Sludge drying treatment equipment and method

A technology of sludge drying and treatment equipment, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high content of organic matter in sludge, secondary environmental pollution, perishability, etc. Small area, the effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

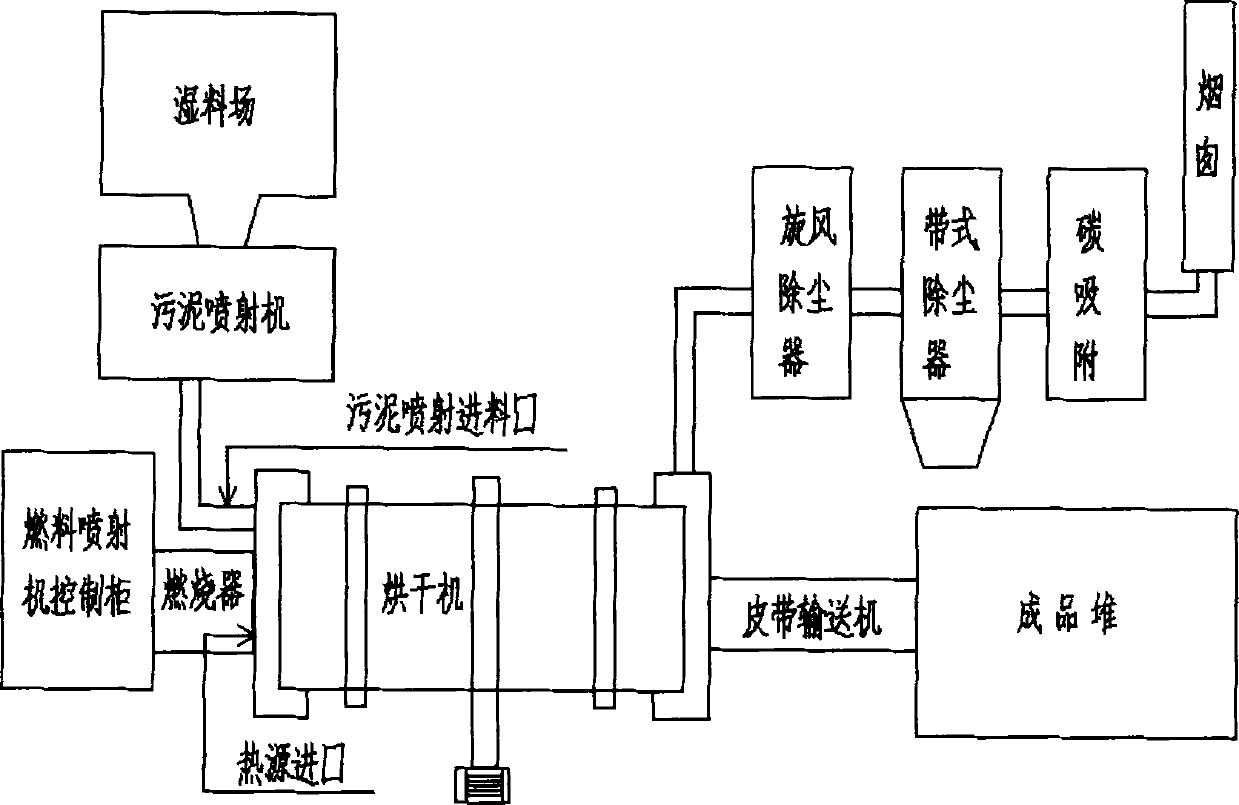

[0019] Attached below figure 1 The present invention is further described with specific embodiments.

[0020] A sludge drying treatment equipment, the equipment includes a sludge spraying device, a spray combustion system, a drying device, a finished product conveying device and a dust removal device; the sludge spraying device includes a wet material yard, a sludge spraying machine and a sludge spraying feed inlet; the jet combustion system includes a coal-fired pulverizer, an ignition device, an injection machine, a burner, a control cabinet, etc.; the drying device includes a tumble dryer, a rotating roller and a rotating mechanism; the The finished product conveying device includes a belt conveyor and a finished product pile; the dust removal device includes a cyclone dust collector, a belt dust collector, a carbon adsorption deodorizer and a chimney.

[0021] The sludge injection device has strong applicability, whether it is activated sludge or raw sludge, as long as it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com