Method and device for immobilizing CO2 by enhancing mineral carbonation

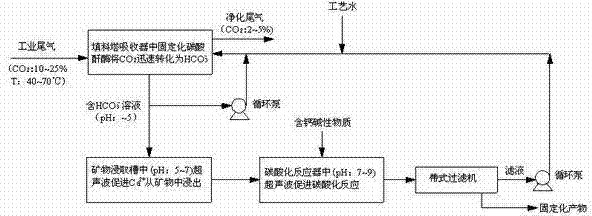

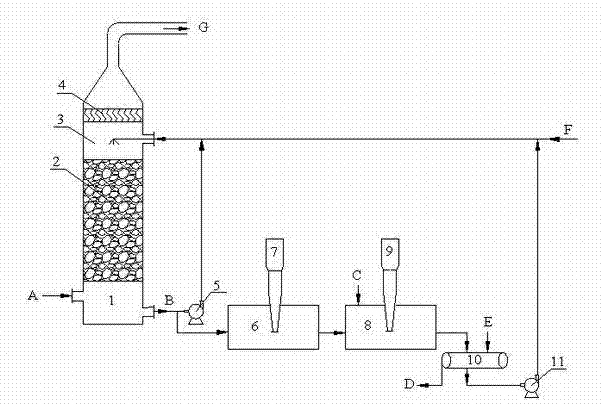

A mineral carbonation, CO2 technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as difficulty in leaching calcium ions, increase effective contact area, strengthen internal diffusion mass transfer rate, particle size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Contains CO 2 The industrial tail gas is produced by a fully automatic coal-fired boiler with a gas volume of 10Nm 3 / h; after dedusting and wet desulfurization, CO 2 The concentration is 13% (V / V), the temperature is 55°C; it enters the packed tower absorber filled with immobilized carbonic anhydrase filler, and the gas-liquid countercurrent contact in the absorber, the contact time is 7s, and the liquid-gas ratio is 5L / Nm 3 ; under the catalysis of carbonic anhydrase CO 2 A hydration reaction occurs and rapidly converts to HCO 3 - , to obtain HCO with a pH approximately equal to 5.1 3 - Weakly acidic solution, remove CO 2 The final tail gas leaves the packed tower absorber from the top of the tower; through the online test of the gas chromatograph, the CO 2 The removal rate was 73%.

[0032] Mix the semi-dry desulfurization ash with the HCO from the packed tower absorber at a solid-to-liquid mass ratio of 1:10 3 - Add the weakly acidic solution into the mine...

Embodiment 2

[0034] The mineral used in the experiment is steel slag, and the rest are the same as in Example 1; after testing, CO 2 The removal rate was 58%, the pH value of the slurry rose from about 5.1 to 6.8 after ultrasonic leaching for 7 minutes, and the conversion rate of mineral carbonation reaction was 71%.

Embodiment 3

[0036] The mineral used in the experiment is wollastonite, and the rest are the same as in Example 1; after testing, CO 2 The removal rate was 57%, the pH value of the slurry rose from about 5.1 to 5.6 after ultrasonic leaching for 7 minutes, and the conversion rate of mineral carbonation reaction was 61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com