Dynamic leaching system and method

A leaching and dynamic technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inconsistency in leaching indicators, difficulty in controlling on-site stabilization/curing quality, differences, etc., to achieve easy operation, high practical application value, Equipment composed of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

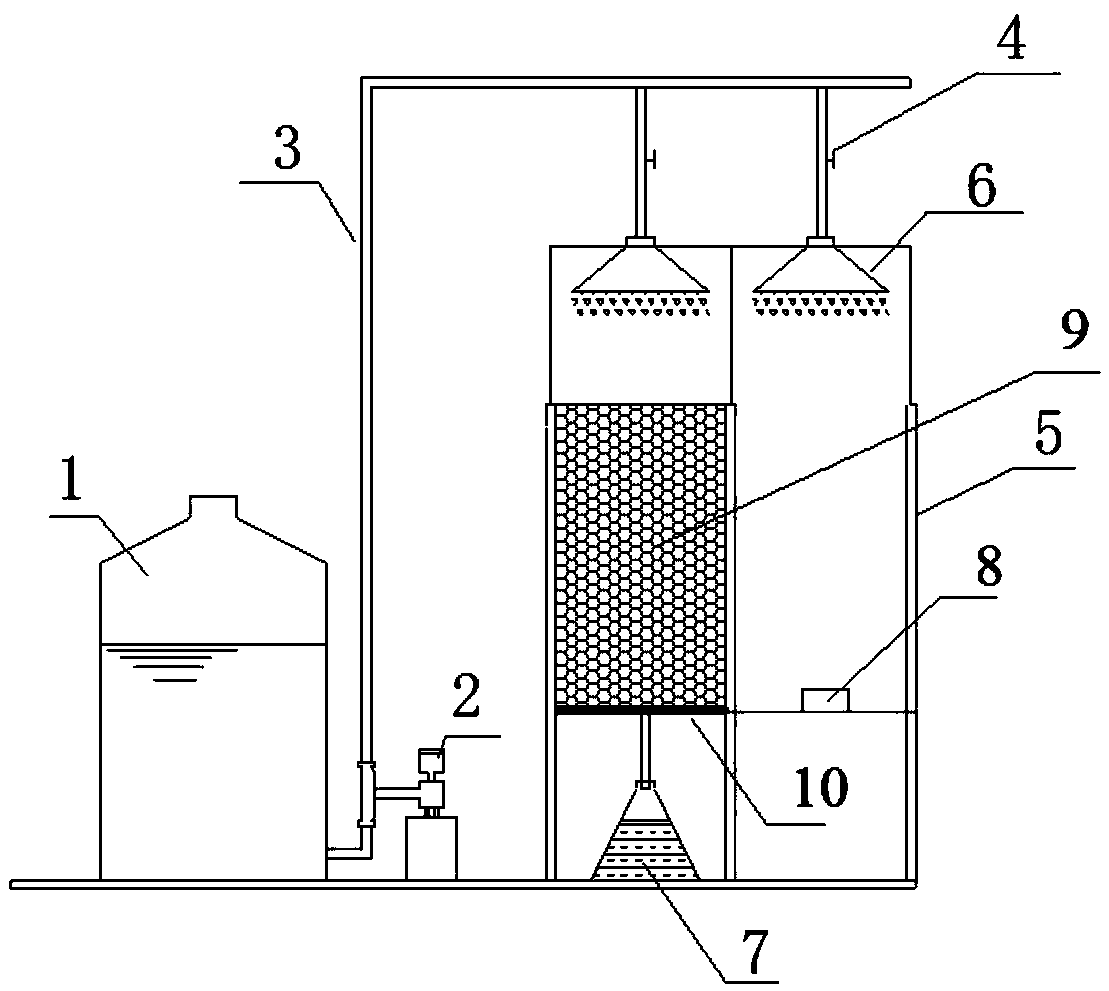

[0032] A dynamic leaching system of the present invention can realize the dynamic leaching of waste incineration fly ash in a simulated field environment, such as figure 1 As shown, it includes a container 1 for containing the leaching solvent, a metering pump 2, a delivery pipeline 3, a timer 4, two columnar containers 5 with the same specifications, and corresponding nozzles 6 for spraying the solution in the two columnar containers 5 ( That is, the nozzle 6) for spraying the leaching solvent in each columnar container 5), the collecting container 7 and the rain gauge 8, and one end (first end) of the delivery pipe 3 is connected (communicated) with the solvent outlet of the container 1 containing the solvent. The output port, and a metering pump 2 for transporting the leaching solvent is provided on the delivery pipeline 3 near one end of the container 1, and the other end (second end) is sealed, and the delivery pipeline 3 is on the other end (second end) near the delivery ...

Embodiment 2

[0047] A kind of dynamic leaching method of the present invention, adopts such as figure 1 The described system carries out leaching, comprises the steps:

[0048] (1) Prepare the leaching solvent in the container 1 according to the water quality of the actual local rainfall; and fill the sample 9 to be leached into a columnar container 5 to form a filling layer. Place the rain gauge 8.

[0049] (2) Start the metering pump 2, deliver the leaching solvent to the two nozzles 6 and evenly spray the leaching solvent into the two columnar containers 5, so that the leaching solvent is synchronized and evenly sprayed on the sample 9 to be leached and the rain gauge 8; specifically, For the metering pump 2, the leaching solvent is transported to each bifurcated branch pipeline through the delivery pipeline 3, and sprayed in each columnar container 5 through each nozzle 6 communicated with each bifurcated branch pipeline, and the spraying situation of each nozzle 6 includes The spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com