; one rain gauge is arranged in a cavity of one corresponding columnar container, and other columnar containers are used for containing to-be-leached samples and are provided with water outlets in the bottom walls; a filter is arranged above the bottom walls; and the obtained lixivium flows into the collection container through the water outlets. The invention further discloses a dynamic leaching method. The dynamic leaching system is simple in structure and can simulate toxicity dynamic leaching on solid waste, such as fly ash, in an on-site environment; and the method is simple to operate, wide in application and high in simulation effect.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

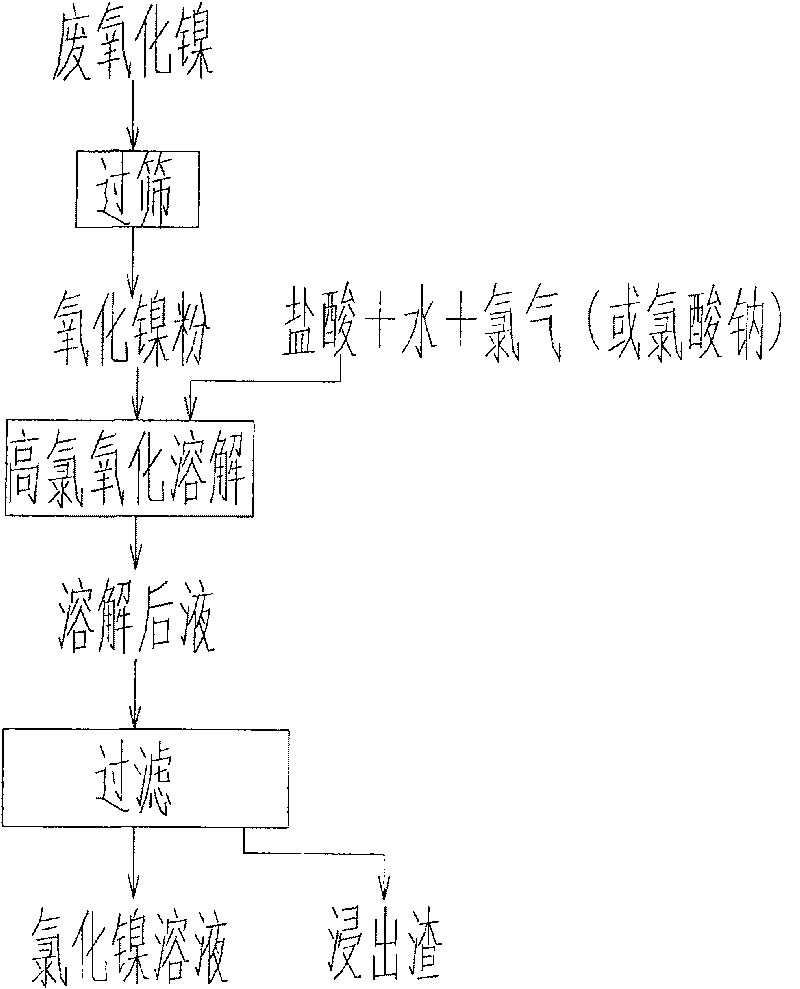

Nickelous oxide waste catalyst dissolution processing method

ActiveCN101219814BEfficient recyclingEnhanced leaching processNickel halidesChemical recyclingElectrolysisSodium chlorate

The invention relates to a dissolution method for treating nickel oxide waste catalyst, which is characterized in that the dissolution treatment process comprises the steps: the nickel oxide waste catalyst which is screened blocky material such as scree and slag is put into the hydrochloric acid solution with a concentration above 5N / L; under a temperature ranging from 85 DEG C to 100 DEG C and under a stirring condition, the oxidant sodium chlorate is added or the chorine is implanted and the oxidation potential is controlled to be 0.5-1.0V; the dissolution reaction is carried out for 1-5 hours to obtain green nickel chloride solution. The method of the invention has high leaching rate and dissolution ratio; high temperature treatment and pressure treatment are not required, which reducescost and solves the difficult problem of production technology. Combined with prior process of nickel electrolysis, the nickel in the waste catalyst can be effectively recycled.

Owner:JINCHUAN GROUP LIMITED

Preparation method for extracting water-soluble polyose from black pine needles according to decompression inner-boiling method

The invention discloses a preparation method for extracting water-soluble polyose from black pine needles according to a decompression inner-boiling method. The preparation method comprises the following steps: putting the black pine needles in a constant-temperature drying cabinet for 24 hours' drying at 40 DEG C, milling the dried black pine needles by a miller, and sieving with a 80-mesh sieve; weighing 1 g of the obtained black pine needle powder, putting the weighed black pine needle powder in a glass device, and adding 2 ml of ethanol for 30 minutes' uniform wetting, so as to ensure that ethanol permeates the black pine needle powder; carrying out vacuum suction to reduce the gauge pressure to -0.080 MPa, carrying out decompression suction till slightly boiled bubbles are generated on the mixture surface, and carrying out filtration; extracting a solution by utilizing hot water of which the volume is 20 times of that of the solution and the temperature is 85 DEG C for 6 minutes; selecting a small amount of the extracted solution for dilution, and measuring the polyose content according to a phenol-sulfuric acid method; precipitating the extracted solution by utilizing a 4% ethanol solution, carrying out still standing for a night, carrying out centrifugation, and then taking out the precipitate for drying in the drying box; preparing the dried solution into a polyose product. Through adoption of the technical scheme, the leaching amount of polyose is improved; the decompression inner-boiling method is low in production cost and simple in process; the preparation method has the advantages that the effective components of polyose can be quickly extracted and separated in an environment-friendly manner.

Owner:杨平

Process for recovery of nickel and cobalt by heap leaching of low grade nickel or cobalt containing material

InactiveUS7758669B2Increase productionImprove permeabilitySolvent extractionIron compoundsLower gradeLow graded

A process for the recovery of nickel and cobalt from laterite ores, the process including the steps of: a) beneficiating the ore to separate it into a beneficiated upgraded ore fraction and a coarse, siliceous low grade rejects fraction which is substantially free from fines and clay materials; b) separately processing the upgraded ore fraction for the recovery of nickel and cobalt; and c) subjecting the low grade rejects fraction to a heap leach process with an acid supplemented solution to create a heap leachate for further nickel and cobalt recovery processing.

Owner:CERRO MATOSO

Copper-catalyzed glycine-thiosulfate composite gold leaching process

ActiveCN112961991AWeaken oxidative decompositionImprove stabilityProcess efficiency improvementSulfate radicalsThio-

The invention discloses a copper-catalyzed glycine-thiosulfate composite gold leaching process. The process comprises the following steps of adding copper sulfate, glycine or / and metal salt thereof and thiosulfate into gold ore pulp, adjusting the pH value of the ore pulp to 10.0-13.0, and then stirring and leaching to complete the gold leaching process. According to the process, in the copper-catalyzed glycine-thiosulfate composite gold leaching process, the glycine or the metal salt thereof is introduced, the glycine or the metal salt thereof can form a copper-glycine chelate with higher stability with Cu<2+> to stabilize copper in a solution, so that the oxygenolysis effect of a copper complex on thiosulfate radicals is weakened, the stability of a gold leaching system is improved, and the consumption of reagents is reduced; and the glycine or the metal salt of the glycine can also play a role of the gold leaching agent together with thiosulfate radicals, so that the consumption of thiosulfate can be further effectively reduced, and the consumption of thiosulfate is reduced to be below 4kg / t gold ore.

Owner:JIANGXI UNIV OF SCI & TECH

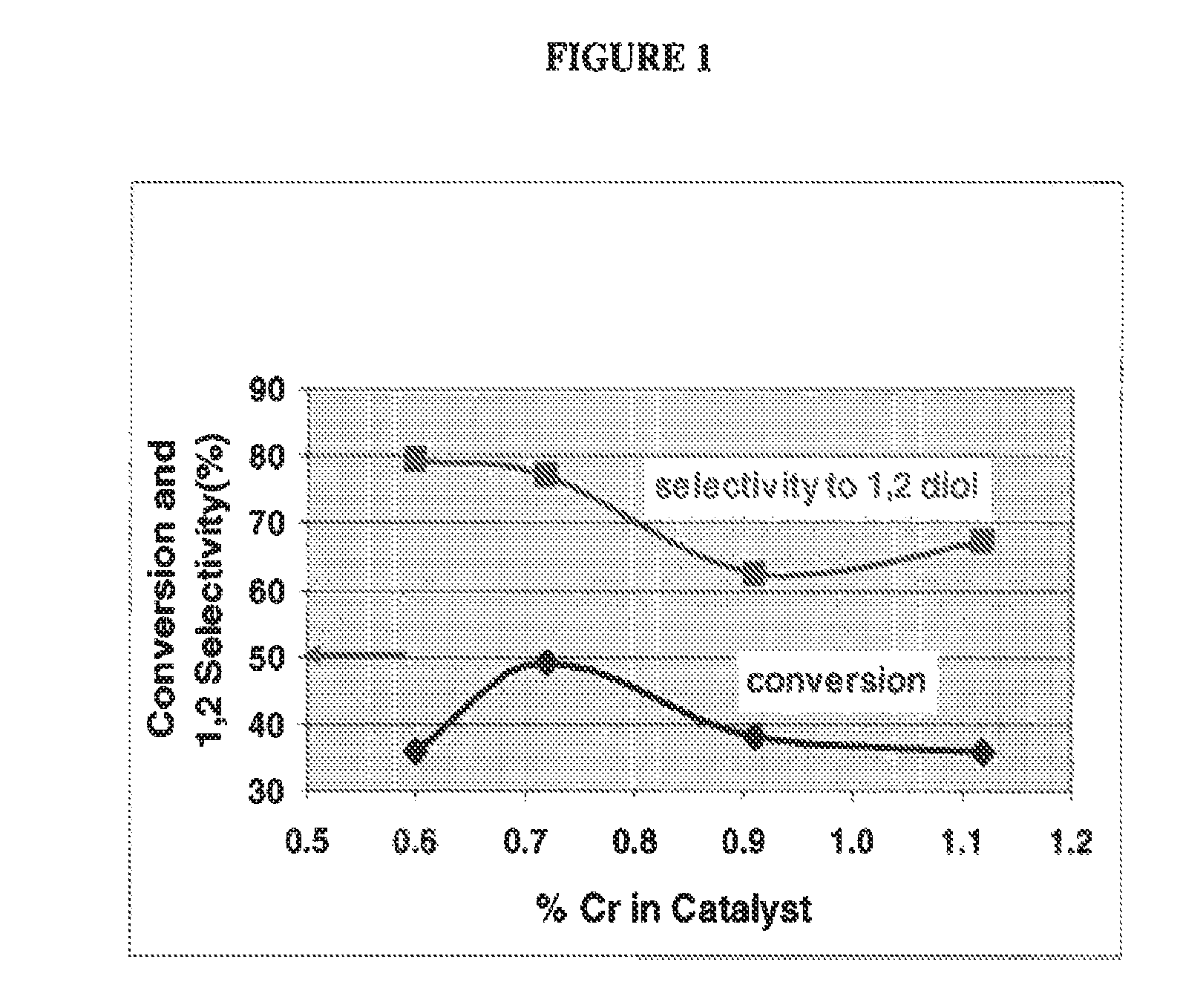

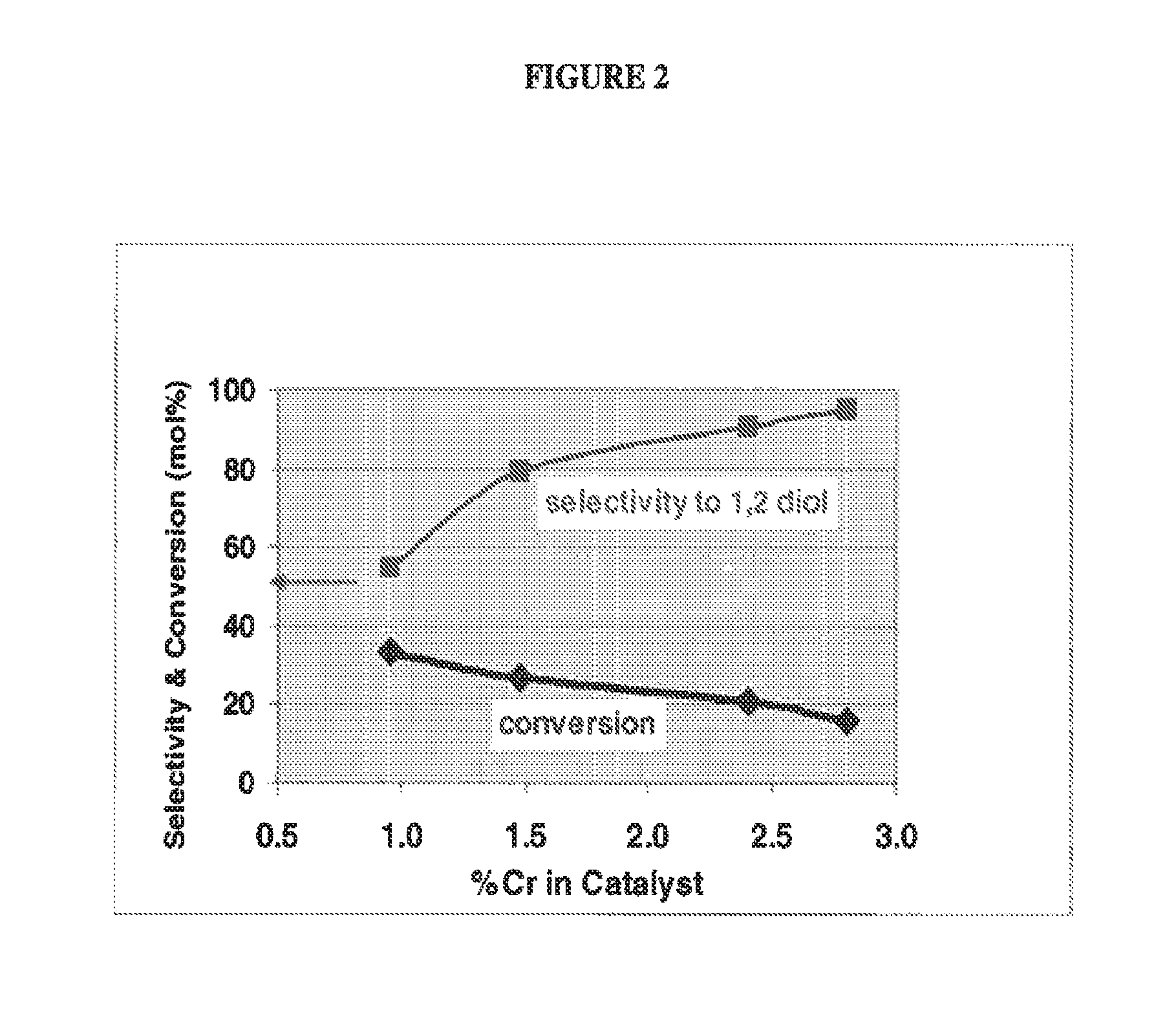

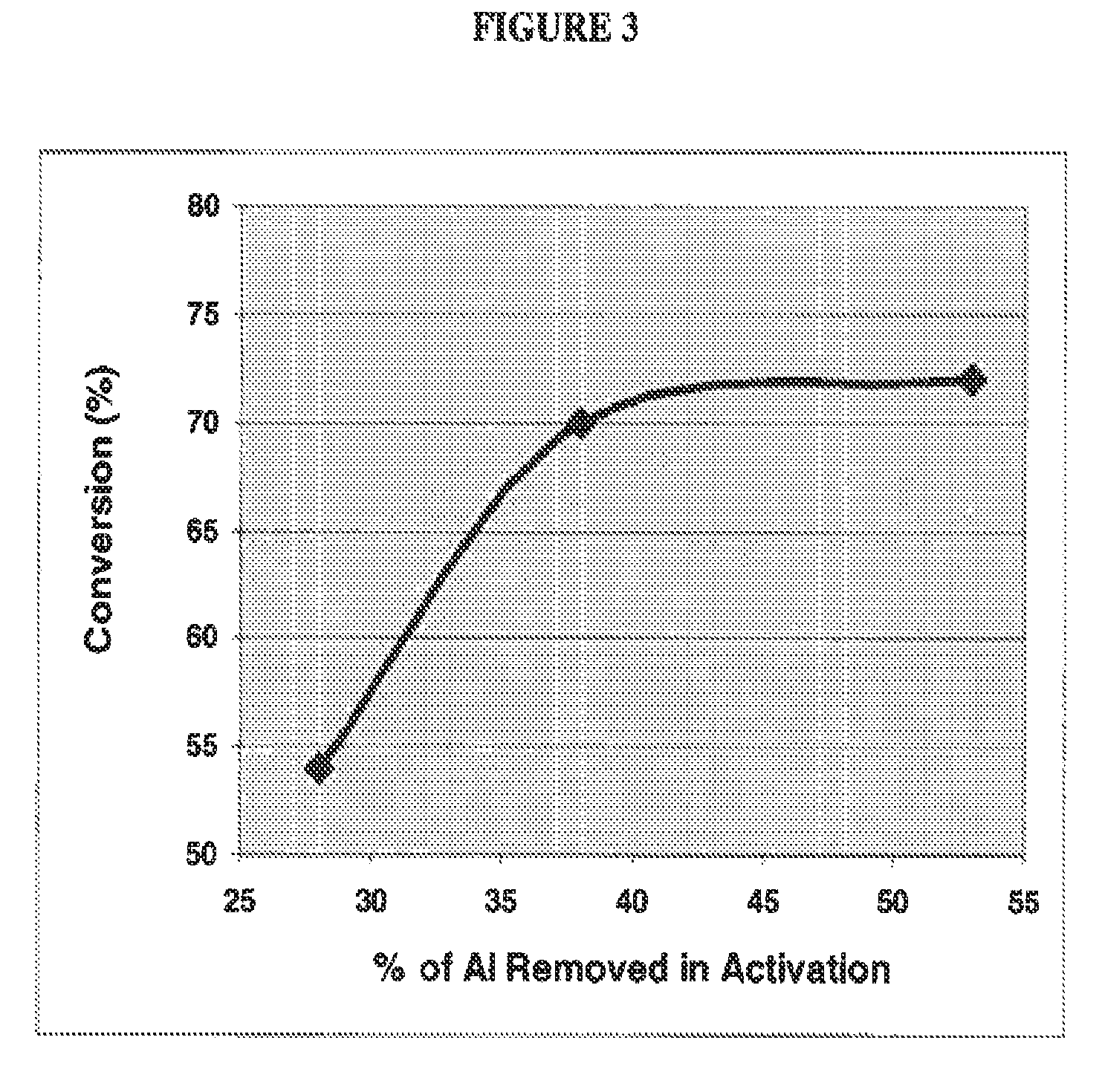

Process for making 1, 2-propane diol from hydrogenation of glycerol

InactiveUS8735635B2Increase production of selected productEnhanced leaching processOxygen-containing compound preparationOrganic compound preparationGlycerolSlurry

This invention is a process for making 1,2-propane diol from glycerol. The process comprises subjecting a glycerol stream to hydrogenation conditions in the presence of a transition metal promoted skeletal copper catalyst to enhance selective production of 1,2-propane diol product. Chromium promoted catalyst is preferred for this invention, and moreover, it is preferred that the skeletal copper catalyst is prepared from copper aluminum alloys that have been subjected to leaching conditions selected to achieve at least 40% leaching of aluminum from the alloy. This process is particularly conducive to conducting the hydrogenation with reactant mixture in the liquid phase. The catalysts used in this invention are particularly suitable for use in a fixed catalyst bed, but can be activated and sized so that the catalyst is also suitable for use in slurry based reactions.

Owner:WR GRACE & CO CONN

Microbial fertilizer applicable to improvement of flaky salinized areas in Ningxia and Inner Mongolia in China

InactiveCN107903130AEnhanced leaching processImprove desalination performanceExcrement fertilisersBioloigcal waste fertilisersBacillus megateriumSoil horizon

The invention relates to a microbial fertilizer applicable to improvement of flaky salinized areas in Ningxia and Inner Mongolia in China. The microbial fertilizer comprises 1 to 1.5 of rice husk, 10to 15 of humic acid, 10 to 16 of balloonflower roots, 30 to 40 of earthworm soil, 2 to 3 of cytokinin, 1 to 3 of gibberellins, 15 to 20 of peroxyacetic acid, 8 of Sulfolobus acidocaldarius, 6 of Bacillus megaterium, 4 of nitrogen fixation bacteria and 2 of ferment bacteria. Directed at the characteristic of soil in flaky salinized areas in Ningxia and Inner Mongolia in China, the rice husk and theballoonflower roots are cooperated with humic acid to improve soil nutrients; the earthworm soil absorbs oozed low-position steam and fully immobilizes the steam on the surface of a soil layer; gibberellin and peroxyacetic acid rapidly fracture one-piece alkalized soil and isolated fractured alkalized soil; and then a great amount of communicating fermentation broth of Sulfolobus acidocaldarius and Bacillus megaterium obtained after glycolysis infiltrates into alkaline soil with biological components, and rapid differentiation and proliferation are realized among blocks, so the leaching and desalination capabilities of soil are improved, and the content of accumulated salt in each alkaline earth block is continuously reduced.

Owner:SHANDONG SHENGJING TOURISM DEV CO LTD

Device and method for extracting and concentrating traditional Chinese medicine

InactiveCN103041614BIncrease pressureIncrease the heat exchange areaEvaporationSolid solvent extractionPharmacy medicineProcess engineering

Owner:GUANGDONG MEDICAL UNIV

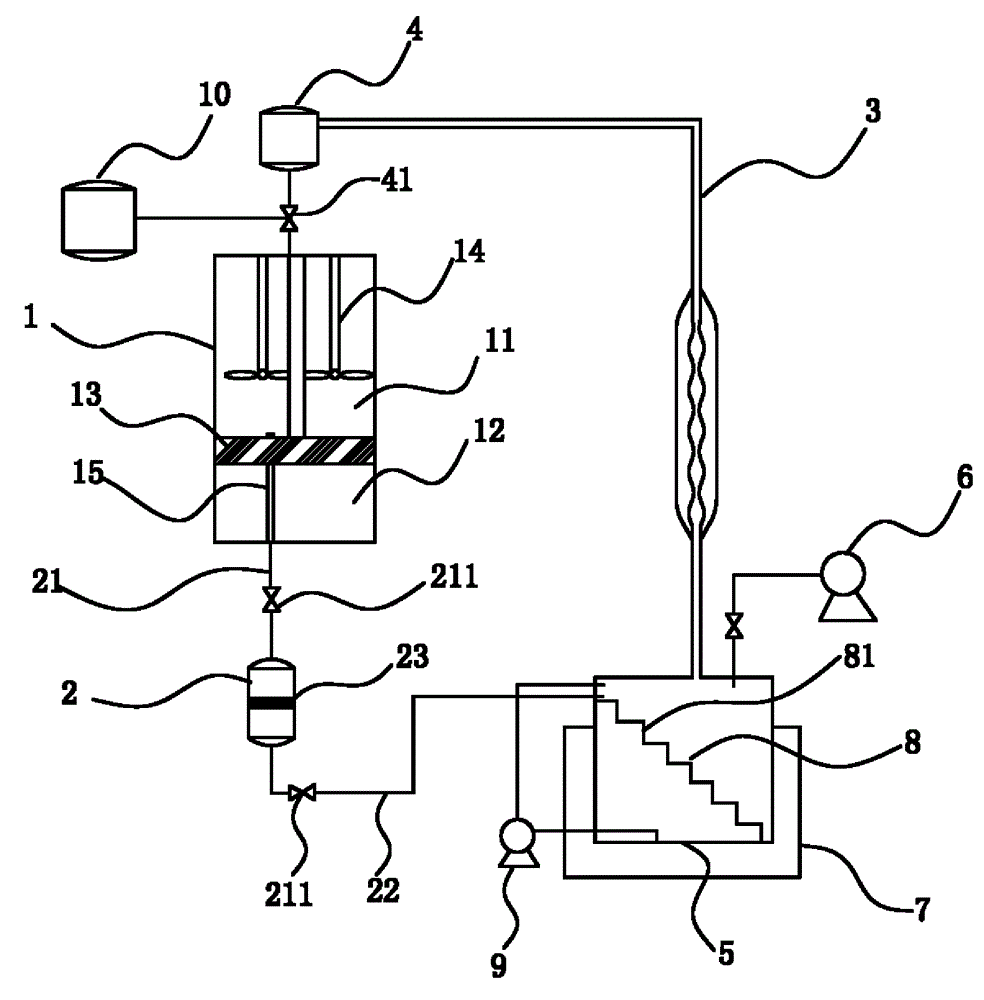

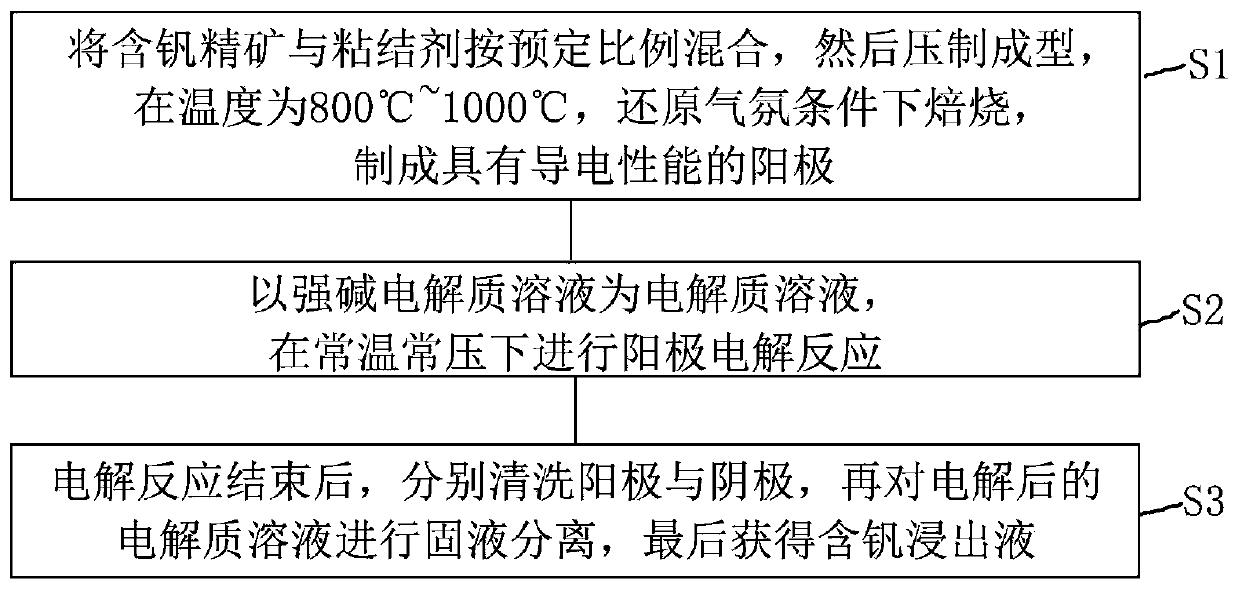

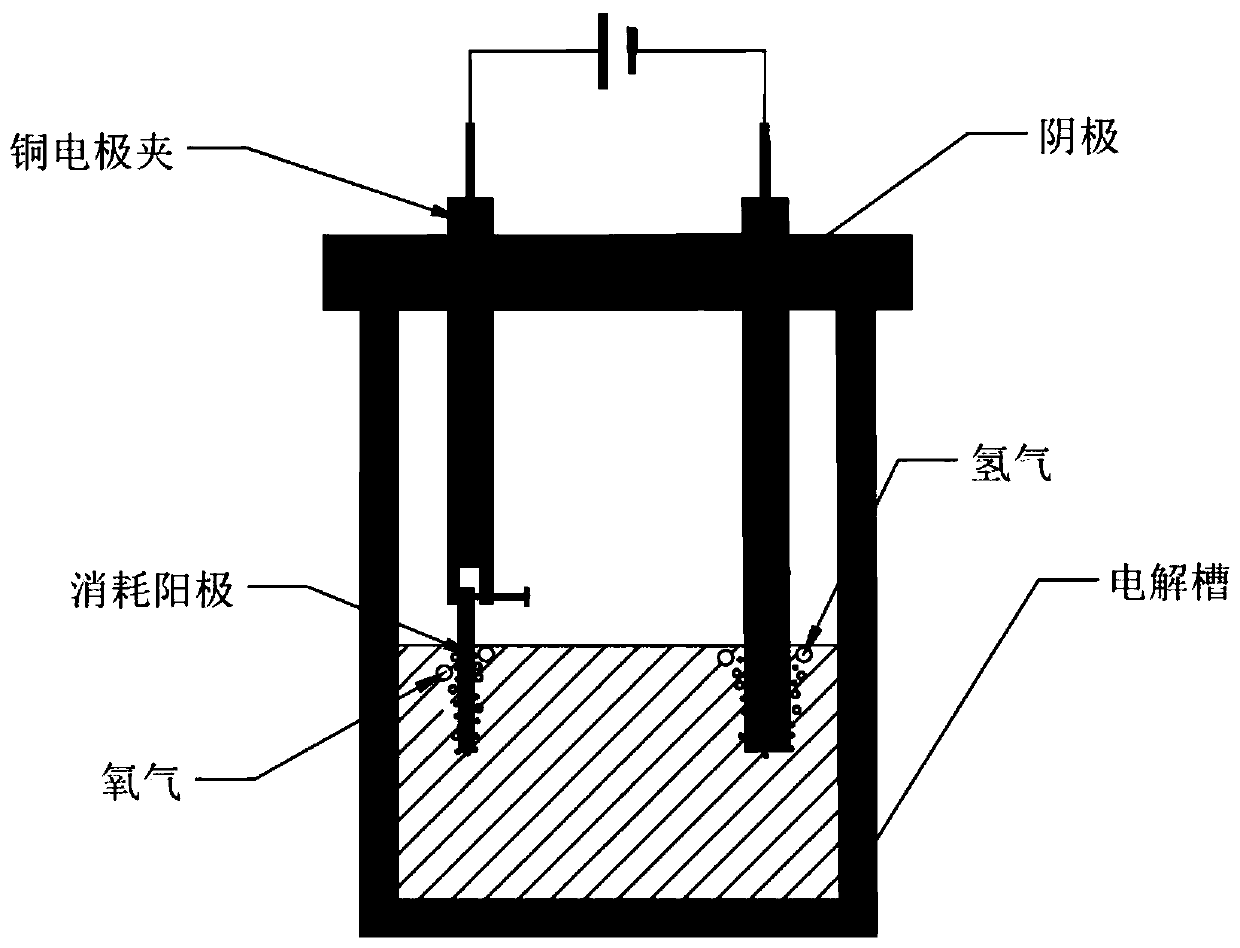

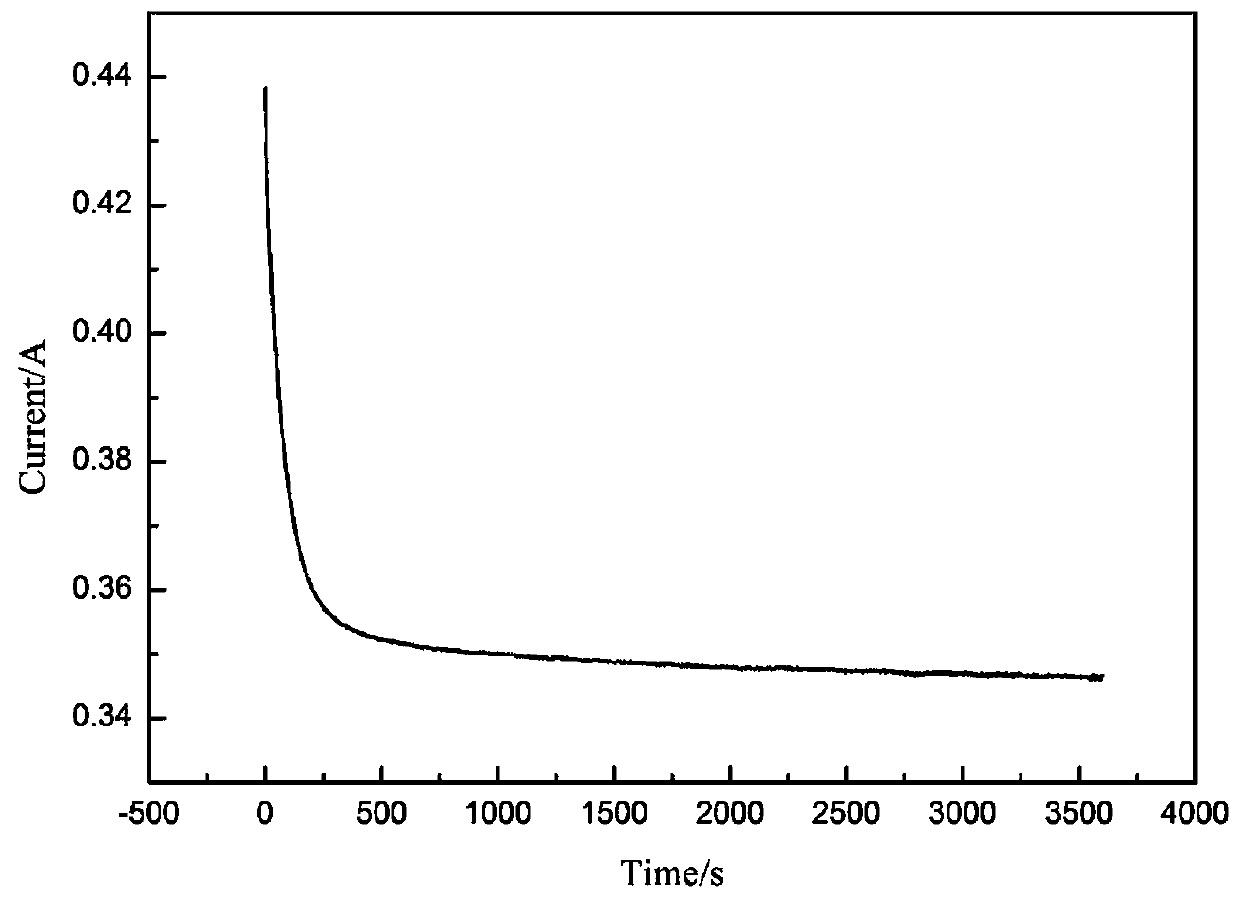

Method for leaching vanadium by anode electrolysis in strong alkali electrolyte solution

InactiveCN110042233ANo addedSimple ingredientsProcess efficiency improvementFerric hydroxideElectrolysis

The invention belongs to the field of leaching vanadium from ferrovanadium spinel minerals by an electrolysis method, and particularly relates to a method for leaching vanadium by anode electrolysis in a strong alkali electrolyte solution. The method comprises the following steps of preparing ferrovanadium spinel type vanadium-containing concentrate into a soluble anode and directly electrolyzingin the strong alkali electrolyte solution to obtain vanadium-containing leachate. In the method, iron contained in the anode is oxidized into ferrate ions which enter the solution, and the ferrate ions further promote the oxidation and leaching of vanadium in the vanadium-containing concentrate, and at the same time, pollution-free oxygen is precipitated on the anode surface. In addition, the ferrate ions entering the electrolyte solution are reduced by water and hydrogen generated by a cathode to form ferric oxide or / and ferric hydroxide precipitate, so that vanadium and iron are separated from the solution. The method electrolyzes the ferrovanadium spinel type vanadium-containing concentrate at normal temperature and pressure without adding any oxidant by utilizing the conductivity of ferrovanadium spinel and ferrate ions with the strong oxidizing property generated by electrolysis.

Owner:UNIV OF SCI & TECH BEIJING

Distilling method for Heiaozi wine

InactiveCN108949481AStrong fragranceIncrease the fragranceAlcoholic beverage preparationAfter treatmentDistillation

The invention mainly relates to the technical field of wine brewing and discloses a distilling method for a Heiaozi wine. The distilling method comprises the following steps: freezing, first distilling, secondary distilling, third distilling and mixing. The Heiaozi wine acquired according to the distilling method for the Heiaozi wine provided by the invention has clear and transparent liquor and strong fragrance, tastes sour, sweet and palatable and has a unique fragrance of Heiaozi wine; fermented grains are frozen at low temperature and then are refrigerated and thawed, so that the materialsin the fermented grains are fully mixed and the taste is mellow and full; distillation head and distillation tail are respectively received in the process of first distillation, which facilitates after-treatment; a double-layer ceramic tank is used for receiving in a steamer fermenting process; condensate water can flow between an inner layer and an outer layer of the ceramic tank, so that the cooling for distilling liquid can be accelerated; and meanwhile, a porous absorbing structure of the ceramic tank can make the wine liquor more flexible and abundant.

Owner:聂林

Method and device for immobilizing CO2 by enhancing mineral carbonation

InactiveCN102343199BFast catalytic reaction ratePromotes hydrationDispersed particle separationUltrasound - actionSlurry

The invention discloses a method and device for immobilizing CO2 in industrial tail gas by enhancing mineral carbonation. The device comprises a packed column absorber, a mineral leaching tank, a carbonation reactor and a belt type filter. The method comprises the steps of: enabling the industrial tail gas containing CO2 to enter the packed column absorber filled with immobilization carbonic anhydrase, rapidly transforming the CO2 into HCO3<-> under the catalysis action of the carbonic anhydrase; with a weak acidic solution containing the HCO3<-> as a mineral leaching agent, effectively leaching calcium ions from minerals in the mineral leaching tank under the action of ultrasonic waves to form a slurry enriching Ca<2+>; introducing the slurry enriching Ca<2+> into the carbonation reactor, adding a calcium-containing alkali material, regulating the pH of the slurry to be 7-9 to ensure that the HCO3<-> is transformed into CO3<2->, and generating a carbonation reaction with the Ca<2+> leached from the minerals to generate CaCO3. The invention can promote the CO2 to be rapidly transformed into the HCO3<->, can promote the calcium ions to be leached from the minerals and the carbonation reaction, and further realizes that the CO2 in the industrial tail gas is immobilized through direct carbonation under normal pressure.

Owner:SOUTHEAST UNIV

Additive formulation for reduction or prevention of microbially induced corrosion in concrete or cementitious material

ActiveUS20220098109A1Improve the immunityPromote migrationBiocideAnimal repellantsFungicideMicroorganism

An additive formulation for reduction or prevention of microbially induced corrosion in concrete, cementitious material (such as mortar or grout), or a combination thereof. The additive formulation comprises a Quat Silane and a fungicide, wherein the ratio of the Quat Silane to the fungicide in the formulation is in a range of about 10:1 to about 1:10, preferably in a range of about 5:1 to about 1:5.

Owner:MICROBAN PROD CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com