Nickelous oxide waste catalyst dissolution processing method

A waste catalyst and treatment method technology, applied in the direction of nickel halide, chemical recovery, etc., can solve the problems of high melting point, refractory melting, low leaching and dissolution rate, etc., achieve effective recovery, high leaching and dissolution rate, and solve production technical problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

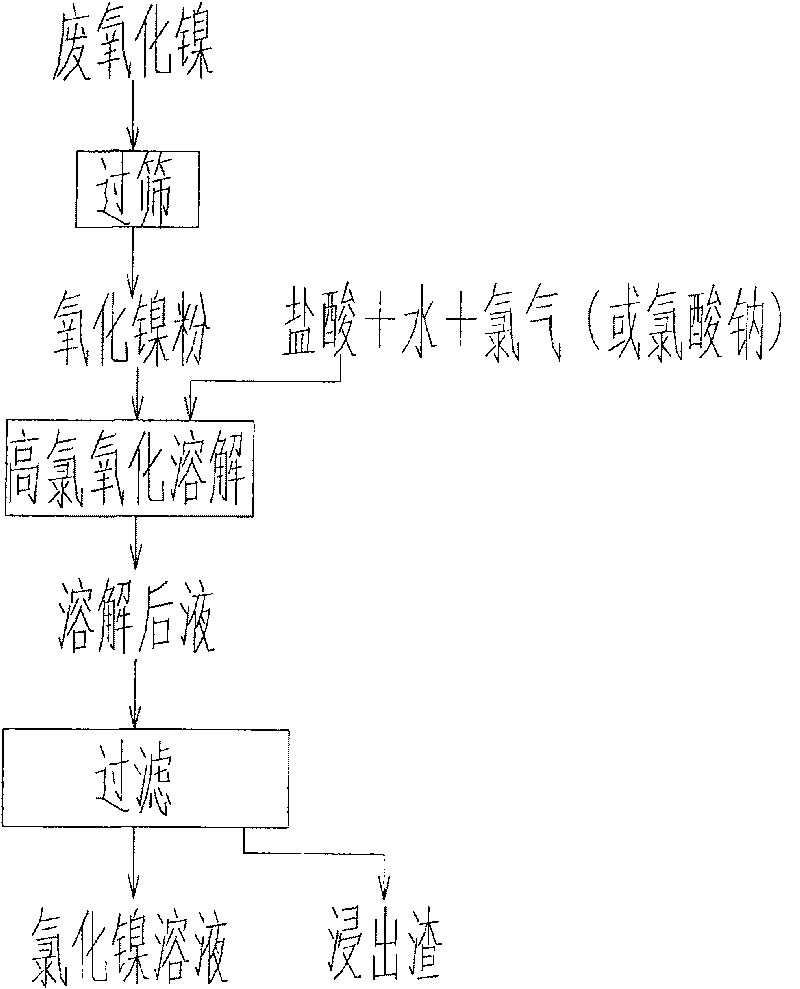

Method used

Image

Examples

Embodiment 1

[0012] Use a 0.9mm industrial sieve to sieve block materials such as small stones and slag in the spent catalyst-nickel oxide; add the nickel oxide sieved to remove block materials in 5mol / l hydrochloric acid, and at a temperature of 85°C, stir Under the conditions, adding the oxidant sodium chlorate, the oxidation potential of the control system is 0.5V; the dissolution time is 5 hours to obtain a green nickel chloride solution; the slag rate of the leached solution is less than 5%;

Embodiment 2

[0014] Use a 0.9mm industrial sieve to sieve the spent catalyst-nickel oxide, such as pebbles, slag and other massive materials; add the nickel oxide that has been sieved to remove the massive material in 6mol / l hydrochloric acid, and at a temperature of 100 ° C, in a stirring Under certain conditions, the oxidation potential of the chlorine gas control system is 1.0V and the dissolution time is 1 hour to obtain a green nickel chloride solution; the slag rate of the solution after dissolution or leaching is less than 5%;

Embodiment 3

[0016] Use a 0.9mm industrial sieve to sieve the waste catalyst-nickel oxide, such as pebbles and slag, add nickel oxide to 5.5mol / l hydrochloric acid, and stir at a temperature of 900°C Under the condition of oxidizing agent sodium chlorate, the oxidation potential of the control system is 1.0V; the dissolution time is 3 hours to obtain a green nickel chloride solution; the slag rate of the leached solution is less than 5%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com